Features of internal and external thermal insulation

Energy experts say that this element is an increased risk zone: a significant part of the leaks of life-giving (and expensive) heat occurs through it. But is it really necessary to force the basement insulation with the help of penoplex or any other modern material? This can be avoided if:

- A basementless house with a low basement superstructure.

- The building is not intended for year-round use (seasonal only).

- The climatic zone does not imply a blizzard and frosty winter (southern regions).

Base / plinth insulation - an important stage in construction

For such situations, it will be quite sufficient to create a warm floor with a water circuit or electric heating.

In all the rest, the basement will have to be sheathed with a layer of insulation, it does not matter - a house is built on screw piles or on an ordinary strip foundation

Warming of the basement of the house is carried out in 2 ways: outside and inside. Without knowing the basics of heat engineering, it is easy to decide that the internal structure of the insulating layer is preferable, since it can be carried out in any weather, with your own hands, and the finish of the basement will not suffer. In fact, such a solution will only disrupt the normal thermal balance in the wall of the building, create a dew point, where condensation water will constantly accumulate. The temperature drop will lead to the gradual collapse of the wall, no matter what durable material it is made of, and expensive repairs.

That is why it is highly recommended to insulate the basement from the outside.

In this video, you will learn how to insulate the foundation:

General Provisions

Polyfoam is widely used to reduce the thermal conductivity of not only the basement, but also the walls, ceiling and floor of any building. Its availability and ease of processing have been to the taste of ordinary people for many years. The most high-quality and durable representative of it is extruded polystyrene foam.

Now let's take a closer look at the technical characteristics of this material.

Extruded polystyrene foam sheets

Dignity

- Very low coefficient of thermal conductivity, similar to that of mineral wool.

- Resistant to temperature changes. Retains its performance after thousands of freezing and thawing processes.

- The operational period is about fifty years.

- Complete waterproofing. Its structure consists of homogeneous closed pores that do not allow moisture to get inside.

- High strength. Carries without consequences a load of up to thirty-five tons.

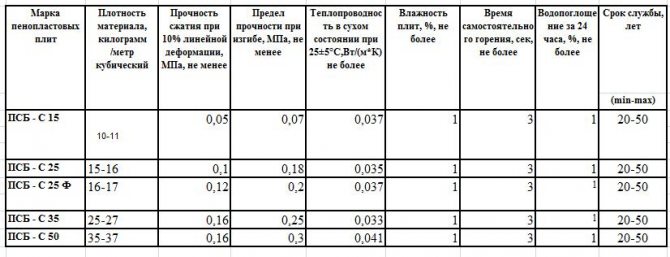

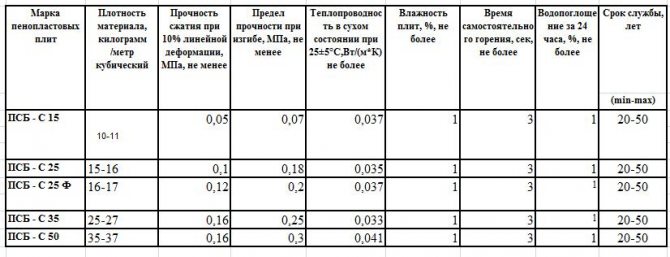

Technical data table for different foam classes

- Low price. The synthetic nature of this insulation makes it much cheaper.

- Non-susceptibility to the processes of decay, the spread of mold and the growth of fungus.

- Sound absorbing properties. Good isolation from street sounds.

- Ease of installation work. Do-it-yourself foam insulation of the basement is not a big problem.

- Fire safety. There is no tendency to catch fire.

- Ecological cleanliness. Completely harmless to humans.

- Assortment of sizes. You can choose the thickness of the slabs from 3 cm to 12 cm, depending on the climate and the material of the exterior finish.

Samples of various thicknesses

Tip: It is recommended to install thicker products on the corners of the building. Because they are subject to the greatest freezing.

