The comfort of a person's stay in a room, whether it be an apartment in a high-rise building, a private house, a workshop or an office, largely depends on the temperature of the surrounding air. At the same time, in the cold season, it is impossible to do without an effective space heating system. And if in urban conditions and in production this problem is solved in a centralized manner, then in private houses the presence of an autonomous heating system is mandatory. As a rule, it is based on a solid fuel, electric or gas boiler. Those who are going to equip a home with such a heating system should pay attention to German products, whose boilers are famous for their operational reliability and economy.

About company

The brand is part of the giant Vaillant Group. It sells about three million units annually. The company's annual turnover is 2 billion euros. The history of "Vailant" dates back to 1874. The company received its name in honor of the founder - Johan Vailant. The company is the leader in the number of wall-hung boilers sold. She, unlike competitors, offers technology that works with renewable energies. Today the brand owns 27% of the world market for wall-mounted heating devices. The European company sells its products in almost all parts of the world. The brand, despite the narrow focus of production, has colossal research and development resources.

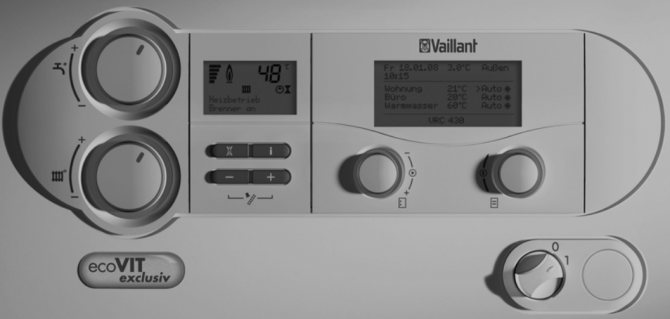

Popular errors and their decryption

Failure or malfunction of the boiler units is determined by the sensor system and displayed on the display as an error code.

The most common ones:

- F00-01... Failure of the temperature sensor on the direct or return lines.

- F02-03-04. Sensor failure due to poor contact.

- F05-06... On atmospheric boilers, the smoke output control sensor has failed.

- F10-11... Short circuit of the extract air temperature sensor.

- F13... Boiler overheating, hot start sensor failure.

- F15-16... Short circuit of the smoke removal sensor (draft).

- F20... Boiler overheating, insulation breakdown or short circuit of wires in the harness.

- F22... Lack of water causes a shutdown.

- F23-24... Temperature rise or drop too fast. Causes unit shutdown.

A complete list of errors is contained in the user manual.

NOTE!

Those that are not indicated can only be eliminated by a specialist of the service center.

What are they?

Boilers are distinguished according to the installation method:

- Wall mounted. Small size and weight. They do not require a separate room. Stylish design - looks great in the kitchen. The described brand offers a large selection of hinged-type models.

- Outdoor. More bulky. More powerful than wall-mounted counterparts. Suitable for heating a large house. There are only three floor models - AtmoVIT (16,000-56,000 W), AtmoCRAFT (65,000-157,000 W) AtmoVIT Exclisuv (up to 47,000 W). Made of cast iron - this extends their service life. Air intake - by means of fans. A capacitive boiler can be connected. The latest modifications of the floor-standing series are equipped with two burners, one - maintains a constant temperature of the coolant, the second is activated when it is necessary to increase the heating intensity.

By the number of contours:

- Single-circuit. They are intended for heating only. "VU" marking. Connection of a boiler is possible.

- Double-circuit. These, in addition to heating the house, simultaneously heat water for domestic needs. "VUW" marking. The efficiency of such devices reaches 93%.

By the method of removal of combustion products:

- Traditional chimney. Models with an open firebox are called atmospheric. Their labeling is AtmoTEC.

- Coaxial chimney. Closed firebox. Marking turbocharged versions - TurboTEC.

Also, Vaillant gas heaters differ in power and configuration. The manufacturer produces equipment with four capacities - 12, 24, 28, 36 kW.

A lot of useful information is encrypted in the marking. For example, the marking Vaillant VU turboTec 362 / 5-5 means - one "VU" circuit, turbocharged - turboTec, 36,000 W, 2 - the smoke is forced out, 5 - the fifth generation.

