Projects of houses from a bar

Number of projects 697

- 4 rooms

- 1 bathroom

House project "Native pier"

- To favorites

- 130² Total area

- 8 x 9m Building area

from 1 999 000 rub.

Construction time 30 days

- 4 rooms

- 2 bathrooms

Hercules House Project

- To favorites

- 125.23² Total area

- 11 x 9m Building area

from 4 110 833 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

Adriatic House Project

- To favorites

- 184.4² Total area

- 14 x 9m Building area

from RUB 2,190,000

Construction time individually

- 4 rooms

- 2 bathrooms

House project "1216"

- To favorites

- 168.3² Total area

- 11 x 10m Building area

from 2,131,000 rub.

Construction time 30 days

- 2 rooms

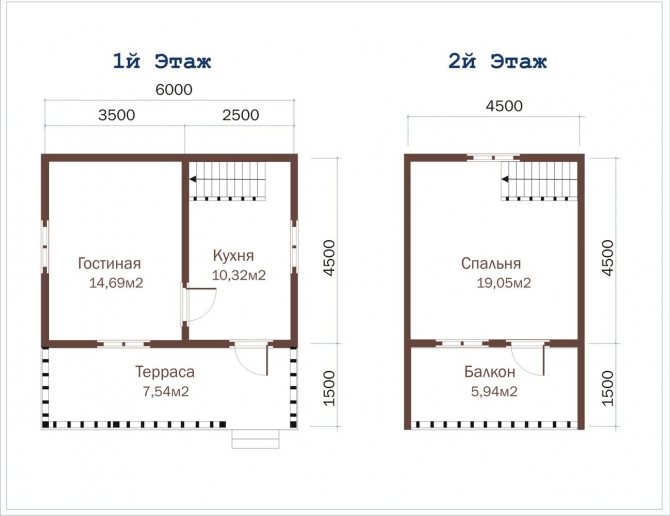

Project Country house "Uslada"

- To favorites

- 36² Total area

- 6 x 6m Building area

from 572 450 rub.

Construction time individually

- 6 rooms

- 2 bathrooms

Borodino House project

- To favorites

- 242.76² Total area

- 12 x 14m Building area

individual calculation

Construction time individually

- 3 rooms

- 2 bathrooms

Ladoga House Project

- To favorites

- 155.5² Total area

- 13 x 16m Building area

from 2,390,000 rub.

Construction time individually

- 7 rooms

- 2 bathrooms

House project "Leona"

- To favorites

- 255² Total area

- 12 x 17m Building area

from 6 375 000 rub.

Construction time individually

- 6 rooms

- 2 bathrooms

Balkhash House project

- To favorites

- 170.4² Total area

- 11 x 10m Building area

from 1 850 600 rub.

Construction time individually

- 4 rooms

- 3 bathrooms

House project No. 17054

- To favorites

- 149² Total area

- 16 x 8m Building area

from 6 921 936 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House project Karelia

- To favorites

- 141² Total area

- 11 x 8m Building area

from 4 842 351 rub.

Construction time individually

- 7 rooms

- 2 bathrooms

Cedar House Project

- To favorites

- 254² Total area

- 14 x 13m Building area

from 7 317 944 rub.

Construction time individually

- 6 rooms

- 3 bathrooms

House project "Lesya"

- To favorites

- 250.4² Total area

- 12 x 14m Building area

from 6 250 000 rub.

Construction time individually

- 3 rooms

- 2 bathrooms

Treasured House Project

- To favorites

- 219² Total area

- 10 x 12m Building area

from 1 661 742 p.

Construction time individually

- 5 rooms

- 2 bathrooms

Taman House Project

- To favorites

- 141² Total area

- 13 x 11m Building area

from RUB 1,529,700

Construction time individually

- 3 rooms

- 1 bathroom

House project no. 3

- To favorites

- 86.1² Total area

from 1 162 350 rub.

Construction time individually

- 3 rooms

- 2 bathrooms

House project no. 62

- To favorites

- 79² Total area

from 1,066,500 rub.

