How justified is a double-circuit solid fuel boiler in a private house

Departure for permanent residence from the city to nature in a private house will inevitably pose two extremely important problems for a modern person: reliable and comfortable heating and a sufficient amount of hot water. It is not uncommon for one more circuit to be added to heating - a warm floor. It is possible to organize all three circuits: heating, hot water supply and underfloor heating are completely autonomous from each other, but equipment with control and piping can take up a significant part of the living space and reduce the reliability of the system, not to mention the higher cost and installation costs.

A double-circuit wood-burning boiler can solve these problems. For those who want to gain independence from expensive gas and reduce electricity consumption, there are many double-circuit solid fuel boilers on the market. Despite the fact that they are more expensive than single-circuit ones (sometimes the price is 30% higher), this is the most budgetary way to organize hot water supply. The correct choice of the boiler will allow you to create a simple, reliable, and with the availability of inexpensive fuel, an economically viable system.

The cost of a low-power solid fuel boiler of 10 kW with two circuits starts from 19,000-20,000 rubles. Higher power models that use different types of fuel, as well as different combustion principles and additional options will cost the buyer 100,000 rubles.

The use of double-circuit solid fuel boilers provides the following possibilities:

- complete independence from gasification and power grids (if the boiler unit is non-volatile or alternative sources of electricity are used);

- real economy due to the relatively high efficiency and the use of affordable inexpensive fuel (wood and its waste, coal, peat).

- ease of maintenance, especially for inexpensive systems without automatic fuel supply;

- reliability and long-term use when properly installed and operated.

On the left is a double-circuit solid fuel boiler. On the right is a single-circuit one with an indirect heating boiler. In the first case, significant savings not only on equipment, but also on strapping, significant savings in space.

But there are also many disadvantages of systems using solid fuel boilers:

- the need to store fuel in stock without getting wet and provide additional meters in the boiler room for loading;

- the need for inexpensive boilers to load fuel manually. Automatic loading, which allows the boiler to operate for several days, is a rare and expensive option that reduces the reliability of the system;

- careful attention to the quality of fuel takes time;

- regular cleaning of ash, cleaning of carbon deposits and inspection of the chimney.

Selection Tips

When choosing a double-circuit solid fuel boiler (reviews below), it is important to correctly calculate the power, that is, the need for additional heat output for heating domestic water.

To ensure a year-round supply of water for hot water supply, it is necessary to additionally install a boiler equipped with a heating element for heating in the summer.

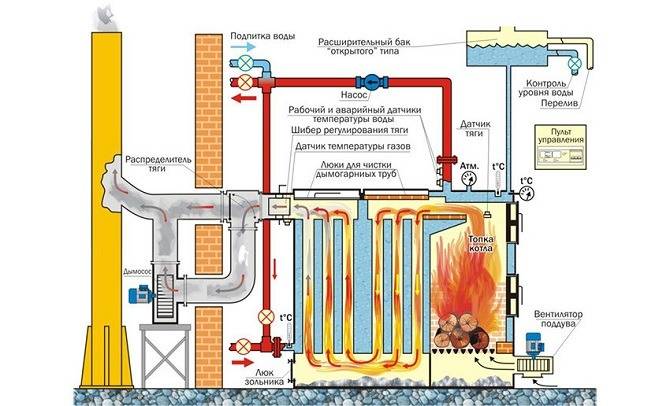

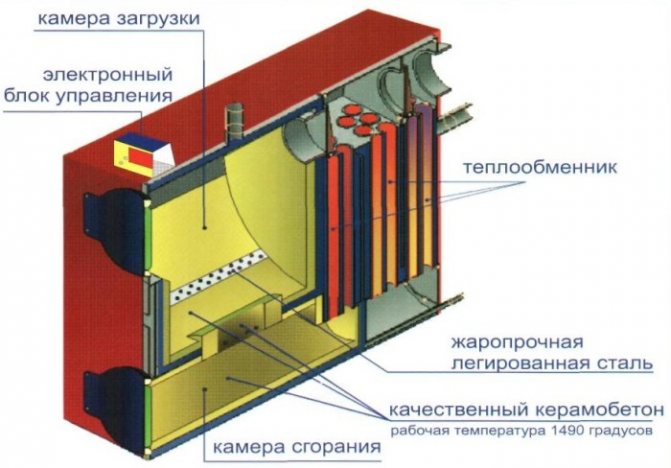

Device and principle of operation

Fundamentally, two-circuit models differ little from classic solid-fuel single-circuit boilers. The only difference is the presence of an additional DHW circuit, in which sanitary water does not mix with technical water in the heating circuit. The second circuit can be organized in different ways, previously the water jacket was simply divided into two parts.