Specifications

Consider the main parameters of Vilant boilers:

| Parameter | Power 24 kW | Power 32 kW |

| Heat output range | 9-24 kW | 9-32 kW |

| Rated heat load | 26.7 kW | 34.8 kW |

| Hot water consumption | 1.5-11.5 l / min | 1.5-15.3 l / min |

| Fuel type | Natural or LPG | |

| Chimney type | Coaxial 60/100 mm | |

| Dimensions (edit) | 800/440/338 mm | |

| Power supply | 220V 50Hz | |

| Gas pipeline connecting size | 15 mm (R 3/4) | |

| Heating connection dimensions | R 3/4 | |

| Water pipes | R 3 / 4- R 1/2 | |

The lineup

The hinged type of equipment remains the most popular option, therefore the German manufacturer offers a wide range of such devices. Products for Russia and Eastern Europe are assembled in Slovakia - the company recently launched its production here. Boilers assembled in Slovakia are marked with the particle "Int". In factories located in Germany, only condensation-type modifications are assembled - Vaillant ecoTEC plus.

Depending on the type of ventilation, wall-mounted devices are distinguished:

- AtmoTEC - natural air circulation. 3 versions:

- Pro VUW - dual circuit. Power is 24,000 watts. They are considered budgetary.

- Plus VUW - 20-28 kW.

- Plus VU - single-circuit. At 24,000 and 28,000 watts.

- Allant TurboTEC - air supply by fan.

There are 3 main series of VUW 2-circuit boilers:

- TEC Plus;

- Turbo FIT;

- TEC Pro.

The "Plus" series differs from the "Pro" by the presence of a "quick start" - thanks to this function, it is possible to maintain a constant temperature in the heat exchanger for DHW.

The latest models are equipped with "ATMO GUARD" - a security system based on two temperature sensors.

Electric boilers Vilant

The Vilant company produces exclusively single-circuit wall-mounted electric boilers, which differ only in power. It can vary from 6 to 28 kW. The power is regulated, so the unit can work in both high-temperature and low-temperature heating systems. The latter includes the "warm floor" system.

An electric heating element acts as a heater.

Features of this boiler:

- there is a built-in expansion tank and pump;

- you can connect an indirect heating boiler;

- there is a mechanical pressure gauge;

- it is possible to synchronize the operation of the boiler according to the weather.

The main malfunctions of the Vilant boiler are associated with the failure of the heating element. This is not a serious breakdown and replacement of the heating element takes about 10 minutes. In such boilers, it is undesirable to use antifreeze, since the heating element overheats it and the anti-freeze turns into acid.

Benefits

It is convenient to consider the advantages of Vilant heating equipment on the example of one model - turboTEC pro VUW INT. This is the most requested modification. It has two circuits and forced gas evacuation. Benefits:

- Modulating burner - a saving factor.

- Power regulation 9,600-24,000 watts. Hot water is enough for 2 points of water intake.

- Expansion tank - 6L. It is possible to arrange 2 circuits for two heating systems.

- Closed firebox.

The efficiency is 93%.

- The copper heat exchanger has a "Suplar" coating for increased durability.

- A flow-through system is used - reduces deposits.

- There is a self-diagnosis.

- Possibility of pump speed regulation. However, the adjustment is done mechanically.

Disadvantages:

- High prices. German quality in this case is estimated at 40,000-100,000 rubles.

- Volatility. To ensure uninterrupted operation of the equipment, you have to connect a UPS - an uninterruptible power supply, battery or generator.

- Noise during operation.

