Home / Gas boilers

Back to

Published: 03/11/2020

Reading time: 7 minutes

0

783

The Navien Deluxe gas boiler is a popular climatic device of the South Korean manufacturing corporation KyungDong Navien.

The company is engaged in the production and design of heating equipment that uses various types of fuel in its work: liquid, solid, gaseous and electricity.

Navien Deluxe is a modern modification of wall-mounted double-circuit gas boilers, released instead of the Navien Ace model.

The complete assembly technological process of the units is carried out at the factory facilities in Korea and meets the quality standards of ISO 9001.

- 1 Advantages and disadvantages of Navien Deluxe

- 2 Specifications

- 3 What's in the box

- 4 Major errors and their elimination

- 5 Installation and connection

- 6 Operating Instructions Navien Deluxe

Advantages and disadvantages of Navien Deluxe

Boilers have been sold on the world market for more than 30 years. They have gained popularity due to their reliability and functionality. A high level of safety of gas equipment is ensured by several protection systems:

- From freezing of the heat supply system, with a prolonged shutdown of equipment in the cold season.

- From destructive modes of operation of the electrical network, with voltage surges.

- From low operating modes of the gas network.

- From emergency modes of operation of the water supply system, with a decrease in the pressure of the coolant to 0.1 bar.

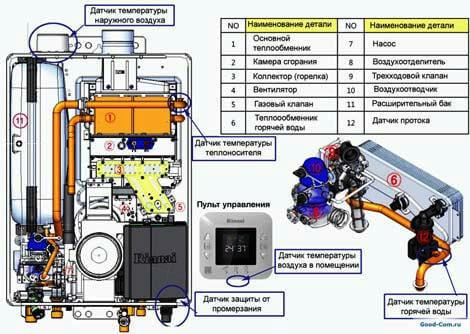

The safety group of the Navien boiler contains primary sensors for temperature and pressure, a control pressure gauge and a safety-relief valve against overpressure in the heat supply circuit. To protect the internal surfaces of water heating from scale, a water purification filter from hardness salts is installed.

An SMPS chip is built into the electronic board of the boiler control system, which protects the boiler equipment from fluctuations in the network +/- 30% of the normal voltage of 220V.

To the minor disadvantages of this brand of heating sources, Russian users attribute a rather high price, volatility and complex installation of a gas boiler, which must be performed by a specialized organization.

Features of Navien Ace TURBO

Compact arrangement of boiler elements.

The wall-mounted double-circuit boiler is characterized by the following:

- application for heating water and heating residential buildings;

- the equipment includes a steel heat exchanger covered with anticorrosive material, which significantly reduces the cost of equipment in comparison with boilers equipped with copper heat exchangers;

- gas boiler Navien Ace (instruction manual is attached to each model) is easy to use;

Wall mounted equipment has brains. This means that the unit makes sure that the coolant does not freeze in the pipelines of the heating system. Automation works in two cases. The first is when the water temperature drops to 10 degrees. At this time, it turns on. The second situation occurs when the coolant temperature is less than 6 ° C. In this case, the gas burner turns on, heating the coolant to 21 degrees.

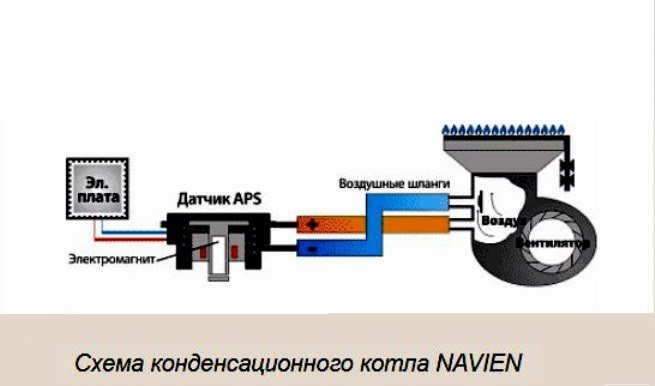

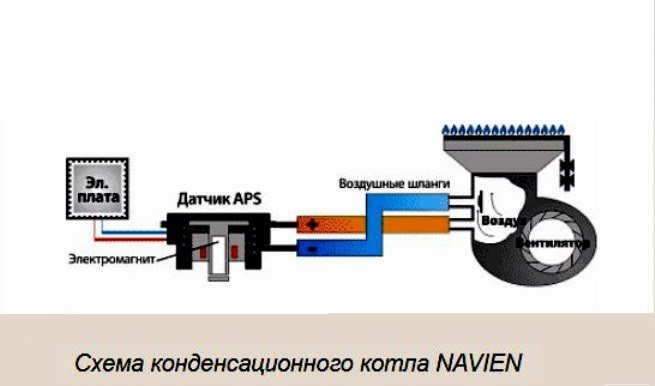

Navien products have positive reviews. This is due to the long period of use, the high efficiency of the unit. The equipment features high fuel and electricity savings. This is facilitated by the presence of turbocharging and an APS sensor that monitors air pressure.

