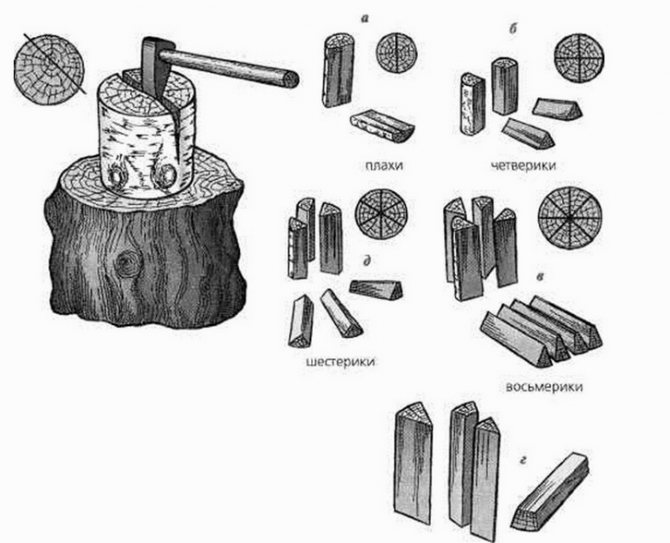

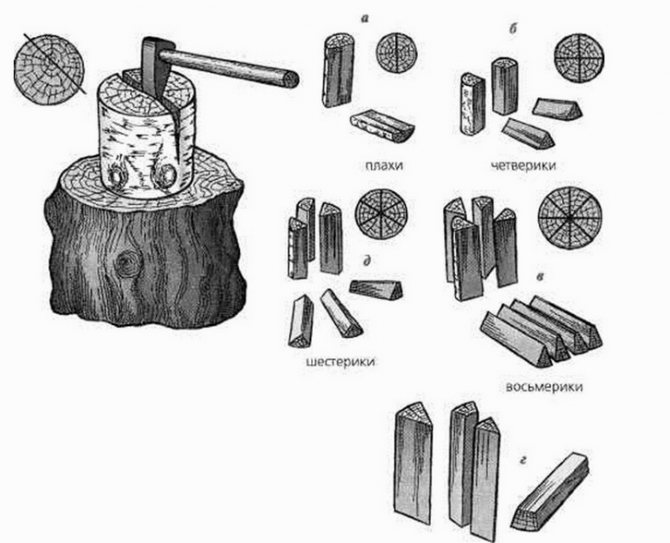

Chopping wood options

You need to understand the difference between the processes of splitting and chopping wood. Chopping is to divide a block or log into large fragments using a cleaver. Chopping is cutting into smaller pieces, chopping off knots, chopping thin trees. Usually they chop thin logs, divide them with an ax into chips and splinters.

There are only two options for chopping firewood, either with the use of special equipment or without it.

Mechanical method

This method involves the use of equipment. The best option is an electric conical screw splitter. A rotating steel threaded cone is placed on the table top, which splits the block supplied to it. The hydraulic splitter works in the same way, but the splitting is done under the influence of the jack.

Both devices are quite dangerous to use. It is better not to use it without experience and first learn how to work with the mechanism.

Manual way

This method involves chopping wood with a cleaver or an ax on a prepared block.

Mechanical wood splitters

In cases where the procurement of firewood is not massive and regular, the task is quite feasible with the help of mechanical wood splitters. They are distinguished by simplicity and low cost of construction; they are made, in fact, from scrap metal.

The unit is very similar, both in appearance and in principle of operation, with a well crane. The difference is that a cleaver with handles is attached instead of a bucket. Racks with a crossbar are connected using hinges, the disadvantage is that the connection will often have to be lubricated.

The principle of operation of the wood splitter is simple - the chock is placed on a stand, the lever is jerked down, the cleaver, under the action of force and gravity, picks up speed and splits the log. The process is repeated, getting thinner and thinner logs.

A device is assembled from scrap materials - pipes and corners, and an old ax without a hatchet is suitable as a cleaver. It is better to provide for the possibility of disassembling the wood splitter, so that it is more convenient to transport it from place to place.

