OPERATING MANUAL Introduction …………………… ..

Page 3

- Picture

- Text

3

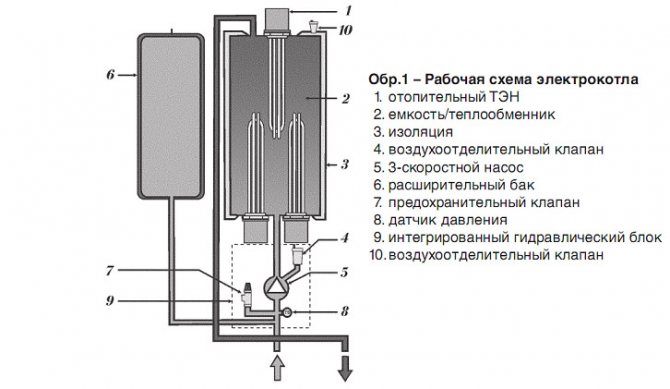

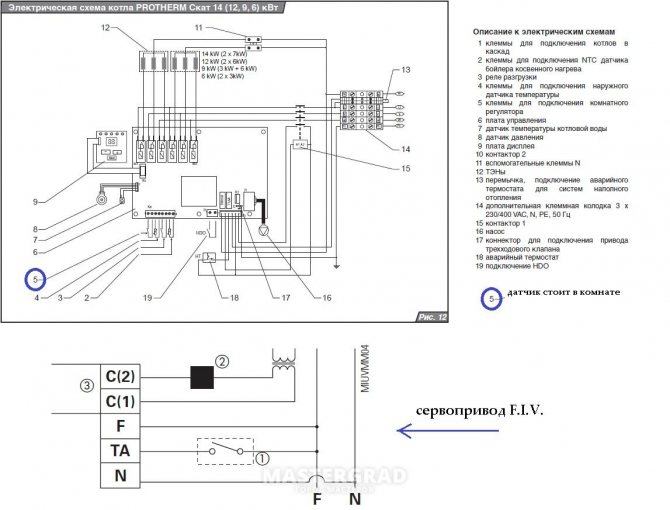

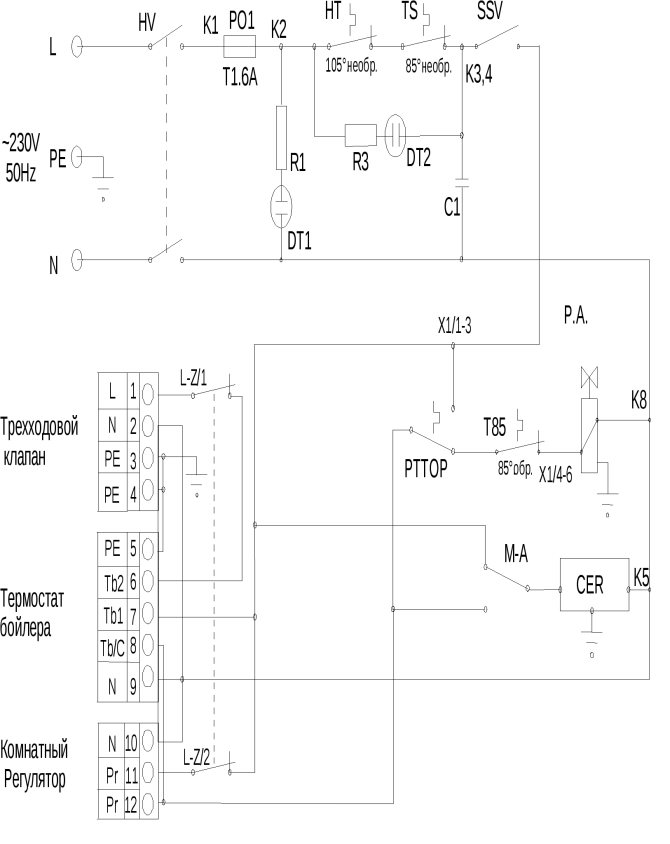

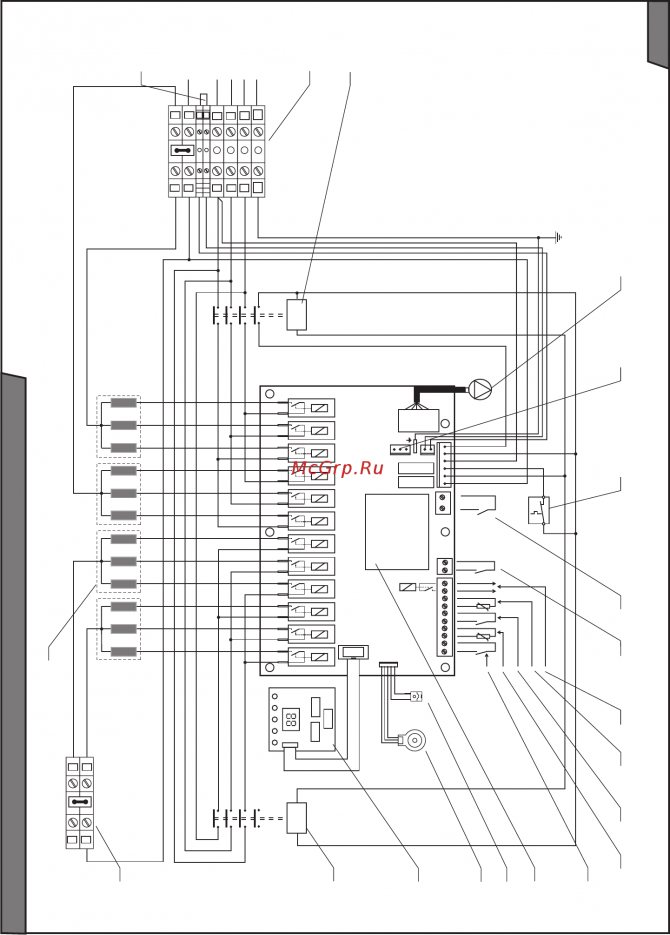

OPERATING MANUAL Introduction ………………………………………………. 4 Control and signaling ……………………. 6 Selecting the reading mode ……………………. 7 Selecting the setting mode ………………………. 8 Boiler malfunction messages …… .. 10 Boiler operation control diagram …………. 11 Boiler characteristics …………………………. 12 Starting up and shutting down the boiler …………………. 13 Boiler operation regulation ……………… .. 13 Boiler safety functions …………………… .. 15 Maintenance and care ………… 17 Transport and storage ……………… .. 