The use of gas boilers for the organization of autonomous heating is considered the most effective and economical way.

Among the many different options stand out for their low price and high quality floor-standing boilers of the domestic company Lemax.

They are economical and do not use electricity, which distinguishes them favorably from most foreign counterparts.

To heat a private house, apartment or other premises, it is necessary to use a unit of appropriate power.

Consider the performance of the Premium 10 model, suitable for heating a medium-sized private house.

Gas boilers Lemax Premium 10

The Taganrog plant Lemax produces several lines of gas boilers, of which the Premium series can be considered the most extensive.

It consists of models of various powers, from 7.5 to 100 kW... All units are floor structures that do not use electrical energy. This feature is very attractive for residents of the private sector or owners of country houses, where interruptions or power outages often occur.

The Premium series offers a wide range of units for rooms of any size and volume.

There are models with a capacity from 12.5 to 40 kW, capable of preparing hot water, which allows us to consider them conditionally two-circuit. They have a copper coil built into the heated water jacket, where heat energy is transferred to the flow of domestic water..

The boilers have a removable top panel for easy access to internal parts and assemblies when carrying out repairs or maintenance.

Gas floor boiler Lemax Premium-40

GK "PROMTEPLO" offers to purchase GRPSh, GSGO, GRPN, GRU, PGB, GRPB, GRP, ShRP, gas meters, gas filters, gas pressure regulators, PURG, ShUURG, TKU, BMK, gas boilers KOV to enterprises of Russia and the countries of the Customs Union. On the website, you can place an application using the feedback form, or by calling us by phone. Delivery of equipment is possible in the following cities Abakan, Aktobe, Almaty (Republic of Kazakhstan), Angarsk, Arkhangelsk, Astana (Republic of Kazakhstan), Astrakhan, Atyrau, Achinsk, Barnaul, Berezniki, Biysk, Blagoveshchensk, Bratsk, Veliky Novgorod, Velikiye Luki, Vladivostok, Volgograd, Vologda, Voronezh, Gorno-Altaysk, Yekaterinburg, Zlatoust, Ivanovo, Izhevsk, Irkutsk, Ishim, Yoshkar-Ola, Kazan, Kansk, Kaliningrad, Karaganda, Kirov, Kokshetau, Kemerovo, Komsomolsk-on-Amur, Kostanay, Krasnodar, Krasnoyarsk, Kuibyshev, Kurgan, Kyzyl, Kyzylorda, Kostroma, Leninsk-Kuznetskiy, Lensk, Lipetsk, Magnitogorsk, Mariinsk, Mezhdurechensk, Miass, Mirny, Moscow, Murmansk, Naberezhnye Chelny, Nakhodka, Neryungri, Novgorod , Novokuznetsk, Novorossiysk, Novosibirsk, Noyabrsk, Ozersk, Omsk, Orenburg, Orsk, Pavlodar (Republic of Kazakhstan), Penza, Perm, Petrozavodsk, Petropavlovsk (Republic of Kazakhstan), Prokopyevsk, Pskov, Rostov-on-Don, Rubtsovsk, Ryazan , Samara, Saint Petersburg, Saratov, Saransk, Symph Eropol, Sevastopol, Skovorodino, Slavgorod, Stavropol, Sterlitamak, Surgut, Taldykorgan (Rep. Kazakhstan), Taraz, Tobolsk, Togliatti, Tomsk, Tynda, Tyumen, Ulan-Ude, Ulyanovsk, Ust-Ilimsk, Ust-Kut, Ust-Kamenogorsk (Republic of Kazakhstan), Ufa, Khabarovsk, Khanty-Mansiysk, Cheboksary, Chelyabinsk, Chita, Shadrinsk, Shymkent, Yuzhno-Sakhalinsk, Yurga, Yaroslavl, Yakutsk and other cities. GRPSh, GSGO, GRPN, GRU, PGB, GRPB, GRP, ShRP, gas meters, gas filters, gas pressure regulators, PUG, SHUURG, TKU, BMK, gas boilers KOV are delivered to all cities of the Republic of Kazakhstan, Belarus and other countries of the Customs Union , upon agreement by phone.For selection and ordering, requesting permits (quality certificate, permission to use, product passport, Gazsert certificate), specification of characteristics, specification of production time, request for dimensional, functional diagram, passport for industrial gas equipment, contact tel.

