What is a floor screed damper tape

Before considering the features of using a damper tape for floor screed, you need to clarify what it is. To begin with, the expansion of a screed made of cement is a widespread phenomenon that can cause real damage when the coating was installed in violation of existing technologies. The processes taking place inside can provoke the appearance of cracks on the surface, which can cause a violation of other structures.

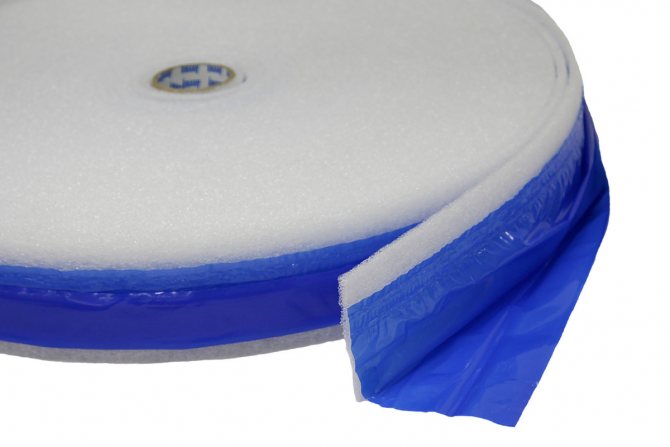

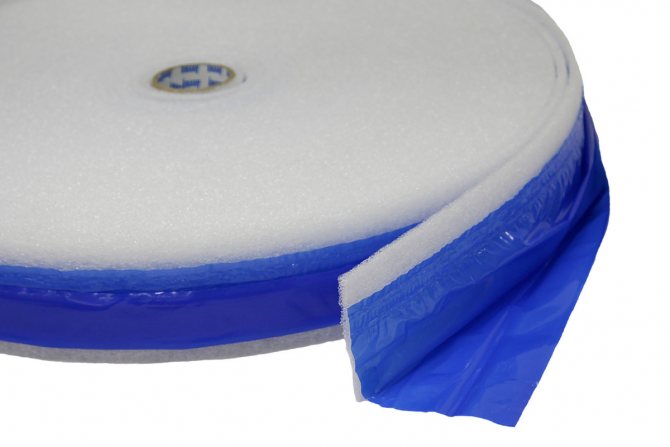

During the creation of the tie layer, a tape is used, it has the appearance of a strip of sufficient length, wound in the form of a roll, made of a foamed type of polyethylene. This material is soft and plastic, can be easily compressed under external pressure, and therefore negates the resulting expansion of the screed.

Important! The buffer canvas is able to act as an interlayer between walls and concrete, preventing them from mutually destroying each other under the pressure formed as a result of such close contact.

In addition to its main function, the canvas is capable of performing a number of other purposes: to provide sound insulation and heat conservation, to divide a large room into compartments during pouring.

Material of manufacture, why is it used

The damper, as described above, is a strip created using modern polyurethane foam, expanded polystyrene materials, supplemented with a layer of glue. The physical qualities of the raw materials allow the finished product to acquire a dense texture, foamed base, which makes it possible to adequately withstand floating dynamic or static loads.

High-quality raw materials are distinguished by complete chemical independence from external environmental conditions. It does not give off the release of extraneous odors during contact with other materials, or changes in the temperature indicators of the environment.

The canvas has zero hygroscopicity, it does not have a single pore, so moisture cannot accumulate here, as well as mold, various kinds of fungi, and other living organisms form.

Decent flexibility of polyurethane foam allows you to endow the canvas with sound absorption qualities. In contact with foamed polyethylene foam, sound vibrations are damped. In addition, the film easily tolerates repeated squeezing and unclenching. This allows the concrete screed to "breathe", which increases its service life several times.

Advantages of the buffer tape

A damper tape with or without a skirt is distinguished by many undoubted advantages due to the presence of the technical characteristics of raw materials in the canvas.

Significant advantages:

- the minimum level of heat conduction;

- absorption of extraneous sounds;

- complete impermeability of water;

- resistance to changes in temperature level;

- durability achieved subject to the basic rules for the installation work;

- environmental safety, which is maintained throughout the entire operational period.

All these advantages explain the active use of the construction edge, both for separating wall and floor structures, and for closing seams and joints.

Specifications

The deformation tape is expanded polystyrene or polyethylene. Material parameters vary depending on the application. It differs in thickness, width and length. Often a self-adhesive layer is applied to one side of this material.

The deformation tape has two other names - edge or edging.

The product is sold in the form of a narrow canvas tightly wound into a roll, the length of which can reach 100 meters. The most common and demanded are rolls of 20 meters. The width can be 5-15 cm, and the thickness can be up to 1 centimeter.

Along the entire length of the strip, every half a meter there are small notches for easy tearing off during installation. The edge band is a quality product, as it is made from a material that has the following technical characteristics:

- does not absorb water, which excludes the appearance of mold, rot and mildew. This is especially important if the tape is used in wooden buildings;

- if the adhesive tape is laid correctly, then it will not deform even under the influence of an aggressive environment;

- easily returns to its original form after prolonged loads and compression;

- installation does not require special knowledge and experience.

