Double-circuit gas appliances make our life more comfortable and enjoyable. They are quite practical to use, suitable for heating country houses and small apartments. They are used for heating industrial or warehouse buildings, the area of which is not more than 500 sq.m.

The advantages of Ariston boilers are that in addition to heating buildings in winter, they heat water used in everyday life all year round. It is quite convenient and does not require the installation of additional equipment.

General characteristics of Ariston boilers

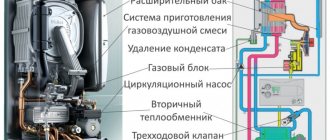

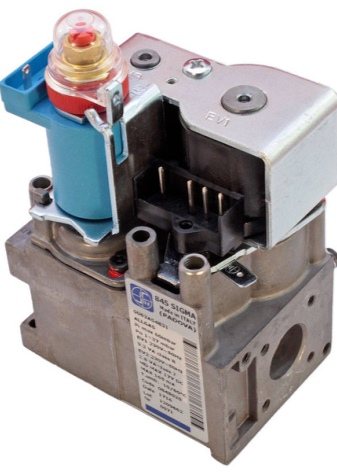

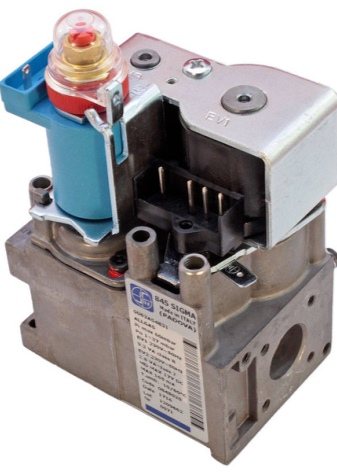

The description of Ariston gas units must begin with the characteristics of their main part - the burner. This element is used to burn fuel and to transfer thermal energy to the heating system.

Types of boiler burners:

- common

- modulation

The modulating burner is more convenient to use. It provides for automatic power regulation depending on the temperature of the device.

By the type of removal of combustion products, burners are divided into:

- closed type

- open type

Units with a closed burner are safer to operate. In this case, the combustion products of natural gas do not enter the room. The use of a chimney is not required. A coaxial pipe is simply connected to the device and brought out.

The design of the coaxial pipe provides for the presence of two layers, which ensures the simultaneous removal of waste and the flow of air from the street into the burner.

Equipment with an open burner provides for the mandatory use of a chimney to remove combustion products.

Descriptions of the double-circuit boiler Ariston

Today, on the market for gas boilers, you can find many interesting models. This is quite convenient, since everyone can choose a device that is most suitable for the price, type, characteristics and installation method. Ariston double-circuit wall-mounted boilers gained their popularity due to rare situations with their malfunction, as well as silence during operation, which is very important for maintaining a calm atmosphere in the house.

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second. When using it, the entire system will be regulated automatically, without human intervention. In this case, the capacity of the installed heating equipment depends on the temperature indicators.

The burner is also divided into 2 types:

The safest is a closed system, since it does not imply the ingress of combustion products into the room in case of emergency. Also, in this case, the owner does not have to worry about building a chimney. A special coaxial pipe must be brought to a closed burner, it can always be brought out in any accessible place.

The open-type Ariston boiler, in any case, requires a chimney to bring the combustion products out into the street. Also, don't forget about natural cravings. Air will enter the system from the living area, so it will have to be constantly ventilated.

The coaxial pipe used in a closed combustion system is good because it is made of 2 layers. One is necessary for the removal of combustion products, and the other will ensure the ingress of fresh air into the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have enough oxygen.

Ariston Gas Appliances Technical Data

- Ariston boilers are used for heating and heating water, that is, they are double-circuit. Each modification has its own characteristics, but the common thing is the type of fuel - gas.

- The gas combustion chamber can be either open or closed. In the presence of a chimney, units with an open chamber are used. And in apartments of multi-storey buildings, where chimneys are not always available, equipment with a closed combustion chamber is used.

- Power. This indicator is used to calculate the gas consumption required to heat the room.