Specifications

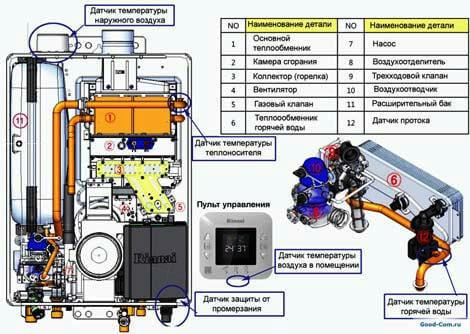

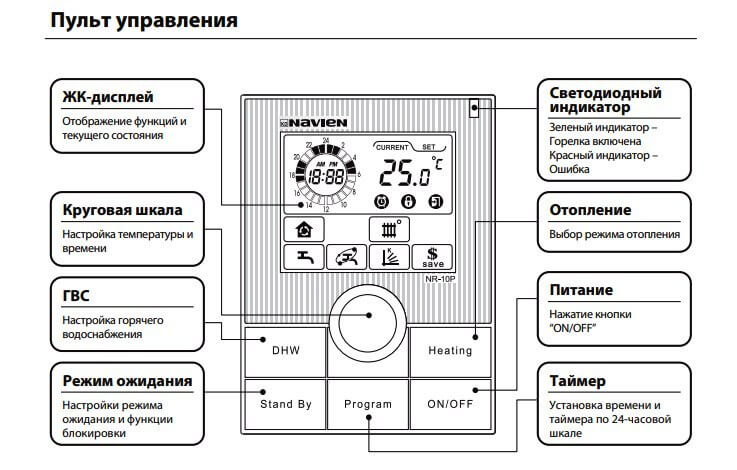

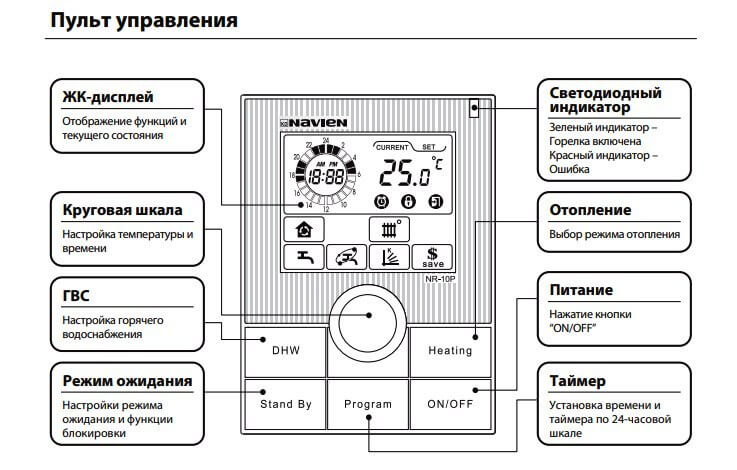

Modern Navien units are equipped with a remote control panel, which receives a signal from a temperature sensor.

Its readings are instantly transmitted to the chip of the control unit, which gives a signal to the actuator to increase / decrease the flow rate of gas supply to the double-circuit boiler. Similarly, a command can be issued to completely shut down the unit if an emergency situation arises in its operation.

The most popular modifications of Navien gas boilers are two-circuit wall-mounted units with a closed firebox, with a thermal power of 20-24 kW, capable of high-quality heating of a room from 160 to 240 m2 and preparing hot water for the household needs of a family of 4 people.

Technical characteristics of wall-mounted gas units Navien with a closed combustion chamber:

- Navien Deluxe Plus - 20k, heating - 160 m2, maximum / minimum capacity - 20/9 kW, expansion tank - 8l, electric pump - yes, heating + hot water supply, efficiency - 91.7% gas consumption - 2.15 m3 / hour, price - 31,080 rub.

