The Lemax gas boiler has long been known to consumers in Russia and the post-Soviet space. The equipment produced by the domestic company of the same name is capable of heating a house of any area, the main thing is to correctly calculate the minimum power. The manufacturer offers several series of heaters - with the promising names Leader, Patriot, Wise, Prime-V and Wester Clever. Each series was developed for domestic conditions. All models have Russified automation, they are easy to maintain and control.

About company

The history of the brand began in 1992, in the basement of the city of Taganrog. The company, having gone from a mini-firm, has grown to a large factory, and has taken a stable position in the domestic market. The equipment is manufactured on high-tech lines, which makes it possible to produce competitive products at prices attractive to domestic consumers. The boilers of the Taganrog plant correspond to the ideal ratio of the price-quality formula.

Benefits

Judging by the reviews, the products of the Taganrog plant evoke more positive emotions from users than negative ones. It really deserves to be commended in terms of design, performance and economy. Its advantages include:

- High efficiency - 90-92%. This is a good characteristic for domestic gas appliances.

- External appeal - the heaters are distinguished by their ergonomic design and look beautiful in modern interiors.

- Safe operation - a reliable, multi-stage protection system is provided.

- Simple connection.

- Long service life - with proper operation and timely maintenance, they can work for a quarter of a century. The warranty is 3 years.

Floor models

Floor standing devices make up the lion's share of the products manufactured by the manufacturer. And the demand for them is greater among consumers. Such versions are usually used for heating a private house - they need more power and reliability. Wall-mounted versions are more often chosen by apartment owners - but they cannot compete with European brands. The principle of operation is simple - a burner built into the housing heats up the heat exchanger of the heating and hot water system - if there is a second circuit. Coolant circulation - natural (non-volatile) or forced (volatile). Piezo ignition is used. Floor-standing gas heaters are available with heat exchangers:

- With steel. Thickness - 2 mm. Steel single-circuit boilers of floor-standing type are non-volatile and operate only for heating. Double-circuit - simultaneously heat water for domestic needs. The models are economical - gas consumption is practically the same as that of Vailant.

- With cast iron. Thickness - 4 mm. The cast iron single-circuit heating boiler has the best characteristics in the entire Lemax model range. Cast iron is resistant to aggressive environments, not afraid of overheating. Heat exchanger type - sectional. Manufactured by VIADRUS (Czech Republic).

Installation process

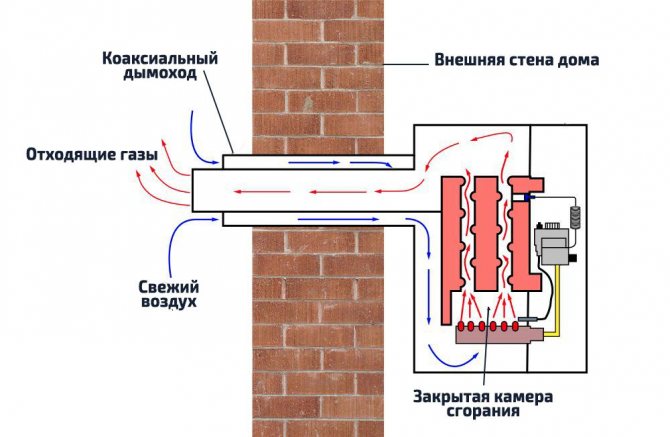

The installation of a parapet gas boiler is carried out in the following stages:

- If the wall covering on which the device will be hung is flammable, it should be removed at least in an area equal to the projection of the boiler onto the wall.

- A hole is made in the wall in accordance with the diameter of the chimney. It must be provided that the pipe is positioned with a slight slope towards the street to drain condensate.

- A coaxial pipe is inserted into the resulting hole and fixed. The presence of a certain slope should be checked. For example, for a wall of one and a half bricks on the outside, the pipe should be 4 mm lower than the inside.

- In accordance with the position of the installed chimney, the places for fastening are marked on the wall. Then the holes are drilled and the fasteners are mounted on the wall.

