Repair and decoration

04/20/2018 Anastasia Prozheva

In recent years, more and more chimneys are made from sandwich pipes. The matter is in the relatively low price, long service life, quite attractive appearance. It is also important that independent installation of a sandwich chimney is possible. This is not a very simple matter - there are many nuances, but you can do it yourself, without the involvement of specialists.

Tinted roofing option

Modern chimney designs

Any chimney performs its only role - it removes carbon monoxide, harmful to the human body. But besides this, modern systems are distinguished by the following design features:

- Lightweight construction. Often, such structures are mounted in frame houses, where excessive stress will only harm the whole house. Sandwich pipes, which are made of thin-walled metal elements, ideally fall under the "light" category. Additional thermal insulation helps to keep warmth, which is why lightweight structures are constantly popular. If necessary, such a structure is very easy to dismantle.

- Compact element design. For such chimneys, ceramic blocks are used. The main advantage of such blocks is a low level of thermal conductivity. The blocks are made with special locks along the edges, which greatly simplifies the laying.

- Economical design option. Ideal for the first time, until funds are available to install a solid system. For masonry, a standard red brick is used, from which a direct-flow shaft is laid. A stainless steel product is brought into the mine and strengthened. At the same time, laying bricks does not require a special kind of mortar or the work of certain masters - everything turns out cheaply, quickly, and of high quality.

This completes the familiarization with the designs of chimneys, now you should proceed to their main varieties.

What to look for when buying

High quality sandwich pipes are made of stainless steel. To distinguish stainless steel from plain steel, you can use a magnet. The stainless steel does not magnetize.

But this is not enough. Technical documentation for sandwich chimneys must necessarily contain information about the brand used in the production of stainless steel. The table below shows which markings can stand and what is their difference.

Number in descending order of quality. Stainless steel grade. General technical characteristics.

| Number in descending order of quality. | Stainless steel grade. | General technical characteristics. |

| 1 | AISI 310S | The most durable brand, with a temperature limit of 1000 c0. |

| 2 | AISI 321 | High strength grade, with a side-altar of 850 degrees |

| 3 | AISI 316 | Contains additives of nickel and molybdenum. High strength and corrosion resistance. |

| 4 | AISI 439 | Contains titanium additives. It is mainly used for gas boilers. |

| 5 | AISI 304 | Alloy with titanium, but in a lower ratio than grade 439. |

| 6 | AISI 430 | Alloy-free grade. |

Depending on the brand, the price also fluctuates, but saving on safety is at least unreasonable.

High quality sandwich pipes are made of stainless steel. To distinguish stainless steel from plain steel, you can use a magnet. The stainless steel does not magnetize.

But this is not enough. Technical documentation for sandwich chimneys must necessarily contain information about the brand used in the production of stainless steel. The table below shows what markings can stand and what is their difference.

Number in descending order of quality. Stainless steel grade. General technical characteristics.

| Number in descending order of quality. | Stainless steel grade. | General technical characteristics. |

| 1 | AISI 310S | The most durable brand, with a temperature limit of 1000 c0. |

| 2 | AISI 321 | High strength grade, with a side-altar of 850 degrees |

| 3 | AISI 316 | Contains additives of nickel and molybdenum. High strength and corrosion resistance. |

| 4 | AISI 439 | Contains titanium additives. It is mainly used for gas boilers. |

| 5 | AISI 304 | Alloy with titanium, but in a lower ratio than grade 439. |

| 6 | AISI 430 | Alloy-free grade. |

Depending on the brand, the price also fluctuates, but saving on safety is at least unreasonable.

The main types of chimneys

Requirements for modern devices for the removal of combustion products:

- High tightness. The system should not let smoke into the room, but bring it out in full.

- High quality insulation. Hot smoke becomes the main cause of fires for wooden partitions, beams and some roofs.

- Thermal conductivity. The heated chimney becomes a source of heat in the room, which is especially appreciated during cold periods of the year.

All of the following types of smoke evacuation systems meet these requirements to some extent.

- Brick. The red brick system was highly functional when using gas or liquid fuels. Firewood, fuel briquettes give smoke at a lower temperature, so brick chimneys have gradually lost their popularity. With a modern solid fuel boiler, such a system does not have time to warm up quickly.

- Ceramic. A versatile material designed specifically for use in high temperature environments. Several layers of smooth ceramic will provide quality traction. Ceramics also withstand high mechanical loads, and their service life is on average 100 years.

- Stainless steel systems. They are durable and resist the deposition of tar and soot on the inner walls. Stainless steel is often used when installing chimneys because of its ability to quickly heat up. Accordingly, less fuel consumption required for heating.

