It would seem, what is possible difficult in the construction of the climate network? According to the point of view of the majority, this is either a heating point of a heating system, or a personal boiler that heats a liquid heat carrier. After that, water or antifreeze flows through pipes to heating radiators, where a secondary exchange of thermal energy with air in the room takes place.

But behind the external simplicity, super-complex engineering solutions are hidden, the operation and maintenance manual of which takes several dozen pages.

Water heating

Most widespread, despite the emergence of more modern systems. The main division is dependent and independent heating. Wiring types:

- One-pipe (this system is also called bifilar)

- Multi-circuit: one of the wiring - two-pipe - is a common system in this category, along with four - and three-pipe heating systems

- A wiring called a manifold

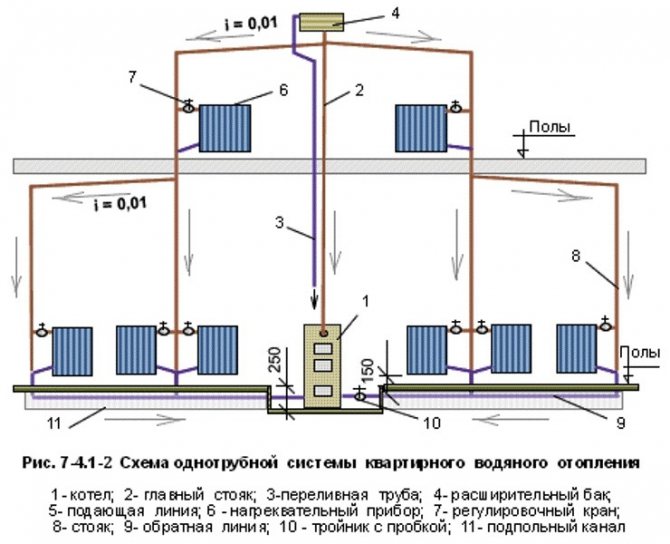

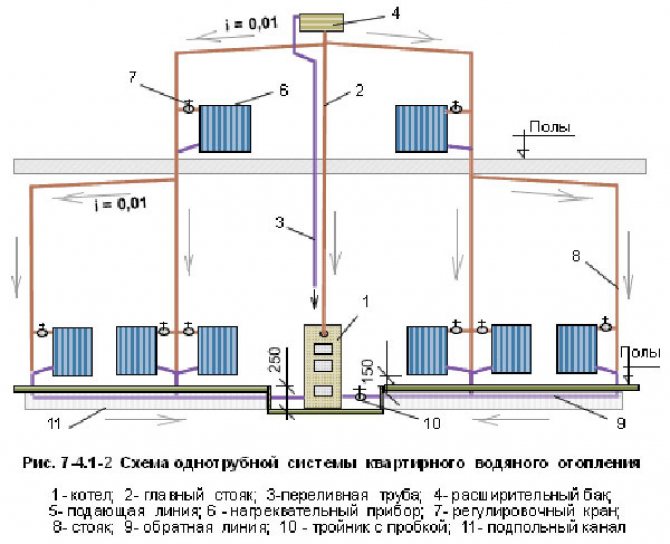

Single-pipe system operation

The heat carrier in this system is water. After heating, the coolant passes through the guide pipes. By the level of the operating temperature conditions of this system are different. A basic example: the heating scheme of a riser system will be one-pipe with hydraulic connection, and two-pipe in the context of heating devices (radiators) operating in it. The connection diagram is dependent, or open, that is, it has a vertical or horizontal riser, as is the case with a bifilar system. The coolant is heated by means of autonomous energy elements, which are divided into coils. The connection is optimally made to the ascending or descending section of the pipeline.

Horizontal bifilar systems have tubular heating devices (convectors, heating ribbed or smooth pipe, steel or cast iron radiator, etc.) When using a horizontal heating system, it is impossible to adjust the temperatures of one or more heating devices - those that need heating at the moment. Adjustment is only possible for the entire heating circuit. These systems are mainly used for heating agricultural facilities.