A more advanced option is to place a coil of pipes for the second hot water supply circuit inside the water jacket with the coolant of the first heating circuit. This interaction of the circuits protects the DHW coil tube from overheating, and they work longer without forming scale inside themselves.

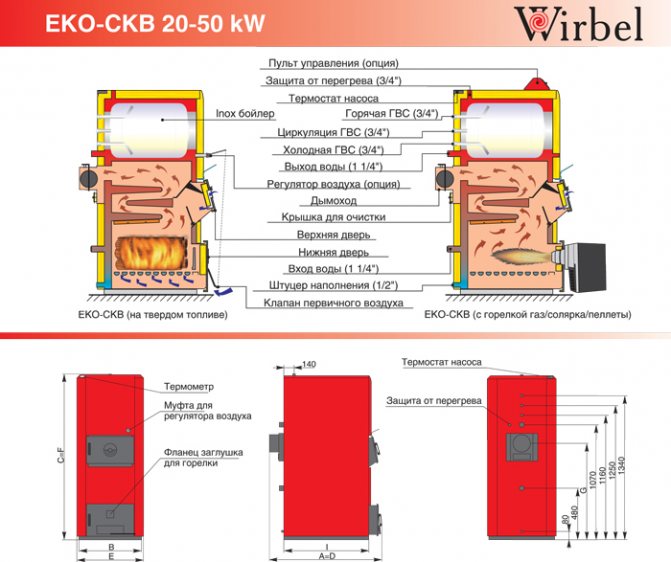

The device of a double-circuit solid fuel boiler on the example of the Wirbel ECO SKB model with a built-in storage tank.

Now the most common are DHW circuits heated by heating elements (tubular electric heaters). In heating mode, the boiler works like the most common classic non-volatile solid fuel, but if you need to heat up the DHW circuit, there is a built-in replaceable block of heating elements, usually with a capacity of 3-9 kW. Otherwise, there are no differences from the classic boiler known to all TT.

Long-burning double-circuit solid fuel boilers

Thanks to the shaft-type chamber and combustion from top to bottom, it is possible to achieve combustion of one fuel load for up to 24 hours or even 7 days. However, it is difficult to make such a double-circuit design, and its cost will be comparable to two separate, often more reliable, solid fuel boilers. Therefore, despite the demand, today there are no two-circuit solid-fuel models for long-term combustion; even local little-known manufacturers are not engaged in the production of such. Nevertheless, if you managed to find long-burning two-circuit models, please let us know in the comments.

Output

The options for long-term burning equipment considered above have both positive and negative technical characteristics, therefore, when choosing for a home, this must be taken into account. We recommend giving preference to models for which there is an abundance of fuel in a given area (see also the article “Infrared heating using various equipment”).

The video in the article will help you find additional information on this topic.

Did you like the article? Subscribe to our channel Yandex.Zen

Fuel options

The fuels used in solid fuel boilers are:

- firewood and wood processing waste (wood chips, sawdust, pellets - pressed sawdust);

- bituminous and brown coal (however, be careful, not all combustion chambers are designed for the high temperature of coal combustion);

- fuel briquettes;

- peat.

Some of the equipment runs on only one fuel (wood or coal), most use any solid fuel, but there are boilers with additional accessories or the possibility of retrofitting a burner, which makes it possible to use liquid fuel in them, if necessary.

It is necessary to clearly understand that the rated power of the boiler depends on the calorific value and quality of various fuels. The maximum boiler output is indicated for certain characteristics of the fuel under optimal operating conditions. Using raw wood or pellets can result in a 30% loss of power, accelerated ash and varnish formation, which will shorten the life of the unit.

Inexpensive solid fuel boilers are almost omnivorous, as long as the fuel is dry, but with the growing desire for automation, the importance of pellets increases. They have a number of advantages:

- it is convenient to load into the furnace manually and automatically from the bunker with a screw;

- easy to organize storage;

- the release of about 5 kW of thermal energy from 1 kg;

- the use of low ash pellets reduces the amount of ash.

The use of coal and brown coal for fuel is justified in places where they are readily available and affordable.

Pellet boilers with automatic fuel supply Burn time from 7 to 30 days thanks to the storage bunker

Reviews of solid fuel double-circuit boilers: advantages and disadvantages

| Benefits | disadvantages |

| This is the most budgetary option for organizing hot water supply in the house. | Fuel loading in inexpensive boilers is done manually and often, if it is necessary to heat the second circuit, the fuel consumption increases |

| High efficiency and low fuel cost compared to gas and electricity makes the economy of use profitable | Creation of a warehouse for fuel supplies, at least under a canopy or tarpaulin. |

| Most models do not need complex maintenance | Cleaning of spools and ash removal - the main work is performed manually on most boilers. |

| The transition from one solid fuel to another is cost-free | Periodic inspection of the chimney, pipes and fittings. |

| Without using the second circuit, these are classic, equally effective TT boilers | Limited choice of double-circuit TT models on the Russian market |

What to look for when choosing

Before choosing a boiler model, decide for yourself the questions:

- Boiler for permanent residence, summer cottages or heating reserve.