Construction time individually

- 2 rooms

- 2 bathrooms

House project "BK 11"

- To favorites

- 8 x 9m Building area

individual calculation

Construction time individually

- 3 rooms

- 1 bathroom

House project "Grodno"

- To favorites

- 97.2² Total area

- 8 x 8m Building area

from 2 619 000 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

Hakob House Project

- To favorites

- 100² Total area

- 9 x 10m Building area

individual calculation

Construction time individually

See all projects

Timber cottages have been actively built in recent years in Russia. There is a logical explanation for this phenomenon - timber buildings are built quickly, are inexpensive, while they are very comfortable and look great. However, timber walls shrink during the first few years of operation, as a result of which cracks can form on them. For this reason, the heat saving rate of the cottage is significantly reduced and there is a need for insulation.External insulation for buildings made of wood is undesirable - wood without contact with open air begins to rot quickly, in addition, the appearance of a wooden house is lost, which has to be hidden behind decoration. For these reasons, homeowners resort to insulating a log house from the inside.

Insulation of a log house from the inside Source belprim.ru

Timber as a building material for cottages

Wood building materials allow you to build beautiful, comfortable, reliable and environmentally friendly country houses. Modern timber is easy to use and practical to operate. It comes in several flavors:

- Planed

... A regular log is given a square or rectangular cross-section, and the result is a planed bar. It is cheap, but in the process of natural shrinkage it can deform and crack. In addition, such material is unprotected from decay, mold and blue.

- Profiled

... It differs from the planed one by the presence of a sample on the working side, which makes it possible to assemble a log house using the “thorn in the groove” or “comb” technology. Thanks to the availability of sampling, ideal walls can be built without cracks and defects.

- Glued

... The most expensive, but also the highest quality material. It is created by connecting thin, well-dried lamellas. A special harmless glue acts as a connecting substance. Glued laminated timber practically does not shrink, does not crack, is not exposed to the negative effects of moisture and insects.

Wall made of laminated veneer lumber Source klm-art.ru

In low-rise construction, glued laminated timber with a section of 150x150 mm is most often used. This type of wood attracts with the optimal ratio of price and quality. But in regions with cold winters, walls of this thickness may not be warm enough. This problem can be solved with the help of elementary insulation of the house from a bar of 150x150 from the inside.

On our website you can get acquainted with the most popular projects of houses made of laminated veneer lumber from construction companies presented at the exhibition of low-rise country houses.

Interior decoration

Decorating a house from a bar from the inside with a clapboard

Having assembled the second layer of vapor barrier film, the walls are finished. The film is fastened using staple staples, and 30x40 mm bars are mounted on top, which are commonly sold.

Before finishing, the walls are plastered and primed. Thermal insulation materials are perfectly combined with a variety of putties and primers.

After installing the timber, decide what you will decorate the house with: wood clapboard or planken. If, when deciding how to insulate a house from a bar from the inside, you prefer a wooden lining with a pronounced texture, then you can preserve the original interior of the house.

It will also be good to choose a horizontal planken. This material looks like a small bar.

Insulation of log houses

Before starting the insulation process, it is necessary to invite a specialist who will give a professional assessment of the condition of the walls, ceiling, floor and ceilings. For this purpose, the entire building is inspected from the outside and from the inside. As a result of the inspection, you will be given a recommendation - it will be enough to re-caulk, or the house needs to be insulated with insulating materials.

Caulking of a log wall Source hi.decorexpro.com

If you decide to insulate the cottage from the inside, you need to choose a good insulator for this, which has the following requirements.

- Efficiency

... After installing the insulation, the house should become much warmer and more comfortable, and heating costs should be reduced by an order of magnitude.

- Environmental friendliness

... This indicator is especially important for internal insulation. They should not emit substances harmful to humans.

- Fire resistance

... Most effective insulation materials ignite when exposed to open flames.You need to choose a material that either burns weakly, or generally has a tendency to fade.

