The concept of polystyrene heat insulators

Polyfoam, like expanded polystyrene, is made from the same material, but using different technologies, therefore they have a number of differences.

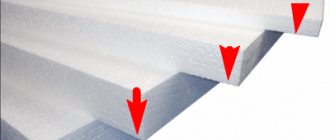

The foam is formed as follows - styrene granules are heated for a long time with steam, it expands and takes the form of a plate. With prolonged heat exposure, the material hardens, becomes solid, and pores form on the surface, due to which the foam breaks down into individual granules over time.

Expanded polystyrene or, as they say, extruded polystyrene foam. Its manufacturing technology is slightly different - styrene granules are initially filled with a certain gas, then all this mass is heated so that it begins to expand. After that, it is squeezed out with an extruder into a special shape, this is necessary in order to obtain a more uniform structure of the material and strengthen the bonds between molecules. When the material fills the entire workpiece (block), it is pressed - this increases the quality characteristics of expanded polystyrene. After the material hardens, a block of penoplex is obtained, which is sold in stores.

Characteristics of Penoplex Fastfix insulation

It has a number of insulating and technological characteristics that are unattainable for other materials:

- Low thermal conductivity at the level of 0.02 ... 0.025 W / (m * С °) or 25 mm of Penoplex coating conduct heat in the same way as 140 mm of wood.

- The foam of the coating has a closed structure (85 ... 95% of the volume of bubbles does not come into contact with the atmosphere), which creates conditions for sound, steam and waterproofing without the use of additional materials.

- Possesses high adhesion, i.e. "Sticks" to all building materials.

- The rate of primary polymerization (1 ... 3 s) and thixotropy (thickening at rest) does not allow foam to drain from vertical and horizontal surfaces.

- Resistant to climatic factors (teks. -40 ... 90 ° C), but is destroyed by direct sunlight.

- Does not support the vital activity of bacteria and microorganisms.

Penoplex

In order not to get confused, you should remember that this is just a brand (subspecies) of extruded polystyrene foam.

Characteristics of materials:

- External differences. Polyfoam - consists of small white lumps. Expanded polystyrene is a very hard material with a uniform structure, which is somewhat like a sponge.

- In terms of thermal insulation, penoplex is somewhat better than polystyrene.

- In terms of air permeability, on the contrary, foam is superior to expanded polystyrene.

- Moisture resistance - expanded polystyrene and polystyrene almost do not allow moisture to pass through. Even after sudden changes in temperature, nothing will happen to them.

- Flammability. Since both materials are the result of foaming of a combustible substance, it burns by itself. But there are different flammability classes. By this concept is meant the reduction of the flammability of styrene. This coefficient can be lowered in two ways - by treating the finished slab with special mixtures, or by filling the granules with carbon dioxide when creating the material.

- Strength. It is this parameter that is most different for polystyrene and foam. The first is almost four times stronger than the second. Depending on the thickness, polystyrene can withstand pressure from 0.2 to 0.6 MPa.

There are a lot of negative reviews that penoplex does not allow moisture to pass through - this is not the case. The vapor permeability coefficient for different types of material can range from 0.005 to 0.008 mg / m • h • Pa.

Reviews of moisture resistance

"Penoplex" for floors is chosen by consumers for the reason that the mentioned material absorbs moisture minimally. If the insulation is immersed in water for a month, then moisture will be absorbed in an insignificant amount only for the first 10 days. After that, the structure stops accepting moisture. At the end of the period, the volume of water in the slabs turns out to be no more than 0.6% of the total mass. Thus, experts note that moisture can only penetrate into the outer cells that were damaged during cutting.

Features of expanded polystyrene

- Relatively low weight - this parameter reduces the cost of installing insulation. In addition, it is much easier to work with light material, especially when it comes to work at height.

- Simple processing, here the absence of special protection means is implied. Like glasses when cutting metal. Also, materials made from styrene are odorless, non-irritating, and dust-free.