External base / plinth protection

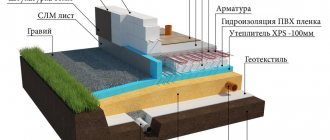

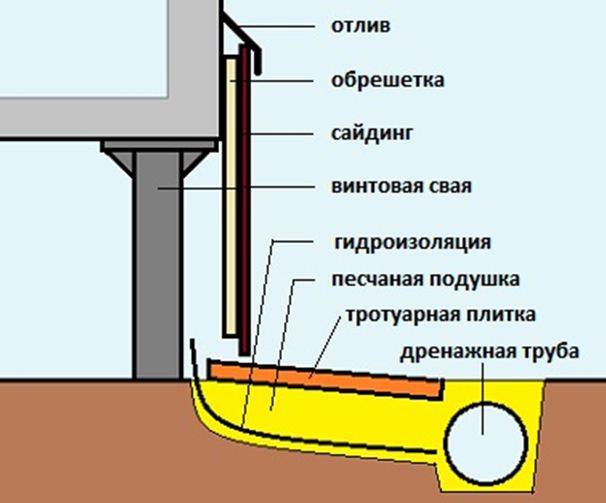

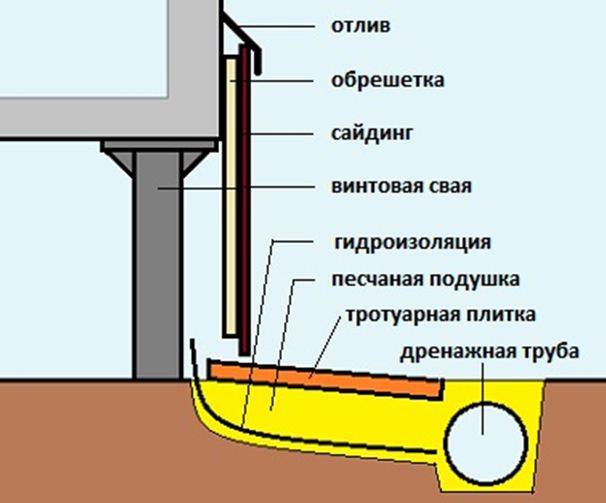

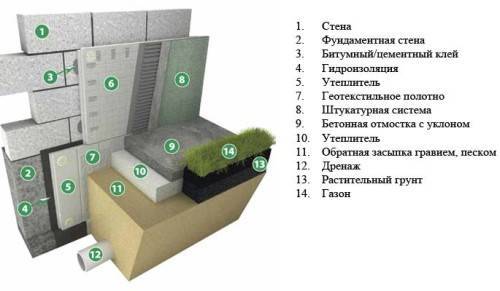

Basement drainage scheme.

Before directly insulating, a drainage system is installed around the house to remove excess moisture. To do this, a trench is torn off around the foundation base, at the bottom of which sand is poured, plastic pipes are laid on top, then everything is covered with earth. The trench should go downhill into the water collection tank. To protect against water flowing from the roof, a concrete blind area is equipped around the house. Now you can insulate the outer walls of the basement.

As a heat insulator, you can use:

- mineral or fiberglass wool, which, when insulated from the outside, is waterproofed on both sides;

- polystyrene with additives to prevent combustion;

- polyurethane foam, which does not require vapor barrier;

- foil-clad penofol, which serves as an additional insulation and vapor barrier;

- inexpensive, moisture-resistant, extruded polystyrene foam with low thermal conductivity.

To insulate the base and prevent moisture from entering it from the outside, it is quite possible to rely on your own strength. First, lists of everything you need are made, then the necessary tools are prepared:

- shovels;

- construction knife;

- drill.

And materials:

- bituminous mastic;

- plates (5-10 cm thick) of extruded polystyrene foam;

- foam for fastening;

- construction mesh;

- dowels with poppet heads larger than mesh cells.