- Navien Deluxe Plus - 24k, heating - 192 m2, maximum / minimum capacity - 24/9 kW, expansion tank - 7.5 l, electric pump - yes, heating + hot water supply, efficiency -90.5%, heat exchanger - steel, gas consumption - 2.58 m3 / hour, price - 31,230 rubles.

- Navien Deluxe Plus -24k COAXIAL, power 24 kW, heating - 240 m2, maximum / minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency-90.5%, heat exchanger - steel, gas consumption - 2.58 m3 / hour, price - 28,500 rubles.

- Navien ACE-20AN, heating -190 m2, natural combustion, maximum / minimum productivity - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 91%, heat exchanger - plate, gas consumption - 2.06 m3 / hour, price - 29 130 rubles.

- Navien Deluxe - 20k White, heating - 186 m2, maximum / minimum capacity - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 90.5%, heat exchanger - steel, gas consumption - 2.15 m3 / h , price - 32 160 rubles.

- Navien Deluxe - 24k White, heating - 220 m2, maximum / minimum capacity - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 91.5%, heat exchanger - steel, gas consumption - 2.58 m3 / h , price - 29 980 rubles.

- Navien Deluxe-20k COAXIAL White, heating - 190 m2, maximum / minimum capacity - 20/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 90.5%, heat exchanger - steel, gas consumption - 2.15 m3 / hour, price - 32 160 rubles.

- Navien Deluxe-24k COAXIAL White, heating - 220 m2, maximum / minimum capacity - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 90.5%, heat exchanger - steel, gas consumption - 2.15 m3 / hour, price - 29,090 rubles.

- Navien SmartTok - 24K, heating - 220 m2, maximum / minimum performance - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 91.0%, heat exchanger - steel, gas consumption - 2.6 m3 / h, price - 34,430 rubles.

- Navien Deluxe S COAXIAL-24k, heating - 200 m2, maximum / minimum capacity - 24/9 kW, expansion tank - yes, electric pump - yes, heating + hot water supply, efficiency - 91.2%, heat exchanger - steel, gas consumption - 2.58 m3 / hour, price - 31,060 rubles.

Classification

Gas boilers "Navien Ace" are divided into two categories:

- Ace ATMO.

- Ace TURBO.

The first unit is a simple and traditional boiler with an open combustion chamber, which uses the atmospheric removal of combustion products. The second is more advanced and has a turbocharged burner. This makes it possible to efficiently supply gas and burn it with an unstable supply, which is associated with pressure surges. In addition, the second version is equipped with a special SMPS control system, which is based on highly sensitive chips. They are responsible for the control and regulation of gas combustion processes. In all other respects, both options are no different from each other.

Both models can be classified as universal equipment. Adapted to difficult operating conditions, they are considered one of the most economical heating devices on the Russian market today. An important component of the design is the remote control panel. This is very convenient when you can set modes and indicators at a distance, quickly making adjustments.

But what is surprising is that Navien gas boilers can work not only in automatic mode, but also in manual mode.This is especially convenient when the temperature outside the window changes dramatically. Manual installation allows you to more accurately set the parameters and indicators, which eliminates the smallest errors during the operation of heating equipment.

Gas boilers navien ace can be called universal units. They run on natural gas or LPG. To change from one type of gas to another, only the burner needs to be changed. No other changes are required.

What's in the box

The equipment of this company provides an extended control principle with a remote control capable of setting parameters and modes. The unit has a built-in thermostat sensor function to control and maintain the temperature in the house.

