Many car owners and owners of their own or cooperative garages like to spend a lot of time in it. This is a kind of male territory. And if in summer it is comfortable to be in it, then in winter the gate will freeze over. Naturally, the question arises of how to insulate garage doors.

After all, among other things, a normal temperature in the garage is a guarantee of long-term car operation. For this reason, it is important to correctly insulate the garage door with your own hands. After all, the gate is the main source of cold getting into the garage.

How to insulate the gate in the garage?

One of the ways to increase the comfort of staying in the garage of a car and its owner is to insulate the garage door. It is necessary to reduce heat loss through the gate. The gate is made of metal, and it has a high thermal conductivity, which increases with decreasing temperature. Thermal conductivity refers to the ability of a substance to conduct heat from more heated objects to less heated ones. In winter, through the iron gates without insulation, even if they are closed, the heat from the heaters will very quickly go out into the street.

Thus, the answer to the question whether or not to insulate metal gates from the inside will be unambiguous. Insulation is necessary.

There are two possible options for warming. The first is to entrust the case to the craftsmen who, for a certain fee, will do all the necessary work. The second is to do it yourself. In the first case, you can save time and effort, in the second case, you can get satisfaction from your own work and save money.

If the choice is made in favor of the second option, the question arises, how to insulate the garage door from the inside with your own hands as efficiently as possible and with a minimum of cash costs and labor costs?

Perimeter seal

An equally important factor, without which it will be useless to insulate the garage door with your own hands.

Entrance door

Choosing a gate, you should prefer a model with a regular door. It is a little more expensive compared to a solid canvas, but it pays off with the saved energy for heating the garage. Obviously, multiple opening of the overall sash will carry away much more heat than a door that is several times smaller in size.

Slots

It is unrealistic to ensure an absolutely tight fit of the sashes along the entire perimeter of the opening. The materials used in interiors for windows or doors are not initially suitable. For garage doors - solid metal construction - the corresponding accessories are produced. A good solution is rubber hoses, hollow or filled with foam or similar material. The seal is sold together with a strip or, if it is not available, is attached to the base with self-tapping screws using mounting strips. If the gaps are very large, laths are additionally used, and brush profiles are placed in the lower part.

Curtain

The accessory familiar to customers of a car service is made in several versions.

Thermal curtain

Acts on the principle of a fan heater, cutting off cold air directly at the inlet. However, both the unit itself and the electricity it consumes are expensive.

Tarpaulin

The same classic sliding curtain, only with a water-repellent impregnation. It is easy to install: a baguette is fixed above the gate or a metal string is pulled. It is easy to hang tarpaulin curtains on them.

Tape

It is made of vertically placed tapes above the entrance. Dense technical polyethylene is cut into strips 10 - 15 cm wide.They are fixed with a stapler on a wooden rail with an overlap of a centimeter and a half. From above, everything is pressed with the same rail for reliability. Whatever the curtain is, it should not reach the floor, but be a couple of centimeters shorter.

Insulation types

There are different types of insulation, which one should you prefer to insulate the door from the inside of the garage? Each of the heaters has its own advantages and disadvantages.