- Durability

... Sheet and roll heat insulators must be replaced periodically. But the less often you have to do this, the cheaper and easier it will be to service at home.

- Ease of use

... The simpler the installation technology, the cheaper each replacement will cost.

Insulation for interior walls Source: advancedhomenow.com

On our website you can find contacts of construction companies that offer a house insulation service. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

What should be considered when choosing a heater?

Range of insulation materials

To choose a heater that is as safe as possible for health, you need to pay attention to the combination of material with wood. Insulation must not only be well ventilated, but also must be in harmony with the properties and vapor permeability of wood.

Attention: Many people prefer foam. But, it is worth noting that such a material does not allow moisture to pass through well, therefore it is not worth using it for internal as well as external thermal insulation of the room (condensation will drip onto the tree, which will lead to rotting of the timber).

Despite the fact that basalt and fiberglass are unnatural materials, they have excellent vapor permeability properties. If there is a ventilation system, moisture will not accumulate.

But it is worth noting that such materials emit harmful substances that, during the ventilation process, enter the room. As a result, a person breathes them. Of course, if you install the film, then no harmful particles will enter the room, but the beneficial microclimate of the tree will also disappear.

As for flax fiber and fiberboard, they are best combined with the properties of wood.

Materials for warming a log house

Internal insulation of a house from a bar is most often performed using the following materials:

- mineral wool;

- ecowool;

- penolirutan;

- Styrofoam.

Minvata

It is a very effective insulator with low thermal conductivity and good sound insulation properties. It is quite safe in terms of ignition, resistant to temperature changes, and has a low cost.

However, this material has its drawbacks. For interior decoration, it must be laid in a thick layer, otherwise condensation may accumulate with all the negative consequences. In addition, mineral wool particles can cause an unpleasant reaction on contact with the skin. Therefore, you need to work with her in a special suit and a respirator.

Ecowool

Modern advanced material. More effective than mineral wool. The main advantages are vapor permeability, which allows you to preserve the characteristics of wood walls, and the ability to maintain thermal insulation qualities even when wet. Ecowool is environmentally friendly, durable and economical. The disadvantages here are as follows - since ecowool is made from waste (usually from waste paper), its quality is quite difficult to control even at the production stage. In addition, the installation of such insulation requires the involvement of highly qualified specialists.

Thermal insulation of the house with ecowool Source 24dom.ru

This might be interesting!

In the article at the following link, read about log houses with a terrace.

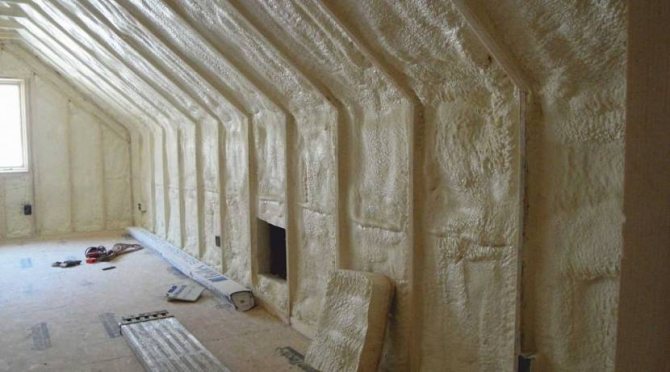

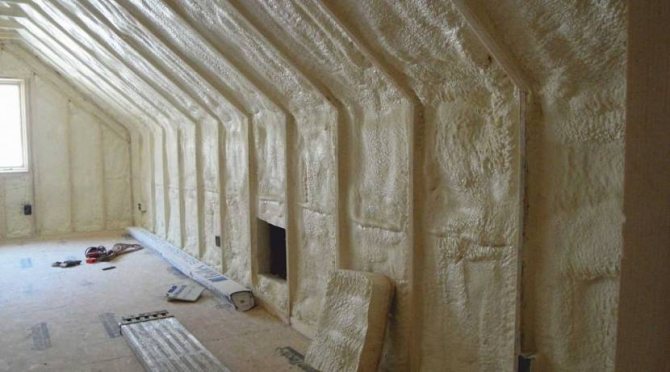

Polyurethane

Another version of modern insulation with improved properties. This is the most effective insulation to date. Its thermal conductivity is minimal. It is achieved due to the porous structure of the material. It is applied by spraying, due to which the formation of "cold bridges" is excluded. Polyurethane can be used to insulate vertical and inclined surfaces. It is vapor permeable and has the ability to damp when ignited.

