Autonomous heating systems based on gas boilers are widespread in Europe.

In our country, they are less popular, however, the situation changes every year. Users are actively switching to heating with the help of imported and domestic heating installations.

The choice of boilers is very wide, which makes it possible to choose the appropriate installation for any conditions or room size.

Consider floor standing gas boilers produced by the domestic company Lemax.

Floor standing gas boilers Lemax

Lemax was founded in 1992 in Taganrog. Gas boilers manufactured by this company are assembled from imported components from leading European manufacturers.

Floor standing boilers are non-volatile, operate on natural draft and do not need to be connected to the power supply, however, they have the ability to connect water heating units and turbo nozzles to create forced draft.

Floor-standing boilers Lemax are presented in a large assortment, the model range has samples with a capacity of 6 to 100 kW, which allows you to heat apartments or large houses.

NOTE!

The main feature of the units is the simplicity of design and the absence of unnecessary assemblies and parts that complicate the design of boilers and increase the risk of failure.

Boiler classification

produces gas and solid fuel boilers. Gas devices are made in a wall-mounted or floor-standing version. Buyers often find it difficult to independently navigate among the variety of heating devices. In this situation, advice from professionals helps.

Floor standing boilers Lemax are distinguished by the number of circuits and the shape of the heat exchanger. The equipment is intended for heating residential and office premises of medium and large areas.

By the number of contours

Single-circuit units are intended for heating only. Getting hot water is possible by connecting an external boiler.

Double-circuit ones carry out heating of liquid for the heating system and domestic needs. They can have separate or combined heat exchangers.

By design of the heat exchanger

uses heat exchangers made of steel, as well as cast iron from, covered with thermal insulation. With the right choice of model, you can significantly save on heating the whole house. Cast iron heat exchangers are more resistant to corrosion and last longer. Steel is easier to clean. They are more durable and are not afraid of accidental blows.

Parts are cylindrical and rectangular in shape. The former have a large area and remove the maximum amount of heat. Models with a rectangular heating element have a few percent lower efficiency.

Types

There are two types of construction of floor-standing gas boilers Lemax:

- Single-circuit.

- Double-circuit.

Single-circuit models only work for heating the home. They perform a single function, therefore they do not have any superfluous elements and demonstrate maximum reliability.

Double-circuit models, in parallel with heating the house, prepare hot water for domestic needs.

Inside the tank with heating water (heating water, or heat carrier) there is a copper coil through which water is passed from a separate make-up line.

They do not mix with each other, heating is produced by transferring a certain amount of heat from the hot coolant to that part of the flow that is currently passing inside the coil.

If the water intake is not too active, the amount of DHW is usually sufficient to meet all needs.

In addition, there are models with different types of heat exchangers.:

- Steel.

- Cast iron.

Stainless steel can withstand significant heat and is resistant to galvanic corrosion. wall thickness 2 mm, welded construction. Cast iron heat exchangers have an increased wall thickness of 4 mm and are used on high power boilers.

Ductile cast iron of special grades is resistant to temperature changes and is able to compensate for different degrees of heating at individual points.

Advantages and disadvantages

The advantages of Lemax floor-standing gas boilers include:

- Simplicity, reliability and durability of the design.

- Energy independence, increasing the stability and reliability of work.

- Ease of Management.

- Low fuel consumption.

- Relatively low price with high quality components.

- It is possible only to heat the dwelling, or to additionally prepare hot water.

There are also disadvantages:

- Firing up Lemax boilers is quite difficult, especially in the absence of skill.

- Natural cravings are very unstable, depending on many external factors.

Disadvantages are inherent in all non-volatile models of gas boilers. However, they are repeatedly compensated by undoubted advantages, therefore it is more correct to consider them as design features.

Lemax brand

Today the Lemax company is the largest manufacturer of heating equipment, mainly specializing in gas boilers. It was opened in the city of Taganrog in 1992 and within a few years from a small manufacturer turned into a solid company.

At the very beginning of its activity, it acted as an intermediary between manufacturers and buyers, and after a while it became a major manufacturer of boilers, radiators, boilers and other related equipment. Dealers of the company successfully work not only in Russia, but also abroad.

The manufacturer offers a large line of heating equipment, but the greatest popularity and demand was acquired by floor-standing gas boilers.