The design has some disadvantages. First, to stop the cleaver after he splits the log, you have to make an effort. Secondly, the device is rather bulky - a long lever is required to reduce the applied force.

Despite the disadvantages, such a device greatly simplifies the process of splitting firewood. In order for it to work as it should, it is required to weight the cola with a blank welded to it, or a pipe filled with concrete.

Spring log splitter

If you modify the above-described mechanical wood splitter, you can make a smaller device, while requiring less physical strength when working with it. For this purpose, a spring is attached to the frame, one abutting against the crossbar, which also serves as an attachment for the cleaver.

The principle of operation is similar to the previous device, except that the load after the log is split is damped by a spring. The main task is to select a stop and a spring so that with the least effort the greatest result is obtained. For the convenience of adjusting the effort, the emphasis is made movable.

But if it is envisaged that the same person is working as a wood splitter all the time, a stationary emphasis is made, its height, like the spring rate, is selected experimentally. The connection of the frame to the lever is made movable, on bearings of good quality.

The height of such a wood splitter should be at least 80 cm. True, at this height, it must be installed on a platform or work in a bent position.

It is more reasonable to calculate the height of the wood splitter for your build; for this, the height of the bed is calculated as follows - a convenient height for the location of the log plus the maximum possible height of the split logs. In this case, it will be necessary to bend only to place the logs on the stand.

For its manufacture, in addition to a cleaver, you will need a meter pin of circular cross-section, a piece of pipe of a slightly larger diameter and a massive platform, to which the lower part of the pin is welded. The cleaver is welded to the pipe cut and put on the pin.

Principle of operation - the cleaver is raised manually, a log is placed on the platform, then the cleaver is lowered with force. If a very strong log is caught, they hit the cleaver from above with a hammer.

We offer you to familiarize yourself with the Greenhouse with your own hands drawing with a wooden frame

The principle of operation of the mechanism - a steel cone with a thread of 3 depth and a pitch of 7 mm (most likely, it will have to be ordered from a turner) is put on an electric motor gearbox. Rotating, the cone works like a drill and breaks the blocks. Thicker logs begin to rip at the edges and then rip in the middle.

An electric motor is needed with a speed of 250-600 rpm, and a power of at least 2 kW. At low speeds, less than 200, the productivity will be too low, and above 500 it becomes dangerous to work.

The main problem when assembling a structure is to find a suitable cone; with an electric motor and a gearbox, the situation is somewhat simpler. It makes sense to make such a device if you need to harvest large volumes of firewood.

What is needed for wood splitting?

To chop wood correctly, you need to have the appropriate tool.

- Deck.

This is a thick saw cut from a tree, set vertically. The deck must be at least half a meter high and large enough in diameter. The gnarier the deck, the stronger it will be. A couple of knots should be left outside, which will serve as dragging handles.

The stump for the log is best taken from oak or elm. If there are none, you can use thick birch, but such a deck will last less.

Oak logs last about 8 years. To prevent the deck itself from splitting from blows, it is reinforced with a metal strip or chain.

- Ax or cleaver

An ax with a sharp blade is needed for cutting thin logs, removing knots, and preparing chips. Cleavers are different. A heavy cleaver with a blunt blade wedges thick blocks of wood, dividing them into pieces. Lightweight cleavers have the shape of a sharpened wedge blade or classic.

The cleaver must be chosen correctly. Of course, the handle should be comfortable and fit the width of your palm. Weight is also selected "for yourself" taking into account the fact that you have to do the swing. The handle should be birch, the hand rests well on it. Plastic or metal will slide. There are rubberized handles, they are comfortable, but they are usually found on expensive instruments.

- Wedges.

May be useful for splitting hard, thick tree cuts. Applied in addition to the cleaver, with which the block is made. A wedge is inserted into the crack formed. Hammered with a sledgehammer to split the log. Wedges can be smooth or serrated.

Splitting process

Initially, you should remember about caution, the splitting technique with a cleaver does not tolerate frivolity and haste. Beginners need to work calmly and measuredly to get their hands on it. To begin with, a small or medium-sized deck is installed on the stand, do not start with large ones. When installing, pay attention to the cut of the log: if there are small cracks on it, then the blow must be applied along the axis of the largest of them. Rotate the deck so that you aim correctly.