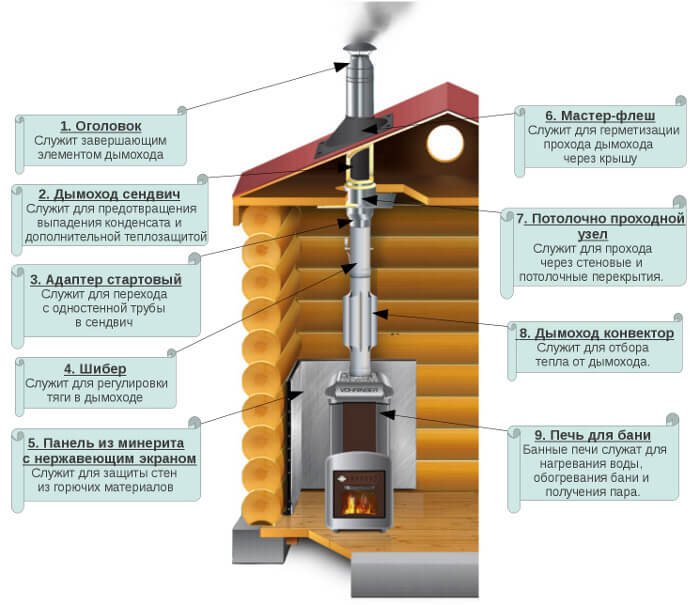

- Sandwich pipe. It is unique due to its design, which reduces the installation time of the chimney, for example, for a boiler room or in a bath. A sandwich pipe consists of three main elements: internal, external and insulation. All connections of such elements are made only using expensive argon welding. As a metal in the manufacture of sandwich pipes, both galvanized sheet and stainless steel sheets are used.

- Cast iron. In modern construction, cast iron is not often used, due to its shortcomings such as slow heating, a tendency to rapid accumulation of soot and tar. Cast iron structures must be cleaned often, otherwise the system will quickly lose its efficiency.

Equipment

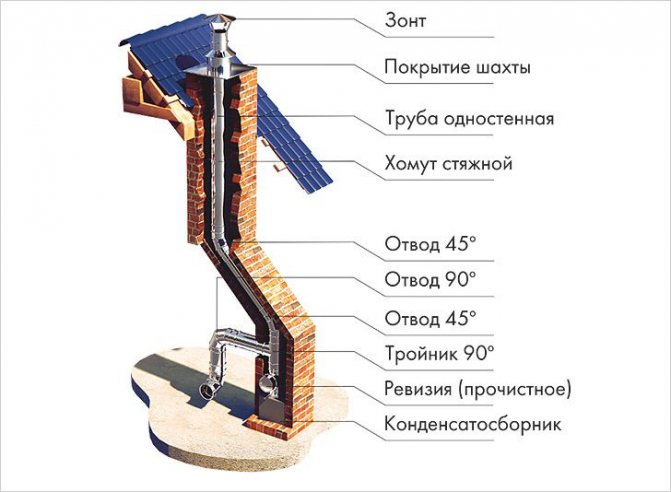

Metal chimney device

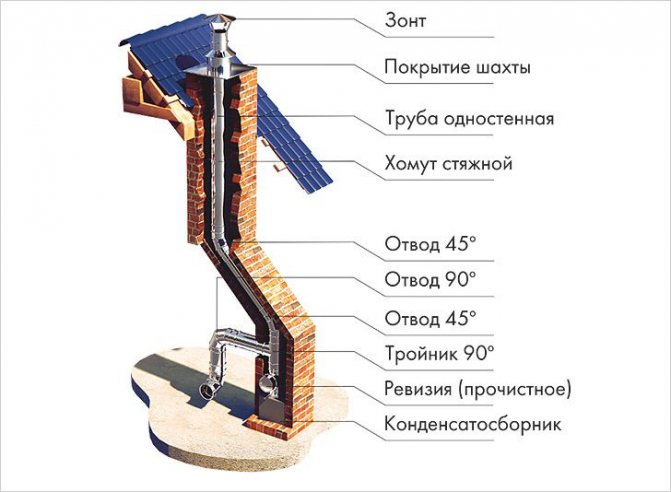

The stainless steel chimney consists of several modules connected in sequence. The kit includes:

- tees installed at the points of connection of several elements;

- straight pipe from 0.33 to 1 m long;

- 45 ° reversing knee;

- 90 ° bend for connecting the outlet and the chimney system;

- container for collecting condensate;

- element for revision and cleaning;

- head with a cap;

- fasteners.