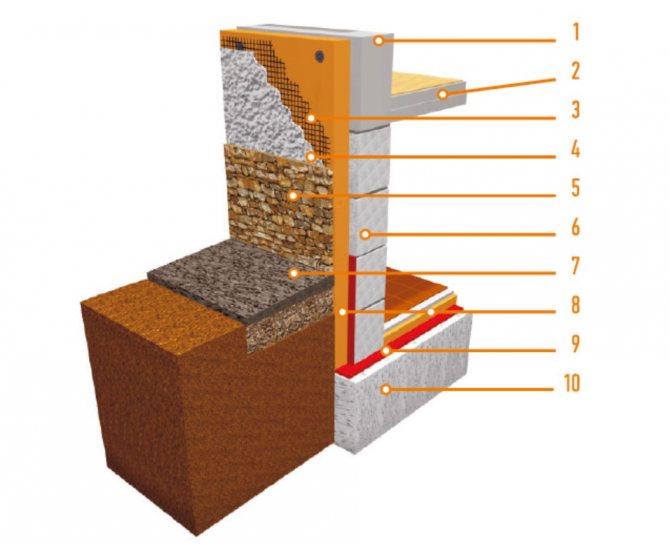

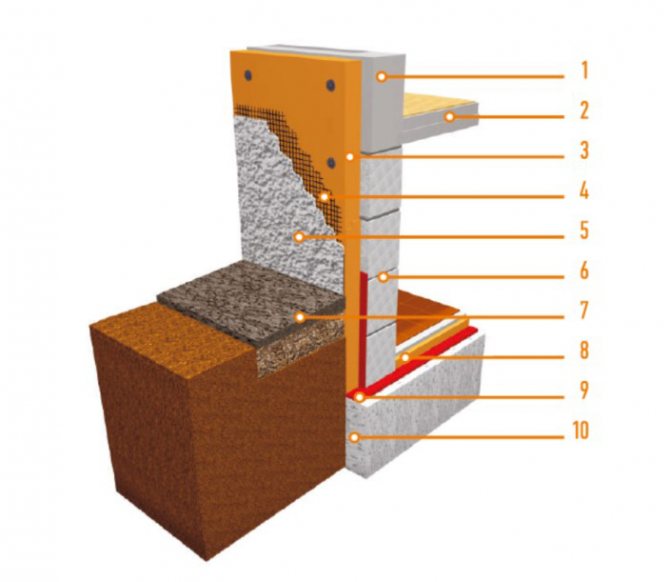

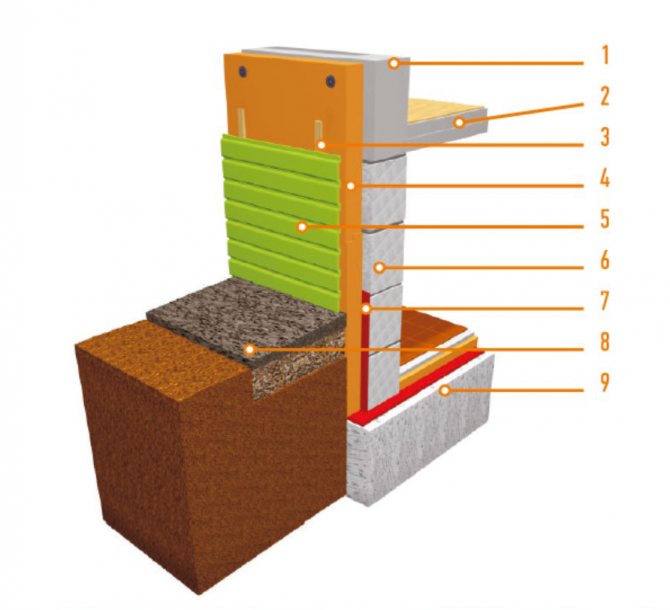

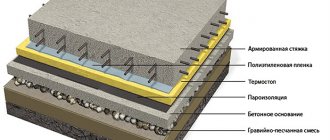

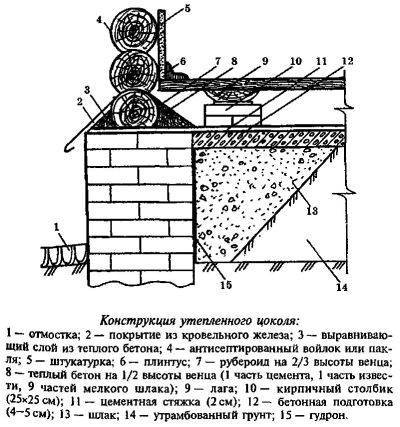

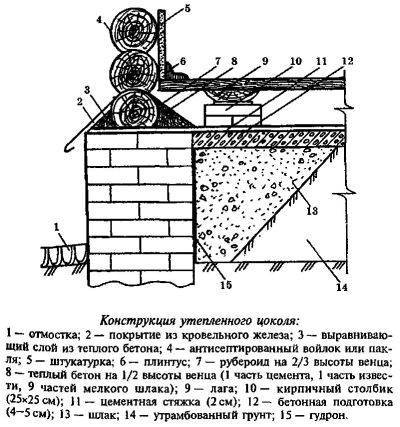

Insulated basement diagram.

Work is carried out:

- Open the foundation of the house 1 m deep and leave it to dry.

- Level the surfaces with a knife for a better fit of the styrene boards.

- From bottom to top, polystyrene foam plates are fixed (without gaps, making mismatching seams) using fixing foam.