Of the minuses, it should be noted the complexity of the installation of this material.It is also important that polyurethane is vapor-tight, which means that when using it, it is necessary to equip a ventilation system.

Polyurethane as insulation for the attic of a log house Source vashdomtc.ru

Styrofoam

Traditional foam has proven itself as a reliable and effective insulation material. It is an excellent noise isolator, self-extinguishing, easy to work with and inexpensive. But at the same time, it is distinguished by high water absorption and low vapor permeability. Among other things, rodents love him.

Polyfoam for insulation of premises Source applesakhalin.ru

Ventilation and wall decoration with plasterboard

Plasterboard wall decoration

We said earlier that the internal insulation of a house made of ecowool, leads to an increase in humidity. Therefore, you should make the insulation ventilated. Wall decoration with plasterboard or clapboard should be with a gap of several centimeters from the vapor barrier layer. To do this, after covering the mineral wool with a vapor barrier, additional bars of 30x40 mm are mounted, on which the false wall is attached.

To ensure ventilation and a normal microclimate in the house, an exhaust hood should be made by tying together all the air ducts from the rooms into one. For a supercharger, you should choose a fan with a low power. We hope that this information will help to insulate a private house from a bar inside. In the video you can watch a master class on insulation from a leading manufacturer of thermal insulation materials.

Stages of work on the insulation of internal walls

Warming of the premises of a log house must be done very carefully and carefully. Poorly performed insulation work will lead to the fact that cold and dampness will still penetrate into the house, and the insulation will have to be shifted again.

Preparation of premises

First you need to remove trim, dirt and dust from the walls. After that, the wooden walls are treated with a special septic tank that protects the tree from mold and insects. In addition, it is necessary to treat the timber with a composition that reduces the flammability of the wood material. During preparatory work, all wiring must be separated from the walls. Then it can be returned to its place.

Caulking walls

At this stage, you should walk along the walls and close absolutely all cracks, including the smallest ones with jute fiber. This procedure is carried out on the outer walls every 2-3 years, and on the inner walls with each replacement of the insulation.

Vapor barrier

In order for the tree not to deteriorate from the accumulating condensate, before laying the insulation, it should be covered with a vapor barrier film. Vapor barrier is especially important when insulating internal walls with mineral wool or foam.

Vapor barrier in a house from a bar Source optopg.ru

This might be interesting!

In the article at the following link, read about log houses with a garage.

Lathing

At the next stage, a frame is constructed that will hold the insulating materials - the crate. It must be installed before insulating the house from a bar from the inside with any roll or sheet material. Spray-applied liquid insulation does not require a frame. For the lathing, bars with a cross section of 50 to 50 mm are used.

Insulation laying

Insulation is placed between the battens of the crate and fixed to the wall. It is important to cover the entire surface with an insulating material so that there are no gaps between it and the sheathing bars. Particular attention should be paid to the high-quality fastening of the upper and side edges of the insulation.

Laying insulation in the frame of the sheathing Source sovetclub.ru

Ventilation system

A too humid microclimate is created in a house that is insulated from the inside. As a result, condensation settles on finishes, furniture and other interior items. To avoid this, you need to immediately think over a good forced ventilation system when arranging insulation.

Experts recommend, in each individual case, to develop a layout for the air ducts, which will be hidden under the outer cladding and connected into a single system through the attic ventilation openings.

Finishing work

After laying the insulation, the wall is sewn up with sheets of drywall. Previously, you can lay a second layer of vapor barrier on the insulating material. After installing drywall, the walls are decorated with any material to the taste of the homeowners. This can be a natural timber finish or any other option.