Types of damper tapes

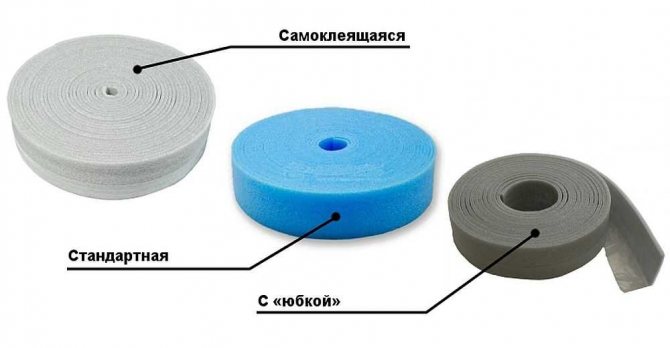

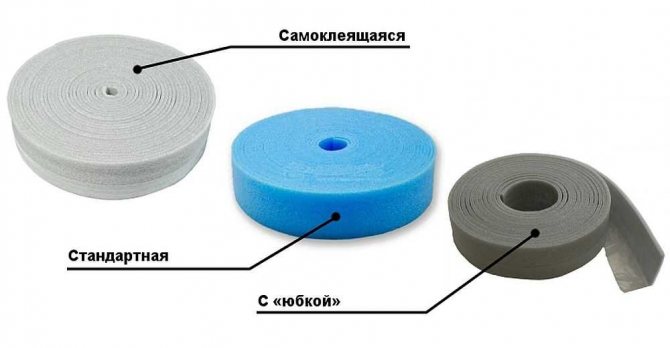

Buffer cloth is available in several types:

- standard;

- having a kind of "skirt";

- equipped with a self-adhesive layer.

The correct selection of the variety of raw materials makes it possible to easily compensate for the arising pressure indicators, due to the natural expansion of the screed layer. In addition, it allows the possibility of reducing heat loss through wall structures, minimizing the penetration of noise and vibrations into the room, and increasing the level of its sound insulation.

Standard

The standard type of edge does not have a special layer on which the adhesive is applied. Fixation of this buffer to wall surfaces occurs using double-sided livestock. Another installation option can be the use of a separate adhesive.

A feature of this compensation tape is the need for preliminary preparation of surfaces for gluing. It is important to remove the smallest debris, of which there may be a lot on the construction site. Otherwise, one cannot expect a strong and reliable adhesion of the canvas to the walls and floor.

With a skirt

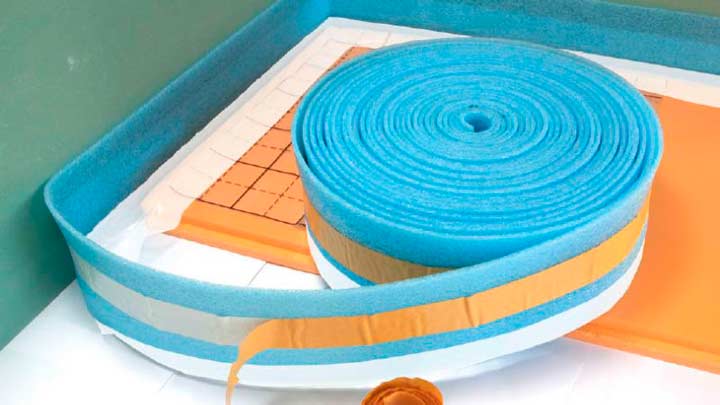

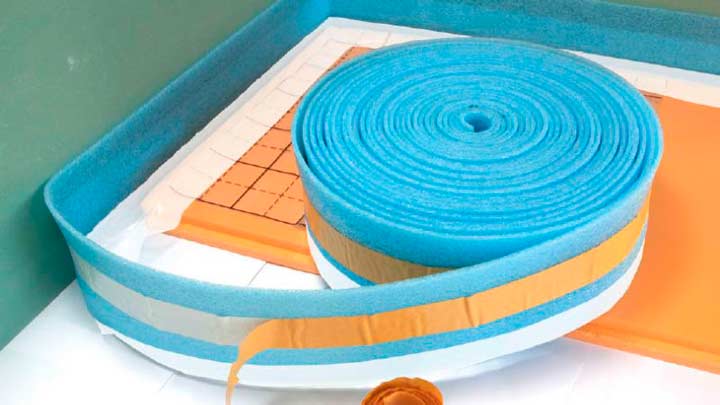

The hem, equipped with a "skirt", is distinguished by one important characteristic feature, the presence of a special strip created from a durable material on an oilcloth base. This part is subject to spreading over the floor surface, which gives the maximum possible sealing of all seams available here.

A distinctive feature of such a model is a braid with a bottom addition measuring 3-10 cm. It is placed on the base of the coating, which significantly increases the level of space tightness.

Self-adhesive

A buffer of this type has the distinctive feature of having an adhesive strip on the back side with a protective backing. The latter does not allow the web to adhere to the surface until the moment when it is required during installation work. This protective layer is removed directly during edge attachment.

Here, just as with the first type of raw material, a thorough cleaning of the surface used from the smallest particles of debris is required. This is necessary in order to ensure the most accurate and tight fit of the material to the selected surface.

Experts believe that it is the self-adhesive options that are distinguished by their economy of expenditure, as well as the maximum possible convenience of installation work. Therefore, such models are most often purchased for independent construction.