- Polystyrene foam, resistant to biological effects, is not absorbed by animals, and also due to its very dense structure, fungus does not start in it. Many are indignant that mice eat penoplex - this is not true, but just another marketing ploy of competitors. Expanded polystyrene has a chemical composition, therefore it is not of interest to rodents.

- Processing with chemical materials is acceptable - cement, glue, saline, putty, primer and so on.

- Even extruded polystyrene foam can be cut and installed without the use of special tools. An ordinary construction knife will do.

- They will withstand a high load when exposed to the entire area of the material.

- Demonstrate high performance in energy saving.

- Suitable for insulation, both from the inside of the house and from the outside.

Now that you have a general idea of the material, you need to figure out where and how it is used. Reviews of penoplex agree on one thing - people are happy with the ease of installation of the material and durability. After all, expanded polystyrene can last up to 50 years.

Applications

Considering all the above properties of the material, it becomes clear what its advantages are. Therefore, polystyrene, like expanded polystyrene, is mainly used as insulation. In this case, polystyrene is often used indoors, and expanded polystyrene - outside.

More precisely, the materials can be used in the following cases:

- To protect the foundation from the outside, it is more correct to use extruded polystyrene foam;

- To make thermal insulation in the basement, you can use both polystyrene and polystyrene;

- Floors - the most dense material is needed, that is, penoplex;

- Ceiling and ceiling slabs - both materials are suitable for their insulation;

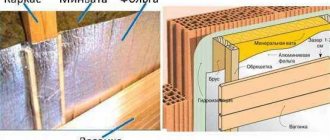

- It is better to insulate the walls from the outside with expanded polystyrene, and from the inside - with foam.

- Both materials are also suitable for thermal insulation of loggias, but in this case, expanded polystyrene is preferable so that the room remains dry in any weather.

High-quality penoplex

How to insulate walls with expanded polystyrene:

- Any repair work should begin with surface preparation, this case is no exception. It does not matter from which wall the insulation will be made, it must first be prepared. This means - to clear of wallpaper, paint, tiles, plastic and other finishing materials. Check how well the putty holds when it comes to internal insulation, or level the wall outside the house.

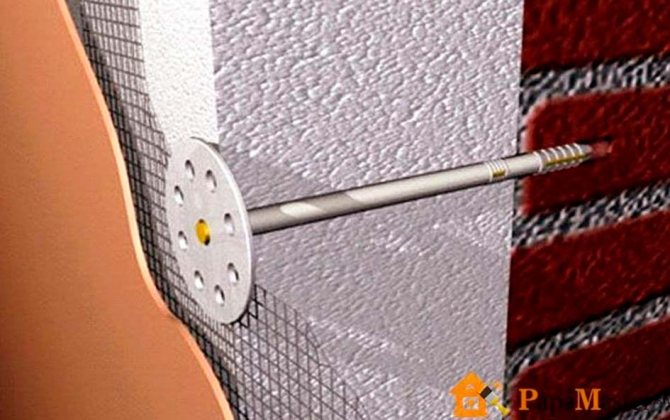

- When the outer layer is reliable, you can proceed with the installation of expanded polystyrene. The insulation is fixed very simply - a special glue (both a dry mixture, which is diluted with water, and foam glue) is applied to the panel along the perimeter, and then the block is glued to the wall. To keep it more secure, fix it with dowels from above. At the rate of one sheet - 5 dowels.

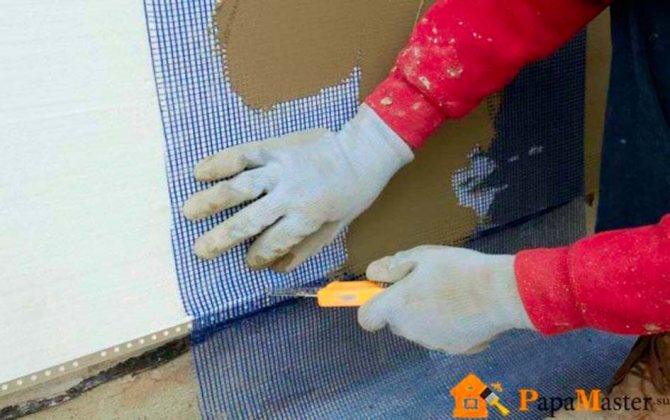

- Next, the insulation is covered with a thick layer of glass mesh glue (reinforcing mesh). A mesh is laid on the uncured layer and rolled with a roller until it disappears. Another layer of glue is applied on top. After the surface has dried, finishing work can be carried out - plastering, painting.