Typical malfunctions

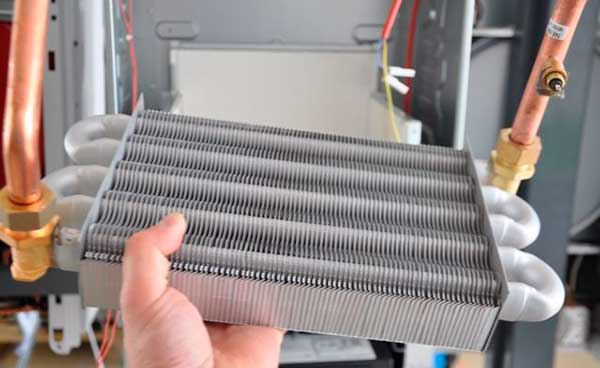

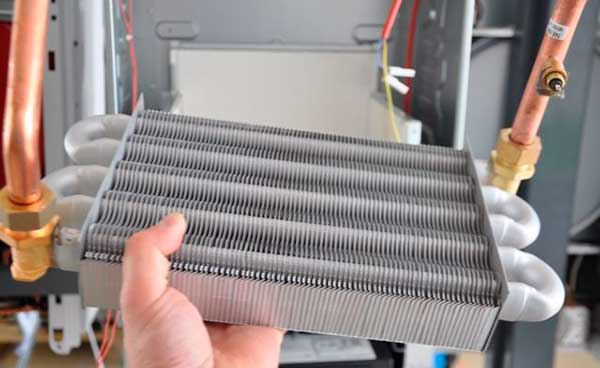

A common cause of malfunctions in gas boilers is the clogging of heat exchangers with scale.

Despite the high reliability inherent in all Vaillant products, there are several disadvantages. More often than others, users note:

- Plate heat exchangers quickly become clogged with scale, and therefore it is necessary to install special filters to soften the water.

- Increased noise level during the operation of the built-in fan.

- Water ingress into the pump, which is caused by insufficient reliability of its seals.

- unstable operation of electronics caused by voltage fluctuations in the centralized power grid. Such disadvantages are eliminated by installing a voltage stabilizer.

Avoiding troubles during operation will allow competently performed installation work.

After installing and connecting the boiler to the existing communications, the following work must be performed:

- check the correct installation of the check valve in the heating system;

- remove air from the heating system;

- before the first start-up of the boiler, carefully check all the settings of the heating circuit;

- carry out a test run, during which check the functioning of all systems in heating and water heating modes;

- check the operation of all automation, control and protection systems.

It is better to entrust the performance of the listed work to a qualified specialist who has permission to perform such work.

troubleshooting

In the event of a boiler malfunction, the system displays the corresponding information on the display

All Vaillant boilers are equipped with an integrated fault testing system. If any error occurs, the system displays the corresponding information on the display screen. Errors blocking the operation of the boiler can occur due to unstable power supply or broken contacts in the connections of the wires going from the sensors to the electronic module. Such faults can be eliminated by checking the signal lines for:

- wire breaks or oxidation of lamellas and contact groups;

- shorting wires to the body or to each other;

- damage to the insulation of wires;

- loose contact in the connectors.

Having eliminated the identified malfunctions and provided the supply of stabilized power, the error can be reset by pressing the "Reset" button.

More serious errors, for example, F20 (overheating), F26 (problems with the gas valve), F28 (unsuccessful ignition), F68 (unstable flame), etc. can be caused by various reasons, the search and elimination of which is best left to professionals.

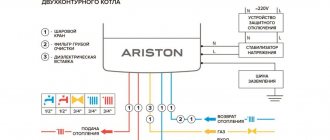

TurboTec Pro device

Double-circuit devices are equipped with two heat exchangers. The first is made of copper - it heats the coolant, the second is made of stainless steel - for heating running water. The copper heat exchanger has a large number of plates.

The gas burner modulates the flame in the range of 40-100% of the power. There is a built-in hydraulic unit - there is a secondary heat exchanger, a security system, a circulation pump, as well as a variety of sensors.

The main competitors of the brand are German boilers Viessmann. Vailant has an undeniable advantage - water-gas elements are made of high-quality copper, while competitors are made of composite material.

The device is economical in gas and electricity consumption. Thanks to the use of low-voltage equipment, less electricity is consumed.

Operating principle

The coolant entering the boiler under the action of a circulation pump is fed into a primary heat exchanger connected to a gas burner.

Receiving heat energy in it, the extract air is supplied to the secondary heat exchanger, where hot water is heated.

Then the coolant enters the three-way tap, where it partially mixes with the cooled return flow and receives the set temperature, after which it again enters the heating circuit pipelines... The whole process is continuously monitored by a system of sensors that send signals to the control board.

In the event of abnormal situations, the boiler is blocked, and the display shows an error code that identifies the problematic part or assembly.