- Compactness. Wall mounted appliances are used in small, narrow rooms. Floor-standing units used in production or storage areas are heavier and require more installation space.

- The presence of a control unit. This element is irreplaceable when the water is turned off, the gas drops sharply. In case of any malfunction, the unit will immediately turn off the device, which will prevent damage. It also helps to save fuel consumption.

Ariston boilers are used for heating and heating water, that is, they are double-circuit

Operation, repair and maintenance of the Ariston Genus gas boiler

_______________________________________________________________________________

_______________________________________________________________________________

Ariston Genus 24 FF boiler does not start up. As long as you hold down the start button, the burner functions. But if you don't fix the button, the device starts to go out. Explain the cause of the malfunction? Apparently, the thermoelement is out of order or the gas valve is broken. There may also be a decrease in gas pressure on the inlet line. Sometimes there is insufficient voltage on the electronic board. There was a problem recently. Firing up is difficult. The igniter ignites, but there is no fire on the main burner. I just can't understand what is the reason? It looks like damage to parts of the ignition mechanism. It is necessary to service the unit and clean the ignition unit. Why can't the Ariston Genus gas boiler turn off the moment it reaches the required temperature? Heating occurs up to 90C, followed by a malfunction. After the restart operation, the situation follows again. The control board may be defective, the boiler water temperature sensor is defective, the overheating protection button is broken. It is possible that there was a violation of the automation settings. Please tell me why the boiler does not heat the water more than 70 C? We need to tweak more, but the screen shows that this is the maximum. How can the heating temperature be adjusted? When the appliance is unable to raise the temperature in the heating system, the following problems can be assumed. In the given adjustments, the maximum heating temperature is limited to 70 C. A decrease in the draft speed in the chimney is observed. The wall-mounted Genus Premium Evo boiler does not function well during the heating cycle of the DHW system. From the faucet in the kitchen there is a mixture of cold and hot water. Tell me what reason could it be? The reasons for the appearance of damage are most likely the following. There is a mixture of cold water due to the failure of the 3-way valve. The heat exchanger is clogged with debris. You need to clean it. There is a tap at the bottom of the boiler, from where water regularly leaks. The device itself does not start. What should I do? Apparently, the coolant was discharged through the protection valve. This symptom indicates an increase in system pressure. In addition, the filling valve of the system might not be closed, or it might be necessary to pump in the expansion tank. Could you tell me what the problem is, if the pressure continuously jumps up, and also the safety valve comes into operation? The display shows permanently the heating symbol in boiler heating mode. What happened? There is a breakdown of the heating circuit temperature sensor. Lack of necessary circulation in the heating line. For what reason did Ariston Genus One 24 turn off all the time? Recently, the piezo igniter did not work at all.The boiler was serviced at the beginning of the month. What's the matter? We assume there is a problem with the fume extraction process. You need to perform a chimney inspection. Inoperability of the piezo igniter may indicate a breakdown of one of its parts due to unstable voltage or water leakage. Can anyone please help me figure out the chimney? Soon the second day, as there was a return thrust, in which the smoke began to pour directly into the room. The chimney was handled independently. It is made of steel pipe. Perhaps there is a mistake in something. The device works fine on hot water supply, and when you start the heating, the water starts to boil, and the device gives out a failure. What is the problem and how can you fix it? We assume that the circulation pump has a defect, the electronic board is out of order, the temperature sensor is broken. It is also possible that the filter mesh is clogged. In the DHW cycle, the device began to dispense hot and cold water in turn. Help me understand what is the reason. How to set up water heating? Apparently, the heating system is dirty or the heat exchanger is clogged. In addition, the pressure control sensor may break down or the circulation pump could fail. An important reason may be an incorrectly made chimney structure. It is possible for soot to accumulate on the pipe walls, which greatly reduces its capabilities. In addition, it is recommended to control the hood in the room. In operation Ariston Premium Hp. It quickly sets the temperature over 96C, but then crashes with an error. Subsequently, when it cools down, it starts to start on its own. What does it depend on? Failure of overheating functions means termination of the circulation process. Initially, you need to pay attention to the taps on the radiators. They are set open. Next, a check is carried out for clogging of the filter, and you should also make sure that the heat exchanger is not clogged. Launched this boiler in the fall of that year. Presumably six months later, the device sometimes began to make a lot of noise. Please tell me what is causing the noise in the boiler? There may be scale in the heat exchanger. If the water has hardness, then later lime accumulates in the radiator pipes. I decided to mount a Genus Evo 24 FF gas boiler at the dacha. Tell me how to correctly put such a unit into operation? For the correct start-up of the boiler apparatus, the following procedures must be carried out. Connect the power supply to the