It is quite easy and simple to make insulation in this way, you don't even have to hire workers. Many people have made their own wall insulation.

Review of expanded polystyrene

“Many people say that expanded polystyrene is fire hazardous. Nonsense! He burned it himself, because he doubted whether to insulate or not to insulate. As a result, I insulated the facade of the house, it turned out well, warm. There are no difficulties, and the top of the expanded polystyrene is reliably covered with plaster. "

Vladimir, Kaluga

What does a master need to know when using Penoplex?

In order to maintain the invariability of the size and shape of the canvases, it is necessary to maintain the maximum permissible ambient temperature at which the described heat insulator can be operated. As a rule, this parameter is indicated in the material passport. If the insulation is exposed to excessive heating, then the characteristics and dimensions of Penoplex may change, it can ignite and begin to melt.

Thermal insulation of surfaces

For floor and ceiling insulation, both polystyrene and expanded polystyrene are equally suitable. The process of insulating the ceiling is as follows:

- Cleaning the ceiling to the concrete surface;

- Surface treatment with a primer, and if it is strongly absorbed, then it must be treated several times. This step is necessary to protect the ceiling from bacteria and fungi.

- Blocks are glued to a special glue, it is applied either directly to the ceiling or to the material. There is no fundamental difference here. After applying the adhesive, the expanded polystyrene panel is applied to the ceiling and held until the adhesive begins to set. Then they are additionally fixed with dowels. The principle is the same as for the walls - five pieces per surface.

- When the entire ceiling is covered with expanded polystyrene, a reinforcing layer is applied and a reinforcing mesh is added. This is necessary to improve the waterproof performance and elasticity. Due to the mesh, polystyrene foam cannot be broken. But the main thing is that the flammability of the material decreases.

- When the surface hardens, they carry out finishing work, putty the joints, glue the wallpaper, paint the ceiling.

Floor insulation

Extruded polystyrene foam is suitable for all types of floor insulation, that is, on the ground, under a wooden floor, for concrete screed. It is better not to use polyfoam for these purposes at all. You can, of course, put it down, fix it, but as a material it is quite fragile, especially under constant loads. Therefore, it is preferable to use extruded polystyrene foam.

Laying extruded polystyrene foam on the ground.

Initially, a mound 10 cm thick is made of gravel or slag, the voids are then filled with expanded clay. If there is no basement, then the material of the greatest thickness should be chosen for insulation. Then logs are fixed on top - these are wooden beams several meters in length, which serve as a support for the floor. Install them so that the distance between them is 40-50 cm. All the remaining free space is sealed with penoplex. Important! From above, the material should be covered with a waterproofing mixture, paying particular attention to the joints.

For wood floor

The technology is the same, only a cement screed is made on top of the logs insulated with extruded polystyrene foam. A wooden floor, laminate, linoleum and so on are laid on it.

Concrete floor

If there is a ready-made concrete floor that needs to be insulated, then the following is done:

Check how smooth the surface is.If the differences are no more than 2-4 mm, then the foam plates can be laid without additional supports, like the same logs. If there are more irregularities, then there are two options - to equalize the floor, or nail logs, and lay polystyrene foam between them.

Floor insulation also needs to be reinforced with a reinforcing mesh and a layer of waterproofing. Then, usually, the floor is finished.