How to lay the material

The width of the tape is chosen so that in the future it protrudes above the surface of the screed by 1-2 cm.In fact, the technology of laying this material itself is as follows:

- remove the protective film from the edge of the tape;

- press the material tightly against the wall in the corner;

- begin to unwind the roll, gradually removing the protective layer.

Using this simple technology, the bottom of the walls is glued with tape along the entire perimeter without joints.If the length of the strip is not enough for the entire room, an overlap of several centimeters is made at the joints.

Tapes without an adhesive layer are usually attached to the wall using self-tapping screws. In this case, plastic gaskets are used, purchased or cut, for example, from bottles. The use of gaskets in this case is mandatory. Without them, the material will be very easy to damage with self-tapping screws. The fasteners for the expansion bands themselves are supposed to be used only with coarse threads.

After the concrete hardens, the outwardly protruding edge of the damper tape is cut off with a sharp construction knife. This procedure must, of course, be carried out only after the already finished screed has been poured.

How to choose a damper tape

The purchase of a damper tape for floor screed is an important event. When this process takes place on its own, without the involvement of experienced specialists, you need to pay attention to a number of parameters.

- The integrity of the material, and absolute.

- No visible deformation elements.

- Smooth, neat coating.

- The protective backing (subject to inspection of the self-adhesive damper) must not move away from its base.

- The appearance of the roll should be attractive, dense, should not have delamination, cracks.

Damaged versions, even those sold at a significant discount, must be discarded immediately. They will not be able to fully cope with the responsibilities assigned to them, therefore they will become a waste of financial resources.

It is important to remember that high-quality raw materials cannot have a low cost, so such discounts can only indicate one thing: the material has a defect, possibly invisible at first glance to a layman.

When choosing a suitable covering, you need to pay attention that there is a special lined graph on it. It will help facilitate the work of cutting off excess that will exceed the level of the screed.

The main high quality compensating tape will be raw materials that meet the following requirements:

- polyethylene foam, polyurethane foam in the composition;

- incombustibility;

- ecological cleanliness;

- chemical neutrality;

- closed cellular structure.

Only a material that meets these requirements will be able to cope with the functions assigned to it to ensure sound insulation, heat, moisture, high resistance to direct sunlight.

Important! So that the raw materials do not lose their properties, the damper must be stored at room temperature, in a dry room.

Roll size and length

The thickness of the damper tape, as well as its length and width, are parameters that must be carefully considered even at the stage of purchasing raw materials.

Manufacturers offer a variety of dimensional grid, which differ between companies from Russia and foreign brands.

It is considered optimal products where the width is 150 mm, the thickness is in the range from 4 to 10 mm. A similar damper is available for rolls up to 50 m long.

Table: main typical dimensions of the expansion tape

| Length | Thickness | Width |

| 25 | 10 | 100 |

| 11 | 10 | 150 |

| 11 | 10 | 100 |

| 25 | 10 | 100 |

| 50 | 10 | 150 |

| 20 | 8 | 80 |

| 25 | 8 | 100 |

All indicators in the table are shown in millimeters.

The width of the edge band is selected based on the indicators of the thickness of the screed concrete layer. When the screed is roughly cast, you can stop at a product with a width of 100 mm. The thickened version of the screed is equipped with stripes slightly wider, about 150 mm.

When it comes to creating a wall seam, it is imperative to take into account the coverage area that will be filled with cement mortar, as well as possible temperature drops that are typical for a given room.

When choosing a suitable model, it is necessary to take into account the conditions that it will have during its entire service life. For example, if you plan to install a "warm floor" system, the damper must be heat-resistant, because heating can be carried out up to 65 degrees.

Manufacturing companies

Today, experienced specialists give their preference to those models that are admitted by proven firms that have been working with building products for several years. They guarantee the proper level of quality, high performance, and a long period of use.

Most often, the following brands can be found on the market:

- Tilit-Super;

- Knauf;

- Teploflex;

- Uponor;

- Soundguard Band Rubber;

- Wolf Bavaria Viles Band;

- Valtec;

- Energoflex Super;

- Uponor Minitec.

Table: Traditional edge expansion joints and damping tapes of specialist recommended brands

| Manufacturer | Important benefits | disadvantages |

| Uponor minitec |

| High cost of the canvas |

| Tilit-Super |

| Absent |

| Energoflex |

| It is not very convenient to carry out installation with a screed, whose area exceeds 10 square meters |

| Knauff |

| High material cost |

| Valtec |

| Absent |

| Soundground Band Rubber |

| Occasionally, additional vibration isolation washers are required |

Purpose of modern material

The main purpose of the damper tape is to protect the floor from deformation that can occur due to thermal expansion during a concrete screed. Temperature fluctuations that occur during the installation of a warm floor system can lead to deformation of the concrete, which can damage the base, as well as the appearance of cracks in the tile or parquet.

The purpose of the product is, first of all, protection, but it is also excellent:

- creates additional heat and waterproofing;

- absorbs vibrations of various origins;

- fills in flaws formed on the surface;

- forms expansion joints;

- plays the role of a barrier when pouring the screed mixture.

Thus, polyethylene raw materials are an important element in the art of building.