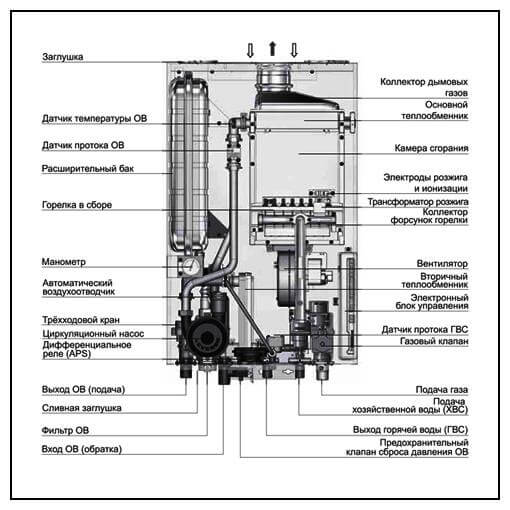

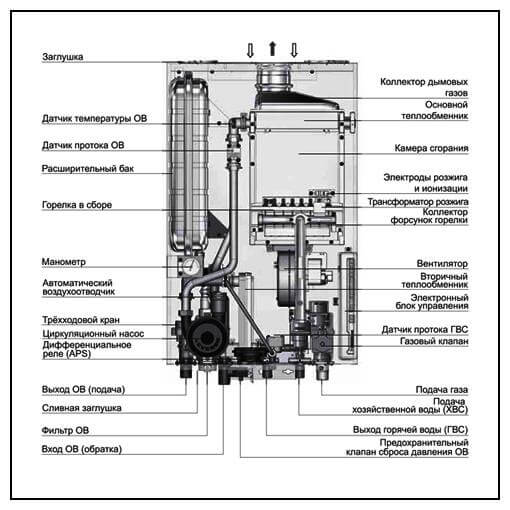

Engineering distinctive characteristics of the modification:

- Highly efficient stainless steel heat exchangers, separate on the heating and hot water supply circuit with a high heat transfer coefficient.

- Automatic maintenance of the set pressure of the coolant in the heating system.

- Filter for purification of make-up water from suspended solids and hardness salts.

- Drainage system for draining the coolant from the coils of heat exchangers.

- The circulating pump, providing constant circulation of the heat carrier, provides the maximum heat removal in the boiler and the reduction of heating costs.

- Setting the temperature mode with an accuracy of 0.1C.

- Setting the summer and winter operating modes of the unit.

- Safety group with safety relief valve and air vent.

- Boiler make-up group with a centrifugal pump.

- Chimney system.

- Turbocharger fan installed at the inlet to the firebox.

Features of operation of boilers "Navien"

Navien - household double-circuit boilers with an open or closed combustion device are used for heating residential and public premises and heating water for domestic and technical purposes.

The boiler control is Russified and adapted to the real operating modes of Russian engineering systems.

The APS mechanism ensures a stable fuel combustion process with minimal consumption. The blower fan for supplying air and creating a working pressure of the gas-air mixture has different operating speeds and allows the operator to control the rotation speed for complete combustion, preventing condensation.

Complete set of boilers Navien:

- Circulation pump;

- universal heat exchangers for the heating circuit and hot water system;

- safety automation;

- expansion tank;

- selection of heating mode and timer for stopping the unit;

- boiler Navien, instructions for setting up and operating.

The advantage of using the heating unit is that the burner with premixing of the gas-air mixture has a modulation range of 30-100%.

Basic errors and their elimination

Gas boilers are equipped with a good diagnostic system that scans the parameters of the boiler every minute and, in the event of a violation, issues a coded signal to the operating panel to eliminate the malfunction:

The main codes for the failure of gas boilers Navien:

- E01 - overheating of the coolant in the boiler. Insufficient water circulation through the device, it is necessary to check the operation of the pump, the presence of leaks and blockages in the heat exchanger. If the latter is found, before eliminating the error, it is recommended to flush the heat exchanger from scale using the technology specified by the manufacturer.

- E02 - error 02, low coolant pressure in the heating circuit. Check for leaks in heating networks, if necessary, recharge the circuit.

- E03 - problems in the boiler electric ignition system. It is necessary to check the presence of power supply in the system, the presence of pressure and the electrode for the presence of a spark.

- E04 - there is no flame in the boiler. Control of the piezo igniter for the possibility of generating a spark and checking the grounding system.

- E05 - the temperature sensor of the return heat carrier at the inlet to the device does not work. Check the performance of the primary temperature sensor and, if necessary, replace it with a similar version.

- E06 - the temperature sensor of the supply heat carrier at the outlet of the boiler does not work. Check the performance of the primary temperature sensor and, if necessary, replace it with a similar version.

- E07 / 08 - the DHW temperature sensor does not work at the inlet or outlet of the boiler. Check the performance of the primary temperature sensor and, if necessary, replace it with a similar version.

- E09 - the centrifugal fan does not work. Check the operation of the inlet air filter for clogging.

- E10 - error 10, problems in the chimney system, there is no vacuum in the boiler. The gas outlet channels are monitored for blockages.

- E13 - error 13, problems in the circulation circuit.