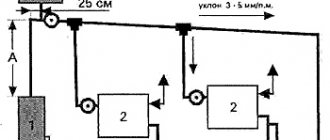

According to the method of moving the coolant, internal heating systems are divided into systems with natural and forced circulation (the pressure in the system is maintained by means of a circulation pump). In the case of natural circulation, there are subspecies - with top filling and with bottom filling. Installations with top filling work according to the scheme: lifting the heated coolant upward along the supplying vertical riser and distributing it into horizontal pipelines and then to radiators. After the heat energy is transferred to the devices and further into the room air, the heavier cooled water goes to the boiler unit.

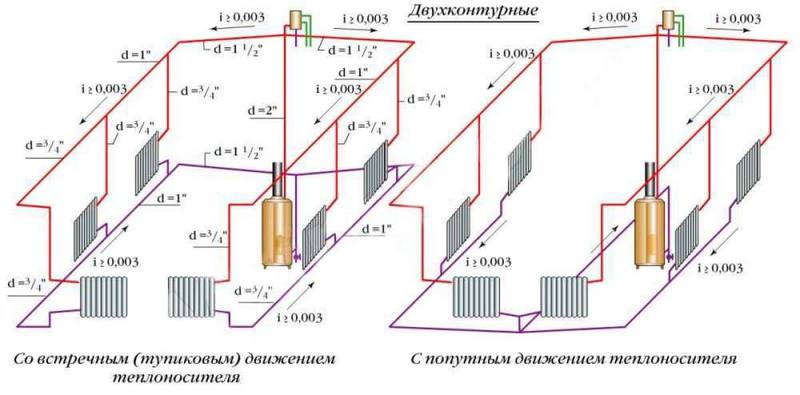

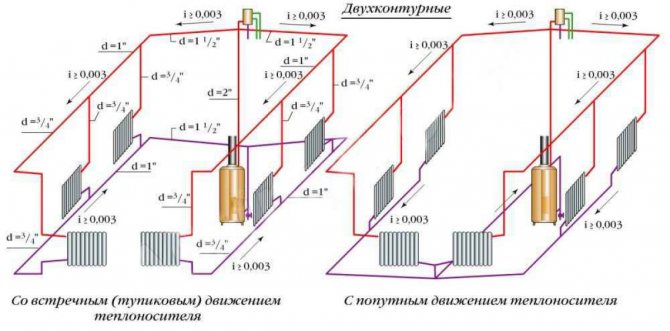

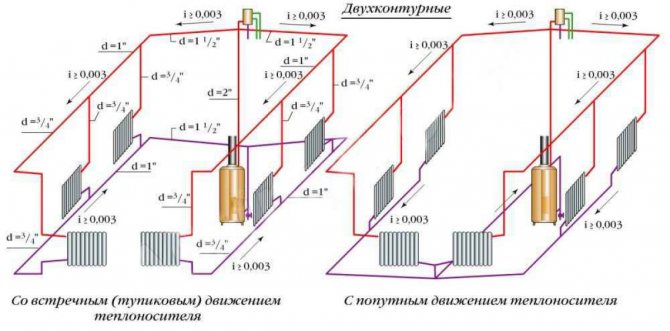

Through the main pipeline, the coolant can be directed in various ways, in a dead-end or a passing scheme. When using a dead-end scheme, the heated coolant from the boiler has the opposite direction relative to the cooled water. The "sign" of this system is the presence of one or more loopbacks, or circulation rings. In the case when the heating radiators are located next to the boiler, the lengths of the loops are reduced. Accordingly, with distance from the main riser, the lengths of the circulation rings increase. Therefore, the most appropriate scheme is in which the circulation rings are minimally removed from the autonomous boiler unit.Ideally, this is not one extended system, but several shorter ones.

Piping methods

Having dealt with the boiler, it is possible to proceed to the choice of the pipe laying scheme. There shouldn't be any difficulties.