It is not so difficult to chop wood with a cleaver when it is free of knots. Unfortunately, this rarely happens, there are knots of different sizes on almost all logs.There is a trick here: the deck must be installed so that the imaginary split line does not pass through the branch, otherwise it will not allow you to cut the block. If the work is done correctly, then at the end the twig will remain on one of the logs.

You can not put the deck somehow and hit anywhere. You will spend a lot of energy, get tired quickly, and you will not achieve the result. It is easier to use some kind of wood splitting device, but this will be discussed below.

If there are no cracks at the end, then take a cleaver and strike hard right in the center. When there is no effect and the cleaver blade bounces off, you come across hard or too dry wood. This means that it will not be possible to chop wood without an ax, it also happens. We take a heavy ax and try to do the same.

What if the ax gets stuck? You should not engage in tricks with throwing it over yourself along with the deck in order to hit the stand with a butt. This is the lot of craftsmen, and not every log can be lifted in this way. Just take a wood splitting wedge and hitting it next to the crack that formed from the ax, so you can free it.

We suggest that you familiarize yourself with Tincture of garlic and lemon with honey: useful properties and contraindications.

Preparatory stage of cutting firewood

The preparatory stage involves sawing trees manually or mechanically. Better to use a chainsaw. You can saw it by hand, then you need goats in which the log is placed. It is faster to work together, but you can act alone.

The sawn tree is pricked into logs, which must be 20% shorter in height than the length of the fuel compartment of the boiler or stove. The bark can be left on for now. Separate the knots with the same saw or ax.

Preparatory stage

It is recommended to dry the tree, that is, it is not immediately possible to chop the tree. Cutting fresh wood is not easy, the tool gets bogged down in raw wood. If the work is carried out in the winter, it is necessary to let the logs freeze well, then it will be easier to chop them.

Then the equipment and the area for work are prepared. The deck is placed on a flat area near the sawn logs and starts to work.

Equipment

When chopping wood, the right equipment is just as important as the tools.

For work, you need to prepare protective accessories:

- Gloves. They should fit the hand well and not slip on the handle. Better to take cloth with a rubberized handheld or old leather. It is not recommended to use gloves, as they can fall off the hand. If the handle of the ax slips out along with the mitten, it can end sadly.

- Safety glasses, half mask. The glasses must be clean (not scratched or dirty), this will reduce the accuracy of the impact.

- Comfortable shoes or boots.

- Clothes can be any, but not open or very wide. Nothing should accidentally fall under the ax or interfere with the power of the swing.

How to chop stubborn logs with a sledgehammer and wedges.

1. Determine what you need. If you are splitting logs of normal size, unless they are very knotty or sticky, you most likely will not need a wedge. If the wood is very hard and a few blows with an ax leave marks or cracks, but do not split it, then a few more tools must be used.

2. Bring an extra block splitting tool. When one ax is not enough for this, it means that you need to use a long metal wedge and a sledgehammer. You can buy them at your local hardware store, or maybe even get them from your neighbor.

3. Identify a central rift or hopeful rift. Even if the ax did not split the log, it may have left deep cracks or splits from several blows.Look for the deepest ax mark or crack in your block - this is where it will be easiest for you to split wood - Several wedges may be needed to split some particularly large or complex blocks of wood.

4. Drive in the wedge. Since wood is softer than a metal wedge, it should split the wood without any problem and you probably shouldn't have a problem with the wedge getting stuck in the block that needs to be split. If a very hard type of wood is to be chopped, it may be necessary to hammer in the wedge with a sledgehammer.

5. Prepare to work with a sledgehammer. You need to prepare in the same way as for working with an ax - feet are shoulder width apart, the dominant hand is close to the butt of the sledgehammer, your eyes are focused on the back of the wedge and raise the hammer over your shoulder.

6. Hit with a sledgehammer. Allow your dominant hand to slide down the handle of the sledgehammer towards your other hand holding the handle of the hammer still. And hit the butt of the sledgehammer quickly and hard down the wedge. - This blow should drive the wedge deeper into the block, so that the trail from the ax turns into a crack, which will deepen. - You may have to hit with the sledgehammer several times to drive the wedge deeper into the wood.