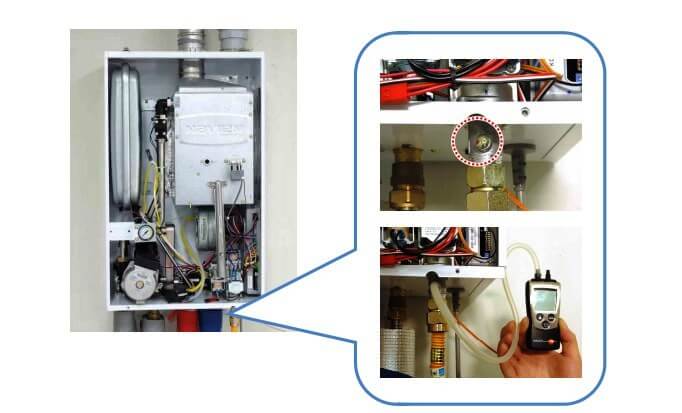

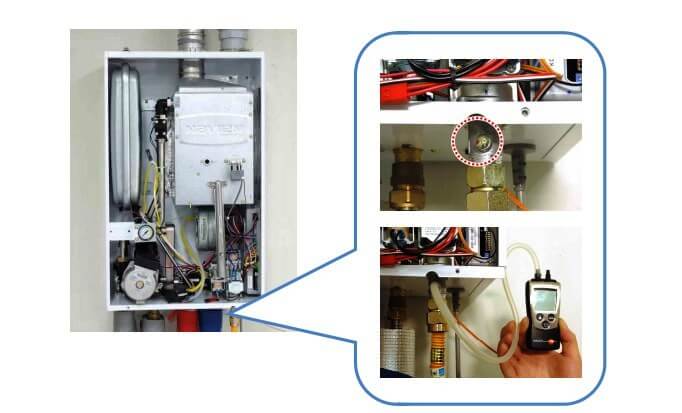

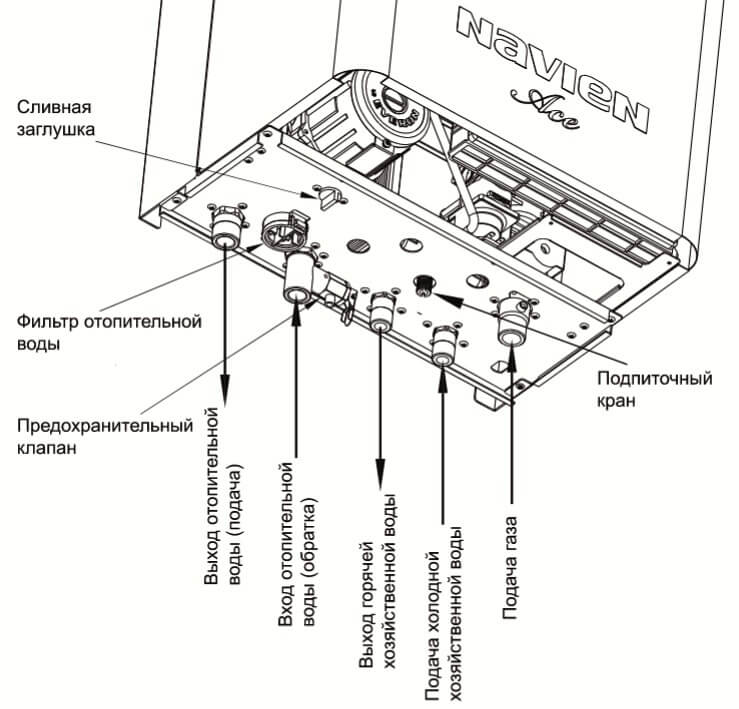

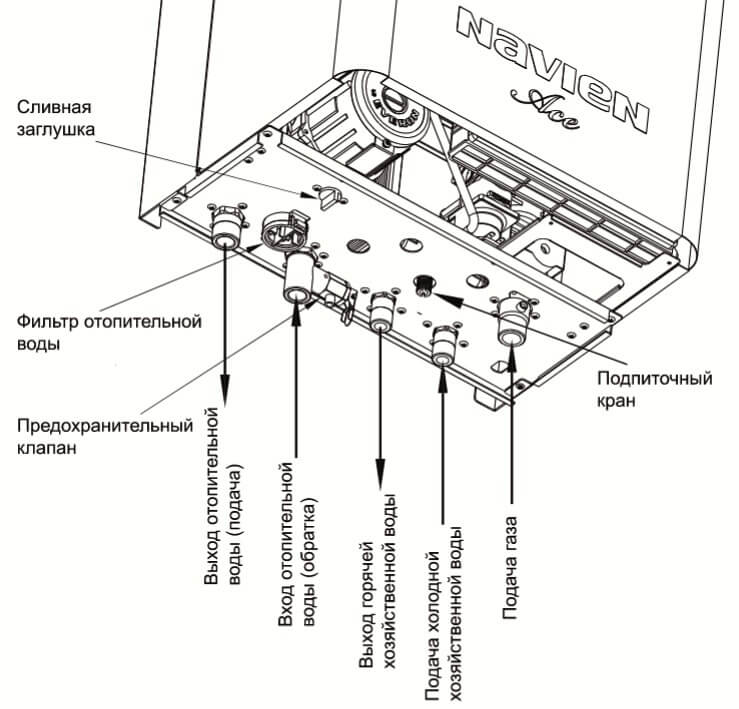

Filling the boiler and heating system with water

Error code 02, indicates that there was an attempt to start the boiler, but there is no water in the system, or there is not enough water. What to do:

- The appliance is disconnected from the socket and the gas supply is shut off.

- In the bottom of the boiler, among the many elements, you need to find a make-up tap. Turning it counterclockwise opens it, and clockwise closes it.

- When the tap is open, observe the pressure gauge reading. You need to close the tap when it shows 1.3 - 2 bar.

- Now the boiler is reconnected, gas is supplied and starts up.

Don't worry if error 02 reappears. This may be due to the fact that after bleeding air (which is automatically performed at start-up), the water level is again insufficient. The filling operation must be repeated.

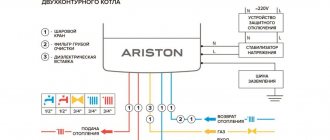

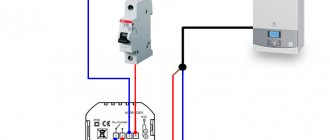

Installation and connection

Installation, commissioning and the first start-up of any modification of the Navien gas boiler must be carried out by the service department, and the gas equipment must be launched by representatives of the gas company.

However, the owner of the heating equipment will need to know the main points of putting the boiler into operation in order to control the progress of installation and construction work.

The gas boiler is not allowed to be installed in damp, basements without ventilation. Usually, such mounted units are installed in kitchens, if free space allows, and floor options in a special furnace.

Basic rules for the location of the wall-mounted boiler Navien:

- The boiler is installed on a solid wall made of heat-resistant materials.

- The gap from the front of the boiler to the opposite wall must be at least 1.0 in order to be able to service the device.

- The gap from the boiler to any electrical appliance must be at least 0.6 m.

- The gap between the side surface of the boiler and the walls must be at least 0.2 m.

- The gap between the floor level and the lower plane of the boiler must be at least 0.8 m.