- The boiler, depending on the model, is either wall-hung or floor-mounted.

- The pipe connection is attached to the unit. Heating sections are being installed.

- Heating and water supply pipelines are connected to the boiler nozzles (depending on the model).

- The gas connection to the device and the first start-up must be carried out by a gas specialist.

Depending on the model of the unit, some of the installation items may be slightly different.

Note! In order for the heat exchanger of the parapet unit to work as long as possible, it is recommended to install a filter on the tap water inlet pipe.

Mounted models

The wall assortment is more modest. All models are volatile. Automation - made in Italy. Factory settings. During operation, nothing needs to be adjusted. The main thing is to ensure voltage stability. Automation, if desired, is connected to the unit of remote thermostats. There is protection against:

- overheating;

- blowing out the fire;

- soot formation;

- reverse thrust.

Minus - there is no protection against freezing and pump jamming. The modulating burner, like the automatics, is Italian. The modulation principle allows economical consumption of gas and increases the efficiency of the device. Connection is classic. Connection to a regular chimney is required.

Installation of boilers "Lemax"

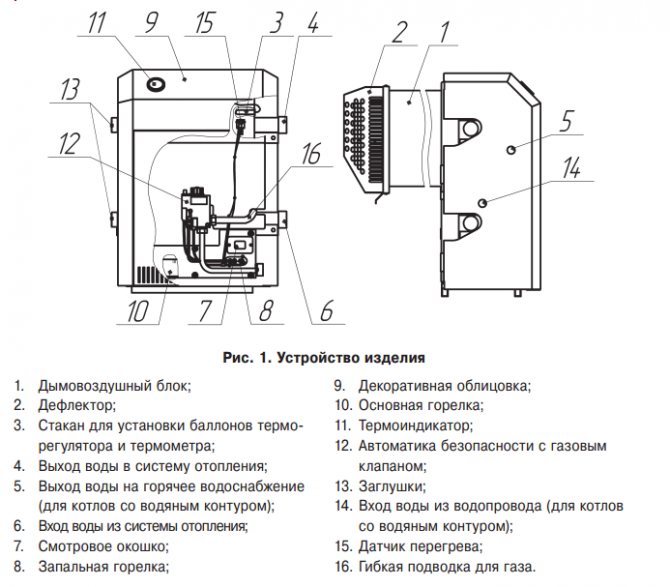

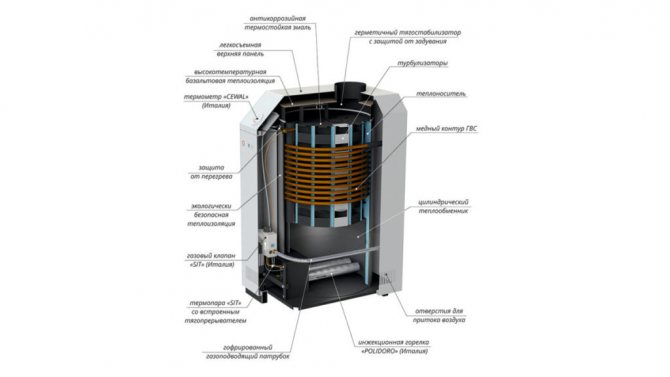

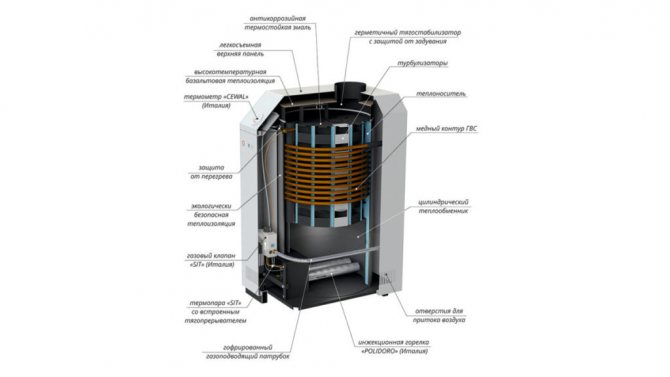

The main components of any gas heater:

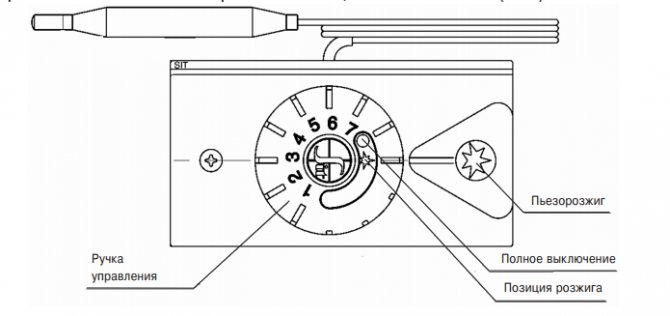

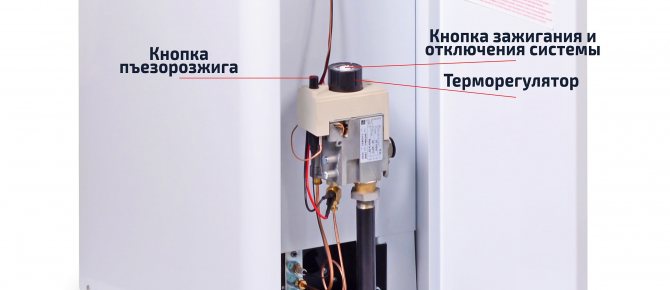

- Gas burner block - burner (POLIDORO, Italy), wick (igniter), piezo ignition. By pressing the button, the piezoelectric element is activated, and the wick is set on fire with its help. The main burner is ignited by the pilot.

- Heat exchanger. Tubular type, nozzles are connected to the heating system. The coolant is heated in it. If there is hot water supply, it is necessary to take into account that when the water heater mode is turned on, the heating system stops working.

- Automation. Control board and sensors from NordGas. Gas valve Sit.

- Expansion capacity CIMM.

- Circulation pump Wilo.

The company independently develops the layout of elements and assemblies, operating instructions, expands the network of service centers. The brand has repeatedly become a sales leader among floor-standing boilers for autonomous heating of private houses and industrial premises.