There are three main varieties:

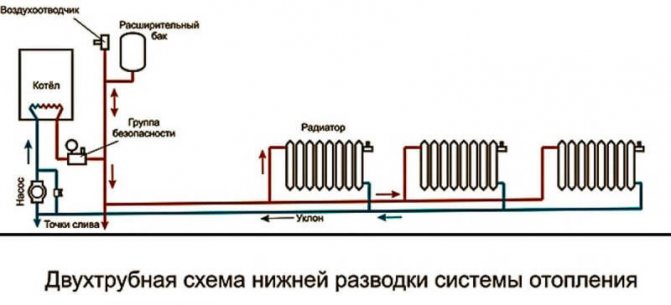

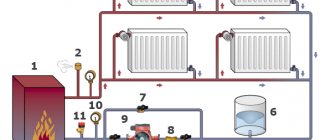

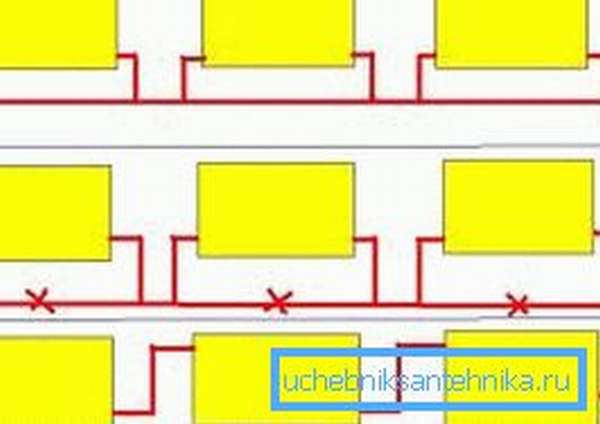

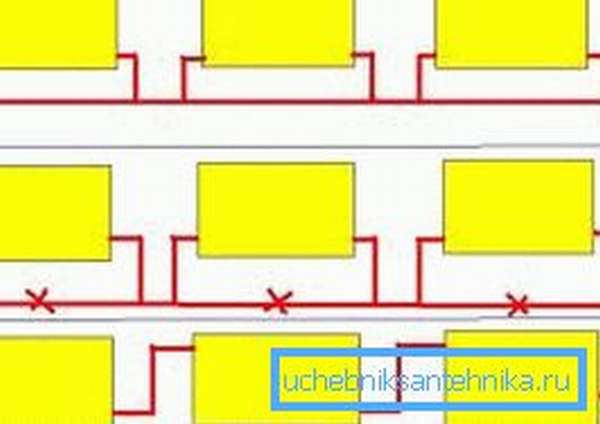

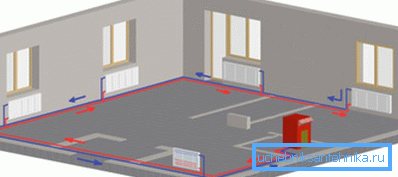

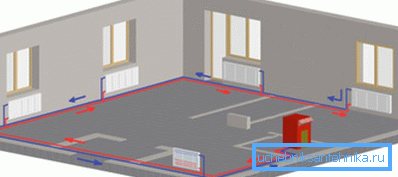

- One-pipe. In this case, a main pipe is laid along the perimeter of the room, into which the batteries are cut. The installation diagram of the latter is possibly sequential (the coolant flows through any heating element, it has no other path) and parallel (water flows through the pipe and enters the batteries through the branch channels going to the inlet and outlet pipes of the radiator).