18 Warranty and warranty conditions …………… 18 Technical parameters ……………………… .. 19 Connecting dimensions ………………. 20 Schematic diagram ………………………… 21

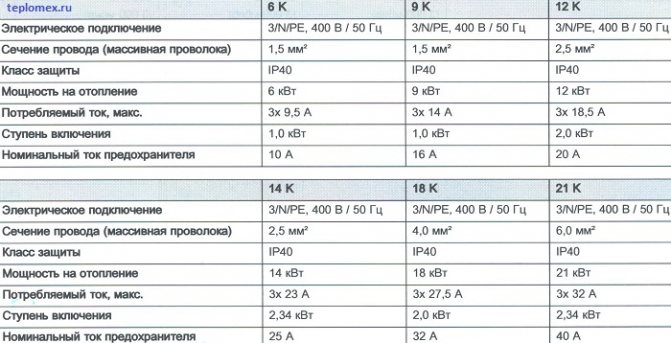

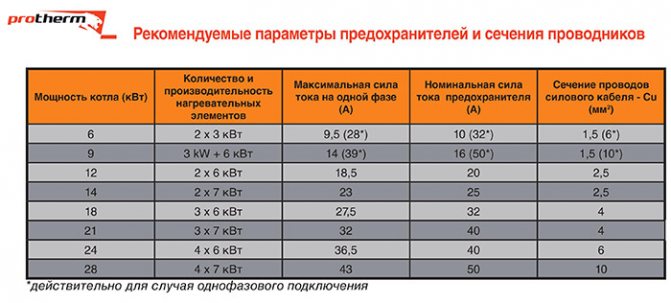

CKAT 6, 9, 12, 14, 18, 21, 24, 28 K

Serial number, type designation, boiler technical data are indicated on the nameplate

located on the bottom panel of the boiler drum. To read information on

on the nameplate, it is necessary to remove the front panel of the boiler casing.

The section "Operating instructions" contains a description of the main functions of the boiler.

and recommendations for its safe use. Section "Installation instructions"

intended only for specialists of service and installation organizations.