Reviews of compression and mounting features

If you decide to use Penoplex floor insulation, you can count on high compressive strength. This indicates excellent strength characteristics. Even heavy loads are not able to change the size of the material. Home craftsmen prefer Penoplex for its ease of processing, it can be cut using an ordinary knife. Plates can be used for insulation even in difficult conditions, when the work is accompanied by snow or rain. Thus, the insulation does not need to be protected from bad weather.

Reviews about insulation with expanded polystyrene

“I myself insulated the ceiling with penoplex. It’s how it happens - the warm air flow rises upward, and due to the fact that there is a layer of insulation there, it doesn’t cool down. Therefore, heat is significantly saved. And you don't need to hire anyone for repair work, he did it himself. Personally, everything suits me. The house is warm and very pleasant to be. "

Victor Smolensk

“A year ago I first insulated the floor and then the ceiling in the house. I didn't touch the outer walls yet - I decided to see how it would hold up. There is an effect - in winter, the thermometer's mark rose to 25, instead of the usual 20, with the same gas consumption. Therefore, I am satisfied. The floor, of course, has become a little higher, by some 5-6 cm, but now it's not cold to walk on it without slippers. So my review is only positive. "

Dmitry Belgorod

“You know what amazes - the amount of advertising, moreover negative. Apparently, manufacturers of more expensive materials are afraid of competition. So they are trying to prove that their material is better. For a long time I doubted whether to insulate the ceiling in the whole house with penoplex. At first I thought to do it out of drywall, even sheathed the ceiling in one room. But drywall, firstly, is more expensive, and secondly - all these metal frames, again, the ceiling goes down. Therefore, I bought penoplex and insulated it with it. Class, honestly! Fast and easy. I repaired the seams, putty on top, painted - everything is ready. Both warm and good in the house. Fungus on the walls and does not smell. Therefore, I am very pleased. "

Gennady Omsk

Security measures

In the hardened state, the insulation is completely safe and non-combustible, but when spraying, dust particles are not allowed to enter the respiratory tract, for which it is necessary to work in a petal respirator.

Testimonials

According to user reviews, the prices for sprayed insulation Penoplex Fastfix allow it to be used on relatively large areas of premises in which it is not required to maintain a certain temperature (for example: outbuildings to the house; roof not used for housing or from metal tiles; walls and gates of a metal garage and etc.). The cost of Penoplex Fastfix and the time spent on work are incomparable with the cost of insulation by other materials or methods.

The Remonstr online store sells Penoplex Fastfix insulation and other building materials at democratic prices, which is possible thanks to well-thought-out logistics and contacts directly with manufacturers. To get full information about the range, prices, promotions or get a price list, just call or fill out the feedback form.

The use of insulation followed by a screed

If you decide to use "Penoplex" for underfloor heating, then after installation you can equip the underfloor heating system. Gravel 40 cm is laid on the surface of the soil in an even layer. The material must be compacted, sand must be laid on top.The backfill thickness should be slightly less than the previous layer. This figure is usually 10 centimeters. The sand must also be carefully compacted.

At the next stage, a concrete screed is poured over the ground, however, the reinforcement cage must first be laid. After all the above manipulations have been performed, you can begin to insulate the floor. To begin with, waterproofing is done, then Penoplex is laid, the next step will be to pour the concrete screed. If "Penoplex" is used for the floor under the screed, then this option is the most optimal solution. However, it is necessary to install underfloor heating mats before pouring concrete.

At the final stage, the finishing flooring is equipped.

Where do doubts come from?

There is an opinion that polystyrene is not very suitable for insulating wooden houses from the outside. Some people doubt and study this issue before insulating a wooden house with polystyrene foam.

This is due, in particular, to such material characteristics as vapor conductivity. Hence, it is concluded that such insulation will not be able to prevent moisture, and, consequently, decay of the walls. At the same time, in fact, the foam plastic has a steam conductivity commensurate with the steam conductivity of pine wood itself, so it is logical that the fears are groundless. The main thing is to observe the technology of insulation, then the house will be warm and the walls are not moistened. The only thing that is not recommended is to choose polystyrene for external insulation of baths, saunas and similar rooms. It is better to dwell on other material here. If you have a house, then use it for health!

