Nowadays, such energy carriers as electricity, gas and solid fuel materials are becoming popular. Some users are trying to combine options and heat a private house with a gas, and, for example, a solid fuel boiler. A controversial question arises: does this method really allow you to save money? Not always. One of the most profitable options for heating a home (if it is impossible to connect to the main gas pipeline) is the use of gas cylinders. Of course, this method, in addition to its advantages, has its own disadvantages, which every owner of a private house planning this type of heating should know about.

Any type of heating has its pros and cons - the use of bottled liquefied gas is no exception.

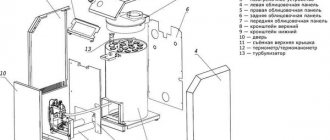

The main elements of gas cylinder heating

For a gas heating system, the home owner needs to purchase the following:

- Boiler operating both on mains and on liquefied gas. Of course, if you have extra funds, you can buy 2 boilers, each of which will be adapted for a certain type of gas. But, as it turned out from user reviews, such a decision will only lead to a waste of money. You should be aware that before connecting another type of gas, the jets or the entire burner should be replaced on the boiler. In more modern devices, it is also necessary to reconfigure the automation and control system (see video below).

Gas boiler room in a private house

- Shut-off valves. It allows you to shut off the gas flow in emergency situations or as needed, for example, during repairs. A common element of any gas line is a standard valve.

Gas ball valve - handle painted yellow

- Automation and control system. There is no particular need to install this system, but automation eliminates human intervention. Also, such systems are very often equipped with additional protection elements.

Important! Cylinder gas is heavier than air and will accumulate in the lower part of the room if it leaks. For this reason, a ventilation system must be provided that will work effectively throughout the entire boiler room. Refer to the services of qualified specialists!

- Gas reducer - a device for lowering the pressure of a gas or gas mixture at the outlet from any container (for example, in a cylinder or a gas pipeline) to a working one and for automatically maintaining this pressure constant regardless of changes in the gas pressure in the cylinder or gas pipeline. The correct functioning of the system is impossible without a gearbox.

Gas cylinder reducer

If possible, you should use gas cylinder units, one of the manufacturers of which is the German company GOK.

All of the above elements of the gas cylinder system have a different pricing policy. It all depends on the owner of the house, but it should be remembered that the operation of low-quality and cheap gas cylinders can lead to very bad consequences.

How to connect a gas boiler to cylinders?

Most gas boilers can operate on both natural and bottled fuel. When choosing a unit for operation on liquefied gas, it should be borne in mind that some models come with a set of nozzles, with which you can convert the boiler to work on bottled fuel. If this equipment is not included in the package, you can purchase it separately. In some units, the entire burner will have to be replaced.

The connection of the gas pipeline from the cylinders to the gas boiler is carried out in the same way as the connection to the gas pipeline.It will only be necessary to take into account the nuances of storage of cylinders in accordance with all fire safety standards.

A significant disadvantage of using gas cylinders is the need for their constant refueling. A standard container of 50 liters is enough for an average of 2-5 days, depending on the temperature outside. To reduce the frequency of refueling and to avoid the situation when the gas in the tank will take you by surprise at night, you should combine several tanks with one ramp. This device allows the simultaneous connection of up to ten cylinders.

Note! In order to achieve uniform fuel pressure when it enters the gas boiler, a special reducer of the appropriate capacity is connected. A device designed for a fuel consumption of up to 2 m3 / h is suitable for heating.

The ramp is a two-arm manifold, and it works as follows:

…

- cylinders are divided into two groups;

- first, the gas comes from the tanks of the first group;

- when the fuel runs out, gas begins to flow from the second group;

- after refueling the main cylinders and connecting them, fuel will again come from them.

A pressure gauge must be connected to the cylinder system to continuously monitor the gas pressure.

A bit of theory

Before installing gas equipment in the house, you should find out its principle of operation, as well as familiarize yourself with the device of the entire system.