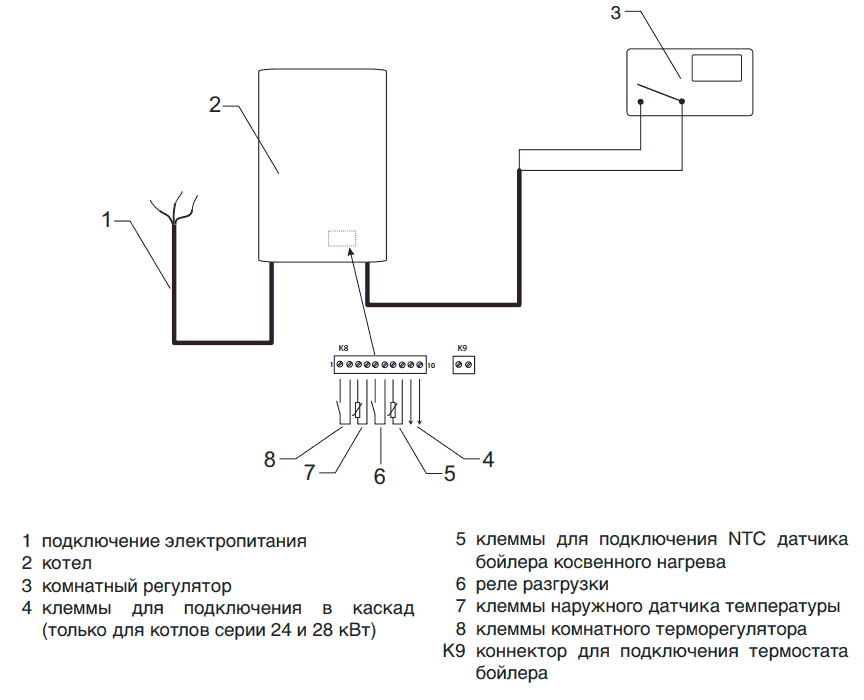

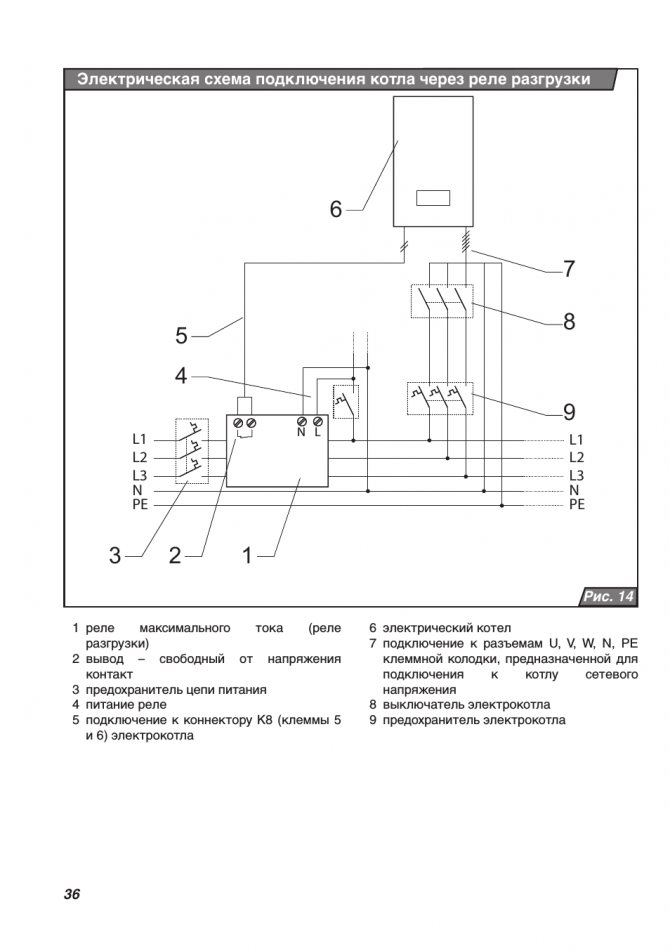

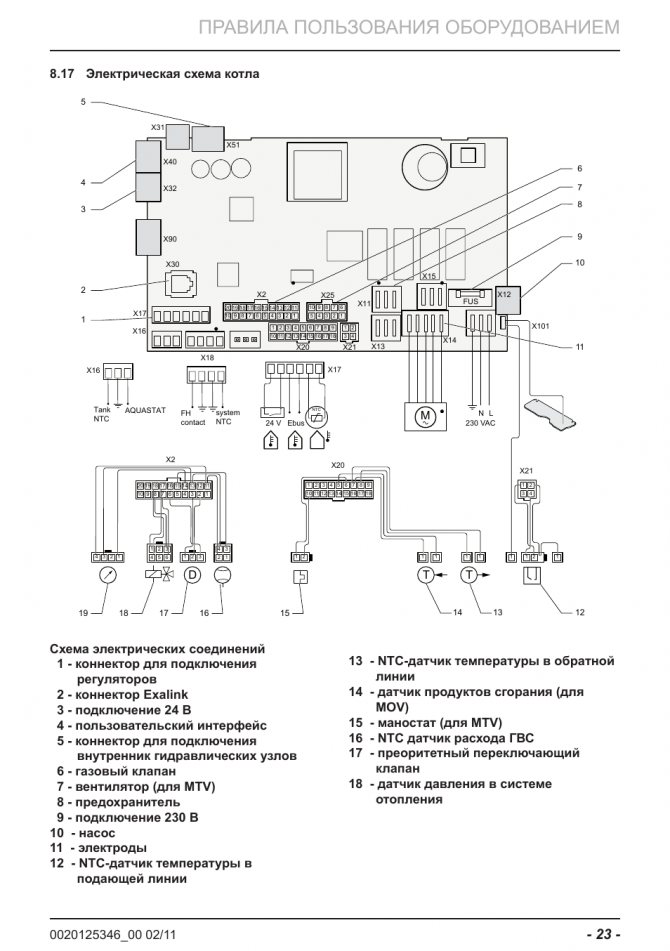

INSTALLATION MANUAL Introduction ……………………… .. ……………………………… .. 25 Connecting the boiler to the power supply network ………. 26 Wiring diagram for connecting an indirect heating boiler …………………. 28 Boiler wiring diagram …………………. 30 Boiler malfunctions …………………………… 37

0020095669_04

Popular models

Electric boiler Protherm Skat 9 KR 13 is the most purchased. It is used for heating rooms up to 90 sq. m.

As we have already said, electric boilers from Protherm are represented by the only Skat line. Therefore, all equipment has similar characteristics, differing in electrical power and current consumption - all other data are identical, up to dimensions and weight. As for the most popular models, they are 9 kW, 12 kW and 21 kW designs..

In addition, the Skat model range includes models with a capacity of 6 kW, 14 kW, 18 kW, 24 kW and 28 kW - the maximum heating area depends on the power (in the calculations, it is necessary to take into account heat loss and the possibility of connecting a boiler).

Introduction

Page 4

- Picture

- Text

4

You have become the owner of a direct-flow electric boiler for central heating systems with the ability to regulate thermal comfort. We hope that the Skat electric boiler will serve you for a long time and reliably. When installing and maintaining it, certain rules must be followed. Therefore, we ask you to carefully read the contents of this maintenance manual and, when working with the boiler, act in accordance with the recommendations and instructions given therein. We believe that the SKAT electric boiler will help you create a pleasant atmosphere and optimal thermal comfort at home. Please pay attention to the following main points:

1.

The boiler, together with the associated equipment, must be installed and used in accordance with the project documentation, the relevant laws and technical regulations in force, and the manufacturer's instructions.