Model overview

TurboTEC plus VU 122 / 5-5

The simplest single-circuit model of the Turbo line. Wall execution. With a closed combustion chamber, as befits a trumpet apparatus. Capacities range from 12 to 36 kW (4 kW step). Easy maintenance - the owner of the equipment can handle it on their own. True, for this he will need instructions - to get acquainted with the device of the device and the options for its maintenance. Design Features Specifications:

- Efficiency - 91%

- Power consumption 145,000 watts.

- Heats up to 120 sq. M.

- Weighs 34 kg.

- The cost is 45,000 rubles.

- Heating capacity (min / max) - 6 400/12 000 W.

- Auto ignition.

- Weight - 34 kg.

AtmoTEC plus VUW / 5-5

Wall-mounted model for autonomous heating systems, Similar designs and technical characteristics:

- Two contours. Plate heat exchanger.

- Protective systems. Electronic ignition.

- Electronic control. Information output on the display.

- Heating capacity (min / max) - 9/24 kW. The manufacturer offers models for 28, 24 and 20 kW. Open firebox Gas outlet is natural.

- The cost is 63,000-73,000 rubles.

- Heating capacity - 9,000/24,000 W.

- Volatile.

- Auto ignition.

AtmoTEC pro VUW240 / 5-3

This range has been produced since 2020, so the latest technology and innovative ideas have been used here. Wall execution. Two contours. Natural chimney. Built-in strapping. Electric ignition. Security systems. The primary heat exchanger is made of copper, for hot water supply - steel. Some technical characteristics:

- Heating capacity and 24,000 W is enough to heat a house up to 240 sq.m.

- The DHW circuit productivity is 11 l / min at a temperature of 30 ° C.

- Fuel consumption - 2.4 m3 / h.

- Weight 28 kg.

A complete analogue of the above atmospheric boiler is turboTEC pro VUW240 / 5-3. This is a turbocharged version - combustion products are discharged forcibly.

EcoTEC pro VUW INT 286 / 5-3

The EcoTEC pro series equipment is characterized by increased environmental friendliness. This is a wall-mounted 2-circuit condensing unit. The series is presented with powers of 24.28, 34 kW. A high-performance DHW circuit was used. There is all the necessary piping - an expansion tank, a safety group, a circulation pump. Simple operation and simple operation are the characteristic features of condensing boilers. Complex, high-tech technologies help to achieve such simplicity. VUW INT 286 / 5-3 specifications:

- 24 kW.

- Efficiency - 107%

- Weight 35 kg.

- Estimated price - 80,000 rubles.

- Turbocharged.

- Heats an area up to 192 sq.m.

- The limiting pressure in the heating / hot water circuit is 3/10 Bar.

Includes display and backlit panel. Power regulation - 28-100%. There is a summer mode of operation - only for hot water supply. All components are made in Germany. As the manufacturer assures, such devices can save up to 25% of gas compared to analogs of the convection type.

EcoTEC plus VUW 246-346 / 5-5

Economical equipment with lightweight management. Fast heating of water. Increased environmental friendliness - less concentration of harmful substances in emissions. Informative control unit - on the display, in addition to error codes, their decoding is also displayed. EcoTEC plus series is presented in three powers - 24, 30, 34 kW.

- Heating capacity 24 kW.

- Efficiency - 108%

- Weight 35 kg.

- Estimated price - 98,000 rubles.

- Turbocharged.

- Heats an area up to 192 sq.m.

- The limiting pressure in the heating / hot water circuit is 3/10 Bar.

Such devices are suitable for heating any home - houses or apartments. Do not need frequent maintenance.