- Having drilled holes in the plates, they fix the insulation in the corners with dowels so that they go through the insulator, at the same time reinforcing the structure with a mesh.

- The foundation surface is covered with soil, carrying out its layer-by-layer compaction.

On top of the mesh, a solution of cement and sand can be applied to the surface of the basement, on which the cladding is attached (for example, an artificial stone), or the base can be primed and plastered with facade plaster. A blind area is arranged around the base of the house.

A few points to pay attention to when insulating a basement

Thermal insulation of the basement with foam must be carried out only in conditions of positive air temperature. Operation at above-zero temperatures guarantees the strength and durability of the adhesive connection of the insulation board with the plinth.

Before using this or that glue (mastic), make sure that it does not contain any organic solvents (for example, gasoline, toluene, acetone, etc.). Such solvents destroy the internal structure of the foam. This means that the insulating material will be short-lived and loose. The high-quality finish of the base does not allow this.

When carrying out a preliminary marking of the place of installation of foam panels, it should be borne in mind that the upper line along which the entire future structure is aligned should traditionally be either 2-4 cm below the threshold of the entrance door, or exactly at the level of the site in front of the entrance door.

Following these simple recommendations will help any person, even those who do not have a construction specialty, make a sufficiently high-quality insulation of the basement of the house with their own hands.

Why do insulation

If the house has a basement (or semi-basement) room, then the question arises of how to insulate the basement. It should be insulated in any case, both with a heated basement and in the absence of heating. When the soil freezes in winter, the basement cools down, the cold penetrates the upper floors.

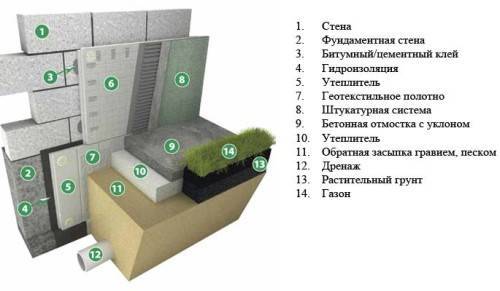

External basement insulation scheme.

There is a collision of cold air from below and warm air from the house, leading to condensation of moisture on the ceiling of the basement and the floor of the upper floor, due to which mold and mildew spread. From seasonal temperature jumps, cracks form in the concrete structures of the basement, and they gradually collapse. Up to 20% of heat is lost through the underground part, which leads to financial losses. Because of these phenomena, it is required to be performed both externally and internally.

Simultaneously with insulation, steam and waterproofing of the basement is often done, because in their absence, some insulation materials get wet and cannot maintain the body. Protection of the base from dampness provides for:

- ventilation device in the basement room;

- a building around the building of the blind area, the width of which is 200 mm greater than the width of the eaves overhang (protection from precipitation);

- arrangement of vertical insulation to the height of the basement and insulation of the basement floor (protection from water in the ground);

- protection device against water penetration through concrete capillaries;

- thermal insulation of the blind area (protection against heaving of the soil during freezing).

Thermal insulation with extruded polystyrene foam

It is very similar to polystyrene, they are practically relatives, but extruded polystyrene foam (penoplex) is much tougher, stronger, and therefore more durable. It is also successfully used to insulate the basement, to protect the protruding foundation from the outside. The material does not rot, is not hygroscopic, it is not damaged by rodents, a service life of at least 50 years is an ideal choice.

This material is tough

Necessary materials

This is penoplex and glue - polymer, based on natural binders or special foam in aerosol cans. The composition of Ceresit CT-85 is also recommended. Nothing else is needed if the insulation of the basement with slab foam does not imply the simultaneous facing of the facade or its plaster.

Features of use

A serious drawback of the polymer, like its other counterparts, is the large number of seams when insulating the basement floor. All of them will need to be monolithic. Sometimes, to simplify installation, special plates with a lock connection are used. Otherwise, the thermal insulation of the basement with such material does not cause questions for experienced installers.

Insulation instructions

Before starting work, the surfaces are thoroughly cleaned, all gaps and crevices are sealed with a cement-sand mortar: they will become sources of heat loss. An adhesive mixture based on one of the selected compositions (for example, Ceresit CT-85) is prepared, if the technology requires it - it is diluted with water, various components are mixed, and so on. The solution is applied not quite usually: around the perimeter - completely, in the center - pointwise. The plates are pressed against the walls, it remains to wait for the glue to set, and then to perform the sealing of the seams.