2. The boiler must only be installed in

specially designed premises.

3. Putting the boiler into operation after

installations can only be carried out

a specialist from a specialized organization certified by Protherm.

4.

The boiler complies with the requirements of standards and regulatory documents in force in the territory of the Russian Federation, which is confirmed by a Certificate of Conformity issued by an authorized body, a Permit for use from the Federal Service for Environmental, Technological and Nuclear Supervision.

5.

In the event of any malfunctions, contact only a specialized service organization - non-professional

Introduction

tampering may affect the warranty of the equipment.

6.

The employee of the service organization putting the boiler into operation is obliged to familiarize the user with safety precautions when servicing equipment and controlling the operation of the boiler; operations that the user has the right to perform independently and operations that only a qualified specialist of the service organization has the right to carry out. If the specified service organization is also a supplier of the boiler, it is obliged to ensure that the original packaging of the boiler is kept in case of possible transportation.

7. Check the integrity and completeness.

delivery.

8. Make sure the type supplied to you is

the boiler according to its input parameters (indicated on the nameplate), is suitable for operation in this region. Input parameters mean: voltage of the electrical network.

9. In the case when you do not have a certain

to be sure of the correctness of your actions on boiler maintenance, find and carefully study the relevant instructions and recommendations contained in this maintenance manual, and act exclusively in accordance with them.

10.

Do not remove or damage the markings or inscriptions on the boiler.

Keep the original boiler packaging in case of possible transportation intact until the boiler is put into operation.