- for brick surfaces, plastic dowels and self-tapping screws or dowel-nails are perfect;

- adhesives are excellent for post-ridge slabs;

- long brackets are ideal for aerated concrete and aerated concrete walls.

Alternatively, liquid nails can be used.

This product is made on the basis of polyethylene foam, which has the property of compressing, which allows it to compensate for significant expansion of concrete.

Without tape, a screed that expands under the influence of temperature changes will abut against the walls, which can lead to damage to building structures.

In addition, the damper tape has other equally important qualities, such as:

- low thermal conductivity;

- good sound absorption;

- increased level of waterproofing;

- resistance to sudden temperature changes;

- durability and environmental safety.

All these properties make it possible to use polyethylene tape to seal existing gaps during various types of construction work.However, it is primarily used as a separation layer between floors and walls.

There are two types of such a product - regular tape and self-adhesive. The first is simply laid along the perimeter of the room, along the walls. The second one has an additional self-adhesive strip. It is protected by a backing that is gradually removed as the material is glued to the walls. Both products can be with a "skirt" made of thin oilcloth, the width of which is 3-10 cm. In the unfolded position, this element serves to seal the joints between the floor and the wall.

Sometimes they find a replacement for the damper tape in the form of an isolon, or use wooden slats, which are wrapped in polyethylene. However, professionals do not advise using such alternative options, since Izolon does not have heat and sound insulation properties, and the tree is short-lived, as it is prone to decay.

Step-by-step instructions for installing a damper tape

A damper tape with a skirt or with a self-adhesive layer is attached in a special way. When the product does not have an adhesive base, then the use of additional compounds is required for its strong fixation.

Alternative fastening methods:

- masking tape: suitable for temporary use, for example, when pouring a screed;

- construction stapler: suitable for interior installation work, used for fastening to walls made of wood, aerated or foam concrete;

- liquid nails: the best method for even the most uneven surfaces.

Holding fixing measures using self-tapping screws or dowels is suitable only when there are brick walls in the room. These are exceptional cases, because the metal is capable of violating the integrity of the tape, which will reduce its elasticity and resilience.

The process of laying a damper on a concrete screed includes the following important points:

- prepare a work surface, remove as much as possible all, even the smallest, dirt;

- start work before the screed is poured;

- laying begins from the corner, gradually unwinding the required amount of raw materials. When the version with the presence of self-adhesive tape is used, the layer protecting it is successively removed during installation. The standard version is fixed with glue or other fastening methods;

- carry out the process without interruption, create an overlap of the bonding points of different rolls;

- lay the damper a little further than the level of the finishing screed, the excess can be removed with a construction knife;

- pay due attention to the corner parts, where the compensation sheet requires particularly careful fixation;

- to increase the adhesion indicators, the surface of the screed can be pre-degreased, then dried;

- the installation ends in the same place where it was started. The tape is cut with a knife, leaving a slight overlap.

Important! The edge should lie on all protruding elements, including thresholds, columns.

The finished version is subject to complete fixation, if this parameter is not met, there is a possibility that the edge will not cope with the duties assigned to it.

When the main work is completed, a roller is passed along the edge to seal its connection to the surfaces.

All work is best done not alone, but with the involvement of a partner. One will roll out the roll, remove the protective tape, if any, the other will press the web.

How can it be applied

When pouring a concrete floor in city apartments and private houses, damping tapes are usually laid only around the perimeter of the premises. Indeed, in this case, due to the small area, the concrete expands evenly.

When pouring concrete floors in very large rooms, for example, workshops of enterprises or warehouses, this edging material is laid a little differently. In this case, the tape is also necessarily laid around the perimeter, along the walls.But at the same time, several dividing strips are also made from it for the concrete surface itself. After all, a screed that is large in area can expand very unevenly in areas.

In not too large rooms, the damper tape is also sometimes used to equip compensation bridges. But it is used in this case only when it is impossible to fill in one cycle. Due to the unequal water content, concrete layers poured at different times can also press on each other and collapse.

In buildings with complex layouts, the damper tape can be laid not only along the perimeter of the walls, but also around columns, various kinds of supports, the soles of concrete stairs, etc. In addition, without fail, such an edging material is mounted when pouring screeds around the foundations of furnaces, fireplaces and boilers.

What can be replaced

A damper tape with a skirt, or its standard version, is quite expensive. Therefore, sometimes the thought arises of replacing it with other materials, possibly with a lower cost.

Substrates, foam foams are created from foamed polyethylene, the same from which the compensation coating is created. However, such materials will have to be cut, measuring the width, competently organizing the joints.

Polyfoam easily loses its original shape, therefore it quickly forms cracks. The wood is not like because of its fragility, exposure to moisture, and the rapid development of decay processes. Any of these materials requires additional costs for the purchase of special fixing elements.

There is no complete replacement of the damper yet, especially when it is planned to equip the "warm floor" structure. Therefore, even before pouring the screed, it is important to provide for the need to purchase a sufficient amount of high-quality raw materials.

Installation features

Ribbon with skirt. It's not about women's accessories, but about a kind of building material. It is called a damper tape. It is she who happens with a skirt, and sometimes without it. How so? Let's figure it out. Let's start with a description of the material, an acquaintance with its purpose.