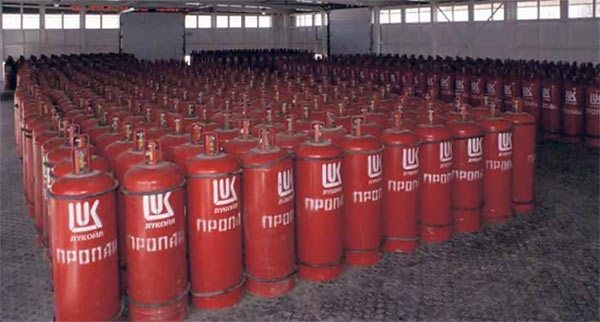

Propane-butane is to be pumped into cylinders.

Propane-butane - universal synthetic gas obtained from associated petroleum gas or from oil refining, i.e. in fact, for most manufacturers it is a by-product.

In order for the gas to be transported and used in cylinders, it is necessary to transfer it from a gaseous to a liquid state. Therefore, before filling the tank, the gas is liquefied, this allows it to be pumped in a larger amount.

Cylinders "Lukoil" in the warehouse, ready for shipment

After connecting the cylinder to the main line and opening the tap, the gearbox begins to work. The reducer lowers the pressure several tens of times, because of this, the gas returns to its original state and can be used as a fuel for heating rooms. The reducer allows you to use the entire capacity of the cylinder.

It should be remembered that any gas cylinder has a high pressure inside, and therefore requires proper handling and maintenance.

The main advantages of heating a house with gas cylinders

This system is most often used for heating a small area - up to 100 m². Ideal for country houses, cottages, as well as small private houses.

The main reasons for choosing gas cylinder heating:

- The cylinder heating system has a higher efficiency than solid fuel or electric boilers. On average, 6 to eight cylinders per month are enough for heating an area of 100 m².

- To re-equip the system, you do not need to purchase a special boiler, it is enough to install new nozzles on the old one. In the same way, the system can be returned to its original state.

- When installing cylinders, the heating system becomes autonomous - the owner of the house becomes independent from breakdowns and maintenance of the central highway.

- When buying high-quality LPG equipment, the user can be sure of its durability. For a long service life of this system, it is only necessary to carry out maintenance on time, for which time is usually allocated before the heating season.

- High demand for heating systems with cylinders. This means that the system can be sold quickly, if necessary, both as an assembly or separately.

Of course, no system can be perfect. Disadvantages exist in any design: high fuel consumption, insufficient level of efficiency, high cost of maintenance and repair.In gas cylinder systems, this is additional costs for filling and transporting containers (cylinders). Also, the installation of the system and the purchase of the following elements are at a high cost: a boiler, a gas cylinder installation, cylinders.

Organization of heating from gas cylinders

To make gas heating on cylinders, you need to choose a suitable boiler, since not every equipment is capable of using liquefied gas as a heat source. This requires a special burner designed to operate from a cylinder. It is recommended to choose a device with a power of 10-20 kW, depending on the area of the heated premises.

The gas boiler is connected to the cylinder using a special reducer. Consumption is approximately 1.8-2 m³ per hour, in the case of a conventional gearbox - 0.8 m³ / h.

You can also use a burner designed to work from the main pipeline, but in this case you have to adjust the valve for proportional gas supply, since the pressure in the main pipeline is lower. In addition, in such devices, the opening in the valve is larger.

Each burner, designed for heating with gas from cylinders, is regulated in its own way. A detailed description can be found in the instructions for this equipment. In order to save money, old boilers can also be used, but in them it is necessary to replace the jet with another product with a smaller hole.

When buying a burner, you need to take into account that some stores are trying to sell more expensive devices, arguing that the selected product will not work on liquefied gas. In this case, you need to look at the instructions for the selected device.

Selection and operation of a gas boiler

As mentioned above, there is no need to look for a "special" heating boiler that runs on liquefied gas - modern products can work both on natural gas and on liquefied gas. Accordingly, when choosing a boiler, one should proceed from the total area of the heated room. A convection or condensing boiler can be installed. The convection unit is wall-mounted and can handle areas up to 300 m². Condensing boilers are not only more powerful (heated area - at least 400 m²), they are also more economical.