11.

Use only original spare parts for repairs. It is forbidden to tamper with the internal structure of the boiler and make any changes to its design.

12.

In the event of a prolonged shutdown of the boiler, it is recommended to empty it and disconnect it from the power supply. This recommendation is made taking into account the general

Operational safety

Heating a room with an electric heat generator must be completely safe. Operational safety is ensured by the following systems:

- Emergency shutdown system. It is initiated by a special overheating sensor. An emergency shutdown occurs when the coolant reaches a temperature of more than 1000 degrees.

- Automatic delay of turning on and off heating elements according to the set power.

- Emergency pressure sensor. The mechanism is triggered as a result of a decrease in the coolant pressure below 0.8 bar.

- Five degrees of protection of the device, depending on the voltage.

Electric boilers Proterm, used for the equipment of an autonomous heating system, are high-tech modern devices. They are suitable for use in climatic conditions typical for our country.

What is a deaerator in a boiler room is a noteworthy issue for people who are not familiar with this device.

Read about the types of deaerators here.

Without fail, boilers are equipped with electronic control and a security system, which makes their work as safe as possible. The devices have a very high efficiency (99.5%), which significantly reduces the cost of heating a house or other premises.

Installation of equipment is not difficult, does not require later on the availability of special skills for maintenance.

Instruction ↑

- The boiler is installed by a specialist in accordance with the project documentation.

- Before starting, a specialist instructs consumers on the principles of equipment operation.

- Before turning on the boiler, it is necessary to connect it to the network, open the taps on the heating circuit and check the pressure level in the system (it should be within 1-2 bar).

- The display shows the setting options.

- The consumer sets the required temperature for the heating system, the water supply circuit (when the boiler is connected) and the required power.

- If the pressure in the system drops, the “bar” light flashes on the display. This indicates the need to add water to the system. If the pressure still drops, you need to see a specialist.

- If the boiler is stopped for a long time, it will be necessary to disconnect it from the power supply and turn off the taps. If this happens during the winter, the water must be drained from the system to prevent freezing.

Attention: Do not use abrasive or other chemical agents to clean the boiler. The surface of the housing can be wiped with a damp cloth and then wiped dry.

8. Any malfunctions in the operation of the equipment are diagnosed by electronics and information with an error code is displayed on the display. Code numbers are deciphered in the instructions. 9. If the boiler is faulty, for example, water starts to drip from the heat exchanger or it is frozen, it is prohibited to connect it to the network. You need to call a specialist for diagnostics and repairs. 10. Boiler parts can only be replaced with original spare parts.

Model range of Protherm boilers - single-circuit and double-circuit

Proterm gas equipment is produced by a European manufacturer in several modifications, which allows you to choose the model that is optimal in terms of functionality, as well as a practical and most convenient model in operation.

Wall type

Wall-mounted gas equipment has undeniable advantages, including compact size, external aesthetics, excellent operational properties, the ability to adapt to operation with different energy carriers by means of a standard nozzle replacement, as well as cost effectiveness.

- "Panther". Inexpensive model with two heat exchangers for space heating and water heating. A modern heater with the ability to operate in a closed system. It has reliable frost protection, automatic gas cut-off and pump control.

Inexpensive heater option in the Protherm line

- "Jaguar". A low-cost option of equipment that does not have a winter / summer mode. Double-circuit unit with a closed type of combustion chamber and control by means of handles.

Simple model with the minimum required set of functions

- "Cheetah". Double-circuit turbocharged boiler with a capacity of 11-23 kW and a closed type of combustion chamber. Even low-power models are capable of heating 10-11 liters of water in one minute. A wall-mounted device in which the movement of the heat carrier is carried out forcibly.

Turbocharged boiler with high efficiency

- "Tiger". It features a neat appearance, informative LCD display and very simple operation. There is a possibility of programming for different modes of operation or functioning in the automatic mode "comfort". There is a possibility of automatic regulation of the combustion process, it is distinguished by a special ignition system.

Compact equipment with different operating modes

Main characteristics of the boiler

Floor type

Floor standing single-circuit and double-circuit boilers have several advantages that make this type of equipment in demand among consumers. It is impossible to ignore high performance indicators, maximum heat transfer efficiency, economical fuel consumption, wide functionality and guaranteed durability.

- "Bear". The high quality cast iron heat exchanger makes the unit durable and very reliable.The model has a "Winter-Summer" mode and convenient traction control. It has automatic regulation of the combustion process and is distinguished by a special ignition system.