device. We put the gas valve open. Then we start up the gas burner equipment. At the end, we set the required temperature. We are planning to do service maintenance. Instruct on how best to drain the water from the appliance? According to the manual, this work is implemented as follows. Disconnect the unit from the electricity supply. We close the gas tap. We open a little automatic air vent. We turn the drain valve. Next, remove the spilled liquid. If required, the water can be drained through the relief valve. This component is located at the bottom of the boiler. Can you tell us how you can check the 3-way valve? I think this component does not complete the opening. In the heating cycle, the extreme batteries cannot pump, and the coolant supply pipe under the boiler is very hot on the DHW. We definitely recommend inspecting the 3-way valve for stem acidification in the intermediate state. We also recommend checking the heating system itself. We use Ariston Genus 35 at our dacha. Until now, I worked without interruption. Currently, 5 seconds after turning on, the unit began to go out. It seems that he is unable to deliver water to the system. Explain what is the reason? A probable factor in this malfunction may be an ionizer electrode that does not detect fire, or a lack of circulation. Recently, a problem with the heating device was discovered. During the heating cycle, it whistles.I tried to reboot it - I succeeded, but nothing changed. Maybe someone will explain why the unit is whistling? In many cases, a loud whistling sound occurs when the pressure at the burner nozzles is incorrectly set. It is necessary to check the established indicator and correct it if necessary. Water got into the gas boiler yesterday, and the device began to work with errors. For example, if you set an arbitrary temperature, but the heating reaches from strength to 25 degrees, Celsius, after which it turns off. I would like to know what could be out of order? If water gets into the electronic board unit, most likely the board has deteriorated. Try to zero it using a direct disconnection from the power supply to the unit. Then run it again and diagnose its performance. The boiler Ariston Premium 24 was put into operation. Now, at the moment of start-up, the wick burns for five seconds, the main burner does not support the flame, which is why the device begins to extinguish. How can this problem be solved? Based on your words, the automatic ignition is not working or there is a problem with the burner. Just in case, you need to check if the phasing is not lost when connected to electricity. The repairmen made the connection of the same model at the beginning of August. Approximately three months later, there was a problem with the DHW circuit, while the heating works smoothly. I tried to turn on hot water, but it only indicates the temperature, and does not want to perform heating at all. What is the problem? It can be assumed that the 3-way valve is faulty. He needs to be replaced. Please tell me why the boiler is equipped with a safety thermal sensor? This component stops the gas supply to the burner in case of overheating of the water in the primary system. It is required to flush and clean the main water heat exchanger. Tell me how to remove this component according to the instructions? This element can be easily removed from the unit using a simple screwdriver. Disassembly procedure is shown below. We drain the water from the appliance using the outlet valve. Then you need to empty the hot water system. Unscrew the fixing screws of the primary heat exchanger and remove it from the frame. I launched such a model. Approximately after 4 months, the water pressure in the unit dropped. Often he slows it down and turns off. That is, he cannot hold pressure at all. What is the reason? If the unit does not build up water pressure, there is probably a leak from the make-up valve. When a shutdown happened and the water pressure drops to zero, the three-way valve broke. Tell me how to clean the cold water filter? First, you need to drain the hot water circuit. Secondly, unscrew the flow sensor nut. Then we take out the sensor together with the filter from the cavity. After that, we remove the accumulated debris and dirt. The device had a humming sound during start-up, but now it is louder. At first the sound disappeared quickly, but now it lasts longer. Has anyone observed this issue? The formation of an additional unpleasant sound indicates the presence of scale inside the heat exchanger, which heats up unevenly due to the different wall thicknesses. The more the heat exchanger is clogged, the louder the unit makes noise, and, accordingly, the heat output decreases. The device works, although water apparently does not circulate through the system. Return pump very hot. Help me find the reason? Most likely, the filter is dirty or the tap is shut off somewhere, which blocks the movement of the coolant. The circulation pump could also be damaged. Because of what mountains are not prepared. water? The water is barely warm. Can you explain what happened? The search for damage is carried out in the next directions. For example, a breakdown of the DHW temperature sensor, you need to replace it. There is also a possibility that there was a failure in the power control for heating the hot water supply. Flame breakdown is periodically observed during ignition. There is no dirt in the burner, everything is normal with the chimney, the draft is excellent.Where can I find the problem? The unit cannot detect a spark due to poor notification from the combustion control unit. You need to check the wiring between the ionization sensor and the electrode. You probably need to tighten it up. The insulation of the sensor could also burst, which must be replaced.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler is turned off with an E35 error (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production.It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a fault