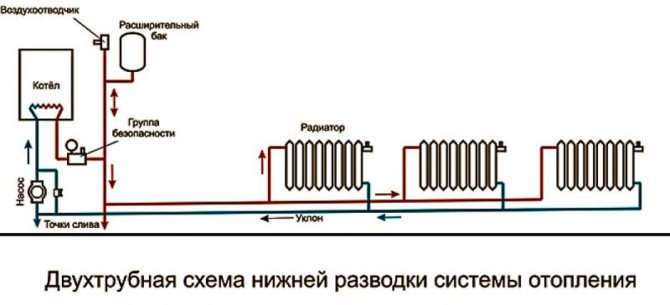

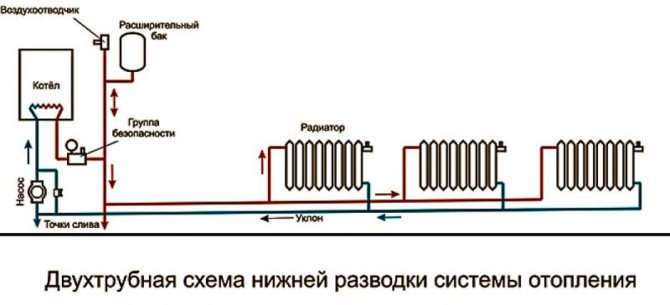

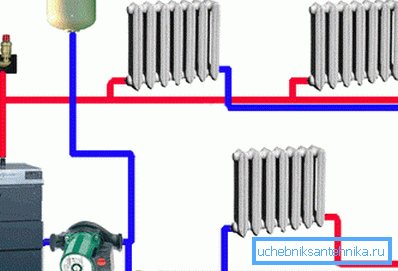

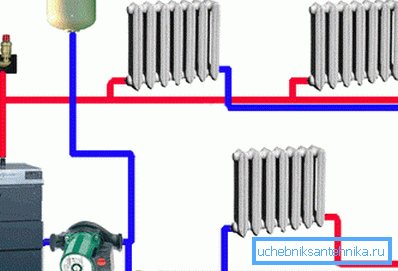

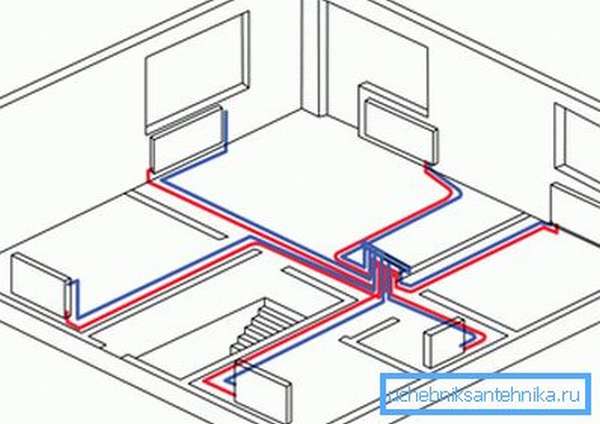

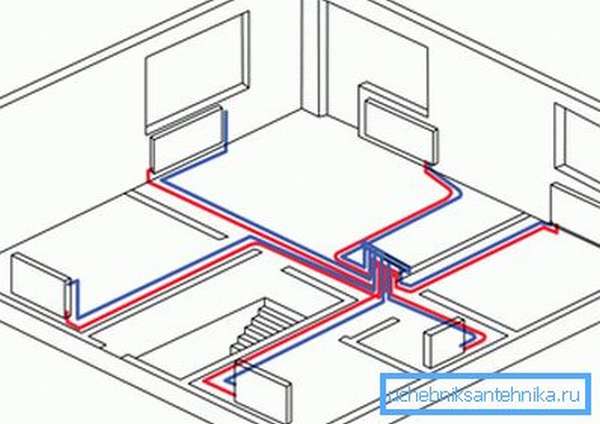

- Two-pipe. Two channels are laid here - one for supplying warm water, the other for returning the coolant to the heating equipment. A more flexible system that allows you to accurately regulate the temperature in the rooms and allows you to repair or change radiators without interrupting the operation of the entire heating system.

The two-pipe scheme has two types:

- dead-end heating system - in this case, a pair of highways goes to the last room, where it is connected by a jumper,

- associated heating system - pipelines with a coolant bypass all rooms and return to the boiler.

The second type is preferable: it will take less materials to produce it.

- Collector... The coolant is supplied to the collector, which distributes it to each battery separately. The most flexible system, but installation requires a lot of solid financial investments.

Hot water heating systems are distinguished:

a) according to the scheme for connecting pipes with heating devices:

- one-pipe with serial connection of devices;

- two-pipe with parallel connection of devices;

- bifilar with a serial connection first of all the first halves of the devices, then for the flow of water in the opposite direction of all their second halves;

b) according to the position of pipes connecting heating devices vertically or horizontally - vertical and horizontal;

c) by the location of the highways:

- with top wiring when laying the supply line above the heating devices;

10.3. Heating system design sequence

Initial data for design: purpose and technology, layout and building structures of the building; climatic conditions and the position of the building on the ground; heat supply source; room temperature.

Calculation of the thermal regime. Thermal calculation of external fences of structures, calculation of thermal conditions in rooms, determination of thermal loads for heating (see Section I and Chapter 8).