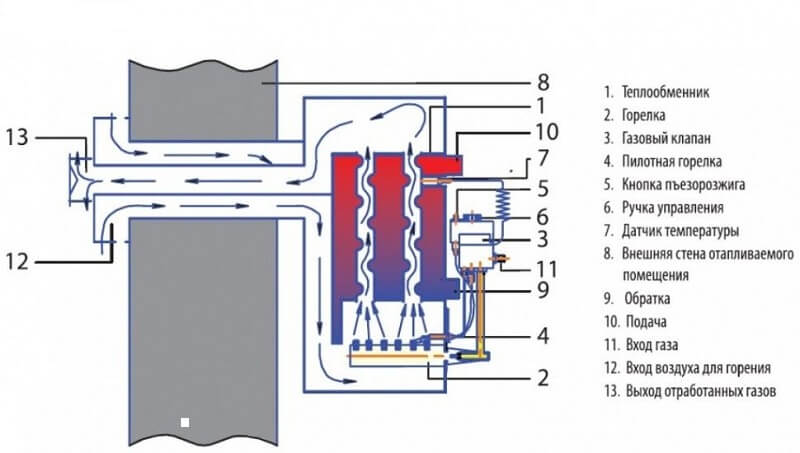

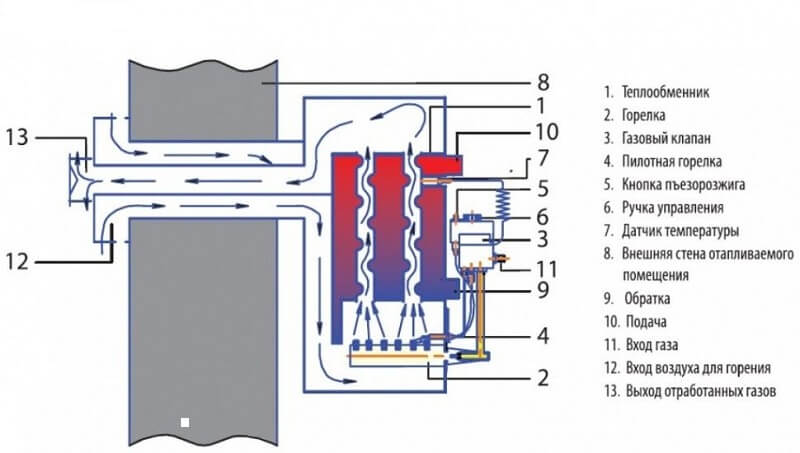

The principle of operation of parapet gas equipment

- The burner device is ignited with a wick or igniter.

- Combustion gas generates heat, which heats the boiler.

- Mains water with the help of a circulation pump or with natural circulation, when heated, leaves the boiler and enters the heating devices located in residential, public or industrial premises.

- The gas combustion process will continue until the water in the heating circuit heats up to a predetermined level, after which it will be automatically turned off by the gas valve installed in front of the boiler.

- The wick continues to function, and will re-ignite the burner when the temperature of the heating water drops.

Pros and cons of parapet boilers:

- Indoor use.

- Affordable prices.

- Small geometrical dimensions of the installation.

- Speed and ease of installation work.

- Can be used without installing additional radiators.

- Large power range.

There is only one drawback - volatility.

Installation

Violation of the installation rules leads to breakdowns and malfunctions. It is recommended to trust the installation to specialized specialists. Requirements for the installation of Lemax heaters are no different from the usual ones, but there are nuances that are important to consider:

- The automation unit contains a thrust sensor. If the combustion products are not discharged sufficiently intensively, the burner will turn off. During installation, it is necessary to provide for the creation of conditions for traction.The manufacturer advises to connect the device to a chimney made of sandwich pipes.

You don't have to spend time or money to connect and launch - everything is simple and fast. The settings, as mentioned above, are factory settings, and the adjustment is mechanical.

Automation unit

The gas valve plays a key role here. It is controlled by analog sensors (in non-volatile versions) or electronic controllers that receive data from electronic sensors (in volatile versions).

The valve of the combined type is assembled from two valves - simple and electromagnetic. The first is held open by a spring. During start-up, the second valve is opened by pressing a button - to ignite the wick. It is held for some time - the igniter warms up a special element that reacts to heating. This element starts generating electric current - it keeps the solenoid valve open, the user can release the button. When the igniter is blown out, the thermoelement cools down - the generation of electric current will stop, the solenoid valve will close. Another valve - with a spring, will close after a signal from the traction and temperature sensors.

What is a parapet boiler

The boiler body is made of steel with a thickness of 3 mm, painted with a special refractory anticorrosive spraying, which ensures its resistance to mechanical and corrosive influences.

The main elements of the boiler:

- closed type firebox;

- gas burner with igniter;

- coaxial chimney;

- two heating circuits with independent boilers made of copper and steel.

Control unit: pressure and draft sensors, thermometers and thermocouples, they protect the boiler from overheating. When the draft in the firebox drops to 0 mm.w.st, the boiler instantly begins to overheat the water, when the temperature rises above 65C, the signal from the plate will go to the cut-off device, it will shut off the gas, and the combustion will stop.

The thermocouple, under the influence of heat from the gas flame, creates a small voltage that drives the gas valve. During the absence of combustion, the voltage in it drops to 0 V, the valve instantly cuts off the gas supply to the boiler.

Possible malfunctions

The equipment of Taganrog manufacturers undoubtedly requires some improvements. Often there are problems with water heating - the devices cannot provide users with the desired amount of hot water in the required volume. Therefore, it is more profitable to buy a single-circuit device, and already connect a BKN to it - an indirect heating boiler. You can also choose a hinged or parapet (with a closed combustion chamber) boiler. Possible problems:

- The burner shuts down spontaneously. The reason for this may be insufficient traction or breakdown of the thermostat.