- The unit must have an independent power supply line 220V / 50Hz.

- The boiler body must be grounded without fail.

- The room in which the gas apparatus is installed must have a 3-hour supply ventilation system.

What to look for during installation?

Steel gas boiler Navien Ace

Since the instructions are attached to the equipment, there are no problems with installing and connecting the device. Doing it yourself is not a problem. Even a layman can understand the instructions. Moreover, it is written in Russian.

The only thing that specialists ask to pay attention to is a way to remove carbon monoxide gases. They can be discharged through a conventional atmospheric chimney, connected to the chimney system of the house or installed as a separate structure. But if you are not satisfied with either option, you can make a coaxial chimney. Its installation is several times easier. But keep in mind that coaxial structures are used only when the heated area of the house does not exceed 110 m². They can be installed with boilers with a capacity not exceeding 11 kW.

Decoding the error

Gas path blocking - a primitive interpretation of the problem that has arisen.The manufacturer does not specifically indicate all the probable causes of the malfunction in order to exclude user intervention. The Navien boiler is complex equipment, and taking into account the type of fuel, it is also explosive. This explains the minimum of information in the documentation for self-elimination of the problem with the heating system.

Error 03 should be understood as follows: the ionization sensor does not "see" the flame. That is, either gas does not flow to the burner, or there is no ignition. Knowing this, it is easy to work out an algorithm of actions to eliminate error 03 of the Navien boiler.

Expert opinion

How to increase the time between starting and shutting down a gas boiler?

If there is a problem of frequent switching on / off ("clock") of the gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and hold down two buttons "+" and "-" simultaneously.

- The display shows a number from 2 to 20. Usually 8 or 10.

- Use the "+" and "-" keys to increase the delta value between start and trip.

- After 5 seconds, the remote control goes out.

- The boiler is unplugged and then switched on again.