© GK "PROMTEPLO" +7

Privacy Policy.pdf

Features of the model

The Premium 10 model has a power of 10 kW, which is optimal for heating a house up to 100 m2.

Thanks to their simple and reliable design, the units demonstrate stable and efficient operation. The efficiency of the Premium 10 boilers is 90%, which is achieved by the absence of losses for their own heating or for the transfer of energy outside the heat exchanger.

The model has a sturdy 2 mm steel tank for long-lasting and stable operation.

The Italian automatic equipment Sit was used, which regulates the operation of the unit.

The weight of the boiler is significantly lower than that of other units of this class and is only 41 kg. The heat exchanger has high-quality protection from a layer of anti-corrosion enamel, as well as an inhibitor coating to eliminate operational deposits (soot, soot, other layers).

What functions does

Lemax Premium 10 boilers are completely single-circuit, capable only of heating the coolant for the heating system.

An additional function of the boiler is convection heating of the room in which it is located, which makes it possible not to install radiators in it.

In addition, the following functions are available:

- Heat exchanger overheating control.

- Protection against the disappearance of draft or blowing out of the burner.

- Pressure control with a pressure gauge on the front panel.

The boilers do not differ in the abundance of functionality, but this is what allows to reduce gas consumption and increase the reliability of the system.

Lemax boilers of the Premium series

The boilers run on natural gas GOST 5542-96 and are supplied assembled with a gas burner device.

The working water pressure in the heating system is not more than 2 kgf / cm2, in a closed heating system it is necessary to install a security system with a safety valve for a pressure of not more than 1.5-1.7 kgf / cm2

- Extended range of capacities from 10 to 40 kW.

- New design.

- The presence of a protection system against overheating, interruption of traction, soot formation, as well as from blowing out the boiler.

- Convenience of boiler maintenance due to the use of removable cladding elements and profile accessories.

- Convenience of boiler cleaning due to the use of a removable top panel.

- Improved safety protection system (installed heat exchanger overheating sensor).

- The maximum efficiency is achieved due to:

- increasing the heat exchange area;

- changes in the design of the turbulator for maximum delay of exhaust gases.

- Increased primary and secondary air flow.

- Hot water function.

- 3 year warranty.

- Read this manual before using the boiler.

- Installation work, instruction in operation, commissioning, preventive maintenance and repair of the boiler are carried out by a specialized organization and the local administration of the gas industry in accordance with the "safety rules for gas distribution and gas consumption systems" approved by the Gosgortekhnadzor of the Russian Federation, and building codes and regulations SNip 11-35 -76; SNip 2.04.05-91 Gosstroy of the Russian Federation, according to the project for the installation of the boiler and the mandatory filling of the control card.

- The assembled boiler can be put into operation only after it has been accepted by the gas industry specialists, instructed by the owner and the mandatory filling in of the control coupon for the installation (page 21 of the operation manual)

- Inspection and cleaning of the chimney, repair and supervision of the hot water heating system are carried out by the owner of the boiler. When replacing an old boiler with a low efficiency with a modern one, you should pay special attention to the design of your chimney. When the boiler efficiency is below 80-85%, the flue gas temperature is about 200 ° C, which ensures good draft even with a poorly insulated chimney. With an efficiency of 90%, the temperature of the flue gases drops to 110-120 ° C, and, in the case of an outdated chimney, the draft disappears, which leads to the operation of the automation and shutdown of the boiler. Failure statistics show that 94% of problems with boilers arise from an incorrectly executed chimney.

- Natural ventilation must be provided in the room where the boiler is installed. Do not cover the grilles of the ventilation ducts.

- The use of boilers at hazardous production facilities is prohibited.

- The volume of the room in which the boiler is installed must be at least 8 m3. The distance between the boiler cladding and the walls must be at least:

- Natural ventilation must be provided in the room where the boiler is installed.

- When installing the boiler to the heating network, it is necessary to lay a sheet of non-combustible heat-insulating material on the floor, on top - a sheet of iron, install the boiler on it.

- The connections between the boiler and the heating system and the gas main must be threaded so that the boiler can be disconnected if necessary. If the boiler is installed instead of an old boiler, it is imperative to flush the pipelines and radiators of the heating system from rust, scale and sludge deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer of the boiler. In this case, claims regarding the temperature indicators of the coolant during the operation of the boiler are not accepted by the manufacturer.