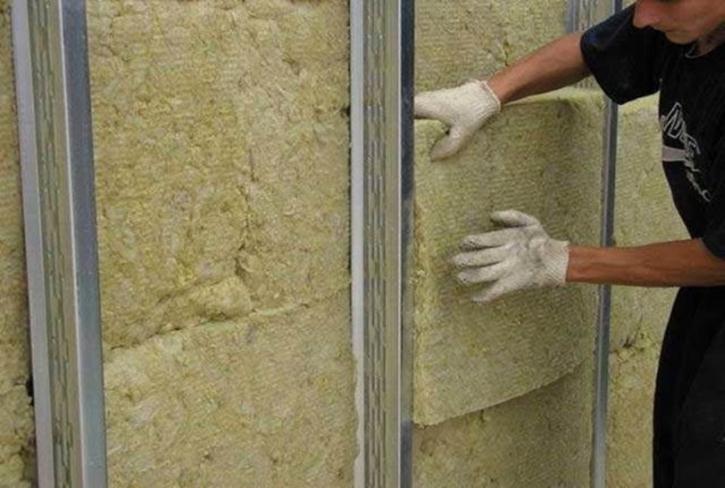

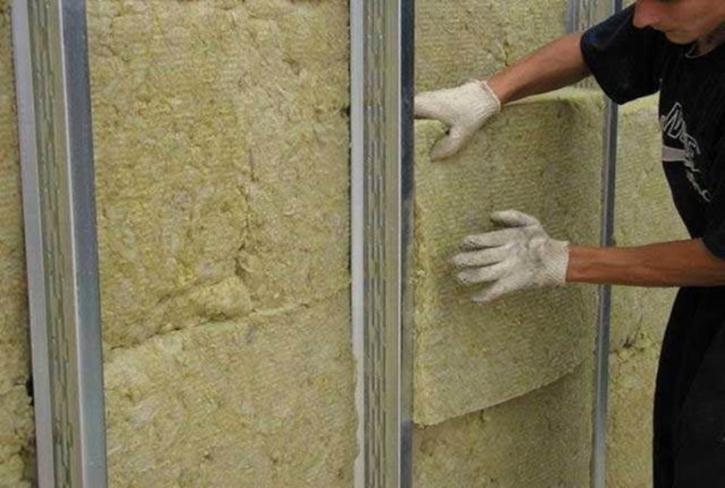

Mineral wool

Mineral wool

One of the most common insulation materials in the construction industry. There are three main varieties:

- glass wool;

- stone wool;

- slag wool.

The first is obtained from glass melt, the second - from the melt of igneous rocks (sometimes it is called basalt); the third - from the blast-furnace slag melt.

Depending on the raw material, mineral wool has a different fiber structure. The fibers form air pockets, which ensures good thermal insulation properties of the material.

In addition, cotton wool is resistant to chemicals and high temperatures.

Disadvantage - mineral wool absorbs moisture well, which seriously impairs its thermal insulation characteristics.

Therefore, it is necessary to install cotton wool with hydro and vapor barrier.

There are doubts about its relative environmental safety, in particular, by the International Agency for Research on Cancer, mineral wool qualifies as a likely carcinogenic agent for humans. But here it should be noted that a person does not live in a garage, therefore, cotton wool does not pose a serious danger.

Produced in the form of plates, rolls, cylinders, bulk. Installation is not difficult.

Styrofoam

Styrofoam

It is a foamed plastic mass. The bulk of the foam is gas. This circumstance explains the heat-insulating and sound-insulating properties of the foam. The industry produces polystyrene of various densities, strengths, depending on what raw materials and what technologies are used for its production.

In domestic conditions, people most often have to have one of the types of foam - expanded polystyrene. It is obtained by polymerization of styrene with the addition of pentane (pore-forming agent).

- Polyfoam is safe for human health. For example, the contact of polystyrene foam with food (packaging) is allowed.

- Styrofoam is very lightweight and easy to handle.

- Low water and vapor permeability is characteristic. For example, extruded polystyrene foam absorbs no more than 0.4 percent of its volume after ten days of being in water.

Disadvantage - it is easily destroyed under the influence of various technical fluids and their vapors (benzene, acetone, etc.). Therefore, if the surface was covered with expanded polystyrene, it is necessary to carefully approach the selection and use of paints and varnishes.

The process of spraying polyurethane foam insulation

Polyurethane foam

Available in two types:

- hard (sheets, panels, cast shells);

- liquid (a heat-insulating coating resembling solidified polyurethane foam is formed during the spraying process).

Polyurethane foam has a very low thermal conductivity. It is less than that of mineral wool and foam.

The material has good sound absorption properties.

Chemicals have less destructive effect on it than on expanded polystyrene.

Not afraid of moisture.

Builders value polyurethane foam for its durability. Insulation from it can last more than thirty years.

Resistant to fire. According to fire resistance, three material classes are distinguished: self-extinguishing (marking C), hardly combustible (TC), hardly flammable (TB). Maintains its performance in the temperature range from -200 to + 200 degrees Celsius.

Sprayed polyurethane foam adheres well to various surfaces (concrete, metal, glass, brick, etc.).

It is necessary to spray polyurethane foam using protective equipment and in a ventilated area, but after drying it is harmless to humans.

There are also disadvantages. The material does not tolerate ultraviolet radiation well. Under the influence of sunlight, it collapses. It is also worth noting the high cost of insulation.

For what types of garage doors is insulation done?

Insulation of swing metal gates

Most often, swing structures are installed in garages, which must always be insulated. They are completely metal, and steel has a very low thermal insulation rate. There are practically no obstacles between the street chill and the inside of the garage.

Sectional and overhead doors are very popular. They are mainly made from sandwich panels in the factory. A layer of expanded polystyrene insulation is applied to the steel outer shell. The high thermal insulation characteristics of this material make additional insulation of the garage door unnecessary.