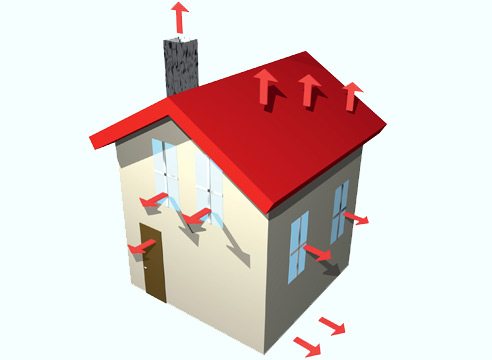

Thermal insulation

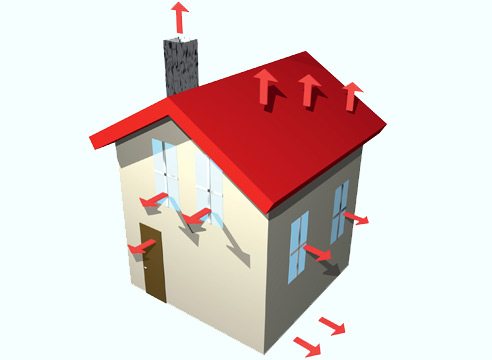

The main causes of cold indoors are:

The most vulnerable areas in a house for heat loss

- Errors during installation or selection of the thickness of the heat insulator;

- Gaps between the beams due to improper laying, shrinkage, etc.

The sequence of work, indicated in our photos:

- preparing the surface;

- caulk the cracks;

- we create a vapor barrier;

- we mount the crate on load-bearing walls;

- we lay and seal the insulation;

- competently create a ventilation system;

- we carry out interior decoration.

Advice! A good addition to insulating a house from a bar from the inside is to replace old wooden windows with plastic ones or put new wooden ones with double or triple glazed windows.

Before you carry out work on the insulation of a log house, prepare everything you need. To complete the work you will need:

- necessary tool;

- experience in external wall insulation;

- high-quality materials for thermal insulation;

- vapor barrier film.

The video in this article will help you insulate your home with high quality.

Surface preparation

First of all, you need to assess the condition of the walls and the quality of previously done insulation work at home. It is necessary to carefully inspect the condition of the corners, joints, joints of the timber, evaluate the compaction of the surface of all walls. If you find any defects, be sure to fix them.

Before you start insulating a log house from the inside with your own hands, you must:

- Remove possible dust from load-bearing walls.

- Then the surface is carefully treated with a special emulsion against insects that live in the wood.

- Apply to the surface with a special liquid that protects it from rotting and burning.

Also, when preparing the surface, special attention is required to be paid to electrical wiring. If there is surface wiring on the wall, it must be separated from the wall surface.

Caulking cracks

How to properly seal the cracks

- After you have cleaned and processed the walls from the inside, you need to seal the cracks. The house from the beams will be caulked again a year after its construction due to shrinkage, if the house has not been lived. If the house is residential, then it will be caulked again after 2-3 years, so the process of shrinkage is slower.

- The slots are predominantly sealed with jute fiber. The resulting voids are filled using a special chisel.

- Sometimes it is necessary to caulk a wide gap. Then use a tape tow, which is rolled into a small roller. When caulking at home, both outside and inside, the gap is filled until the tourniquet ceases to fit.

Formation of a vapor barrier

When insulating walls from a bar from the inside, it is necessary to be aware that after all the work has been completed, the base of the wall made of bars will be enclosed between 2 heat-insulating layers (if the house was insulated from the outside). The humidity in the house will rise, a thermos effect will form and the building will not be able to breathe.

Humidity can be reduced by using forced ventilation. It is necessary to ensure that the wood does not get damp in order to prevent rotting of the walls.

To avoid this, before the internal installation of the heat-insulating layer, it is necessary to mount a waterproof and vapor barrier film. It must be placed with a rough surface to the timber.This will protect the tree from the ingress of humid air and will partially ensure the "breathing" of the house and the removal of excess moisture.