- With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the coolant is significantly exceeded - the number of radiators, pipes) from the established standards, the temperature of the coolant may not reach 80 ° C, which does not mean boiler failure.

- The capacity of the coolant in the heating system should not exceed:

Comparative table of technical characteristics of boilers Lemax Series Premium

| GSU 12 | GSU 15 | GSU 19 | GSU 24 | GSU 30 | GSU 35 | GGU 40 | GSU 45 | |

| Rated heating capacity, kW | 10 | 12.5 | 16 | 20 | 25 | 30 | 35 | 40 |

| Efficiency% not less | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Exhaust gas temperature ° С, not less | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 |

| Vacuum range at which stable operation of the boiler is ensured, Pa | 4-25 | 4-25 | 4-25 | 4-25 | 4-25 | 4-25 | 4-25 | 4-25 |

| Nominal gas pressure, Pa | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 |

| DHW circuit performance ∆ 30 ° С, l / min. (at an inlet water temperature of at least 15 ° C) | — | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Maximum gas consumption, m3 | 1.2 | 1.5 | 1.9 | 2.4 | 3 | 3.5 | 4 | 4.5 |

| Maximum water temperature at the outlet of the boiler, ° С | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Chimney diameter, mm | 100 | 130 | 130 | 130 | 130 | 130 | 140 | 140 |

| Gas pipe diameter, inch | 1/2’’ | 1/2’’ | 1/2’’ | 1/2’’ | 1/2’’ | 1/2’’ | 3/4’’ | 3/4’’ |

| Diameter of connected branch pipes, inch | 1 1/2’’ | 2’’ | 2’’ | 2’’ | 2’’ | 2’’ | 2’’ | 2’’ |

| Overall dimensions, mm: | ||||||||

| - Height | 748 | 744 | 744 | 961 | 961 | 961 | 1016 | 1016 |

| - Width | 330 | 416 | 416 | 470 | 470 | 470 | 532 | 532 |

| - Depth | 499 | 491 | 491 | 556 | 556 | 556 | 608 | 608 |

| Weight, no more, kg | 39 | 53/58 | 53/58 | 75/80 | 80/85 | 80/85 | 100/106 | 100/106 |

General Notes

Installation, preparation for work

Premium 10 - 150 liters Premium 25 - 375 Liters Premium 12.5 - 180 liters Premium 30 - 450 liters Premium 16 - 240 liters Premium 40 - 600 liters Premium 20 - 300 liters

Warranty obligations

The warranty period of the boiler operation, if the obligatory annual preventive maintenance is performed and the consumer observes the conditions of transportation, storage, installation and operation, is 36 months from the date of sale.

Specifications

Consider the parameters of boilers Lemax Premium 10:

| Parameter | Value |

| Boiler type | Floor standing gas convection |

| Number of contours | 1 |

| Volatility | Not |

| Fuel type | Natural gas |

| Power | 10 kW |

| Maximum heating area | 125 sqm |

| Gas pressure | 13 mbar |

| Gas consumption | 0.6 m3 / h |

| Heat exchanger material | Steel 2 mm |

| Dimensions (edit) | 738 × 330 × 499 mm |

| Weight | 41 kg |

Advantages and disadvantages

The advantages of the Premium 10 model can be considered:

- Economical, low gas consumption.

- Energy independence.

- Structural strength.

- Ease of Management.

- Repairs and maintenance are not significant problems.

The disadvantages include:

- Lack of water heating function.

- There is no circulation pump, which makes it necessary to install an external unit.

IMPORTANT!

The absence of some units is not so much a disadvantage as a specific feature of the units, which simplifies the design and increases its reliability.