Materials used to insulate the basement

You can make the basement of a wooden house dry and warm using various materials of natural and artificial origin. The decision on how to sheathe the basement of a wooden house, in each case, must be taken individually, taking into account the advantages and disadvantages of each of them.

Priming

The easiest way is to fill the space between the base of the foundation and the basement with ordinary earth mixed with sand. This "finish" has been used since time immemorial, when other heaters did not exist.

Warming the basement with soil is as old as the world

The undoubted advantages of soil insulation include the relative simplicity and availability of the material. This method has many more disadvantages:

- low efficiency,

- a large number of land works,

- primitive appearance.

That is why it is practically not used at present.

Expanded clay

Insulation with expanded clay is a universal option to increase the protective properties of any building structures - walls, roofs, ceilings, etc. It is also used for the basement. In this case, you should adhere to the following order of work:

- a trench 1 meter wide is dug around the entire perimeter of the house;

- a primer and waterproofing is applied to the surface of the walls outside;

- formwork is installed throughout the trench. Filling height - up to the floor surface;

- a pre-prepared mixture of expanded clay and concrete is poured into the prepared formwork.

Basement insulated with a mixture of concrete and expanded clay

Such a plinth lining retains heat much better than an earthen one. However, expanded clay is a rather fragile material, in addition, concrete noticeably increases its thermal conductivity. The large width of the poured layer also plays a role.

Styrofoam

A wooden house is very often insulated with foam, since it can be inexpensively finished both the internal space of the frame structure and the foundation together with the basement. Foam cladding protects well the surface of the base of the house, and allows you to use all modern decorative materials for finishing the basement.

Since this finish is used very often, here are some important tips:

- The wall surface must be cleaned of dust and primed.

- Since the foam absorbs moisture well, it must be protected with a moisture-absorbing film.

- The height of the foam must be sufficient to cover the entire waterproofing layer of the foundation.

- The strength of the foam is not enough to withstand the pressure of the soil, therefore, a protective structure must be made over its surface. For this, cladding outside with brick or plaster is used.

Extruded polystyrene foam and polystyrene foam

Despite their common origin with foam, these materials have a number of advantages:

- great strength;

- better thermal conductivity;

- moisture resistance.

Finishing with extruded polystyrene foam is carried out using a special glue that is applied to the pre-treated surface. Standard slabs (height 1 m, width 0.5 m) are stacked tightly butt without any gaps. The contact points outside are coated with mastic or glue. If the plinth cladding is carried out in several layers, the slabs are laid with an offset to prevent the formation of "cold bridges". How this is done is shown in detail in the video below:

Polyurethane foam

The highest quality material, the finishing of which is available only with the use of special equipment. It is quite difficult to do this work on your own, therefore, such a plinth facing is the most costly.

For the application of polyurethane foam, special equipment and ammunition are required

But on the other hand, having invested quite significant funds in it, you can be calm about the safety of the foundation with the basement for many years: the service life of such insulation is 50 years or more.

Plinth trimmed with polyurethane foam

It is better to insulate the basement immediately at the construction stage. Correct and timely finishing will help in the future to save significant money on heating and maintaining a comfortable climate in the house.

Warming method

Improving measures for finishing the structures of a house in an already erected building is a very time-consuming task. The work is carried out in cramped conditions. It is inconvenient to use the level and operate with long details.

External insulation technology is used in cases of condensation formation on the inner sides of wall surfaces. Exterior finishing with foam-plastic makes it possible to limit heat escape from concrete, as a result of which the dew point moves inside the room. Adequate external insulation removes it some distance from the wall.Therefore, even with high air humidity in the basement, condensation does not form on the walls.

We suggest that you familiarize yourself with: Vapor barrier membrane which side to the insulation

Thinking in this direction, most developers prefer to do all the work outside.

Thermal insulation of the base with foam

Now this material is used almost everywhere, in addition, with the help of the foam plates themselves, any basement section can be made protruding.

For example, let's take a plinth in a single plane with the outer walls. We use a special paint for finishing. Let's start with our own hands.

Defining boundaries

The foam plates should slightly overlap the waterproofing, so the basement area should be made a few centimeters higher. Take a pencil and draw a horizontal line across the entire wall. You can also pull a regular lace above the waterproofing layer. The border is ready.

At the same stage, we will equip a groove with a depth of approximately 5 cm, in order to then slightly drown the foam plates.

Cleaning the base

The wall surface where you are going to stick the foam must be well cleaned of dirt and dust.