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and sometimes everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow.What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When he works on a unit, he beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently I started showing error 14. How can you fix the breakdown?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?

Choosing a gas appliance for heating

Ariston products can be found in catalogs. There are many models of gas appliances. The main mistakes when choosing the wrong unit are made from a lack of information. Therefore, before visiting the store, you should familiarize yourself with the basic tips for choosing a wall-mounted gas appliance.

When choosing a boiler, take into account the following points:

- The size of the kitchen, as the place where the heating device is most often installed. In the store, the choice begins with considering the overall dimensions of the device and selects it individually for your kitchen.

- Next, they go to the technical data and study the type of water heater in the apparatus. If there are a large number of people in the family, then it is not recommended to purchase a boiler with an instantaneous water heater.

- In this case, it is more rational to purchase a boiler with a storage tank for hot water. and select equipment for the amount of water that you will need for everyday use.

- The combustion chamber of the gas equipment is evaluated. It can be closed and open. It is recommended to choose a boiler with a closed chamber, due to the fact that it is safer in operation. The presence of a chimney is optional, which is important in multi-storey buildings. Enough to buy and bring out a coaxial pipe.

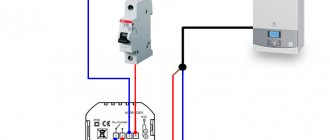

Operating instructions for gas boilers Ariston

Before purchasing a gas boiler Ariston, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the case will end successfully. In this case, there is every chance of damage to the equipment, after which you will have to call repairmen, and this will result in additional costs.

It is very important to keep children away from the equipment.To do this, after installing the gas boiler, it is necessary to have a conversation with them and explain in plain language that nothing can be twisted and displayed on the unit, only an adult should do this. If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all pipes for the supply of gas and water. Only then is the equipment disconnected from the network.

If a display is provided on any model, all the indicators that it displays must be strictly controlled. It can display malfunctions or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety precautions. Before connecting the boiler, you need to familiarize yourself with it first.

Reviews of double-circuit wall-mounted boilers Ariston

The Ariston gas boiler manufacturer has taken a leading position in the market thanks to the quality of its units. This is evidenced by many customer reviews throughout Russia:

A user named oixx1979 from Volgograd notes the quiet operation of the boiler and its endurance. Gives advice on the maintenance of the gas appliance.

The user lenka-angel007 from Kislovodsk, as the advantages notes the compact size and economical mode of gas consumption. The disadvantages include work from electricity.

DrKey from Moscow indicates that this is a very good boiler. Compact and economical. Indicates easy boiler control.

Georgstar from Krasnodar writes that the boiler is convenient and easy to maintain. Mentioned that almost no wall-mounted gas appliance works without electricity.

Sibiriya from Barnaul describes the compactness and good design of Ariston boilers

Characteristic

Ariston gas equipment is produced in two basic versions - floor-standing and wall-mounted. In private houses, as a rule, wall models are used.