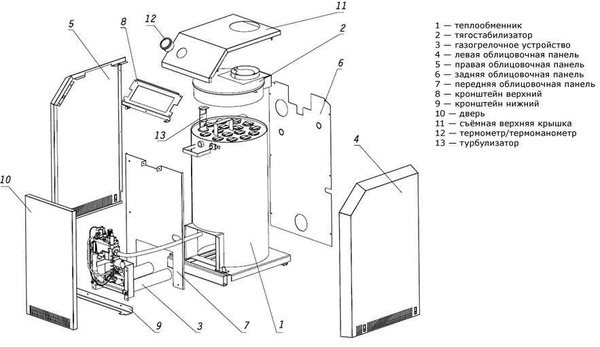

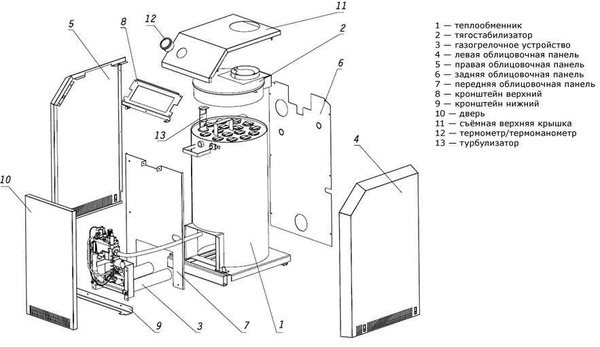

Device

The Lemax Premium 10 boiler is a metal welded container, in the front part with an opening in which the combustion chamber is located. This design is used to apply more pressure to the direct flow of the hot coolant so that a stable circulation is formed.

The upper part of the structure has a branch pipe for connecting a chimney... The inlet and outlet pipes of the heating circuit are located at the back of the boiler, therefore it should not be installed close to the wall.

There are removable panels that can be easily detached and provide access to the control handle and piezo ignition button.

How to connect

After delivery of the boiler, it must be installed in a previously prepared place. There must be at least 15 cm free space at the rear and 10 cm at the sides, as well as 1 m at the front for maintenance or adjustment.

The boiler is installed on a sheet of iron, under which a non-combustible substrate is placed.

The gas pipeline is connected in accordance with the established rules and regulations.

Check the tightness with soapy water. Connect the direct and return pipelines of the heating circuit carefully so as not to confuse them. The installation of the system with natural circulation is carried out at a slight slope, so you need to ensure that the connection is correct.

NOTE!

The boiler connection must be entrusted to a gas service worker or an authorized technician from a service center.

Before using the heating boiler, read ...

Page 5

- Picture

- Text

Premium-M B. 1.03

5

1.

GENERAL INSTRUCTIONS

1.1. Read this manual before using the boiler.

estom.

1.2. installation work, instruction in operation, commissioning, professional

lactic maintenance and repairs of the boiler are carried out by a specialized organization and the local administration of the gas industry in accordance with the “safety rules for gas distribution and gas consumption systems” approved by the State Technical Supervision of the Russian Federation, and building codes and regulations SNip 11-35-76; SNip 2.04.05-91 Gosstroy of the Russian Federation, according to the project for the installation of the boiler and the mandatory filling of the control card.

1.3. The assembled boiler can only be put into operation after its acceptance

by gas experts, instructing the owner and obligatory filling out of the control coupon for the installation (p. 21)

1.4. Checking and cleaning the chimney, repairing and monitoring the water heating system

are made by the owner of the boiler.When replacing an old boiler with a low efficiency with a modern one, you should pay special attention to the design of your chimney. When the boiler efficiency is below 80-85%, the flue gas temperature is about 200 ° C, which ensures good draft even with a poorly insulated chimney. With an efficiency of 90%, the temperature of the flue gases drops to 110-120 ° C, and, in the case of an outdated chimney, the draft disappears, which leads to the operation of the automation and shutdown of the boiler. Failure statistics show that 94% of problems with boilers arise from an incorrectly executed chimney.

1.5. In the room in which the boiler is installed, it is necessary to provide

natural ventilation. It is forbidden to cover the grilles of the ventilation ducts.

1.6. The use of boilers at hazardous production facilities is prohibited.

2.

SET

2.1. A heating boiler with a gas burner installed on it. 2.2. Packaging containers. 2.3. Boiler operation manual.

3.

specifications

3.1. Steel heating boilers premium series

designed for heating and

rye water supply of apartments, residential buildings, cottages, buildings of administrative and domestic purposes, equipped with a water heating system with natural or forced circulation. the boiler meets all the safety and environmental requirements established for this type of product. GOST 20548; TU 4931-011-24181354-2011.

3.2. The boilers run on natural gas GOST 5542-96 and are delivered assembled

with gas burner

3.3. Working pressure of water in the heating system is not more than 2 kgf / cm

2

, in a closed system

heating, it is necessary to install a safety system with a safety valve for a pressure of no more than 1.5-1.7 kgf / cm

2

.

Instructions for connection, start-up and operation

The boiler is started after connecting all communications and filling the system with water.

Its volume should be 150 liters (optimal). After filling and checking the pressure, open the gas valve and turn the control handle to the "On" position counterclockwise. To start, you need to turn the handle and press it all the way.

