People living in the private sector have to deal with the problem of the lack of central heating - the water supply is only cold, all this can darken the joy of living outside the city. An autonomous heating system will save the situation, that is, you need to install a gas boiler. What could be better than deciding for yourself what temperature will be in the house, and if you wish, turn off the heating altogether. And on the correct choice of the boiler, the efficiency, reliability of heating the home, its safety and your comfort depend.

If the area in which you live is gasified, then you just need a gas boiler to heat your house, because modern models are safe, have an ignition and gas control system. But how from the huge and varied offer on the boiler market, choose what is right for you.

Gas boilers from Baxi

The Italian company Baxi has recently become part of the BDR Thermea industrial group.

Baksi is one of the oldest European companies, founded about 100 years ago.

It has been producing heating equipment for about half a century. During this time, a large production and technological experience has been accumulated, the methods of manufacturing complex assemblies and structural elements have been worked out, the most critical structural elements have been identified.

Gas boilers are one of the company's activities. A wide range of equipment is produced for servicing private houses, office or public premises of various sizes and number of storeys.

The main emphasis is placed on installations designed for heating residential premises on the principle of "one boiler - one house". The user has the opportunity to choose an installation that corresponds to the size of his house in terms of power and does not overpay for unnecessary kilowatts.

All installations have a basic set of functions:

- Self-diagnostics (the sensor system provides full control over the condition of the units and elements of the unit).

- Protection against freezing of the system (when the temperature of the coolant drops to 5 °, enhanced circulation starts).

- Possibility of setting the heating mode and operative regulation of the coolant temperature (RH), if necessary.

Additional functions, such as climate control or advanced methods of regulating the operation of units, can be connected as an extension of the installation's capabilities or purchased immediately, as a feature of a certain series or model of the boiler.

Baksi has its own iron foundry and metallurgical divisions, which allows it to produce absolutely all equipment units independently and not depend on subcontractors..

Advantages of electric heating boilers Baxi

There are many advantages of heating devices. These are both affordable prices and excellent job opportunities. But that's not all. Baksi heating units are almost completely autonomous, which allows the owners not to worry about their work.

Positive technical characteristics of heating boilers:

- There are equipment protection systems, thanks to which all the possibilities of an accident are excluded.

- The Baxi boiler automatically supplies fuel and air for heating, so there is no need for human intervention. And if you also connect climatic equipment, then the units can themselves choose the heating temperature on the sensor. This will be especially convenient for those people who have country houses. It is advisable, of course, to connect the generator so that the electric boiler works in the desired mode without obstacles.

- A wide range of operation with modes on the sensor allows you to save money on utilities, as well as to ensure comfortable operation of the heating system.

- The Baxi heating boiler is made from environmentally friendly raw materials, so you shouldn't worry about the environment. These electric boilers are fuel efficient. Some models are around 95 percent efficient. This technological advance keeps the emissions of harmful gases to a minimum.

- The Baxi boiler is considered a safe unit, as it has a flame control system. If the fire is out, the gas supply stops. This protection prevents gas leakage.

- Modern Baxi units already have a system that eliminates overheating. If the coolant stops circulation, then the heating system will automatically turn off. But if you do not need such a function of the electric boiler, then you can buy a simpler unit, especially since it is cheaper.

Almost every Baksi boiler can be connected to climatic or other control equipment, and there is also a system that prevents the condensation effect.

Of the characteristics, you can also name: the presence of a sensor that shows the temperature; the presence of a condensation system that prevents the formation of liquid from vapor or gas; an electric ignition system is present in both floor-standing and mounted electric boilers.

Views

The company produces equipment with various capabilities.

The assortment contains:

- Floor and wall views.

- Single and double circuit.

- Turbocharged and atmospheric (with closed or open burner).

- Cast iron, copper and stainless heat exchangers with different capabilities and efficiency.

This abundance of options allows users to select the optimal installation to suit the needs of the space.

IMPORTANT!

Baksi boilers are initially manufactured to work on natural gas, but at any time they can be reconfigured for liquefied gas, for which it is necessary to change the nozzles of the gas burner.

Types by control method

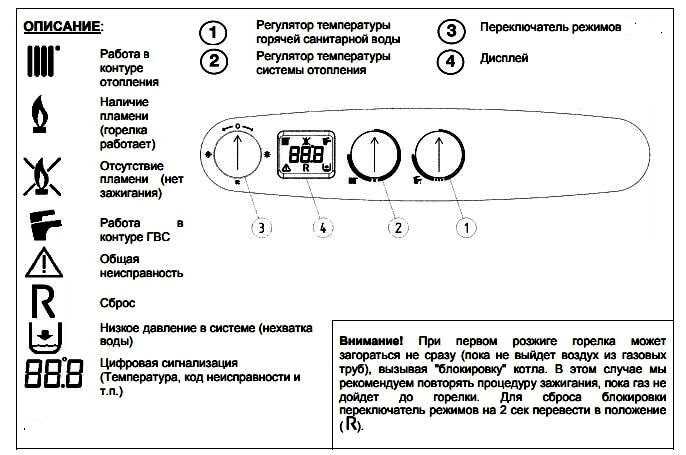

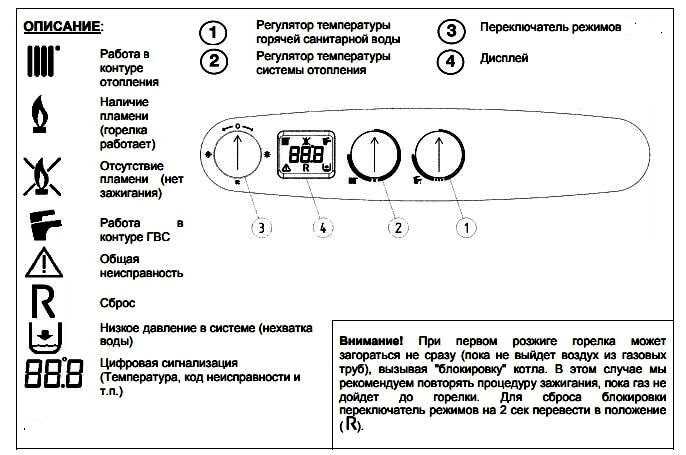

Baksi boilers are controlled from the panel, in the basic version, installed on the unit body.