What series and models belong to the floor

The Lemax floor standing boilers group includes the following series:

- Patriot... There are 6 models with power from 6 to 20 kW, which is optimal for apartments or small private houses. Parapet-type installations are equipped with convection holes in the casing that allow heating the room. If such a boiler is in the kitchen, no radiators are needed. A coaxial chimney eliminates the need for time-consuming connection to a common building chimney.

- Premium... The series consists of single and double-circuit models of floor-standing gas boilers with a capacity of 7.5 to 100 kW. There are 22 models in total. Double-circuit units have the letter B. The most capacious series that allows you to choose the right boiler for any room or working conditions. The simplicity of the design makes them very reliable and durable, and the low gas consumption contributes to the popularity of this equipment.

- Premium N... They differ from the basic Premium series by the presence of the 820 Nova Sit gas valve. The rest of the features and parameters are the same as for the models of the main line, but the power of the models is limited to 35 kW.

- Wise... These boilers are a novelty, they appeared relatively recently. Made of ductile gray cast iron. They are available in 5 models with a capacity of 16, 25, 35, 40 and 50 kW. Single-circuit models with a sectional heat exchanger. They differ from conventional series by the need to connect to the power supply network.

- Leader... They are also a novelty in the Lemax range. Non-volatile single-circuit boilers with a capacity of 16 to 50 kW. Cast iron sectional heat exchanger allows to obtain high efficiency of heat energy transfer.

All models have approximately the same design, differing only in details. The presence of boilers of different capacities allows you to select the sample with one or two circuits most suitable for the proposed conditions.

Specifications

Consider a table of the main technical characteristics of Lemax floor standing boilers:

| Characteristics | The values |

| Boiler type | Gas |

| type of instalation | Floor |

| Type of fuel | Natural, optionally liquefied gas |

| Thermal power | 6-100kW |

| Efficiency | 87 -93% |

| Gas consumption | 0.38 - 2.6 m3 / h |

| Maximum coolant temperature | 90° |

| Coaxial chimney diameter | 250-310 mm |

| Chimney length | 330-800 mm |

| Water pressure in the system nom / max | 1,5 / 2 bar |

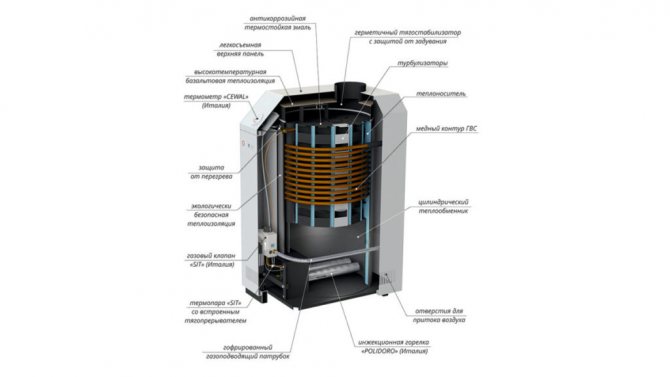

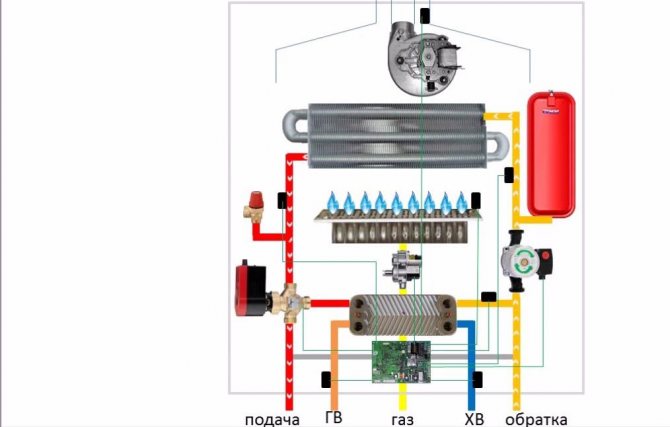

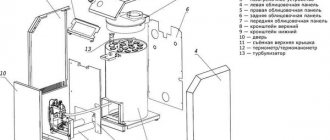

Device

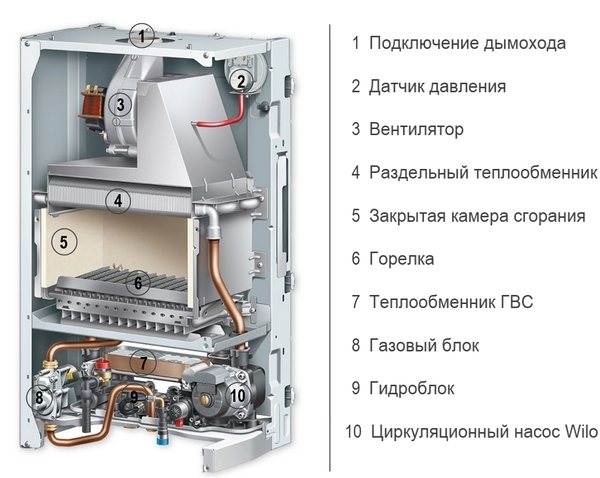

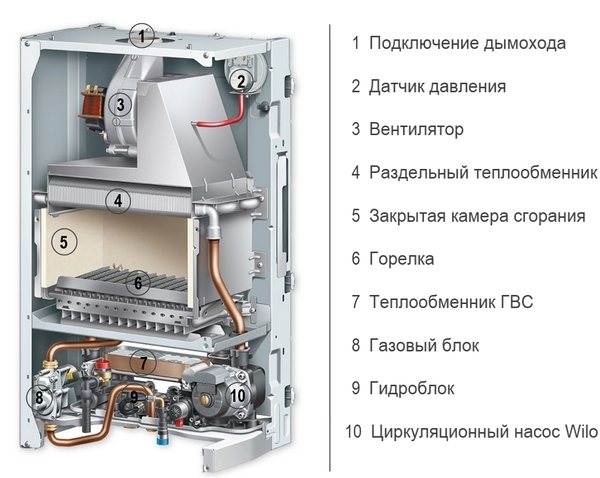

Floor-standing gas boilers Lemax have a heat exchanger in the form of a welded or cast iron container, which forms a water jacket around the combustion chamber.

A gas burner is installed in its lower part, and a gas valve, adjusting devices and connecting pipelines are located under it.... The upper part of the heat exchanger has a passage for installing a chimney, which can be of a classic or coaxial design.

The pipes for connecting the heating circuit for different models are located either on the sides or on the back of the boiler. There is also a DHW make-up pipeline (for dual-circuit models).

The operation of the unit consists in the flow of the coolant into the tank of the heat exchanger, heating and independent exit under the influence of gravity - the density of the heated layers decreases slightly, which contributes to their displacement by colder layers of liquid.

The independent circulation of the coolant is based on this effect. Hot water is heated in a copper coil installed inside the heat exchangerbut.

The smoke is removed by natural oven draft.

INSTALLATION, PREPARATION FOR OPERATION ...

Page 10

- Picture

- Text

10

Premium-M B. 1.03

6.

INSTALLATION, PREPARATION FOR OPERATION

6.1. The volume of the room in which the boiler is installed must be at least 8 m

3

... Ras-

the distance between the boiler lining and the walls must be at least: - 150 mm behind; - 100 mm right and left; - 1000 mm at the front.

6.2. In the room in which the boiler is installed, it is necessary to provide for natural

proper ventilation.

6.3. When installing the boiler to the heating network, it is necessary to lay a non-combustible sheet on the floor

insulating material, on top - a sheet of iron, install a boiler on it.

6.4. The connections between the boiler and the heating system and the gas main must be threaded.

secondary, allowing, if necessary, to disconnect the boiler. If the boiler is installed instead of an old boiler, it is imperative to flush the pipelines and radiators of the heating system to remove rust, scale and sludge deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer from the boiler. In this case, claims regarding the temperature indicators of the heat carrier during the operation of the boiler are not accepted by the manufacturer.

With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the heat carrier is significantly exceeded - the number of radiators, pipes) from the established standards, temperature the heat carrier may not reach 80 ° C, which does not mean that the boiler is defective.

6.5. The capacity of the coolant in the heating system should not exceed: Premium 10 - 150

liters, Premium 12.5 - 180

liters, Premium 16 -

240

liters, Premium 20 -

300

liters, Premium 25 -

375

liters, Premium 30 -

450

liters, Premium 40 -

600

liters.