Externally, the damper tape is a foam polymer tape. This is polyethylene. The tape made of it is soft, flexible, slightly springy due to bubbles inside. Air capsules allow the material to shrink and expand and also block heat waves.

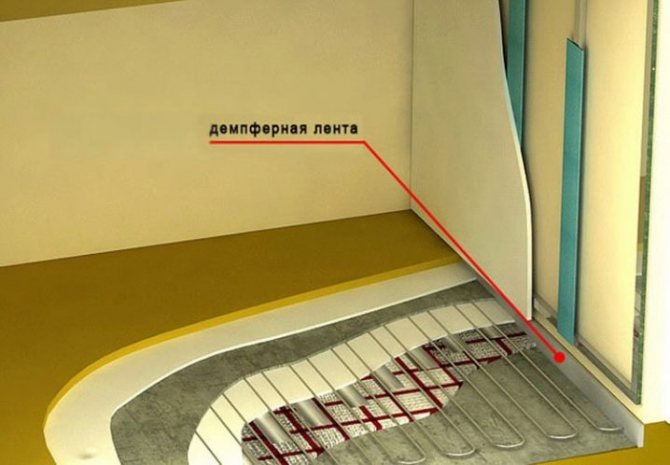

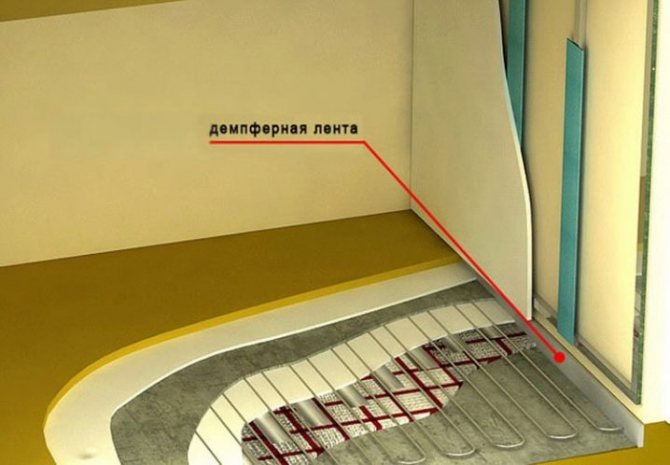

Atmospheric gases are poor conductors of temperatures. This allows the floor screed tape to be used. The damper tape fits between it and the walls.

Here the interlayer compensates for the thermal expansion of the concrete slab. They are expressed with a warm floor system.

It is heated by means of a network of electrical wires or pipes with hot water, poured into a concrete slab.

As the floor screed heats up during the heating season, the floor screed expands slightly, compressing the damper against the walls. After turning off the heating, the concrete takes on its original contours, like the plastic tape.

This avoids the formation of gaps between the screed and the walls, excessive pressure of the floor slab on the sidewalls of the room. In addition, the foamed polymer prevents heat transfer from the floor to the walls. Consequently, it warms up faster and is more pleasant to the feet.

A damping tape for screed in rolls is produced. One has 10-100 meters of braid. Its width is from 5 to 20 centimeters.

The thickness of the foam polymer damper tape ranges from 5 millimeters to a centimeter. On the back there is an adhesive layer.

It attaches the floor damper tape to the walls.

The glue layer of the heroine of the article can be solid or striped. In the latter case, the bonding composition is applied only to a part of the back surface of the braid.

For reliable adhesion, 40% joining with the wall surface is sufficient. Before use, the glue is covered with a tear-off film, like on double-sided tape.

The front side of the damper is covered with silicone. There are no pores in it. Due to this, the coating prevents the tape from adhering to the concrete slab.In liquid form, the mortar can penetrate into the pores of the foam tape.

Due to the silicone, the damper edge tape is easily removed from its groove. However, the need for dismantling is rare.

Polystyrene tape does not decay, is resistant to chemical reagents, does not dazzle from the cold. In addition, the material of the heroine of the article is environmentally friendly.

How to get rid of the excess sticking out from under the floor after pouring. Usually, the notches are located every centimeter. Therefore, it is preferable to take a tape wider than the planned pouring, so to speak, for safety net. You can always remove the excess.

Before the invention of the damper, the floor screed was insulated from the walls with wood strips wrapped in polyethylene, foam rubber and isolon. Each has its downsides. Wood, for example, rots and is affected by fungi, and isolon does not absorb water well enough.

We invite you to familiarize yourself with How to seal a pipe on a roof made of corrugated board

At the end of the chapter, we note that "damper" is a German word. Translated, the concept means "muffler".

So, the name of the tape reflects its ability to absorb heat and sound waves, vibrations.

Taking them from the concrete, the self-adhesive damper tape dampens them, compensating for the negative processes in the tie, prolonging its eyelids and repairs in general.

Being not subject to decay, the damper is not interesting to rodents either. If the sun's rays fall on the material, it does not matter. Unlike many polymers, the heroine of the article does not coarse from ultraviolet radiation and does not change color.

No. 1 Regular is a straight braid without an adhesive layer. Such a tape is simply substituted against the walls, which is inconvenient.

Therefore, builders fix the usual damper with pieces of double-sided tape or separate adhesives in pencils and tubes. However, they are not always useful. The tape is only securely attached to clean walls.

If small construction debris remains on them, it is better to just put the braid.