Cast iron heat exchanger assumes long-term boiler operation

- "Buffalo". An easy-to-use and durable boiler with high efficiency, capable of operating on various types of fuel. A very powerful unit with a high degree of reliability.

Powerful equipment that can run on different types of fuel

The main characteristics of the Bison model

Floor standing boiler with reliable heat exchanger

Main characteristics of the model

Stationary heating gas boiler

Main characteristics of the model Bear KLOM17

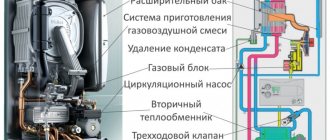

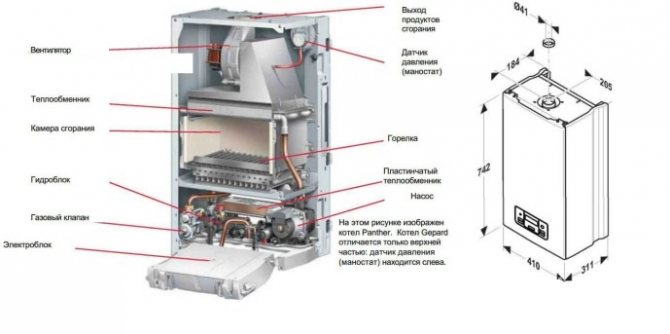

Gas boiler device Proterm

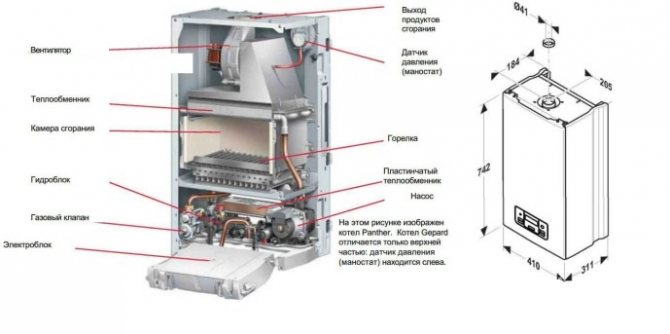

Various modifications of gas equipment have individual characteristics of the device.

The manufacture of boilers using low-temperature cast iron contributes to the effective minimization of heat losses. A feature of the device of heating devices of the brand "Proterm" is also an unusual, rather environmentally friendly way of burning fuel.

The main units of gas heating equipment are presented:

- ignition system;

- burner;

- heat exchanger.

The heat source is represented by the flame of the burner, in which the gas is burned, and the heat exchanger is responsible for heating the heat carrier. The gas supply process is controlled by a thermostat, while the combustion products, represented mainly by water vapor and carbon dioxide, are removed through the chimney system.

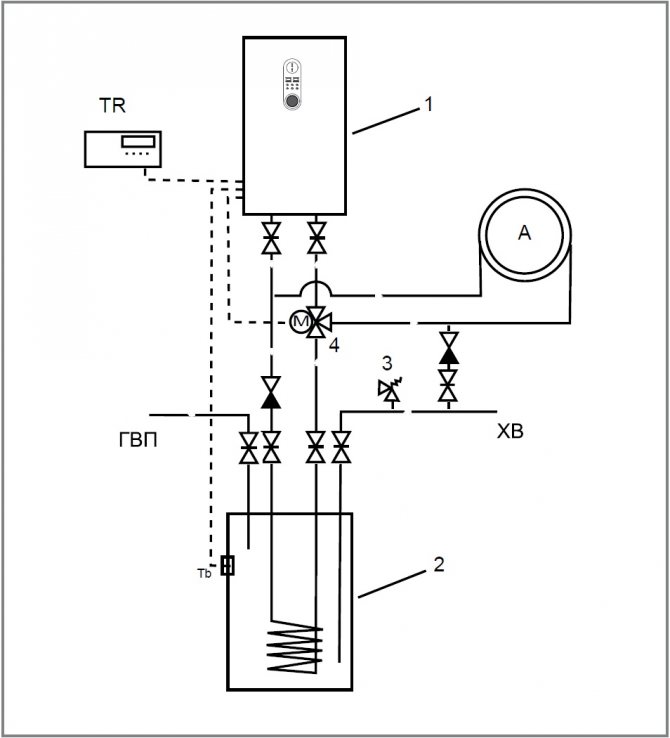

Proterm boilers are used for heating and hot water supply