Depending on the parameters of the model, the unit can have an open and closed combustion chamber.

In the first case, the combustion products are removed from the boiler in a natural way, in the second, the forced gas exhaust system works. Usually, installations with a closed chamber are connected to a coaxial chimney. The coaxial pipeline implies the presence of two structural layers, due to which it is possible to simultaneously remove carbon monoxide and ensure the flow of fresh air into the furnace.

In addition, the chamber has a built-in fan, which is responsible for the timely removal of burnt gas and hot air. These models are more secure than devices with an open camera.

In addition, they take the air necessary to maintain combustion from outside the living space, this is another advantage of them in comparison with closed-type chambers, since they take oxygen from inside the house, thereby worsening the microclimate in the building.

Floor standing boilers have a fairly high power

, therefore, they are used for industrial purposes or in residential buildings with a large area. Usually they are designed only to supply heat to batteries and radiators, so if you need to heat water, you should additionally purchase boilers.

The main element of any boiler equipment is the burner, which is responsible for burning fuel and supplying heat to the heating system. Burners can be conventional or modulating. More modern and technological are modulation ones, since they allow to automatically adjust the power of the device depending on the results of internal control over the temperature level.

Ariston double-circuit boilers have 2 heat exchangers: the first is necessary to provide hot water supply, and the second directly to heat the main heat carrier.Their production can be carried out in three versions: they are separate, bithermic or with a boiler.

Two autonomous circuits are simultaneously placed in the common boiler body:

- heating - he is responsible for supplying radiators with heated water;

- water - this mechanism is connected to water pipes.

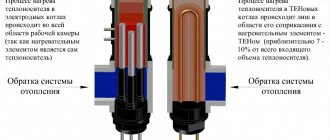

Water heating can be done in several ways:

- flowing - this option works only when hot water is used: after passing through the burner, it enters the end consumer in a heated form;

- boiler room - such a device implies the presence of an additional reservoir in which water heated to a given temperature is accumulated and from there it enters the tap.

A double-circuit boiler operating in boiler mode is more economical.

At the location of the contours, boilers are divided into 2 types.

- Bithermic - in such installations, the water pipe is located inside the heating system. In this case, the heating circuit heats up more actively and gives off part of its heat to the water supply.

- Duothermal - include two tubular heat exchangers that evenly transfer heat to both systems. In this case, the energy is used most rationally, however, the heating rate is also significantly reduced. In addition, this principle of operation creates the preconditions for the appearance of lime deposits, therefore, such devices need regular cleaning.

Depending on the method of combustion, Ariston boilers are conditionally divided into those operating on the principle of turbocharging and on natural draft. A turbocharged boiler has a rather high heating rate, however, gas is also consumed in a large volume. The second type of models heats water rather slowly, but fuel consumption is also more economical.

Gas boilers from this manufacturer are most often produced with a capacity of 15, 18, as well as 24 and 28 kW, the most purchased modification is a 24 kW unit, it can provide heat to a living space of up to 230 m2.

Manufacturer information Ariston

Control panel in the gas boiler Ariston

The Italian company Ariston has existed since the 30s of the last century and is currently a large corporation that has united several firms. The brand is known all over the world and occupies an honorable third place in terms of total sales. The Ariston boiler appeared the first in the Russian market in the field of heating equipment and quickly attracted the attention of Russian buyers. Devices from this brand are successfully sold and in great demand.

Every Ariston double-circuit or standard boiler, including Uno, is distinguished by good technical characteristics, a full range of options and an attractive design that allows it to easily fit into a modern interior. A large model range makes it possible to choose a device taking into account the needs, and the absence of problems during installation makes the boiler a good choice for those who plan to install it on their own.

The brand's boilers operate at temperatures up to -52 degrees and a pressure of 5 mbar, are capable of operating in high-risk conditions and are supplemented with special parts in case of emergencies.

Typical malfunctions and preparation for repair

Before proceeding with the repair of the Ariston water heater, you need to understand the device structure, prepare the necessary tools and other devices. To eliminate mechanical damage, such as leaks, you will need:

- adjustable wrench;

- set of adapters;

- check valve.