It is impossible to insulate roller shutters. This is due to their design features. The anti-vandal and thermal insulation properties of this structure are so low that they can hardly be called a suitable garage door.

Preparing the door leaf

Whichever insulation is chosen, it is necessary to start the insulation process with the preparation of the gate surface. It is necessary to clean it of rust, dirt, oil stains, and other chemicals, if any. The gate is protected with a wire brush. If necessary, use solvents, gasoline.

After cleaning, the surface must be primed. Apply the anti-corrosion primer in two layers.

At the next stage, the crate is mounted on which the insulation will be attached. When spraying polyurethane foam, the sheathing will be needed to attach the cladding.

A crate is made of wooden bars with a cross section of 4 × 4 or 5 × 5 centimeters. The bars are fixed along the perimeter of the gate and across the square. The bars must be dry and treated with an antiseptic. Self-tapping screws or liquid nails are used to fasten the bars. In the first case, it is necessary to mark and drill holes in advance. The step between the holes is 20-25 centimeters.

Additional methods of insulation

To make the garage warmer and reduce heat loss even more, you can resort to various methods.

Garage curtain

A curtain, which is hung directly behind the gate, will help to save heat in the garage in winter.

It is made from material that must meet the following requirements:

- high density;

- resistance to high humidity;

- fire resistance;

- strength and elasticity.

Tarpaulin is best suited for the listed requirements, but at the same time it must additionally have impregnation to repel moisture. Sometimes PVC fabrics are used for the purposes under consideration. To make a curtain from a tarpaulin, in addition to the material itself, you will also need eyelets, which are fixed in the fabric with a step of 20 cm. Hang the curtain on a metal cable, passing it through the rings.

If the gate is not insulated from the inside, and only a curtain is used, it should be raised at night so that the inner surface does not freeze.

Fastening insulation

When installing insulation on the crate, there are nuances associated with its appearance.

- When fixing mineral wool, you will need waterproofing. The simplest and cheapest way to solve this problem is to apply bitumen mastic. Pieces of cotton wool are cut in such a way that they can be placed very tightly inside the crate. No glue is required.

From above, the cotton wool is closed with a vapor barrier film. Close correctly, taking into account the sides of the film. The steam-condensate film is placed with the smooth inner side to the insulation, the fleecy side is facing outward.The energy-saving vapor barrier is laid with the foil side out. If ordinary polyethylene is used, it does not matter which side to lay it on to the insulation.

The joints are glued with tape, the film is fixed with a construction stapler.

- The foam is cut so that fewer pieces cover the area to be insulated. When cutting, you need to leave a small margin so that the pieces fit tightly. The easiest way to cut the foam is with a construction knife, using a ruler as an auxiliary tool.

Pieces of polystyrene are glued with polyurethane foam using a gun. To ensure the required adhesion, the foam is applied at the edges and crosswise with the intersection of the center. The foam must be pressed tightly and supported for a while.

After installation, the joints and free cavities are also filled with foam. After it has hardened, the excess must be cut off with a knife.

- Before applying polyurethane foam, it is recommended to cover the bolts, hinges, locks with foil and secure it with tape. It is advisable to work in a protective suit.

The use of a mask and goggles for respiratory and eye protection is mandatory

- For a garage, a household spray installation is sufficient. Such installations, if their containers run out of components, can be charged again. It takes about a minute to apply a 5 cm layer. After drying, the excess is cut off.

The polyurethane foam sheet is fixed like a polystyrene foam.

Pine lining

Cladding

For finishing the gate are used:

- wooden or plastic lining;

- oriented strand board;

- professional sheet.

The lining is a thin sheathing board that has a tongue-and-groove connection. Popular finishing material. Looks good, made from different types of wood.

The plastic version of the lining is made of polyvinyl chloride. It is less durable than wood, but cheaper and moisture resistant.

OSB

OSB is a multilayer sheet formed from wood chips and glued with various resins with additives of boric acid and synthetic wax. Pluses: low price and nice appearance.

The profiled sheet is made of galvanized sheet steel. Experts do not advise using a profiled sheet for interior decoration of the garage due to the possible formation of condensation on the side where the insulation is located.

Rubber door seals

Professional advice

At the end of the warming process, the heat-insulating material must be hidden. For finishing, professionals recommend using moisture-resistant and durable sheet material. In reality, motorists fix everything that is available: lining, plywood, chipboard, fiberboard, galvanized, corrugated board. For many owners, it is not customary to specifically buy expensive finishes in the garage.

Fibreboard cladding is a budget option. The lining will make the gate really attractive. The artificial leather will create a presentable look, but it will not last long in the garage.