What tools will be required to work

To install a chimney yourself, you need not only patience, but also some tools. If you do everything “on your knees”, it will only lead to more waste of funds in the future. It is not worth saving on construction.

A short instruction and a basic list of tools required for installation:

- Bulgarian. The main tool for those who want to make an even and accurate system for the removal of combustion products. You should not try to replace even the simplest grinder with a hacksaw for metal. It will not lead to anything good.

Bulgarian

- Drill screwdriver. In order not to spend extra money, you can purchase a combined version, since drilling in thin metal does not require a high power drill.

Combined version - drill / screwdriver

- Jigsaw. Only useful in a private house with wooden beams. Using a jigsaw, you can very quickly and accurately make a hole of the required diameter.

Jigsaw

- Trowel with a spatula. When it is necessary to process too large joints, these tools become indispensable. Also suitable for use with refractory sealants.

Important! No work can be started by purchasing protective equipment. Simple construction goggles with clear glass, as well as protective gloves should always be at hand. Especially when working with a power tool.

The main stages of installation of a sandwich chimney

How to install a chimney quickly? The answer is simple: get a sandwich pipe. This material is an ideal solution for a private house, especially if you don't have a lot of experience in construction. You don't even need an assistant to install this material, all the steps can be done independently.

We connect all structural elements

The sandwich pipe has one design feature - ribbed coating on both sides. Such a device allows you to connect elements to each other, simply by inserting different parts into one another. Additional tees should be installed to drain off condensate that will occur during operation.

Series connection of the chimney

All joints must be properly and reliably tightened with steel clamps. To connect the starter part to a boiler, fireplace or other heating device, you must purchase a suitable adapter with two different diameters.

A simple method is used to connect internal products. One inner pipe is taken out at a distance of 10 cm, connected to the second (using a steel clamp of a smaller diameter) and pushed into the outer pipe. For greater tightness, it is not enough to use only clamps; you will also need a special sealant designed to work at high temperatures.

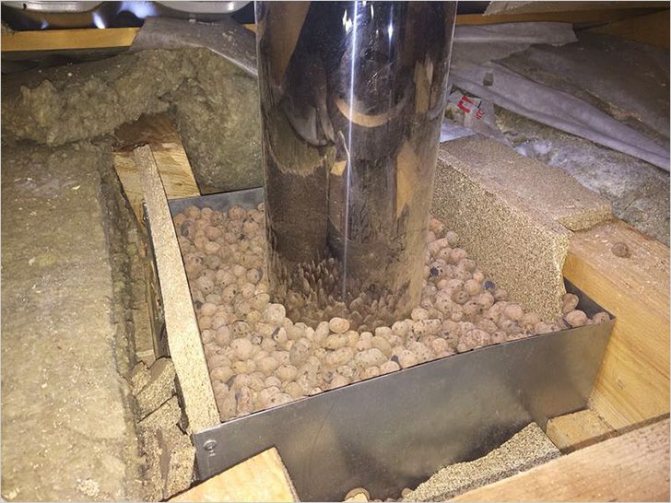

Secure the overlap

When installing a chimney made of sandwich pipes, or other material, through a wall, fire safety rules should be observed. If it is concrete or brick, then it will be enough to simply treat the joint with a sealant. It is much more difficult in wooden houses, where the contact of the chimney with a wooden wall will lead to a fire.

Sealing the pipe passage

How to secure the junction of the drainage system with overlap:

- Use galvanized sheet, which should be fixed to the floor. A hole is cut in the middle of the sheet, and a chimney is inserted into it. The galvanized sheet does not heat up completely and does not transfer excessive heat to the wood surface.

- Treat the distance from the pipe to the nearest wooden surface with insulation. Almost all modern heaters are heat-resistant - they do not ignite at high temperatures.

Instead of galvanized sheet, many builders use asbestos material. It is also highly resistant to high temperatures.

We bring the pipe to the roof

Installing a sandwich chimney and laying it through the roof is the most painstaking part of the job. Here you will need not only to apply physical strength, but also to accurately and correctly calculate everything.

Chimney protective structure

The procedure for bringing the chimney to the roof:

- Make a hole in the roof. To make it neat, the place should be marked in advance using a construction marker. There is no need to rush, because a crooked hole will not add aesthetics to the whole structure. It is most convenient to cut the roof from the inside of it.

- An under-roof sheet is installed from the inside, securely fixed, and from the outside - a roof cut.

- It remains only to bring the outer part through the hole and reliably process the edges with a sealant.