Later samples received a remote control panel, which can be placed separately from the boiler in a more convenient place. This option is designed for homeowners whose equipment is housed in a separate compartment. You do not have to go to the installation every time, but make the adjustment from a more comfortable position.

Finally, there are models that can be controlled from a smartphone.... Such units can be contacted from almost anywhere in the world and make the necessary settings, being at a considerable distance from home.

This is convenient for people who, due to their occupation, often and suddenly leave for other cities or countries.

They do not need to worry about the state of the heating system at home - using the application installed on their smartphone, they can at any time receive a report on the state of the system, the current operating mode, and make the necessary changes.

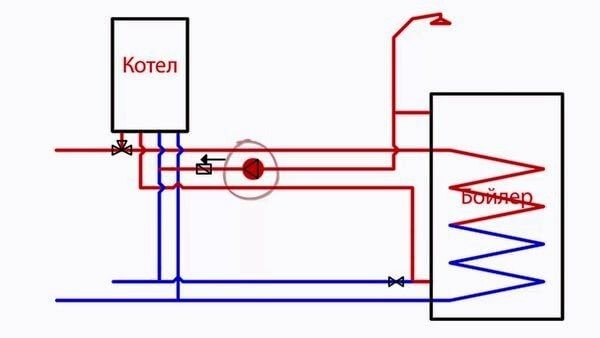

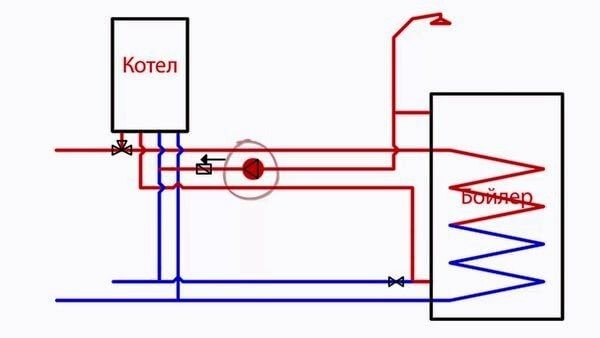

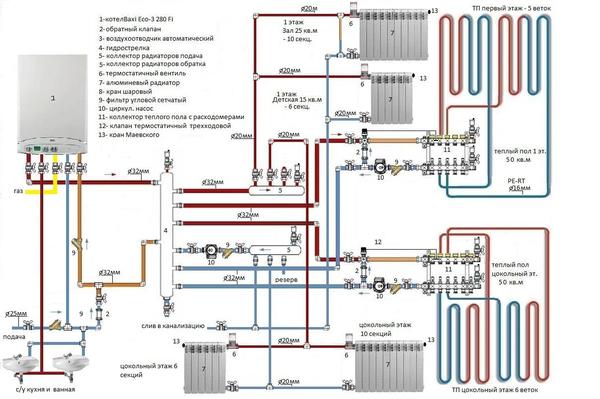

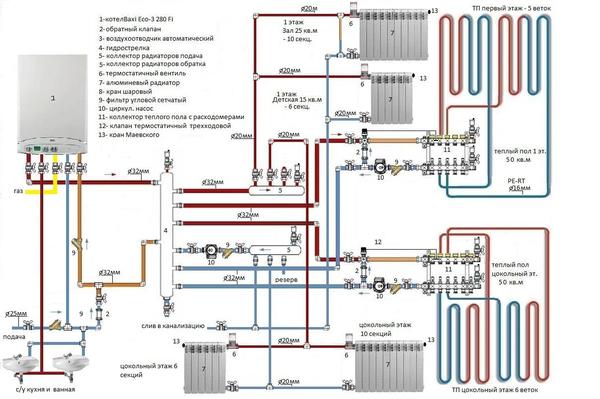

Connecting the boiler to the system

Sometimes it happens that the internal DHW heat exchanger is not enough to provide the hot water load for a large family.

In this case, it will be necessary to install an external indirect hot water boiler, which will act as a storage tank. The design of the Baksi boiler has such an opportunity, the scheme is preferable for the transitional operation of the boiler in the autumn period, when it remains unloaded due to positive outside air temperatures.

Such a hot water supply scheme stabilizes the temperature regime in the hot water supply system, excluding surges. When the volume of hot water is consumed, the boiler is immediately replenished with hot water from the boiler. The connection is made to the DHW pipe.

Specifications

Consider the basic technical characteristics of the units:

| Boiler type | Gas |

| Number of contours | One or two (heating only or heating and hot water supply) |

| Installation method | Floor-standing or wall-mounted |

| Efficiency | 78-92,7 % |

| Fuel type | Natural or LPG |

| Burner type | Atmospheric or turbocharged (closed type) |

| Control method | Direct, remote and remote |

| Heating system type | Radiator or underfloor heating system |

| Power supply | 22 V 50 Hz |

Prevention recommendations

The maintenance for the company's boilers is of a standard type, which includes annual maintenance.