7. Divide the halves of a block or log with your hands or with an axif necessary. Usually the wedge will split the block completely, if not, you may have to break the block or log halves by hand to separate them from each other. Sometimes an ax may be needed to sever the wood fibers.

Wood splitting technique

Compliance with the technique of splitting firewood manually and mechanically will allow you to work without unnecessary labor.

By hand

Large blocks of wood are cut with a cleaver. It has a dull blade that makes a split.

How to chop wood with a cleaver:

- Place the block on the deck by shifting it to the opposite edge of the base.

- Select the largest crack on the cut and hit it with a cleaver.

- For a smooth cut, select a knot-free area for the blow.

- If the cleaver is stuck, you need to hit the butt with a sledgehammer or drive a wedge nearby.

- Continue to divide the split block into smaller parts.

- If the saw cut is too thick, it is better to start splitting from the edges, reducing its diameter.

How to chop wood with an ax:

- You can chop small logs by placing them vertically on the deck.

- The log, divided in half, is again placed vertically and, with an accurate blow of the ax, is split into quarters.

- They cut off the bark from the logs with an ax. The bark can be cut into small strips and used for ignition.

- You can continue to cut the log into chips. Wood chips are also good for ignition.

When chopping wood, legs should be shoulder-width apart

When chopping wood, technique is important. How to cut firewood correctly:

- Legs should be shoulder-width apart. This is essential for better support and safety. If the ax breaks free from the hands, it will not fall on the leg.

- Get up from the deck at arm's length. The end of the ax should touch the edge of the deck.

- Grip the handle firmly with both hands and lift it to a sufficient height. You do not need to lift the tool high, otherwise the impact force will decrease.

- The blow must be sharp, you must use your own gravity and the force of the cleaver.

Mechanically

The steps are very simple. Place the deck on the screw cleaver platform close to the cone. Switch on the unit. Holding the block from above, move it onto a cone, which will screw into the tree and split it. Repeat the operation by turning the log 90 degrees.

Mechanical way of chopping firewood

When using a hydraulic jack, the block is brought under the cutting head. The chopped log is put there again and so on to the desired size.

How to chop wood, choose a cleaver and work according to the rules

Procurement of firewood, their splitting and storage is a laborious process. To facilitate this task, you need to use a good tool - a cleaver ax, work according to the rules, or even mechanize labor.How to chop wood quickly, with the least effort - a few recommendations ...

How to choose a suitable cleaver

A cleaver for splitting firewood is a kind of ax - a heavy and blunt ax-sledgehammer and on a long ax. The main thing when splitting a log is the impact force, the more, the better. The second condition for the successful harvesting of firewood is the creation of bursting forces in the chock, from which it cracks. An ordinary ax - with a sharp, light, thin blade, it is not an assistant here. The cleaver must be heavy and thick.

Experienced craftsmen usually choose a slightly longer handle, but for beginners and general household use it is better to stick to a medium standard.

The mass of the cleaver is recommended on average 2.2 - 2.5 kg. Experienced workers choose a little heavier in order to create a stronger blow with the developed movements.

The ax is made of solid wood, but not hard. Birch is used more often. The softness of the handle material is very important. The material must damp vibration, if it does it badly, it will break itself, and give an unnecessary load on the woodcutter's hands.

Eared or wedge cleaver

Eared cleaver - with a sharp widening of the blade. By design, this leads to better cracking at the same impact force. The tool is used for extremely dry wood with reduced fiber cohesion. In a wet log, he knows how to get stuck tightly.

A wedge-shaped cleaver can also chop a wet tree, which is always more difficult than a dry one.

The expert advises - you should not take it to chop raw firewood. Let the chocks lie down for at least six months - a year under a canopy. But frozen raw wood splits well - frozen water bursts it from the inside. So you can just wait until winter ...

How to chop wood correctly

It is a big mistake in trying to use super-efforts to strike. You need to strike a lot, energetic diligence will quickly take away strength with the help of a heavy cleaver. You need to make the most of the weight of the tool and the length of the handle - the moment of force is directly proportional to both.