Press the piezo ignition button at the same time... Keep both in this position until the ignition burner starts.

After that, you can release the button, but hold the handle for about a minute. If the ignition attempt was unsuccessful, it is repeated after a minute.

Boiler operation is no worries... If necessary, regulate the temperature of the heating water, periodically call a technician for regular maintenance. In case of problems, they also urgently contact the service center.

Download instruction

Download instructions for boilers Lemax Premium 10.

INSTALLATION, PREPARATION FOR OPERATION ...

Page 10

- Picture

- Text

10

Premium-M B. 1.03

6.

INSTALLATION, PREPARATION FOR OPERATION

6.1. The volume of the room in which the boiler is installed must be at least 8 m

3

... Ras-

the distance between the boiler lining and the walls must be at least: - 150 mm behind; - 100 mm right and left; - 1000 mm at the front.

6.2. In the room in which the boiler is installed, it is necessary to provide for natural

proper ventilation.

6.3. When installing the boiler to the heating network, it is necessary to lay a non-combustible sheet on the floor

insulating material, on top - a sheet of iron, install a boiler on it.

6.4. The connections between the boiler and the heating system and the gas main must be threaded.

secondary, allowing, if necessary, to disconnect the boiler. If the boiler is installed instead of an old boiler, it is imperative to flush the pipelines and radiators of the heating system to remove rust, scale and sludge deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer from the boiler.In this case, claims regarding the temperature indicators of the heat carrier during the operation of the boiler are not accepted by the manufacturer.

With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the heat carrier is significantly exceeded - the number of radiators, pipes) from the established standards, temperature the heat carrier may not reach 80 ° C, which does not mean that the boiler is defective.

6.5. The capacity of the coolant in the heating system should not exceed: Premium 10 - 150

liters, Premium 12.5 - 180

liters, Premium 16 -

240

liters, Premium 20 -

300

liters, Premium 25 -

375

liters, Premium 30 -

450

liters, Premium 40 -

600

liters.

6.6. For correct filling and replenishment of the system, be sure to install a waste

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm from the place

valve connection for filling the heating system.

6.7. The expansion tank is installed at the top of the main riser, preferably

in a heated room. Do not install a valve on the signal pipe (see Fig. 2, 3).

6.8. Horizontal sections of pipelines of the heating system must be performed with

with a slope of at least 10 mm per 1 m towards the heating radiators and from them to the boiler. This is done in order to ensure free air outlet when filling the system with water and eliminates the formation of air pockets.

6.9. Pipelines, heating radiators and their joints must be sealed

no water leaks are allowed.

6.10. For a closed heating system it is necessary to install a security system with

safety valve for pressure no more than 1.5-1.7 kgf / cm

2

.

6.11. The chimney device to which the boiler is connected must comply with SP42-

101-2003 "General provisions for the design and construction of gas distribution systems" (see Fig. 4).

6.12. After connecting the boiler to the gas supply system and filling with a coolant

the heating system, employees of a specialized service center or local gas administration must adjust and check the safety automation and temperature control for operation, as well as check the tightness of all threaded connections on the boiler gas pipeline and before it.

6.13. Before igniting the gas burner, check the presence of draft according to item 4.3. With absence

draft, it is prohibited to ignite the gas burner device.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

Why can't you make dumplings on a submerged submarine? Because the instructions for cooking on the back of the package say: - Cook for 5–7 minutes after surfacing.

Manualza! Manualza.ru

Still not with us?

Price range

The average price for gas floor boilers Lemax Premium 10 is in the range of 18-19 thousand rubles. This amount is required only for the purchase of a basic boiler (unit, packaging, instructions).

The purchase of a chimney, delivery, installation and adjustment will require additional costs.

In addition, the warranty contract must also be paid, and the warranty period is 3 years.

IMPORTANT!

The price is indicated for the central regions of Russia... In remote areas of the country, the price will be higher, since shipping and other overhead costs will be included in the price of the item.