System selection. The choice of the parameters of the coolant and hydraulic pressure in the system, the type of heating devices and the system diagram (with a feasibility study, if necessary).

System design. Placement of heating devices, risers, highways and other system elements. Division of the system into parts of constant and periodic action, for zone and façade regulation. Appointment of the slope of the pipes; schemes of movement, collection and removal of air; compensation for elongation and insulation of pipes; places of descent and filling of risers and systems with water. The choice of the type of shut-off and control valves, its placement.

The design is completed by drawing a diagram of the system with the application of thermal loads of heating devices and design areas.

Thermal hydraulic calculation of the system. Hydraulic calculation of the system. Thermal calculation of pipes and devices (see Ch. 9).

What heating system to choose

Construction is always accompanied by a choice of how to equip the heat supply of a new house. A one-pipe or two-pipe heating system is used depending on the tasks and properties of the structure.The solution asks to understand in detail which heating system is best suited.

Pros and cons of a one-pipe circuit

In such a system, one pipe is used to run the heat carrier. Several advantages of this type:

- Lower costs for the material used;

- The easiest and fastest installation;

- Hydraulic stability;

- The usual mounting scheme;

- Low amount of heat carrier used to facilitate drainage of the system.

Single-circuit heating design provides primary cost savings. The number of pipes, wiring, risers and lintels is much less than when equipping a two-pipe heat supply.

Cons of the Leningradka heating system:

- Severe heat loss on the way to distant heaters. The latter, as a consequence, ask for a volumetric increase in order to achieve the optimal room temperature. The reason for the decrease in their heating is hidden in the exchange of hot water with cold water in each device that stands in the way for heating the room;

- The inability to change the temperature of individual batteries. Decreasing the feed in one leads to the cooling of all further ones;

- The need for a large water pressure. The load on the pumps and the entire system in general becomes greater. The occurrence of leaks becomes more frequent, the circuit requires continuous replenishment of the heat carrier.

Important! The single-circuit design is very sensitive to low temperatures. When the smallest area in the path of the heat carrier freezes, all heating is completely blocked. At the same time, the detection of a frozen element is very difficult, and a delay in eliminating the problem leads to freezing of the entire circuit.

Pros and cons of a two-pipe system

Comparison of heating systems is impossible without an overview of the two-pipe system. A fruitful characteristic is the use of 2 different pipes for providing hot water and draining cold water from heating devices.

Heat losses along the path of the heat carrier are insignificant, which saves fuel. The dual-circuit circuit allows you to freely adjust the heating of each individual battery or disconnect them.

The disadvantages of a two-pipe heating system are insignificant. The circuit diagram is more difficult, requires more installation costs and more time. However, this is compensated for by good functional qualities.

Fact! The double-circuit design is not afraid of freezing some areas, and they do not block other heating devices involved in heat exchange. Affected areas are easy to identify tactilely.

Other types of heating circuits

The three-pipe system consists of two supply pipes and one common one for collecting return water. Its advantages are that there is no need to use check valves, only one pump provides circulation. As a result, the three-pipe design is easy to operate, since the heat carrier is spent automatically between devices. The types of such circuits are more flexible when compared with two-pipe, their good qualities lie in good regulation and automated heating of individual parts of the building. When selecting a double-circuit heat supply and having a sufficient budget, it makes sense to pay your own attention to the practicality of a three-pipe system.

A bifilar heating system is something averaged between one- and two-pipe schemes. The entire circuit is divided into two equal parts with its own heating devices, risers and branches. The two ends are connected in stages by one pipe, first all the devices of the first, and then the second end. The water in the heater compartments moves in different directions with the most varied heating, thus maintaining the same temperature throughout the entire system.On this basis, the bifilar circuit refers to a double-circuit heat supply, and according to a series connection with one pipe - to a single-circuit one, which is also comfortable to use.

Open heating system operation

The choice of a heating system also depends on the other qualities of the circuit. When the question is raised, which heating system to choose, it is necessary to take into account the differences between the open and closed heat supply circuit.