When the primer is dry, you can move on to the next step.

Bonding boards

Strengthening the foam with a special adhesive starts from the corner sections. Using a wallpaper or any other sharp knife, mark and cut a couple of pieces of material that will be needed a little later.

Glue application

Apply glue to the basement area with a notched trowel. Having smeared with the composition, we attach the trimmed products to the desired areas. The joints between the plates and the ends are well covered with an adhesive solution.

When a couple of products are glued, we proceed to dowelling using the previously prepared pieces (they will give additional fixation). A hammer drill is needed to drill holes. Dowels are inserted into the holes formed, after which nails are hammered.

So the entire basement surface is completely covered with foam plates. At the very end, a primer layer is applied again. It is used to create a base for subsequent layers.

Installation of a slope corner and reinforcing mesh

For the installation of a sloping corner made of metal, the previously used glue for the plates is suitable. Fortification sites are the upper perimeter and corner sections of the building.

Reinforcing mesh, like a corner, is glued to the foam. This time directly from above. Before starting work, the product is cut, depending on the size of the plates. When the required number of elements is ready, the surface of the future insulation system is covered with glue using a wide spatula. Ultimately, the reinforcement mesh is placed on top of the products and is equal to the spatula.

Putty, painting, installation of ebbs

It is allowed to putty the basement areas only with materials intended for outdoor use with a wide trowel. When the composition is dry, the surface is primed again and then painted.

But for additional protection, ebb tides can be installed to prevent moisture from entering the insulation and other places where it should not be.

Using this technology, you can insulate the basement with your own hands with both foam and polystyrene foam, since they are almost identical. If any defects appear on the surface of the insulation system, they can be easily eliminated by a new primer followed by painting.

Pros and cons of expanded polystyrene

Expanded polystyrene transmits heat very poorly, so its maximum amount is stored indoors.

Against the background of all other materials, expanded polystyrene looks very advantageous. This can be explained by several reasons and advantages of insulation. Expanded polystyrene transmits heat very poorly, so its maximum amount is stored indoors. The material is not afraid of moisture.Even if it is under heavy rain for several days, it will still remain completely dry.

Even taking into account the fact that expanded polystyrene is a material of artificial origin, the insulated structure can breathe freely. At the same time, over time, the insulation will not rot or lose its properties under the influence of the fungus.

Many people choose this particular insulation due to the fact that it additionally is an excellent sound insulator. It mutes even the loudest sounds, so the house will remain quiet. It is worth noting that expanded polystyrene does not lose its attractive appearance over time, it does not deform and does not collapse under the influence of various factors.

Like any other building material, polystyrene foam has some disadvantages, of which there are not so many. The material does not tolerate some types of solvent, so you should be careful with them. Especially with benzene and dichloroethane. The insulation can be damaged by a variety of rodents, so it is worth making sure that they are not in the house.

The downside is that polystyrene foam burns very well.

But today, manufacturers have been able to eliminate this drawback by treating the sheets with a special anti-combustible solution. There are different types of insulation on sale. Additionally, the protected material will have a special marking.

This insulation has a very affordable cost and a minimum number of disadvantages, which makes it so popular in construction. In addition, installation does not require any special knowledge or skills and it will take a minimum amount of time to install the insulation.

Materials (edit)

In order to quickly carry out the process of insulating the basement from the outside, it is worth preparing in advance all the consumables that may be needed during construction work.

- Expanded polystyrene plates. Their number is calculated taking into account the perimeter of the base, which needs to be insulated.

- Film for the waterproofing layer.

- Roofing material.

- Reinforcing tape.

- Special reinforcing fiberglass mesh.

- Adhesive for expanded polystyrene.

- Dowels with umbrella-shaped caps.

- Putty.

- Bituminous mastic.

Materials should be taken with a small margin, so that in case of unforeseen situations during the installation of insulation, there are no hiccups.

Instruments:

It is also worth preparing in advance all those tools that may be required.

- Cart, shovel and bucket. They are used during trench preparation and further soil removal.

- Metal brush and broom, with which the base will be cleaned of soil and dirt.

- A container in which you can make cement mortar, putty knife and trowel.

- You will need a roller or large brush to apply the barrier mixture.

- To cut styrofoam, you should use a hacksaw or a sharp clerical knife.

- A staple gun to install vapor barrier and waterproofing.

- Screwdriver so that you can quickly screw in the screwdrivers.

It is important to prepare all those tools that will be required so that the installation process takes as little time as possible.