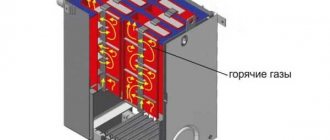

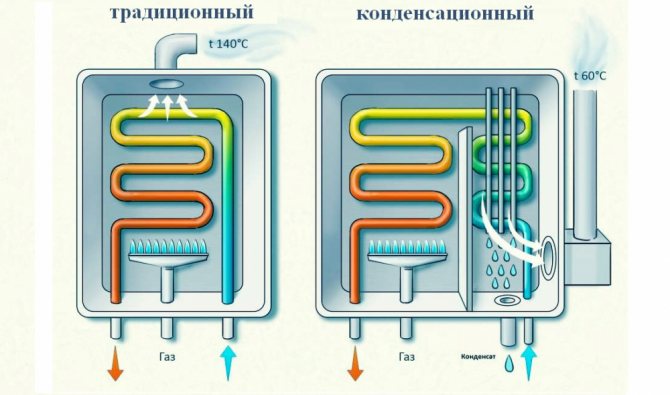

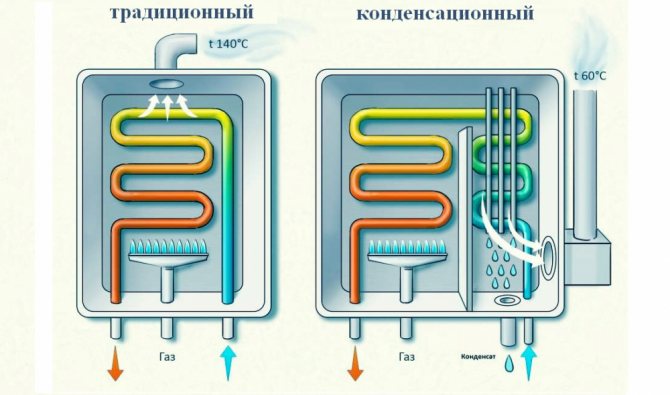

Condensing heating boilers Vilant

The principle of operation of Vilant condensing heating boilers is not at all the same as that of convection boilers. In a conventional boiler, a fire burns on the burner, which heats up the heat exchanger. This produces smoke, which is immediately discharged into the chimney.The flue gas temperature is 140-200 degrees. The gas does not cool down below the lower boundary.

Sectional view of the condensing boiler.

In the Vilant condensing boilers there is a heat exchanger that heats up from the fire and then cools the smoke, taking heat energy from it. That is, the smoke comes out into the street already cooled, respectively, most of the heat goes to heating the room. But there is also a by-product of this work - it is condensation, which forms when the smoke is cooled. Condensate is discharged from the boiler through specially provided channels and enters the sewage system.

Thanks to this principle of operation, the efficiency of the heater increases. Reviews of Vilant gas boilers confirm the efficiency of the units at 98%. Manufacturers' statements about 104% efficiency are sheer nonsense. Heaters differ:

- by the installation method - floor and wall;

- by the number of circuits - double-circuit and single-circuit;

- by the design of the combustion chamber - open and closed;

- the possibility of using in cascade installations;

- power - from 4 to 294 kW.

There can be several options for piping an electric heating boiler. Surely it can only be determined by location.

To understand the device of an electric heating boiler, click here.

The cost starts from 97 and ends at 700 thousand rubles. For condensing units, a special acid-resistant chimney is required. If you use the usual one, then the failures of the Vilant gas boiler are simply inevitable. All heaters are equipped with an electronic control unit, display and a variety of sensors that make the boiler operation safe.

Price range

German gas equipment is an example of quality, and the price corresponds to it. Boilers of this class cost at least 45,000 rubles. And these are the lowest-powered versions, the more powerful ones are twice as expensive. How much a boiler costs depends on several factors:

- Burner type.

- Smoke extraction method.

- The level of automation and packaging.

- Power.

Installation of "Vailant" devices allows saving 30-40% of gas, therefore, it will fully pay off in 2-3 heating seasons.

Owner reviews of Vaillant gas boilers: advantages and disadvantages

Any manufacturer has disadvantages. But it all depends on how significant they are. Therefore, before working on the material, I also studied the reviews of the owners, made a table where all the pros and cons will be briefly described.

| Benefits | disadvantages |

| Often boilers can operate for 5.8 or even 10 years without breakdowns. | The high cost of spare parts and the equipment itself |

| A variety of models allows you to choose a boiler for almost any room | Many models hum and give out boiling water at low water pressure |

| Service centers are present in cities and towns | Vulnerability to power surges, it is recommended to connect through a stabilizer |

| It is easy to find spare parts even for rare models | |

| High efficiency, therefore, gas savings are significant | |

| Quiet, virtually silent operation | |

| Unpretentiousness to the quality of the coolant and gas pressure |

Operation and maintenance

Vaillant devices are reliable and unpretentious, they only need to be connected and configured correctly - then in the future the role of a person in their work will be minimized. The package contains a passport and instructions, which show the connection diagram and device device.