If you find breakdowns associated with the electrical part, you need to arm yourself with a multimeter. The preparatory stages include disconnecting the device from the mains, draining the liquid from the tank.

The Ariston boiler contains the following elements:

- Heating element;

- a thermostat is needed to control the temperature and adjust the heating mode;

- a relay that is responsible for turning on or off the heating element;

- magnesium anode protects the tank from corrosion;

- a safety valve regulates the pressure during water heating;

- signal lights turn on when electricity is supplied, as well as when the device warms up (such a system is present in cheaper models, expensive devices are equipped with electronics).

You will need an adjustable wrench for repairs

Before proceeding with the repair, you need to study in detail the instructions for using the product. According to statistics, malfunctions may occur during the operation of the boiler. Typical malfunctions of the Ariston water heater:

- The water does not heat up - this means that the heating element has burned out.

- Another reason could be the failure of the thermostat.

- The magnesium anode has used up its resource and needs to be replaced.

- A large amount of scale has formed on the heating elements.

The thermostat is located outside the device, so it can be replaced without additional manipulations. In all other cases, drainage of water and disassembly of the product are required. The volume of the water heater does not matter, the dismantling process is the same for any capacity.

Operating rules

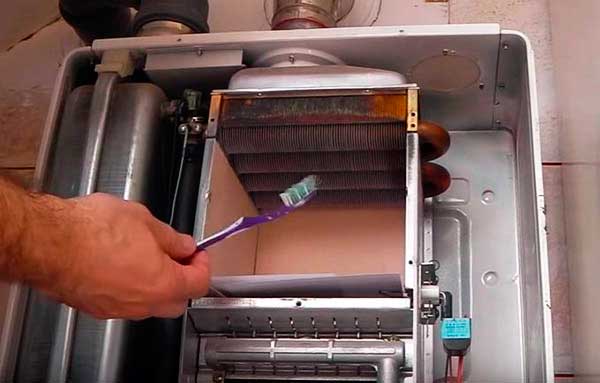

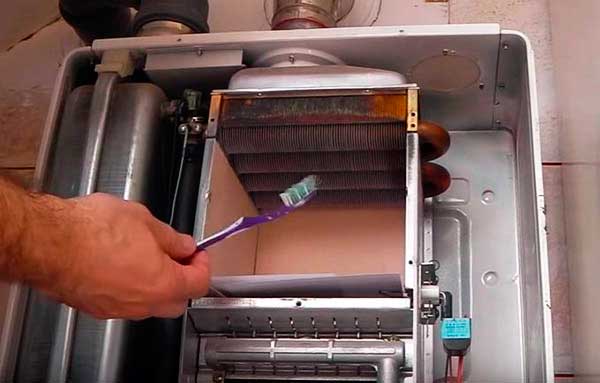

The heat exchanger is flushed once a year.

The operation process and rules of use are described in detail in the instructions for each boiler. It is important to find out in advance what the pressure inside the expansion compartment should be, since it can drop during operation and check the special code. The pressure must be monitored and checked once a year. The owner also needs to monitor the filters, check and clean them as needed, clean the heat exchangers, especially if the boiler is installed in a region with hard water, change gaskets and other parts.

During installation and installation, a service specialist must be present, it will be much better if the master installs the boiler in the house. Self-installation can cause errors and create emergency situations. Experts will be able to install, configure, start and test the boiler, as well as explain exactly how it should be used. The owner will need to additionally conclude a service contract and try to follow the manufacturer's recommendations regarding the operation of the device.

Specialists are called in for inspection at least twice a year, each heating season should begin with a standard inspection. After the end of the season, a service employee is also invited.

Italian boilers from a popular brand differ from their counterparts due to their low cost and are worthy competitors to many devices from well-known companies. Consumers most often prefer wall-mounted and double-circuit models, which are able to quickly solve problems with hot water supply and heating. At Ariston, you can find devices for any house or apartment, choose the best option from a wide range of modifications, taking into account your needs.