# 2 Self-adhesive damper tape ideal for cleaned, even walls. The absence of distances from them reduces the consumption of the tape and excludes its laying in waves when pouring the screed.

# 3 Tape with a skirt, announced in the introduction to the article, is a self-adhesive tape with a 3-10 cm padding on the bottom. The additive is made of ordinary polyethylene and is placed on the base plate. This is an additional sealing of the floor and walls.

No. 4 L-shaped braid replaces ribbons with a skirt, having a different structure. Instead of a layer of polyethylene glued from below, there is an incision. On it, the damper easily bends at a right angle. The lower part of the tape rests on the base of the floor, and the upper part is adjacent to the walls.

The fifth type of the heroine of the article cannot be bought in stores. The design of the tape assumes an independent production. It's about the T-shaped damper. Required for the organization of additional "seams" of deformation in large areas.

Such rooms are considered to be more than 40 squares, or with a side length of more than 8 meters.

The recommendation also applies to the simultaneous filling of the floor screed in several rooms.

Even if they are from the same batch, temperature conditions may vary. Consequently, different areas of the pouring will have a different coefficient of thermal expansion. The damper is designed to compensate for the discrepancies.

A T-shaped damper is composed of two strips of regular and self-adhesive. They are attached to each other with double-sided tape. The tape adjoins the floor with a factory adhesive layer

-penofol

-teplon

-isolone

All 3 materials are made of polyethylene foam. In fact, this is the damper, but without additional layers of glue and silicone, without notches for tearing off the tape. As a rule, the thickness of alternative materials also differs.

Using a floor mat as a damper, for example, will have to be laid in several layers.

In addition, it is necessary to cut straight strips from the rolled polyethylene.It is recommended to choose the densest polymer possible.

In general, it is more convenient to work with a specialized tape. We will tell you how to do this in the next chapter.

Laying the damper tape is required not only for concrete floors, but also for polymer ones. The latter are usually called bulk.

The name is associated with the plasticity of polymers. They spread more easily over the surface than concrete.

In addition, self-leveling floors are less porous and more aesthetic, they are colored, with a 3d effect.

Like concrete, polymer screeds expand at elevated temperatures. Therefore, in warm self-leveling floors, a damper is needed no less than in cement-sand. You can do without tape only in wooden screeds. There, between the floor and the walls, polyurethane foam rises.

Before installing the damper, you need to calculate the thickness of the screed. It usually consists of a foamed waterproofing substrate, a system of underfloor heating, that is, pipes or wires, and a building mixture.

Sometimes, a lower layer of insulation is added to them. You need to calculate the total thickness of the new floor. The damper should correspond to it and even be 2-2.5 centimeters higher.

The stages preparatory to the installation of the tape also include the filling of cracks at the bottom of the walls, at their joints. Seal the gaps with silicone sealant. If the cracks are wide, fill with polyurethane foam.

The third stage of preparation is the lining of the room with a waterproofing substrate.

It will close the circuit with a damper, exclude the penetration of moisture from below to the electric cables of the warm floor.

If the system is water, the substrate will exclude flooding of neighbors if the pipes are damaged.

- the tape is unwound and fixed around the entire perimeter of the room

- a damper is added around the columns and pillars, if they are in the room

- install T-shaped barriers, if necessary

- insulate the joints of the tapes with waterproof tape

No tools are needed for editing the heroine of the article. Installation is within the power of anyone. The main thing is to remember the basic laws of damper laying.

What numbers are we talking about and whether it is worth the "game of the candle", we will figure it out in the final chapter.

The cost of a 10-meter roll of tape varies between 80-700 rubles. The spread is associated with the production of the braid, its type, width and thickness, as well as quality parameters.

The main of the latter is density. Checked on site. Squeeze the tape and look at the straightening speed. Quality tape returns to its original contours in seconds.

If the tape is good, but cheap, it is most likely of domestic production. Maximum prices are set for imported samples. So, for a running meter of German self-adhesive tape with an Uponor skirt 15 centimeters wide and 10 millimeters thick, they ask for 60-75 rubles.

The Russian analogue "Teplopol" already costs 30-40 rubles per square meter. If you take the usual domestic damper "Fregat", give 6-10 rubles per 100 centimeters.

There are a minimum of reviews about the heroine of the article. This is due to the difficulties of checking the quality of the braid after its installation and floor filling. The area where the damper looks out to the surface is covered with a plinth or decorative stone running along the wall.

In general, once they put the tape on, they forget about it.

It is also difficult to determine the quality of the braid by the current state of the floor, and most importantly, to prove that the problems with it are related to the damper.

Most consumers who order work from third-party teams do not even know about the existence of the heroine of the article in their house.

It is easier to focus on the recommendations of specialists. So, at the forum "Question to builders: do you need a damper tape for floor screed" said Konstantin: - "An absorber is mandatory in the system of floating floors with coolants in them.

In addition, tape is required in large rooms.

If there is no film

If the vibrations, which are perceived as extraneous noises, have a small amplitude, then during the thermal expansion of the screed with the absence of gaps from the wall to the concrete base, there is a possibility of strong stress, as a result of which cracks and all kinds of chips inevitably appear. Moreover, such unpleasant phenomena can occur both in the screed and in the wall. Accordingly, the damper edging tape is required not only as a providing sound insulation (however, this task is also very significant), but also to protect the heated floor from premature destruction.