- It smells like gas. Perhaps the leak is due to poor gaskets in the threaded connections - replacement is needed.

- Long, red-orange flame. Burners clogged or insufficient draft.

- Cooled batteries with a hot boiler - there is not enough coolant or installation errors were made.

Choosing a location for the installation of parapet units

Parapet gas boilers are installed in the same way as conventional ones in non-residential premises: kitchen, hall, corridor. They are placed only on the outer wall of the house. If the walls are built of combustible material, then the distance from them to the pipe must be at least 20 cm. The surface on the side of the boiler and pipe must be protected with fireproof materials.

…

The coaxial chimney should not be located next to other facade elements or objects. The permissible distance to the chimney is about 30 cm. The chimney must not go out onto a balcony, loggia or under a canopy.

All about parapet gas boilers here

Single-circuit parapet gas boilers - how they differ from traditional units

The best parapet gas boilers

The chimney should not interfere with people passing by the wall or neighbors who smoke through the window.

For units with a capacity of up to 7 kW, it is allowed to place the pipe at a distance of 25 cm from the window. If the boiler is more powerful, then 50 cm.

…

When a gas boiler is located on the ground floor, the height of the pipe installation cannot be less than 0.5 m. And if there is a passage for people at the outlet of the chimney, its height should be from 2.2 m.

From balconies and other elements protruding more than 40 cm, it is allowed to place a pipe no closer than 2 m (with a unit power of more than 7 kW - 3 m).

The chimney should be positioned in such a way as to provide free access to it, which is necessary for the maintenance and servicing of the chimney.

There should be no flammable objects inside the room near the gas boiler, the permissible distance to them is 30 cm.

Near the unit panel and its shut-off valves, free access of 1 m is required for control, operation and repair.

Service

Some malfunctions revealed during operation can be eliminated by yourself:

- Traction sensor problems. It can cause emergency shutdown with excellent traction. False operation occurs due to oxidation of the contacts - they need to be cleaned. If the sensor is completely broken, it is easy to replace it with a new one.

- Ignition problems. Ignition does not take place due to weak burning of the wick. How to fix the situation? Set the required flame power. You can read about this in detail in the instructions. Also attached to the equipment is a connection diagram and a data sheet.

In almost any specialty store, you can buy units and parts to be replaced. Repairs may only be carried out by an authorized employee.

Features of operation of boilers "Danko"

According to the instructions, the boiler should be put into operation only after the acceptance procedure by specialists from the gas service, as well as after they have given instructions. remember, that repair and maintenance of equipment should be carried out only by qualified specialistswith the appropriate permission.

When buying equipment, be sure to take into account the project developed by the gas service, which indicates the required power and type of unit.

During the operation of the Danko boiler, follow the following safety rules:

- service should be carried out only by those who have been properly instructed;

- if the equipment breaks down, turn off the taps;

- when you smell gas, turn off the gas cock, open the windows and call the emergency service;

- equipment must be kept in good working order and clean;

- periodically clean the chimney;

- once a week, check the filling of the system by the presence of water in the expansion tank;

- after the equipment has reached the end of its service life, call a specialist to decide whether it can be used further.

Model overview

The manufacturer offers several lines, in which all possible designs of boilers are presented - atmospheric and parapet, single and double-circuit, steel and cast iron, floor-standing and mounted.

Wester clever

The line of four models is atmospheric convection boilers, differing only in power indicators. The Wester Clever 20/30 is characterized by high heat transfer, the heat carrier at the outlet is heated up to 90 ° C. Wester Clever 30 specifications:

• efficiency - 90%.

• Heating power - 34,000 watts.

• Weighs 85 kg.

• HxWxD - 961x470x556 mm.

• Fuel consumption - 1.75 m3 / h.