Film - protects wood from moisture

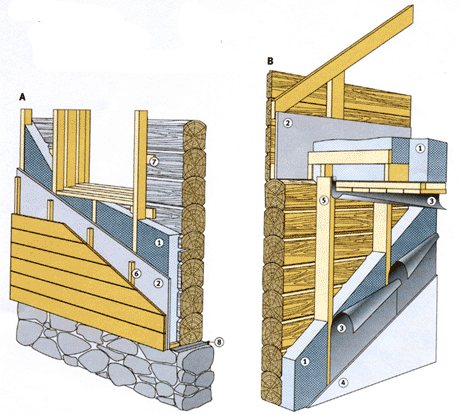

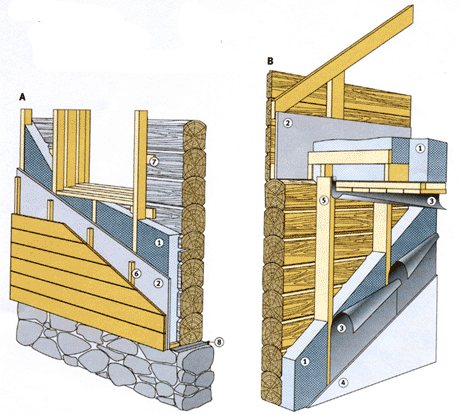

Installation of battens on load-bearing walls

The lathing, which is designed to hold the mineral insulation wool, is made from a bar. It can also be made from a metal profile, if you then sheathe the house from the inside with moisture-resistant plasterboard.

In telling how to insulate a log house from the inside, we will try to help preserve the look of wooden walls, so for finishing it is better to choose a lining made of wood or planken.

Wooden lathing

- To obtain the correct even corners, you must first make the corner posts.

- It is necessary to measure the height of the house and cut off a beam with a section of 100x50 mm of the same length.

- Then a 50x50 mm bar of the same length is cut off and placed along the edge of a 100x50 mm bar and fixed using self-tapping screws. You will receive a stand that is shaped like the letter "L".

- Such racks, one for each corner, are fixed with self-tapping screws right into the corner, controlling the vertical arrangement of the racks with a level.

- Having installed the corner posts, bars with a section of 50x50 mm are vertically mounted on the wall between them, every 500-600 mm.

Note! Do not forget that all used wood must be treated with a liquid that prevents fire and decay.

Selection and installation of insulation

The laid insulation

The choice of insulation for the house is largely determined by its price. You can use expensive imported materials or cheap domestic insulation, which will do well.

But keep in mind that it is categorically not advised to use for insulating houses from beams:

- overall thermal insulation materials;

- expanded polystyrene (for example, Penoplex insulation);

- Styrofoam.

These materials quickly begin to release carcinogens that can cause a variety of diseases. The use of such heat-insulating materials will completely violate the environmental friendliness of a house from a bar.

Use only modern certified insulation. Do not forget that the manufacturer's instructions for their installation must be strictly followed.

Insulation laying and sealing

Having made the crate, lay mineral wool. First, the roll is untwisted, then we cut off a strip of cotton wool in height. The width of the strip should be 1-2 cm greater than the distance between the vertical slats.

Do-it-yourself insulation of a log house from the inside: the stage of laying mineral wool

Next, a strip of cotton wool is placed between the bars and attached to the base of the wall using anchors with round large caps. It is better to do this together: one holds the cotton wool, the other fixes it.

When you fill the entire space between the crate with cotton wool, a second layer of the above-mentioned film is mounted to improve thermal insulation. The film is laid with the rough side on cotton wool. Thus, the ingress of cotton wool particles into the air is prevented.

Fiberglass mats of various sizes can also be used. They can be covered with a vapor barrier film on one or both sides, as indicated on the package. In this case, an additional layer of thermal insulation is not needed.

Schematic representation of thermal insulation of a house wall

Advice! Remember to insulate the area behind the battery. If you do not do this, the heat from it will begin to go outside. Use a special thin foil insulation for this.