In case of malfunctions, it is worth considering several points, including the fact that a professional should be engaged in the repair, since the system requires an accurate and competent approach. Also an important point is the need to replace parts with relatives in case of breakdown. Do not install handicraft or clandestine spare parts. This will only lead to more serious damage.

Annual maintenance includes cleaning the chimney, which is mandatory, and removing scale. These operations are required to be performed at least once a year. Under optimal operating conditions, cleaning should take place every six months.

It is also worth considering that the operating mode should be regulated by technical characteristics and instructions. This will avoid most malfunctions.

Series and models

Baksi units are available in floor and wall mounting options. The difference between these types is in weight and dimensions, and the complexity of the design. Floor standing units usually have a high efficiency cast iron heat exchanger.

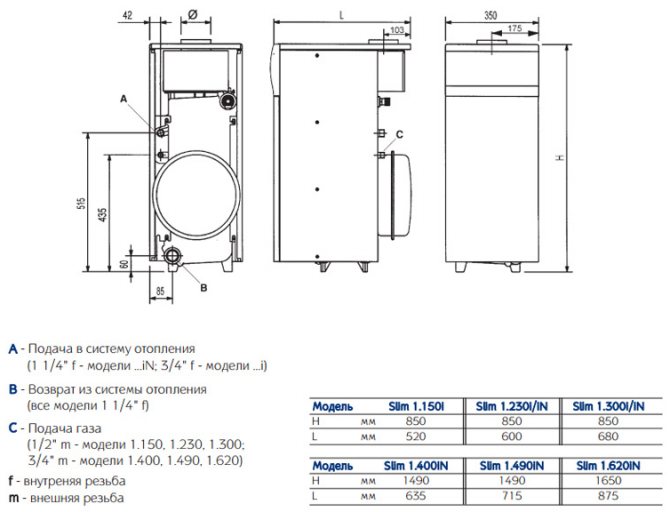

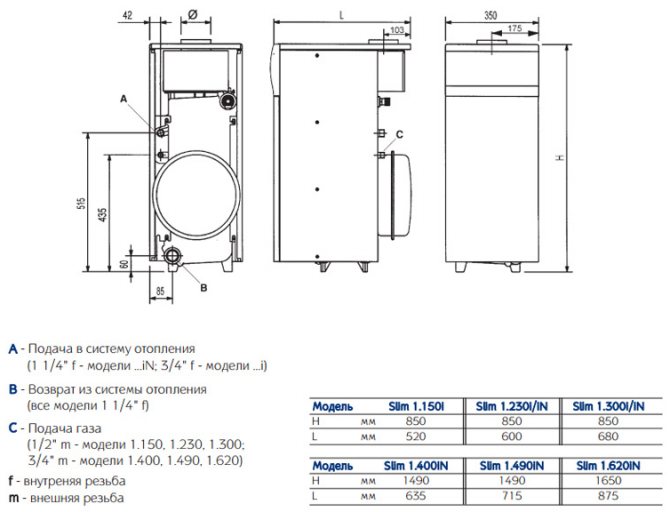

They are represented by the Slim series, which has a wide range of units of different capacities..

The range of wall-hung boilers is much wider.

There are series:

- Baxi MAIN

- ECO

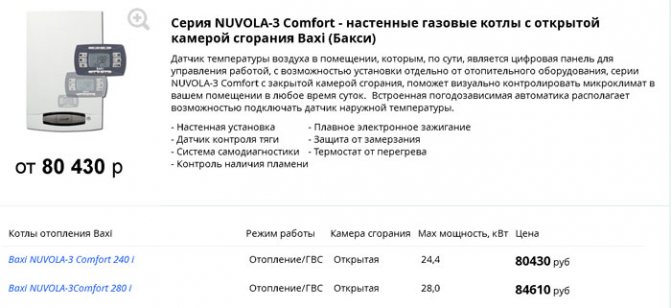

- Baxi NUVOLA3

- Baxi LUNA-3

All series have their own model line of units of different capacities with the same set of functionality. The user can select a sample that matches the power without losing any of the features inherent in this series of units.

NOTE!

The manufacturer is constantly updating the functionality of existing models and introducing new, advanced lines of gas boilers with improved parameters and characteristics.

Equipment classification

Baxi offers its customers a wide range of heating equipment. The model lines are constantly being supplemented with new equipment.

At the moment, the manufacturer offers units of the following types:

- Traditional gas boilers with wall or floor installation.

- Wall-mounted condensing models.

- Double-circuit equipment, where the combustion chamber can be either open or closed.

- Single-circuit equipment with closed or open type combustion chambers.

Both wall-mounted and floor-standing heating boilers are modern and safe equipment, the operation of which is ensured by built-in automation.

Floor standing gas boilers Baxi

All units from the category of Baksi floor-standing gas boilers are models with a cast-iron heat exchanger with a stylish modern appearance. They are suitable for any premises due to their compactness and low weight.