Wester Clever 40 - has a higher throughput. It consumes fuel - 2.5 cubic meters per hour. Heating capacity 45,000 watts. Weighs 110 kg. The most powerful representative of the series is Wester Clever 61.

It can work non-volatile or be connected to the mains. The maximum gas consumption is 3 cubic meters. m / h. Works without interruption even at a pressure of 6 mbar.

Premium

Installed in rooms with chimneys.Power range in the line - from 8 to 100 kW. There are modifications with one and two circuits. Universal - can be connected from either side - left or right. Automatic regulation of the intensity of the fire. Made of 2mm steel sheets. Heat exchangers treated with anti-corrosion agents. Devices are provided to prevent the blowing out of the flame. As an example - Premium 16:

- The efficiency is 90%.

- Single-circuit. Atmospheric type.

- Volatile.

- Heating capacity 16,000 watts.

- Weight - 55 kg.

- Heats up to 160 m².

For heating large areas, Premium boilers 70-100 kW are suitable. These are powerful devices weighing up to 250 kg.

Premium Nova is an upgraded version of the Premium line. There is an automatic system that supports the specified parameters. Adjustment of the coolant pressure is provided.

Patriot

It is possible to work with any type of ventilation - natural or forced. Parapet and wall versions can be installed in apartments. Combustion products are removed through a coaxial chimney. The heat exchanger is treated with an anti-corrosion compound. Power 6-20 kW. There are injection mini-torches and overheating protection. Features Premium -12.5:

• efficiency - 87%

• 12.5 kW.

• Parapet installation.

• Non-volatile.

• Closed firebox.

• 50 kg.

Wise

Material - Czech cast iron (4 mm). Ideal ratio of heat carrier volume to mass and heat exchanger area. They are not afraid of temperature and gas pressure surges. If desired, switch to liquefied fuel. It is also possible to connect indirect heating tanks, thermostats, remote climate control systems. Heating capacity in the line - from 16 to 60 kW. Wise 35 parameters:

• Single-circuit device. Floor installation.

• Open firebox.

• Heating capacity 35,000 watts.

• efficiency - 90%.

• There is an auto-ignition.

• 141 kg.

Operation and setup

The operating requirements are detailed in the user manual, which must be read carefully before using the unit.

The key to successful operation is competent and high-quality installation. Floor-standing models are installed on a non-combustible substrate (a layer of asbestos, on top of which a metal sheet is laid), and wall-mounted boilers are hung on brackets fixed with anchor bolts.

Only strong load-bearing walls are suitable for installation, temporary and plasterboard partitions for hanging are prohibited.

Setting up the boiler consists in adjusting the factory settings in order to increase the efficiency and stability of operation.

The boiler must be adjusted by a specialist from the warranty workshop.... Performing work on your own can damage the unit.

In addition, unauthorized work with gas equipment is an offense and can be punished under the competence of the gas service.

Download instruction

Download the instruction for the Danko gas boiler.

Leader

Equipment with cast iron heat exchangers. Their surface is silver-plated. At the bottom of the furnace is an injection burner. With only one circuit. 19-55 kW. They can heat from 150 to 500 m². Most expensive versions. Service life - 25 years. Automation - Nova Sit. Pressure and temperature are automatically regulated. They can function without electricity. Due to a special turbo nozzle, the intensity of the removal of combustion products increases. Leader 80 parameters:

- Weight 196 kg.

- 92% efficiency.

- Heating area 500 m².

- At the outlet, the maximum water temperature is 80 ° C.

- Open firebox.

- Auto ignition.

Specifications

Consider the characteristics of gas boilers:

| Parameter | Value |

| Boiler type | Gas heating |

| Fuel type | Natural gas with the option of converting to liquefied gas |

| Feature set | Heating and hot water supply |

| Combustion chamber type | Atmospheric or turbocharged |

| Average gas consumption | 1.9-2.7 m3 / h |

| Efficiency | 92 % |

| Heating area | 70-900 m |

| Energy consumption | Non-volatile or single-phase 220 V 50 Hz |