Back to content

Laying technology

The damper tape is laid around the entire perimeter of the room between the screed and the wall.

First, the surface is primed. Then, when it dries, glue the damper to its width to the base of the wall.

If the edge tape is self-adhesive, then it is simply glued to the wall, removing the backing. The strip with the skirt is bent to the floor so that the solution cannot get into the cracks. If the edging tape is without adhesive, then stick it on liquid nails, screw it with self-tapping screws. Sometimes the damper tape is attached to the wall with small nails, a construction stapler, glue, double-sided tape. You can press it down with a solution. The strip must be mounted above the level of the floor screed.

When the flooring is ready, it is not removed, but only the excess is cut off. If skirting boards are installed, then cutting off the excess is not necessary. When installing a water or electric floor heating, the damper tape must be laid between the heating element and the vapor barrier layer. Sometimes the strip can be placed under the vapor barrier. It is also necessary to install a damper in the warm floor system around the perimeter and only then proceed to the doors.

A long strip should be used rather than economizing by folding the damper with several cut strips overlapping. Such poor performance can lead to problems during the operation of the system. After installation, the tape must be smoothed, pressing it carefully to eliminate minor defects. This should be done not with your hands, but with a construction roller, observing the installation rules so that solvents do not get on the tape and do not worsen its technical characteristics.

It is a simple strip of polyethylene foam to compensate for concrete expansion. There is no glue composition on it;

There is an adhesive strip on the seamy side. It is smaller, covered with a backing. The backing is removed and the tape is applied to the wall with the adhesive side. This is very convenient, because when pouring a concrete screed, it fits snugly against the wall and does not move. The adhesive composition under the protective film has high adhesion. The strip quickly and firmly adheres to any building material: wood, plaster, concrete;

- Edging tape with skirt.

The skirt is a piece of durable oilcloth material that recedes from the polyethylene part. When the damper tape is fixed to the wall, it closes the corner between the floor and the wall, thus sealing it. The width of the skirt is from 3 to 10cm. Such damper tapes are found both ordinary and self-adhesive;

- L-shaped damper tapes consist of 2 parts - wide and narrow. With their wide part, they are attached to the wall, narrow to the floor. Such strips are bent at right angles. In order to better lay such a tape, there are cuts on the fold. A skirt can be attached to the L-shaped edge band. Such a damper is ordinary, without glue, and an adhesive composition can be located on each of the parts. Such an edge band best closes the wall from the screed and prevents the mortar from getting into the cracks between the foundation and the wall;

- There are T-shaped ribbons.

They are used for underfloor heating, for long walls (if the wall is longer than 80m), as well as for a large area screed (over 40 square meters) as an expansion joint.

We suggest that you familiarize yourself with How to make a concrete floor screed

The damper tape is sold in rolls from 10 to 100m, widths from 50 to 150mm.

The thickness is also different. It varies from 0.1 mm to 1 cm. The best thickness is 5mm. At the same time, it is argued that the thicker the screed, the thicker the edge tape should be.

In order to quickly and conveniently remove the excess part when laying the strip, longitudinal notches are made every 4-6 mm. By pulling on the edge, you can tear off a part of the tape along its entire length.

To buy a tape of a certain width, you need to calculate it. To do this, find the sum of the thickness of the rough fill and the finishing layer of the floor covering.To this amount you need to add a few cm1-1.5 for the stock.

The length is determined around the perimeter of the room. Increases are made for columns, partitions and a small margin just in case. The thickness depends on the height of the screed.

- The damper strip must be inspected. If it has mechanical damage, then it may be of poor quality, it will not exert its compensatory effect on the screed, which will lead to its destruction, and then damage to the floor covering.

- The tape must be tightly twisted, otherwise the adhesive may move away from the wall during installation. Poorly adhered tape will destroy the screed.

- It is necessary to pay attention to the appearance of the tape, excluding all signs of a poor-quality product: stains, defects.

- It is best to choose a damper with a cut-off ruler to quickly remove excess after work.

- Self-adhesive tape will save you time and secure the material more reliably. But such a tape is more expensive.

Sometimes, wanting to save money on the factory damper tape, alternative options are used. Some people try to make a strip on their own using materials such as polystyrene, isolon, foil-insol. But all these materials do not have all the properties of polyethylene foam. Poor quality damper tape can lead to micro cracks in the screed and reduce the life of the floor covering.

When installing self-leveling floors, additional tools and materials are used. One such device is a damper tape. It protects the floor surface from cracks, prevents its destruction.

The purpose of the tape when installing a self-leveling floor is to isolate it from walls or different rooms in an apartment where there are no thresholds. It is easy to install. Unwinding the roll, glue the tape around the perimeter of the room. Then we proceed to pouring the self-leveling floor. Sometimes builders do not install the tape, as a result of deformation processes of the building, temperature changes, screed pressure on the walls may occur.

Sometimes, when installing a self-leveling floor in different rooms that are not separated by a threshold, damper tapes are used. A damping joint is made from the tape in the passage space, which compensates for the expansion of the concrete screed. After the self-leveling floor has dried, small cracks appear above the damper joints, which should be covered with a sealant if the floor is made of polymer, or with a mortar if a self-leveling concrete mixture is used. In this case, the damper seam saves the self-leveling floors from destruction.