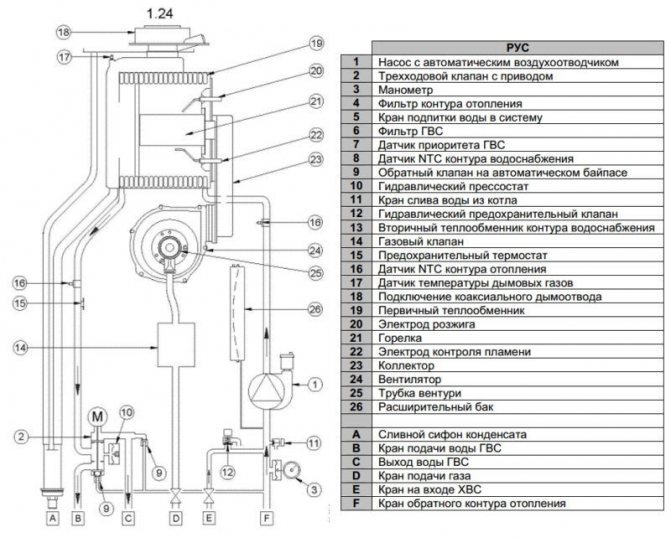

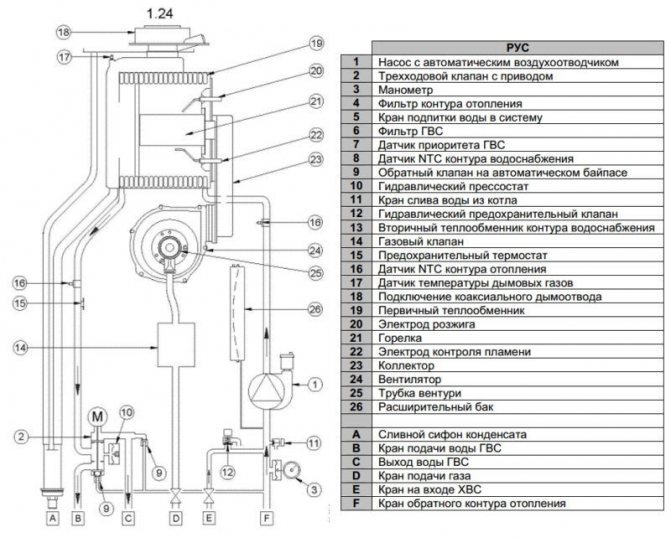

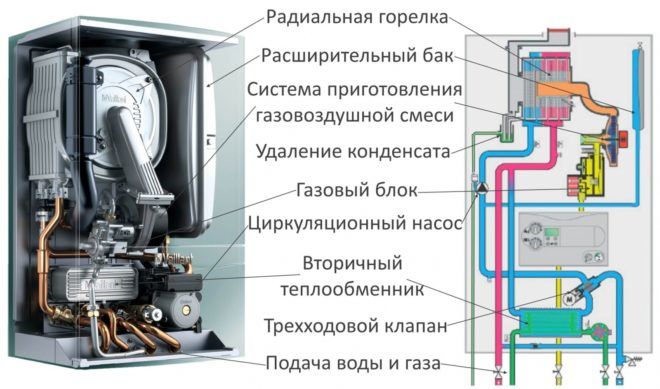

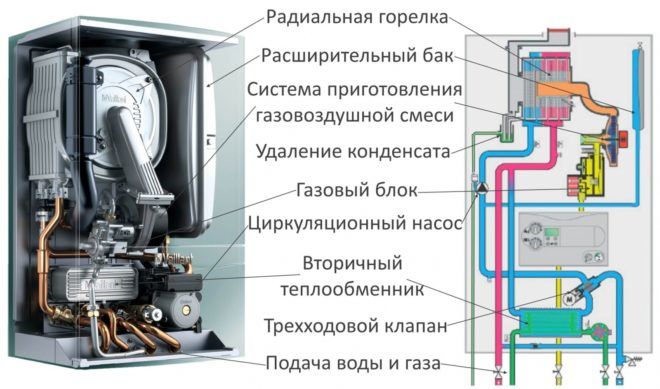

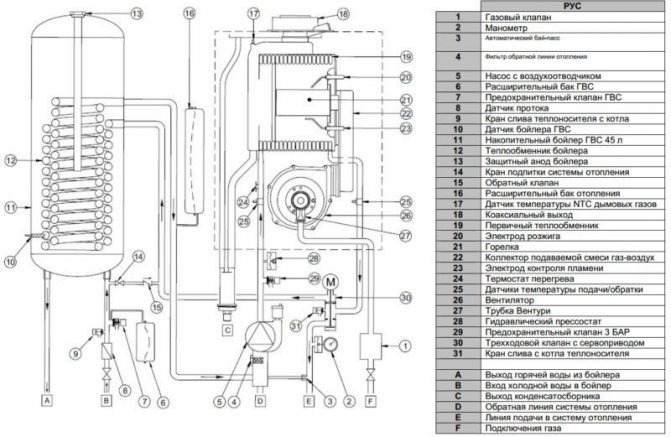

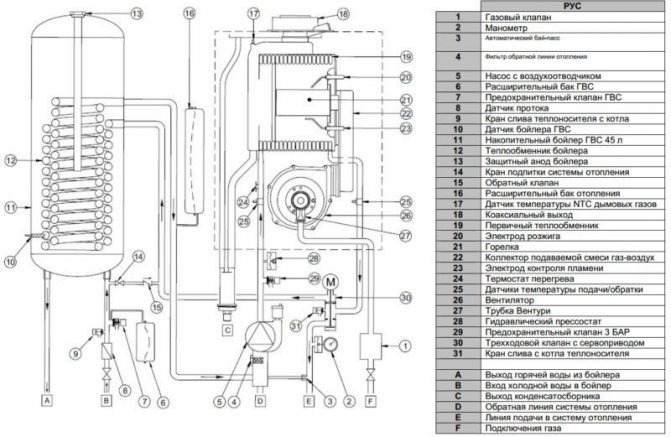

The internal structure of the floor-standing gas boiler Baxi

Their advantage is their good adaptability to existing operating conditions - they do not stop if the inlet pressure in the system drops to 5 mbar.

Gas savings during the operation of this equipment are ensured by permanent modulation for the flame.