Opinions and reviews of various builders and house owners about whether it is possible to insulate a wooden house from the outside sometimes differ significantly, that's what experts say about the pros and cons of foam insulation for wooden houses.

- Traditional inexpensive material;

- Easy process;

- Saving;

- High thermal insulation properties

- Protection not only from cold, but also from heat and noise.

- Worse than some heaters, it releases moisture to the outside, which can lead to condensation;

- It is necessary to observe the technology and think over ventilation;

- Difficult air exchange, but a tree is chosen for building a house precisely so that the house "breathes";

- Combustible material (however, when processing with a fire retardant, this minus can be leveled).

- May begin to crumble over time.

As you can see, styrofoam has its pros and cons. However, like other materials. Consider carefully the choice of insulation, enlist the advice of professionals. And then you don't have to worry about the result! If you have already decided to insulate the house with polystyrene, because of its inexpensiveness and ease of installation, then mount it on the ventilated facade system, and then there will be no problems.

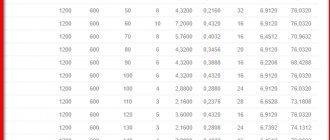

Specifications

Material "Polispen", average density 35 kg / m³, is made with slabs 600 mm wide and 1200 mm long with a quarter processing along the perimeter. By agreement with customers, slabs of various lengths can be produced, both with straight and stepped edges. The technical equipment of the enterprise allows the production of slabs with a rough surface of two types (shallow and deep "notch"), which is very suitable for wall insulation by the method of "wet" facades. The thickness of the slabs is from 20 to 80 mm. Polispen boards are packed in polyethylene film with protection against UV rays. Packaging height 40-42 with the number of plates from 4 to 17 pcs. The volume of one package of boards (standard) is 0.288 m3. Plates can be stored outdoors in their original packaging. When stored unpackaged, they must be protected from prolonged exposure to sunlight to prevent the destruction of the top layer.

Penoplex and expanded polystyrene: choosing the best insulation

If the insulation absorbs water, then over time its thermal insulation qualities will inevitably decrease.Extruded polystyrene foam differs from other heat-insulating materials in minimal moisture absorption, high strength, durability and monolithic structure.

PENOPLEKS - extruded polystyrene foam, the production of which has been established at factories located in many cities of Russia and abroad. The most modern equipment from the world's leading manufacturers allows us to guarantee the highest quality of products under the PENOPLEX brand.

Insulation PENOPLEKS is chemically inert (does not emit harmful chemical compounds during operation within the permissible temperature range (from -50 ° C to +75 ° C), does not rot and biodegradation. You can work with it in any weather conditions without any means The boards are easy to handle (cut well using a conventional knife) and are extremely easy to install.

The durability of the heat-insulating material is confirmed by the protocol of NIISF No. 132-1 dated October 29, 2001 (Russian Academy of Architecture and Building Sciences) and is more than 50 years.

PENOPLEX COMFORT - specially designed for low-rise construction. The balance of technical characteristics of the universal material PENOPLEKS K0MF0RT, such as: strength, zero water absorption, high thermal protection, biostability and environmental friendliness, allow it to be effectively used in all constructions without overpaying for the enhanced properties of professional brands.

PENOPLEX WALL - optimal for insulation of external and internal vertical enclosing structures (walls, partitions, facade systems); minimal water absorption, absolute biostability, low thermal conductivity (1.4 times more effective than mineral wool, and 1.3 times more effective than mineral wool, and 1.3 times more effective than ball foam) provide reliable protection for your facade throughout its entire service life. The flammability group of PENOPLEX STENA is lowered, and the presence of special flame retardant additives makes it possible to exclude self-combustion.

PENOPLEX ROOF - optimal for any type of roof insulation; the compressive strength of this type is 25 t / m2. The flammability group of PENOPLEX ROOFING is reduced, and the presence of special flame retardant additives makes it possible to exclude self-combustion.