- Type of solid fuel in terms of availability and cost.

- Number of circuits (heating, water heating, underfloor heating)

- The minimum required power of thermal energy (1 kW per 10 m2 of heated area + 20-25% of the reserve, the number of liters of hot water per minute).

- The heat exchanger is cast-iron or steel (cast-iron keeps heat longer, is resistant to inevitable corrosion and serves for a long time, steel heats up faster, but can burn out).

- What is the efficiency (high - pyrolysis combustion boiler, low - classic).

- How often you are ready to load fuel.

- Do you need dependence on electricity (ignition and fuel supply by automation).

- Fuel storage capacity and storage quality.

- The budget that you are ready to spend on the purchase and installation of equipment.

Boilers with a burning time of one fuel tab up to 7 days

General operating rules

New Santehsklad

And the last thing to consider when making a choice in favor of solid fuel boilers is compliance with the general rules of operation.

They are as follows:

- Such boilers cannot be left unattended. The installation must not be allowed to overheat, which is very dangerous.

- When laying firewood and controlling traction, it is necessary to put on special gloves on your hands. All parts of the boiler are very hot, so getting burned is as easy as shelling pears.

- Children and adolescents must not be allowed to control the boiler operation. Also, you cannot trust them to fuel fuel.

- Do not store firewood near a solid fuel boiler. The minimum distance between them must be at least one meter.

- Once a year, it is imperative to clean the burners, furnace, existing filters and chimney passages. It is important to constantly monitor the tightness of all pipes, the presence or absence of water in the system.

The best known manufacturers and models: characteristics and prices

Karakan 16TPEV 3 16kW

A popular in the countryside, a double-circuit boiler that uses any solid fuel. First of all, it gained popularity due to the deep firebox, which allows you to use firewood up to 50 cm long and the hob. For boilers of classic combustion, it has a sufficient efficiency of 75%, produces hot water 250 l / h. Preparation of sanitary hot water is carried out using a built-in heating element with a capacity of 9 kW. When operating for heating, the boiler is completely non-volatile, mechanically controlled by a thermostat. The unit weighs 120 kg.

Cost: RUB 25,000-27,000

Dragon Ta-15 Gv

One of the best double-circuit solid fuel boilers for heating a private house. A more advanced, efficient, practical and service-friendly, but also a much more expensive boiler. The efficiency reaches 88%, it was achieved by the construction of a combustion chamber with a longer exhaust of gases, due to which more heat is accumulated by the heat exchanger. Also, of the features, it is worth noting the considerable volume of the firebox - 60 liters, the manufacturer claims 6-10 hours of burning of one tab. In practice, this is true, but when using coal with a low ash content as a fuel.

The design of the door provides for the installation of an oil burner, but we recommend doing this only as a last resort: the efficiency of burning gas, diesel fuel or working out in a large combustion chamber of a solid fuel boiler will be extremely low. Owners also note the cast iron grate. The only drawback is the extremely high price.

Cost: RUB 53,500-62,000

Wirbel ECO CKB 20

Development of Austria, production usually in the Russian Federation. An even more advanced model with a complex exhaust of gases, due to which more heat is accumulated. The main serious difference is the organization of the second circuit by means of a storage boiler of 65 liters or more built into the main circuit, which allows you to always have a certain supply of hot water in stock, but reduces efficiency if the boiler is used only for heating the house. It is also worth noting the reliability of a heat exchanger made of 5 mm thick furnace steel; in practice, in other models, such heat exchangers serve for more than 15-17 years.

The only drawbacks are the high price and low prevalence, the boiler is quite difficult to find on sale in the territory of the Russian Federation.

Cost: RUB 63,000-66,000

Traian T-15-2KT

The boiler is completely Russian production, it differs only in a large combustion chamber of 80 liters, into which logs up to 55 cm are placed, which is extremely practical. At the same time, it has an extremely compact size. As for the rest, it is not as efficient and technologically advanced as the models mentioned above; it loses to its counterparts in terms of a set of parameters. Despite the existing demand and the prevalence of the model, in our opinion, its prices are too high.

Cost: RUB 47,000-58,000

The rating on the Internet is relative, but a comparison of features and prices gives an idea of the models and manufacturers.