Modern technologies ensure the timely execution of diagnostic manipulations aimed at identifying possible malfunctions of boilers - this guarantees their safe operation.An additional advantage of these gas boilers is the presence of a special system that provides protection against bacteria - hot water is regularly heated in the boiler, which leads to the death of all pathogenic microorganisms.

The lineup

Gas boilers Baxi are represented by a wide range of models, in which variants of double-circuit and single-circuit equipment have been developed (power ht, Slim hp, slim).

The purpose of single-circuit units is only for heating.Today this line is represented by baxi slim models (1230 iN, 1.400 iN).

Single-circuit models that provide both heating and hot water in the house are represented by the Baxi SLIM 2.300i, 2.230 I and others line.

The most compact boilers are SLIM, so they are often chosen for home use. An additional connection of a water heater is also possible to them. Here Slim 1 is options with one contour, and Slim 2 is with two. In both categories, there is equipment with open and closed combustion chambers. Power, depending on the specific model, ranges from 15–62 kW.

The positive aspects of floor structures

Advantages of the Baxi Slim line:

- Self-diagnosis in automatic mode.

- Work in underfloor heating mode (up to 45 degrees) or in heating mode (up to 85 degrees).

- Power 15–62 kW.

- Boiler connection up to 60 liters.

- Circulating high-speed pump.

- Electronic modulation for the flame in the burner.

- Programmable timer.

- Maintaining a constant temperature in the boiler.

The Slim 2 model additionally has a steel boiler and an automatic device that changes the operating mode of the unit depending on weather conditions.

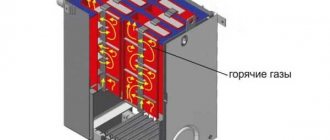

The Slim HP models are equipped with an atmospheric two-stage burner, cast iron heat exchanger. The units are characterized by high power ratings (83-119 kW).

This gas fired boiler is characterized by an increased number of fins, which improves the heat exchange performance. To control temperature conditions, a thermostat is installed, which sends appropriate signals to the burner. Among the advantages are additional protection that excludes overheating, draft control, the possibility of additional connection of cascade automation and a circulation pump, burner flame control.

Another line of compact equipment is Power Ht. These boilers are characterized by the highest power, which can cope with heating large areas.

Condensing boilers "Baksi"

A feature of condensing boilers from the Italian brand Baxi is their increased efficiency, which became possible due to the presence of condensing technology.

The advantages of this type of equipment are as follows:

New technologies used in new generation BAXI condensing boilers

- Differentiated change in the intensity of the combustion process.

- Possibility to operate on liquefied gas in certain installations.

- The presence of an automatic bypass.

- If necessary, a boiler is connected to the equipment.

- Equipment operation depending on weather conditions (provided by modern automation).

- The presence of a three-way electronic valve.

- Reflection of the main operating parameters on the display.

- Efficient use of fuel entering the combustion chamber.

- Steel burner.

- Minimal emission of harmful combustion products.

- Plate heat exchanger.

- Work in post-circulation mode.

- Control of coolant indicators.

- Maintaining temperature conditions inside the heating circuit.

- A wide range of temperature conditions.

- Monitoring key performance indicators to ensure safe operation.

Models on the market

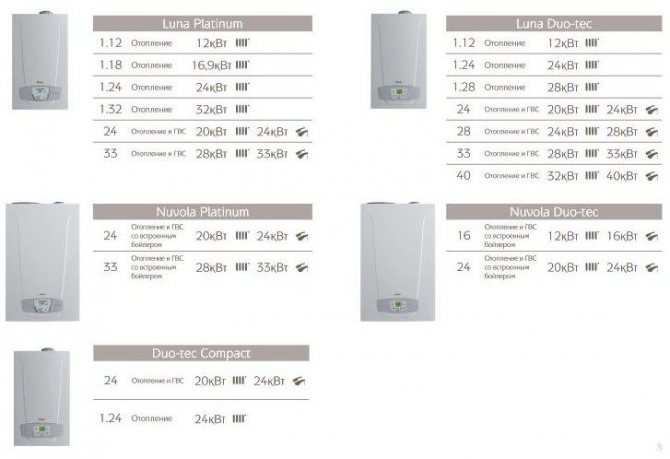

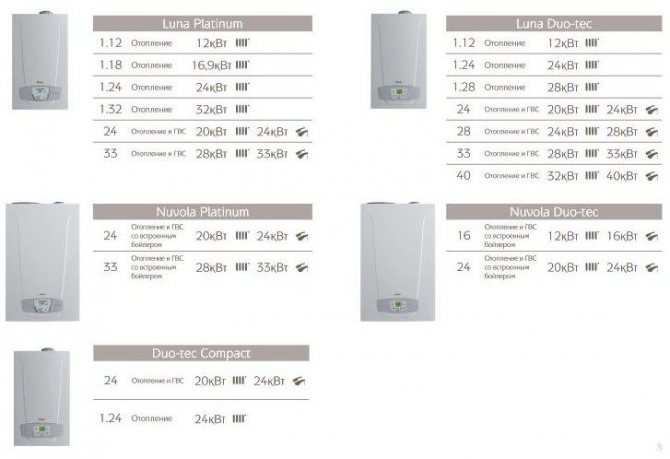

The category of condensing boilers is represented by three lines:

- Luna Duotec;

- Duotec Compact;

- Luna Platinum.

Luna Platinum boilers are wall-mounted equipment, in which the control panel is removable. They are able to maintain the specified temperature conditions in the circuit, the power characteristics range from 12 to 33 kW with the possibility of modulating it 1:10.

Within the framework of the heating system, the coolant flows in forced mode by means of a modulating pump. Automation monitors the main performance indicators - temperature, pressure.