Now you can check the quality of the structure again, and as a final step, remove all the protective film. You can safely melt a boiler or fireplace and watch all the joints and holes treated with a sealant.

Safety regulations

The likelihood of a significant increase in pressure in the channel provides for the closure of the joints with specially designed couplings. It is advisable to seal joints on steel pipes with heat-resistant sealants. Complete insulation of the chimney contributes to the correct draft.

We offer you to familiarize yourself with Sandwich pipe for a bath: installation of a chimney, how to properly install a pipe for a stove with your own hands

Sandwich panels with good thermal insulation characteristics do not exclude the possibility of overheating and possibly ignition of materials located near the chimney. To prevent such a situation, it is recommended to increase the thermal insulation layer at the joints of the structure.

Subject to the main safety rules, it will not be difficult to install the chimney. In addition, it is necessary to provide high-quality maintenance of the canal, including its regular cleaning. This will become a kind of prevention of accidents during the operation of the oven.

Subtleties of installing an external chimney

When installing an external structure, you should know some rules, since it differs from an internal installation. But it is possible to carry out an external system for removing combustion products, as well as dismantling (removing) chimneys, independently, without the help of unauthorized persons.

DIY external chimney installation

Installation sequence for an external chimney:

- Make a hole in the wall opposite the heater outlet. It is much easier if the wall is wooden, then you only need a jigsaw or a hacksaw for wood. If the wall is concrete or made of brick, then you cannot do without the help of a puncher.

- Fix the special brackets along the entire outer wall. It is better to use anchor bolts for fastening. The brackets must be placed at a distance of half a meter from each other.

- Bring the knee out. To do this, first, a pipe is mounted to a heating device, which then passes through the wall and is attached to a metal elbow. The place where the pipe adjoins the ceiling should be properly and reliably sealed with a sealant.

The knee is on the outside of the wall

- After that, the entire outer part of the pipe is assembled, attached to the brackets and to the elbow. The whole structure can be assembled in parts, it will not take much time and effort.

- The installation of the chimney must be carried out in accordance with all the rules of building art, therefore, a head is installed on the upper part of the pipe.

External installation of the structure will not take much time, it is less problematic than internal installation. It is enough just to make one hole and bring out the pipe, and not to run the system through the whole house.

Selection recommendations

Before choosing three-layer pipes, a chimney installation diagram must be drawn. Ideally, such important parameters as the diameter and height of the chimney are calculated by specialists, but homeowners rarely turn to them for help, trying to save money and resolve all issues on their own. To simplify their task as much as possible, we will give several recommendations in this regard.

The diameter of the chimney pipe can be matched to the outlet of the boiler plant.The rule is simple: the flow area of the sandwich should not be less than that of this pipe. More is allowed. As for the height, you can get a guaranteed result if you take its value at least 6 m. Moreover, the height is measured from the grate of the solid fuel boiler to the upper cut of the pipe.

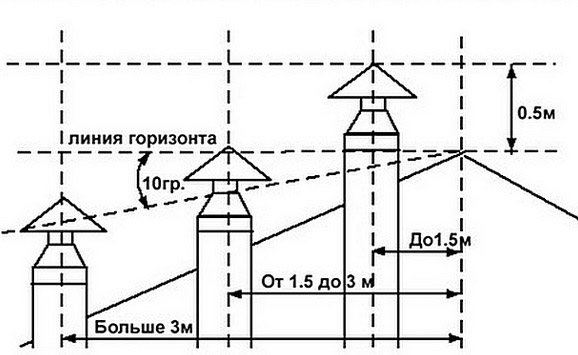

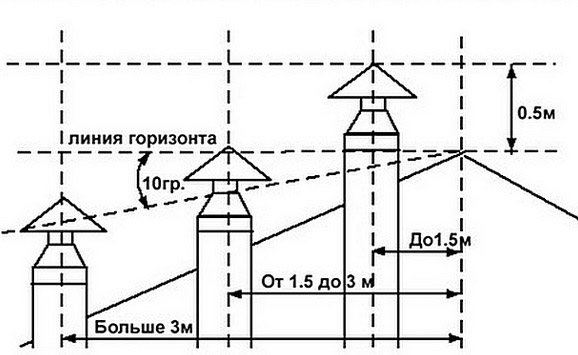

If the boiler is gas, diesel or pellet, then the chimney height must be measured from the burner. In this case, it is necessary that the chimney, or rather, its cut, does not fall into the zone of the wind support, otherwise the natural draft will be very weak. To avoid this, the following scheme is used in the calculations:

In order to reduce the resistance of the smoke ducts, it is not recommended to make a large number of turns, maximum - 3. And then, it is necessary to strive to use bends everywhere at an angle of 45º, not 90. The length of the horizontal section before the tie-in is no more than 1 m. Observing these recommendations, it is necessary to draw a wiring diagram and mark on it the points of attachment of the gas duct to the building structures.