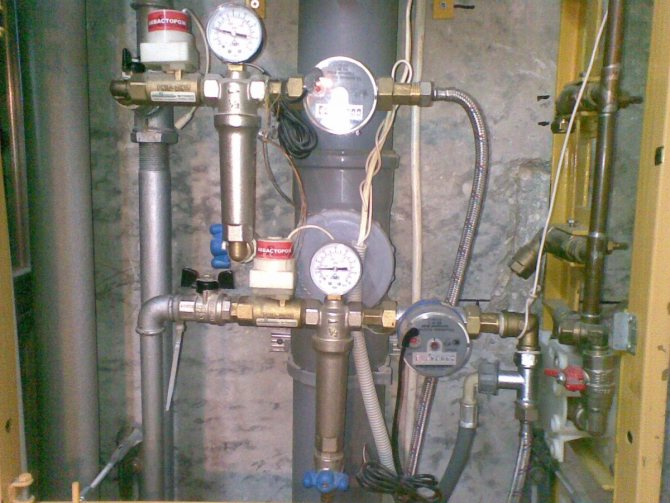

Open system design:

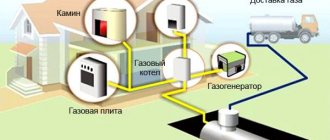

- Boiler. Solid fuel and gas boilers are used;

- Pipelines;

- Batteries;

- Expansion tank.

The heat carrier receives heat energy when the boiler is heated. The circulation process begins under the influence of the zonal pressure difference. The end and starting point is the fuel boiler. In connection with the thermal expansion of water, the circuit asks for the inclusion of an expansion tank, into which the remaining water will fall.

Serious disadvantages of an open design include energy loss and oxygen ingress into the circuit. These moments reduce the heat transfer from the system. There is a risk of air pockets and rust on iron parts.

Advice! In an open plumbing system, it is not necessary to use any type of antifreeze as a coolant. Their property to evaporate leads to a rapid quantitative loss through the expansion tank. Also, their fumes are bad for the health of residents.

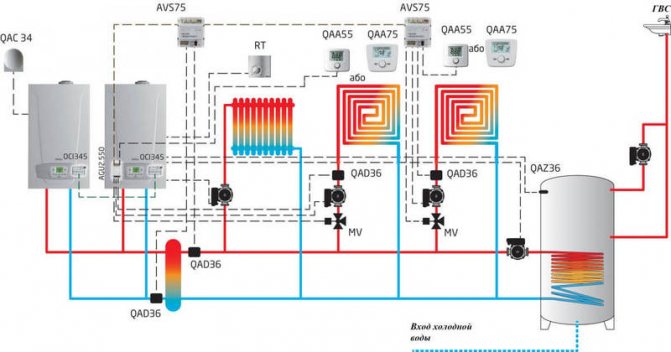

Closed heating system operation

The closed structure, as a result of operation, does not have direct access to open air. The role of the expansion tank is performed by a hydraulic accumulator. Remnants of hot water penetrate into it, pushing through the rubber membrane fabric. In this case, the nitrogen that is in the air chamber is compressed. The heat carrier is removed from the tank with a specialized pump.

The absence of oxygen contact with the components of the circuit prolongs the service life. The thermal medium does not erode and does not require frequent recharge. The closed circuit allows the connection of additional heating sources with their integration into the overall system. The temperature is changed by decreasing or adding a heat carrier.

A closed system asks for continuous access to electrics to operate without various pump interruptions. Regardless of this difference, her work is more effective in small houses. Buildings consisting of several floors require a huge number of membrane tanks and difficult calculations.

Important! The construction of a closed type of heating allows unauthorized air penetration through the deformation of the joints. Their impermeability and the presence of airing must be constantly checked.

Heating system selection

If we compare heating systems for a specific object, then their good qualities are determined by the scale of the structure. An open circuit leads to significant heat loss and the risk of saturation of the heat carrier with oxygen, therefore it is inconvenient for small private houses. The closed structure is acceptable in similar dwellings and has found a lot of use. But in the event of prolonged power outages, its installation leads to freezing of the premises.

In high-rise buildings, the advantages of closed heating are leveled by the need to install rather large membrane tanks. In order for the closed circuit to be practical, they are replaced by specialized free-flow units that work in tandem with pumps - pressure regulators. The open structure stands out for its very simple installation in high-rise buildings. The problem of airing is solved by using Mayevsky cranes.