Gas condensing boiler Baxi Duo-tec Compact

The manufacturer has provided a self-diagnostic function to assess the functioning of the unit. Any errors in operation are saved and reflected on the display screen.

Heating boilers Luna Duotec are presented in versions with one and two circuits with a capacity of 12-40 kW. The system has a built-in pressure gauge for pressure control, a circulation pump.

Duotec Compact units have similar characteristics. Both single-circuit and double-circuit boilers here have a capacity of 24-28 kW and are characterized by particularly small dimensions. They maintain a given temperature regime with greater accuracy, which is made possible by a small heat exchanger.

Wall-hung condensing boilers with built-in boiler

Among the most popular and demanded equipment, a special place is occupied by Italian-made wall-mounted boilers. This category contains models:

- Turbocharged variation where the combustion chamber is closed.

- Atmospheric boilers where the combustion chamber is open.

- Modifications with one and two circuits.

Condensing boiler diagram

Despite the rather high cost, the ratio between price and quality of such equipment is optimal. Wall-hung condensing boilers have the same advantages as other types of equipment. The manufacturer offers several lines, each of which has some features.

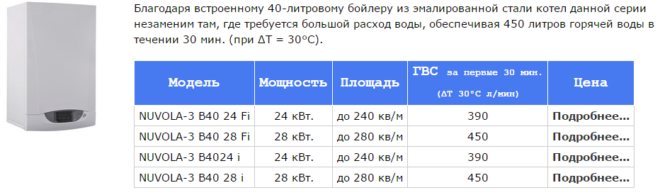

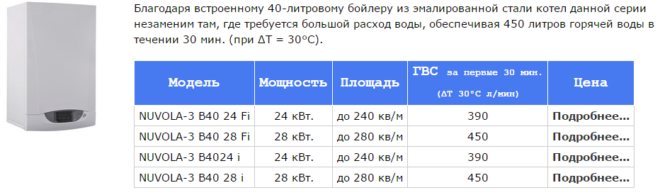

Nuvola Duotec with 24 kW represents equipment with a pair of circuits. Their main characteristics are similar to those of other types. Their main differences are as follows:

- Warning in the event of a drop in pressure and subsequent shutdown of the fluid supply.

- The volume of the tank is 45 liters.

Gas condensing boiler Baxi NUVOLA Duo-tec 16

Nuvola Platinum boilers are equipment with two circuits. Models are characterized by power up to 33 kW. Their features are as follows:

- Antibacterial protection for hot water tank.

- The volume of the boiler is 45 liters.

- Rapid heating of the liquid in the system.

Nuvola Platinum - characteristics

Heating boilers from the Comfort Ht category are the newest line in equipment from the Baxi company. They are characterized by powerful modulation in a ratio of 1: 6. Equipment features:

- Work at high and low temperatures in the system.

- Possibility of additional connection to a solar-powered system.

- The volume of the water tank is 45 liters.

- Power indicators 25–33 kW.

- Operation in several circuits with different temperatures.

Advantages and disadvantages

The advantages of Baksi gas boilers are:

- High performance.

- Efficiency, high efficiency of all units.

- Environmental friendliness.

- Simplicity of settings.

- Stability of work, stability.

- Adaptation of all units to Russian technological conditions.

- The presence of self-diagnostic systems, protection against freezing and other external threats makes the operation of the units reliable and stable.

The disadvantages of Baksi installations are:

- The high price of equipment and, in particular, components.

- Inability to replace boiler parts with cheaper counterparts.

- Demands on the composition of water and the quality of the supply voltage, forcing users to install voltage stabilizers and water softeners.

Knowledge of the features of the equipment will allow timely avoidance of failures or breakdowns of important units of installations. Operation, carried out without taking into account some of the weak points of the units, leads to the appearance of system failures and requires immediate elimination of errors.

Common problems

Even the highest quality equipment can fail. Often, breakdowns are not too serious and arise due to errors during installation and configuration. In most cases, they can be solved by carefully reading the instructions.

More serious malfunctions:

- ignition failure,

- the burner stops turning on,

- pops are heard in the firebox,

- the boiler is overheating,

- extraneous noise,

- the water heats up badly.

The most common causes of breakdowns are voltage drops in the network, moisture ingress into the furnace, as well as unstable pressure in the gas pipeline. It is recommended to call a specialist who will diagnose and repair the equipment.