- A die (deck) is selected - the largest, damp and heaviest, with a flat surface, not high. All the chopped chocks should confidently stand on it.

- It is better to turn the chock so that the knots are at the bottom.

- To split, you need to beat along the visible knot, and not reproach him.

- You need to try to get into the visible crack.

- Too large chunks of wood are first chipped at the edges,

The expert recommends. You should not drive a cleaver ax into large logs, lift them on an ax by weight, turn them over and hit them with a butt on the chopping block - a lot of energy in vain and creating dangers, it is better to chop around the edges.

What size of wood should be

For a confident entry into the winter, it is important that the results of harvesting firewood are pleasing. The length of the poles should be 3/4 of the length of the firebox. Typically, woodcutters (loggers) adhere to the standards in this case. But the splitting is always individual. The average recommended size for a firebox is 10 cm. Thin wood will burn out faster, but during this time they will give up all the energy in their mass. Thick wood will have a smaller burning area, they burn longer, and are better suited to maintain a long burning. In general, there should be both large and small ones in the workpiece, and over time, the optimal size of firewood will be found for a specific firebox and heating system.

Security measures

- The cleaver is heavy. You should not joke with this tool and work drunk or when tired.

- It is important to maintain balance and not put your feet in front of the splitting log, it is more convenient to place them wide apart.

- Crash, the deck should be larger than the chock being processed and stand only firmly and not staggering.

- Do not chop wood under trees, wires. Hooking with an ax on an obstacle, deviating from the trajectory, can be too expensive ...

- Work in tight clothing with a headdress and glasses. The flight of the chips is always unpredictable.

- Soak the splitting ax in water for several hours before working to make the wood swell. Do not work with a tool that is not in good working order. The reliability of attachment to the ax must always be monitored.

Chopping firewood on video

Many procurers have their own technique of work. It is advisable to split firewood with a minimum of effort. How to swing a hatchet to deliver maximum energy to the impact, and at the same time make the best use of inertia. Let's look at the video of the personal experience of people who often have to do this. Individual cleaving technique when chopping wood - the main thing is a high toss, without much effort.

Ordinary broken-down car tires will also help chop firewood. They can be used as a bandage, which makes work faster and easier.

How to chop wood with mechanical devices. A selection of videos of mechanized harvesting of firewood. A lot of presses, wood processing lines, self-made and in design bureaus that can chop wood have been created. Is it cheaper for them than for a lumberjack…. Watch a video about wood chopping machines ...

How to chop wood easily and quickly?

There is a little trick that allows you to easily and quickly chop wood. With the usual splitting, the blocks are scattered far from the deck. You have to spend energy on collecting and installing them again on the deck. For the back, the felling process is already very difficult, but here you still have to spend efforts on bends.

It is necessary to take a tire, fix it on a deck and install a block of wood in it. If there is a metal cord on the tire, it must be removed. In case of accidental slipping, the cleaver can get a notch. When the block in the tire is split, the saw cut will not fly off and you can continue to divide it into small parts.

Security measures

Any operations with piercing and cutting tools must be carried out in compliance with the appropriate safety measures:

- Strengthen the ax the day before splitting. Dip it in a bucket of water, the ax will swell, and the cleaver will sit firmly. It is better, of course, to keep it in water for several days. This measure is only applicable for tools with a wooden handle. If the handle is made of metal or plastic, then the operation is useless. We'll have to check the strength of the structure manually.

- If an ax is used, it must be well sharpened. It is necessary to sharpen the ax before each felling.

- Make sure that no one is within a radius of three meters from the deck. Also, do not chop wood close to the windows, a piece of wood may fly off there. An inexperienced woodcutter can leave a lot of empty space around.

- Do not try to split along a knot, the cleaver can either fly off or get stuck tightly.

- Do not wear gloves, they can slip off your hand or change the force of the blow. This threatens injury. Only gloves can be worn.

- When using means of mechanization, keep your hands as far as possible from the cutting tool.

After felling, you need to put the firewood in a woodpile, leaving an air space between them. It is best to stack the woodpile after the entire felling process has been completed. Gradually, chopping wood will become familiar and the speed will increase significantly.