By analyzing breakdowns, the manufacturer adjusts the design and control. Most of the possible problems are considered in the instructions, here it is also indicated how to fix them. 80% of breakdowns are repaired on their own - without the intervention of specialists.

User's manual

Operation of floor standing units does not require any special actions from the user. After installation and initial settings, which must be carried out by the technical personnel of the service center, the owner only sets the most comfortable temperature for himself..

You don't need to do anything else.Moreover, independent intervention in the operation or design of the boiler will mean the termination of the warranty agreement.

In any doubtful or incomprehensible situation, you should immediately invite a specialist from the warranty workshop, otherwise there is a high risk of serious breakdowns and expensive repairs.

Download instruction

Operating instructions for floor standing boiler Vaillant.

Installation features

Installation of gas devices must comply with the manufacturer's instructions and SNiP. Room requirements:

- The connection room must be fenced off from the living rooms by a door.

- The dimensions of the room depend on the type of firebox. For turbocharged versions, the minimum area is 8 sq. m. Appliances with a closed firebox can be built into furniture.

- AtmoTEC absorb air from the room - ventilation is mandatory and triple air replacement is provided. TurboTEC take air from the street, the requirements for them are less stringent.

- To prolong the operation, a filtration system is installed.

Installation, configuration and first start-up is the task of specialists. The work is monitored by a controller. Before starting the device, a specialist, using special software, checks the operating parameters.

Types of produced boilers

Vilant manufactures gas and electrical equipment. Electric boilers are limited to one EloBLOCK model in several power options.

Gas appliances are presented in a more diverse assortment.

Among them:

- traditional (they emit part of the useful heat along with the smoke);

- condensation (use additional energy of waste gases);

- single-circuit VU;

- double-circuit VUW;

- atmospheric Atmo (uses air from the room for combustion, and a standard chimney for removal);

- turbocharged Turbo (allows you to arrange an underwater and branch path through the wall);

- hinged;

- floor.

Single-circuit

Boilers with one circuit are designed to heat only the heating medium of the heating system. An external boiler can be connected for water treatment.

With two contours

In double-circuit models, water is separately prepared for heating and for domestic household needs.

Wall mounted

Hinged boilers are mounted on the wall using fasteners. Save space due to small dimensions. Household units of low and medium power are manufactured in the wall version.

Floor standing

Powerful household and industrial boilers are installed permanently on the floor. They have significant weight and dimensions. In some cases, they require a separate room - a boiler room.

Formation history

In 1874, in the small Prussian town of Remscheid, the engineer Johan Weillant founded the private company Vaillant, which very quickly achieved success, becoming a company that is known all over the world today.

The first gas water heater was released 20 years later, in 1894. It had a floor-standing design, a closed circuit and large dimensions. In 1905, a fairly compact wall-mounted gas-fired water heater appeared, which was widely used throughout the world. This was followed by:

- electric heaters;

- flow-through electric heaters;

- wall-mounted one- and two-function boilers using gas as fuel.

The famous trademark of Vaillant products in the form of a funny hare in an egg appeared completely by accident.

The founder of the company stumbled upon the picture while flipping through one of the magazines issued for the Easter holidays in 1899. Johan Vaillant became interested in the "find" and decided to acquire the rights to the picture, making it a symbol of the Vaillant company. More than 100 years have passed since then, but the hare in the egg invariably adorns any product, catalog, and now sites related to the production and sale of Vaillant Group equipment. Today the brand name is the guarantor of the reliability and quality of the goods produced by the Vaillant Group.

The company currently has 13 factories in seven countries of the world located in Europe and Asia, near the most promising sales markets.The manufactured equipment is supplied to more than six dozen countries, including Russia, where products with the "hare in an egg" trademark appeared in 1994. Vaillant Group has more than twenty of its own sales offices, ready to cooperate on favorable terms for the parties, and many certified service centers.

The company already has 30 million satisfied customers living in different parts of the world.

The main focus of the Vaillant Group specialists is the development and production of equipment for heating and ventilation systems, as well as for air conditioning. The company produces energy-saving and environmentally friendly products. It is a leader in the manufacture and marketing of wall-mounted heating boilers and hot water devices, and also holds leading positions among well-known European brands in other positions.