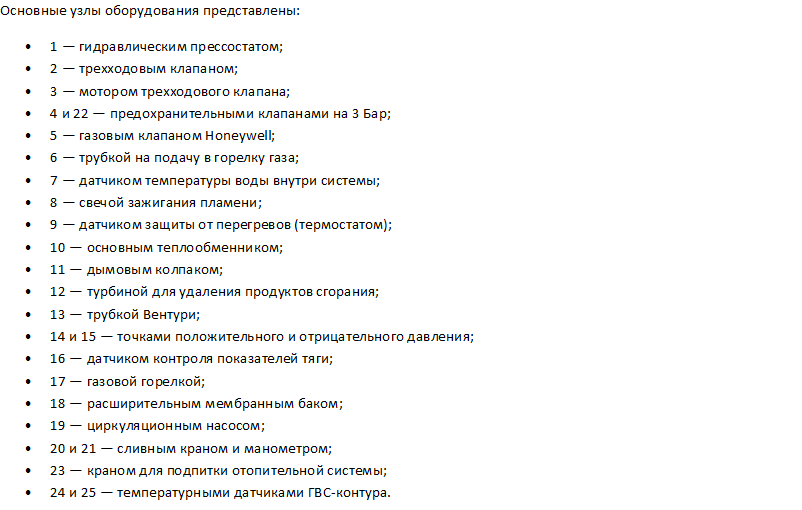

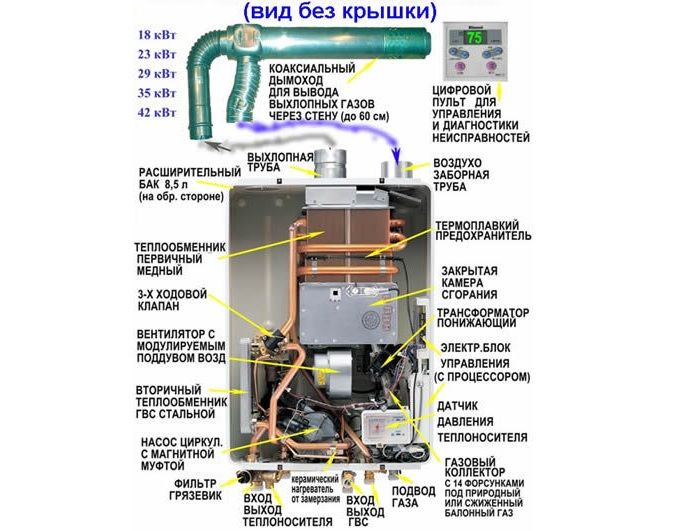

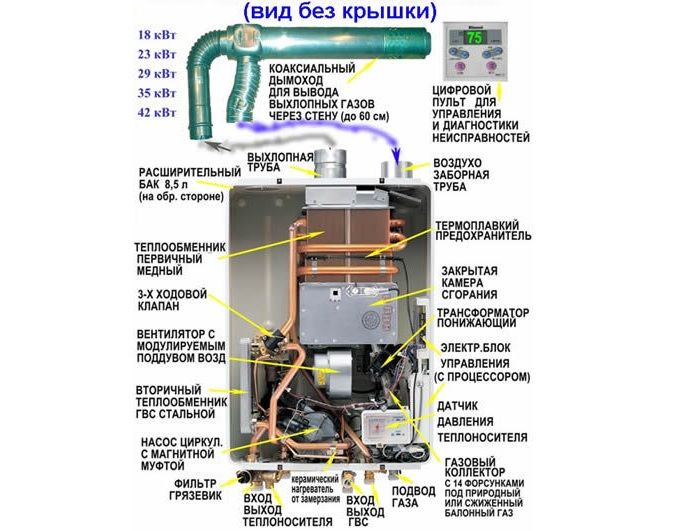

Device

Baksi gas boilers consist of the following units:

- Gas burner open or closed.

- Turbocharger fan (for closed burner models).

- Heat exchanger (primary and secondary if the boiler is double-circuit).

- Three-way valve.

- Circulation pump.

- Gas valve.

- Sensor system connected to the control board.

- Housing with connections for gas and water lines.

Some models have additional elements that provide climate control or advanced system management capabilities.

You can look at the device below in the photo.

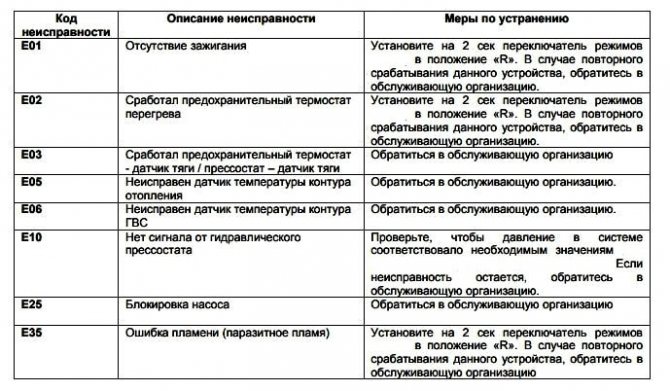

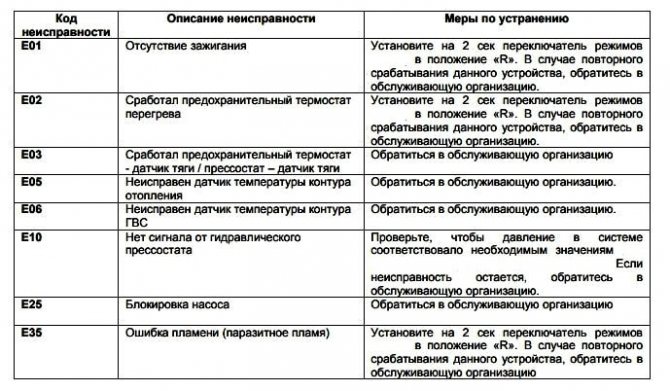

Baksi boiler error codes

Units of the Italian brand Baksi, according to customer reviews, rarely go out of service with serious breakdowns. Most failures can be corrected by users on their own, the reason for this is a very functional diagnostic system for the operation of the equipment.

It issues an error code to the operating panel, according to which the user can independently determine the cause of the failure.

The most common types of Baksi boiler malfunctions:

- "01" - no ignition.

- "02" - overheating of the coolant, airing of the system or malfunction of the impeller of the circulation pump.

- "10" - the hydraulic circuit is faulty.

- "011" - low quality make-up water.

In case of the most serious failures, leaks in the boiler systems, when the heat exchanger is broken, malfunctions of electronic control units or primary sensors, the user should contact the service center to eliminate them.

Operating principle

The operation of the boiler consists in heating the coolant entering the primary heat exchanger using a circulation pump... At the outlet, the hot air passes through a three-way valve, where it mixes in a predetermined proportion with a colder return flow, as a result of which the temperature of the coolant acquires the required value and is sent to the heating system.

Hot water is heated in a secondary indirect heat exchanger... The heat source for it is the hot OM, which has not yet entered the three-way valve.