6.6. For correct filling and replenishment of the system, be sure to install a waste

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm from the place

valve connection for filling the heating system.

6.7.The expansion tank is installed at the top of the main riser, preferably

in a heated room. Do not install a valve on the signal pipe (see Fig. 2, 3).

6.8. Horizontal sections of pipelines of the heating system must be performed with

with a slope of at least 10 mm per 1 m towards the heating radiators and from them to the boiler. This is done in order to ensure free air outlet when filling the system with water and eliminates the formation of air pockets.

6.9. Pipelines, heating radiators and their joints must be sealed

no water leaks are allowed.

6.10. For a closed heating system it is necessary to install a security system with

safety valve for pressure no more than 1.5-1.7 kgf / cm

2

.

6.11. The chimney device to which the boiler is connected must comply with SP42-

101-2003 "General provisions for the design and construction of gas distribution systems" (see Fig. 4).

6.12. After connecting the boiler to the gas supply system and filling with a coolant

the heating system, employees of a specialized service center or local gas administration must adjust and check the safety automation and temperature control for operation, as well as check the tightness of all threaded connections on the boiler gas pipeline and before it.

6.13. Before igniting the gas burner, check the presence of draft according to item 4.3. With absence

draft, it is prohibited to ignite the gas burner device.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

- You will be engaged in eyewash. - But i can not. - There, in the instructions for the ointment for hemorrhoids, everything is written, patient.

Manualza! Manualza.ru

Still not with us?

User's manual

The operation of Lemax floor-standing gas boilers is reduced to igniting the burner as needed and setting the desired temperature. All other operations - replenishing the volume of water in the heating circuit, installing the chimney, connecting the boiler - are performed without interfering with the boiler design.

To ignite the burner, turn the knob to position 1, which means it is switched on to the operating mode. Then it must be drowned all the way and held while pressing the piezo ignition button.

When the pilot burner lights up, the button is released, but the regulator is held for about a minute.

It is periodically necessary to clean the internal components of the boiler from carbon deposits and soot.... You also need to monitor the condition of the heat exchanger, gas valve and other units of the unit.

Periodic maintenance should be performed by a service technician. It is not recommended to engage in these works on your own, especially if the warranty period has not yet expired.

Download instruction

Download the instruction for the floor-standing gas boiler Lemax.

Testimonials

The opinions of users are controversial enough on gas equipment to raise doubts about their reliability. This is not surprising, because Lemax is engaged in the layout and design of gas boilers on third-party elements and main functional units, as well as assembly. This gives a lot of freedom in choosing relevant approaches, forming and adjusting the model lines that are in demand at the moment on the market. However, this also brings a negative point. There is no way to accurately characterize and verify the durability of equipment. The operability is tested only at stands or under conditions of short-term operation. Cases of ineffective combination of individual components are not excluded.

In fact, reviews on equipment written, for example, 5 years ago, no longer relate to the modern range of the company, and cannot indicate their effectiveness or attractiveness. At the same time, there is simply nowhere to get significant and reliable information about the current models with all their features.

A frequent problem was previously indicated that the distribution of key components, such as the heat exchanger and the combustion chamber, was insufficiently thought out, which is why, at the beginning of operation, a lot of condensate flowing out of the boiler body was often formed. This problem goes away with time. Another point concerns the incomplete compatibility of individual components. So the used system of forced removal of gases from the combustion chamber often does not allow efficiently and in full range to use the gas valve control unit and, conversely, due to which, in fact, the output thermal power of the boiler suffers.

However, Lemax gas boilers have won a leading position in the market for a reason. They show themselves well in our realities and taking into account the peculiarities of the gas distribution system, water quality, etc. The price / quality ratio is higher than that of many domestic and awakened counterparts, albeit with a bias only towards a low price.

Price range

The model range of Lemax floor-standing boilers is very wide, so the price range is also quite large. The lower limit is about 18 thousand rubles, and the upper one is approaching the mark of 100 thousand rubles.

For remote or hard-to-reach areas, the cost will be noticeably higher, since transportation in difficult conditions is a very expensive undertaking.

NOTE!

When buying a boiler, you will have to make expenses for the chimney, delivery and installation, warranty agreement and other necessary additions. you need to be prepared for these costs, the amounts can be found out in advance.