When the circuit is ready, you can safely select sandwich chimneys. There are a few caveats here related to the quality of the products and the presence of a large number of counterfeits on the market. The first moment: high-quality stainless steel alloyed with chrome does not attract a magnet at all. This fact should always be checked by taking with you a magnet wrapped in matter. The latter is needed in order not to scratch the shiny surface of the metal during inspection and not create a reason for conflict with the seller. If the magnet attracts at least a little, then you have a low-quality product.

Pay attention to the thickness of the steel from which the chimney sandwich is made. For example, high-quality Russian-made products sold under the VOLCAN brand are made of 0.5 mm thick metal. When you come across a thinner stainless steel, know that it will burn out just as quickly, be guided when choosing a thickness of at least 0.5 mm.

And the last thing. Take a close look at the tee where the horizontal section cuts. For convenience, ask the seller to attach a condensate collection unit to it. Then the opposite end of the tee, where the chimney sandwich pipe joins, should have a bell, not a narrowing. If not, you should refuse such a purchase.

Note. When connecting three-layer flue modules, the inner contour of the upper section enters the bell of the lower one, and the outer one, on the contrary, is put on the lower pipe. Therefore, on the tee, the socket must be observed from above, in the inner contour. You will get more information about the choice of sandwich chimneys by watching the video:

Installing a cast iron chimney

The combustion product removal system has its own advantages and disadvantages. The main plus is the low cost, minus - now such systems are practically not used, finding cast-iron pipes is quite problematic. Cast iron cannot be called a durable material, unlike steel pipe. It resists frequent temperature changes, but is very sensitive to mechanical damage.

Stages of installing a cast iron system:

- The preparatory stage, in which it is necessary to qualitatively fit all the pipes to each other in order to assemble the entire structure. Important! Pipes should be fitted very carefully, since cast iron is a brittle material. The slightest blow can cause chips or even cracks. To connect the elements of the system, you must use special clamps or metal braces.

- Fasten the pipe in the hole all the way to the roof. It is best to make straight-through systems, without any branches or sleeves. Then there is less chance that the chimney will clog up soon.

- Connect the pipe to the heater. To do this, you must use special cast iron adapters.

- The joints should be properly treated with a refractory sealant.

- After the sealant has dried, you can start covering the chimney with an insulating layer.

- Install and fix the head on the upper part.

After finishing the installation of the system, it should be checked. It is enough to melt the heating device, then inspect all joints. At the slightest smoke transmission, the joint should be re-sealed with a sealant.

Possible installation errors and how to avoid them

The presence of errors during the installation of the chimney can lead to a fire in the ceiling, roof or wall. It is important to keep the minimum distance between flammable objects and the chimney.

Errors and remedies:

- A common mistake is saving space. Sandwich pipes should not heat up as long as they are in good working order. But over time, it is possible for warm air to pass through the thermal insulation layer. In this case, nearby flammable materials may ignite. The presence of sufficient space between the chimney and building materials excludes this possibility.

- Another mistake is neglecting the tightness of the compared parts. It is recommended to cover all joints between the constituent parts of the chimney with a layer of sealant, otherwise the passage of combustion products from the chimney into the environment is possible. The joints between the pipes can be additionally tightened with special clamps.

- The third common mistake is matching pipes only by smoke or condensate type. Smoke matching means that the bell of the overlying pipe is pushed onto the underlying pipe. In this case, smoke will not accumulate in the pocket formed between the pipes, but condensation can drain there. Condensate matching means that the funnel of the underlying pipe is pushed onto the overlying pipe. Condensation cannot drain into the resulting pocket, but smoke will accumulate there. In the first case, there will be a lot of condensation in the chimney, in the second - soot. In order to take advantage of both options in a sandwich pipe, it is sufficient to match the inner cylinders “by condensate” and the outer ones “by smoke”. Matching both cylinders in the same way can quickly clog the chimney.

- A gross mistake is the use of general construction insulation instead of thermal insulation. Many insulating materials are used in construction, but when arranging a chimney, it is necessary to choose materials with the best thermal insulation. This material is mineral wool. When installing external insulation, the use of basalt wool is allowed, but if the pipe heats up significantly from the outside, after a few hours the basalt wool will begin to heat up.