The operation of all nodes is constantly monitored by a system of sensors that transmit a signal to the control board.

When changing the nominal mode, the display shows an error code related to a specific unit or part of the boiler.

Download instruction

You can download the instruction here.

User's manual

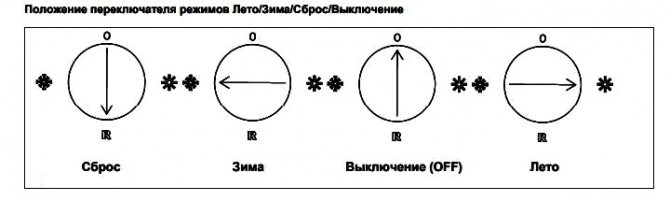

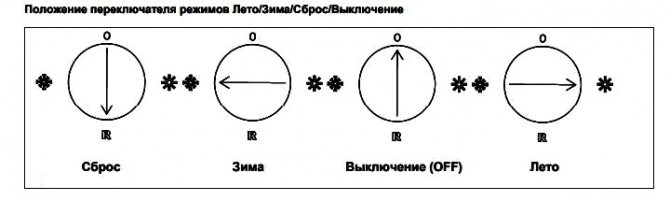

The manufacturer provides the user with rather detailed instructions for operating the equipment, which boils down to switching between the "winter / summer" modes.

During the operation of the boiler, it is necessary to control the presence of traction in the combustion chamber, the absence of noise and vibrations, and also to monitor the correct operation of control devices and shut-off valves.

During operation, the user will need to periodically clean the chimney system from soot deposits, and descale the internal water circuit.

For descaling, a special flushing valve is installed in the system, which allows flushing without dismantling the heat exchangers. The technology is carried out in accordance with the recommendations of the manufacturer, indicated in the production instructions.

For efficient and safe operation of the unit, at the end of the heating season, it must be provided for maintenance by a qualified technician. It is not allowed to carry out external cleaning of the boiler with abrasive, caustic or flammable means.

Installation technology

Installation of boilers is not difficult.Floor-standing models are installed in a designated place, wall-mounted samples are hung on solid walls that can withstand the weight of the units and connecting pipelines.

In this regard, there are certain conditions that prohibit the installation of equipment on plasterboard or plywood partitions and fragile surfaces.

Outcome

Recently, Italian wall-mounted Baxi appliances have been in demand, since they provide a high level of comfort and are able to heat residential buildings with different areas. Each model is equipped with a set of safety electronics, which reduces the risk of accidents or damage to a minimum.

In Russia, Baxi brand equipment is popular, especially among owners of cottages and country houses. This is due to the fact that wall-mounted devices fit well into any interior; they do not need to be provided with a separate room. That is why they are used to heat apartments.

How to set up correctly

The boilers are set up according to certain rules detailed in the user manual.

The point of the whole procedure is to set the minimum and maximum gas pressure, determine the parameters of the heating water and hot water supply. All actions are performed during initial start-up or after routine repairs (maintenance).

During the operation of the boiler, the current regulation of the heating water temperature is performed, which does not affect the general settings of the unit..

IMPORTANT!

Self-tuning of the parameters is not recommended, since such actions must be performed by employees of the service center. Most organizations have a negative attitude towards independent action and may refuse warranty service.

How are double-circuit boilers Baksi arranged

Baxi double-circuit boilers are designed to heat water in the heating and hot water circuit. In fact, such units are an improved single-circuit modification, implemented with a hot water boiler in the form of a conventional or bithermal heat exchanger. In the first case, the transfer of heat in the DHW circuit occurs by the heated coolant coming from the heating boiler.

The bithermal heat exchanger does not stand out from the outside from the standard boiler heating boiler. Only inside the heating surfaces for heating and hot water are separated by pipes of a complex configuration, similar to a diamond.

Water flows along the outer loop for heating, and inside the rhombus for DHW. This design more effectively removes heat from the heating medium, but has problems when cleaning surfaces from scale.

Therefore, for such devices, it is mandatory to install filters for preliminary purification of make-up water with a softening function.

Price range

The company's products have a wide range of series and models, so the price range is very wide.

The minimum ones are in the range of 25-30 thousand rubles, these are single-circuit installations of relatively low power.

More productive models with a wide range of options are much more expensive - up to 200 thousand rubles. and even higher. Installations of an industrial level have a price of over one million rubles, which is explained by their high productivity and the ability to serve large areas.

The cost of equipment is significantly affected by logistics - for areas located far from densely populated centers, the price is always slightly higher due to the complexity of delivery.

Testimonials

Reviews of the company's products indicate that it is possible to choose any option that will be both convenient and safe to use.

You will be interested >> Causes of malfunctions in Vilant double-circuit boilers

Maxim: “We have been choosing equipment for a long time. The choice fell on BAXI quite by accident. I just came up with the characteristics. It turned out to be quite a convenient thing, which is safe, and completely easy to operate. "

Stanislav: “I have been using the products of this company for several years. The only thing that happened was the change to a more powerful one when moving. And so everything suits.It’s even surprising, but there are no complaints ”.

Valentina: “When my husband bought it, I was not very happy. Still, there were cheaper options. But after two years I realized - the price was worth it. So far there have been no breakdowns, and this is already something. "

Marina: “Several years ago we bought a small boiler from Baksi. I thought that such a miniature unit would not be able to fully work out its cost. I was pleasantly surprised. "

Victor: “I bought a boiler that year. I was attracted by the ability to regulate the system using electronics. Really very convenient and practical. In addition, I have not noticed any malfunctions yet. Everything works like clockwork. True, for such a price it should be so. "