In order for all the work on laying the damper tape and installing the screed to be of the highest quality, it is worth following certain rules.

- Before starting work on laying the tape, the floors and walls must be well cleaned of dust. If it is planned to lay a waterproofing layer, then the tape will be installed after these works.

Floor preparation for screed - For better adhesion of the tape to the wall, it is advisable to degrease and dry the surface of the latter.

- It is important to work at room temperature.

- The installation of the tape is made 1.5-2 cm higher than the estimated level of the screed will be.

Scheme of laying a warm floor using a damper tape - Excess material is removed, but if you plan to install a plinth, then you can leave them - it (plinth) will hide the tape.

- When laying the tape with the skirt and pouring the screed, it is important to ensure that the skirt is completely covered with the mortar.

Damper tape with a skirt for floor heating - If you plan to install an electric or water underfloor heating, the tape should be laid between the heating elements and the vapor barrier layer or under the vapor barrier.

- There should be no empty areas while the tape is being laid. It is also undesirable to join tape segments too often.

Laying floor screed tape

The installation process of the damper tape is quite simple.The work is carried out in accordance with the following stages:

- It is necessary to install the tape even before the installation of the concrete base. If there are different architectural elements, the tape should wrap around them. The expansion joint must be laid continuously. In this case, breaks should not be allowed.

- Before work, you should clean the room. Dust must be removed to help secure the tape to the surface.

Sometimes the tape is not completely adjacent. This is usually due to a factory defect in the material. The base on which the tape is mounted. It must be carefully leveled, dry and degreased.

There are several features of the damper tape:

- After laying, you should walk along the tape with a roller. This will ensure a reliable connection. In this case, small defects will be smoothed out, and the strip itself will press more tightly against the wall.

- The tape is made in rolls. This form of sale is quite convenient.

- The width of the expansion joint must be matched to the height of the screed. The tape is laid slightly above the concrete pouring level. When the mixture hardens, excess material is cut off.

- The tape must not be pulled out completely. If the flooring is made of ceramic tiles, the tape is removed only after the seams have been rubbed. This will result in a high quality result.

If, after laying the decorative covering, it is decided to install a plinth, the protruding part of the tape is not cut off. Using these tips when installing the damper tape, you can properly install it. It is also worth understanding the characteristics of different types of tape.

To properly fill the screed, you should think about the intricacies of filling the gap between the walls and the base. This will ensure a long service life for the building as a whole.

Introduction

So, What is a damper tape for? The main functions of this tape are fully revealed by the translation of its name, - muffler, shock absorber... This is an edge banding film designed to reduce vibrationsarising in the construction of the heating coating. It should be noted, however, that damper products, in addition to absorption of vibration effects compensate, and at the same time slow down more serious processes that can have very unpleasant consequences for a warm coating. In particular, this concerns screed expansionarising for the following reasons:

- During heating, the cement base, like other solid structures, tend to expand, and when it cools down, on the contrary, shrink. Of course, against this background the edges of the base also move;

- The monolithic base is effective translator of soundsthat come from heating pipes;

- In addition, the screed perceives vibrations from any movement on the floor.

Back to content

Advantages and disadvantages

The damper has practically no competitors in its properties.

Its advantages include:

- High heat and sound insulation performance, as well as absolute moisture resistance.

- This material absorbs the stresses of the concrete layer;

- High ductility is inherent in the damping layer. It compresses and expands many times without breaking.

- Ability to absorb vibrations.

- This layer is characterized by the absence of deformation with temperature drops, the invariability of indicators with their sharp changes (when turning on and off the underfloor heating system).

- Environmentally friendly and safe: the damper does not rot. Rodents and insects do not like it, and it does not form toxic compounds during operation, and it also has no smell.

- The damper is characterized by a convenient shape, flexibility, ease of transportation and installation, manufacturability and durability.

The only drawback of the edge seal can be considered a relatively high cost, but the use of this material significantly pays for all the costs incurred.

Why damping tape has no competitors

To show how convenient and technologically attractive a special tape is, consider the materials that can be used to replace it.

- Foamed polyethylene. It will have to be cut into strips and overlapped. It is inconvenient to fix individual sections, it is difficult to maintain the uniformity of the height of the damper layer.

- Penofol will also have to be cut into strips, observing the installation flaws inherent in polyethylene. In addition, the material is significantly more expensive.

- Polyfoam tends to disintegrate into granules, is characterized by a shorter service life and, most importantly, does not recover its shape after long-term compression. With the onset of winter, cracks may form along the perimeter of the screed, where moisture will enter, and debris will clog. This will negatively affect the overall life of the coating.

- Wood cannot damp well - the material is hard enough. In addition, decomposition is bound to occur over time.

- Cloth and similar fillers do not last long, become a breeding ground for bacteria, collect dust, and can form suspensions of fibers in the air, which negatively affects the respiratory system.

The damper tape is a specially formulated product based on analysis of other materials that offers optimum performance. The product will ensure the durability of the screed, will not affect health, will speed up the repair and will not require significant costs. Therefore, the use of tape is recommended by many masters and looks rational.