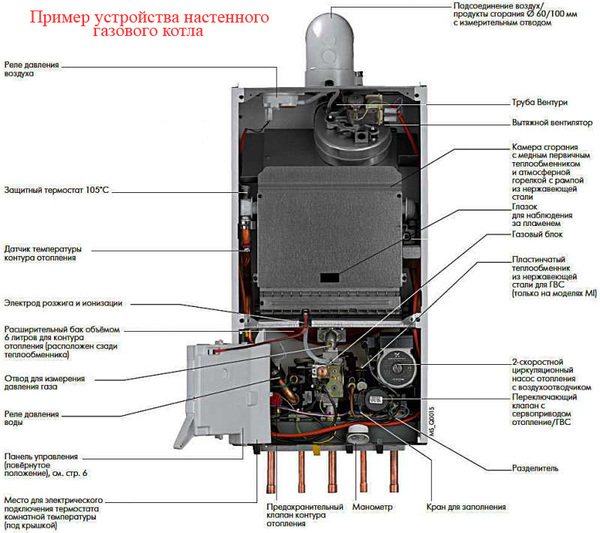

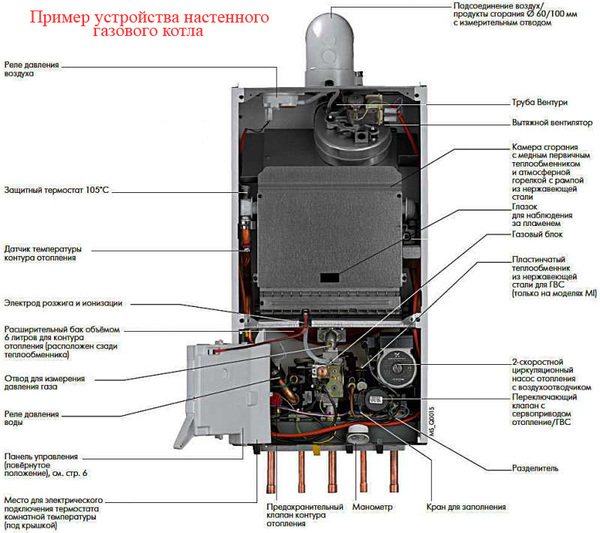

Gas boilers for heating a private house

In our store, anyone can choose gas boilers, electric boilers, boilers as well as gas and electric stoves, built-in appliances, water heaters, pumps, radiators and much more to their liking and budget. We bring to your attention the advanced equipment from the best foreign and domestic brands for every taste. All gas and other equipment has all international and Russian quality certificates.Our experts will help you to understand the range of gas boilers, both floor-standing and wall-mounted, accessories for boilers, spare parts and gas stoves. what is best for you amazes with its variety of models and prices. Our installers will perform high-quality installation, advise on various issues. Let's say which boiler is better for you, floor-standing or wall-mounted, single-circuit or double-circuit. The main advantage of floor-standing gas boilers is its heat exchanger. It is much more durable than wall-mounted. And if the floor stand is single-circuit, then an indirect heating boiler can be connected to the boiler for preparing hot water. There are also combined boilers of different volumes from 50 liters to 200,300 liters or more, in which water can be heated both from the boiler and from the electric heating element built into them. We have been selling gas equipment for more than 3 years and have managed to accumulate enough experience for you to make your purchase quickly and easily. We also organize delivery in the city for free and in the Republic of Belarus from 200 to 600 rubles! And also the whole complex of works on commissioning of the boiler, installation of the ventilation and heating system.

Household stoves

In everyday life, two- and four-burner gas stoves as well as combined ones are used for cooking. They come with and without an oven, as well as built-in hobs.

Both the hob and the oven may have electric heating elements, electric burners and an electric grill. This combination of gas and electric heating elements somewhat expands the functionality of the stove. Stoves that combine a gas hob and an electric oven provide more advantages: as a rule, electric ovens have several heating modes (up to 5-8), are equipped with an electronic programmer and are safer to use. Heating in the oven compartment of a gas stove can be upper (grill) and lower, or only lower. It should be borne in mind that the upper and lower burners cannot work both at the same time. To turn on the top heat, you need to turn off the bottom one. Moreover, the oven can be located both in the same case with the hob, or separately from it. The separate arrangement of these elements of the gas stove is assumed in a built-in version. When buying a gas stove, you must take a copy of the certificate of conformity and permission for use in the store at the place of purchase. Certificates are included in the set of executive documentation upon delivery of the constructed object to the acceptance committee. If two pieces of equipment are installed, for example, a hob and an oven, then two disconnecting devices (taps) are mounted with them. It is not allowed to connect two devices to one ball valve. Correct use and careful maintenance of your gas stove is a guarantee of a long and better service of your equipment! An optimal solution and a good choice!