Separately, the topic of hot water should be touched upon. Many users specifically install an electric boiler, believing that in this way great savings are achieved - this approach is incorrect. It will be correct to purchase a double-circuit gas boiler. At the same time, the gas consumption does not increase much, but the quality of hot water changes dramatically.

Popular models of double-circuit boilers include Buderus Logamax U072-24K - designed to operate on both natural and liquefied gas.

Gas wall-mounted boiler Buderus Logamax U072-24K with a closed combustion chamber

Specifications

Heating boiler type - gas, convection Burner - gas Number of circuits - double-circuit Heat output - 7.20 - 24 kW Heat load - 8 - 26.70 kW Combustion chamber - closed Heated area - 250 sq.m. Efficiency - 92% Control - electronic Installation - wall-mounted Material primary heat exchanger - copper Mains voltage - single-phase Built-in circulation pump - yes Built-in expansion tank - yes, 8 l Fuel - natural gas, liquefied gas Consumption of natural gas - 2.8 cubic meters. m / h Consumption of liquefied gas - 2 kg / h Nominal pressure of natural gas - 10.50 - 16 mbar Allowable pressure of liquefied gas - 35 mbar Temperature of the heating agent - 40 - 82 ° C Temperature in the DHW circuit - 40 - 60 ° C Productivity of hot water at t 30 ° C - 11.4 l / min Hot water output at 50 ° C - 6.8 l / min Max. water pressure in the DHW circuit - 10 bar Max. water pressure in the heating circuit - 3 bar

In order for the boiler to function properly, maintenance should be carried out correctly and in a timely manner, which includes:

- Replacing the coolant in the heating system (at least once every 5 years) if non-freezing liquids such as "Warm House" are used, etc. When using water as a heat carrier, no replacement is required.

- Cleaning the internal parts of the boiler from carbon deposits.

- Heat exchanger maintenance.

- Replacement (if necessary) of rubber components - rings, gaskets, bushings, etc.

A device with a boiler for heating with your own hands

To form a heating system with your own hands of this type you will need:

- Gas boiler with liquefied gas burner. Models with low pressure and highest efficiency are suitable.

- Gas cylinders with a volume of 50 liters.

- Shut-off valves.

- Reducers.

- Ramp (used to connect several tanks).

- Gas pipeline, formed from hoses and pipes and designed to connect elements to the heating system.

Boilers are floor and wall, single and double-circuit. The latter allow not only to increase the temperature in the room, but also to heat the water.

The cylinders are connected to the system by means of a reducer with a capacity 2 cubic meters m / hour. The reducer can be one or separate for each tank.

Connecting several cylinders to a gas boiler increases the period of their necessary refueling. For such a connection is used ramp - a device that divides tanks into main and reserve. First, gas is taken from the first group, and as it ends, from the second. The moment of transition is sounded by a signal.

To fix a gas boiler with a gas pipeline, use flexible eyeliner, and for the reducer - a durite hose. The wall thickness of a gas pipe made of metal is not less than 0.2 cm... In the wall, such pipes are brought into a case and foamed.

The boiler fuel consumption is about 9 kg of gas per day. A large amount of resource will go away at the very beginning to warm up the heating system, and later - will decrease by 4 times.

Photo 2. A red gas cylinder and a flexible hose that is used to connect to the boiler.

Refueling cylinders produced weekly specialists. Before this process, condensation is removed from the tanks. You can independently take the tanks out into the open, ground and remove the reducer. 2 hours laterwhen the remaining gas has disappeared, and the water has dropped into the ground, the cylinders can be taken to the refueling station.

Important! Not allowed for simultaneous refueling more than three cylinders.

Setting the boiler for liquefied gas

The pressure of the gas coming from the cylinders is much higher than the natural pressure. For this reason, the purchased boiler must be reconfigured. As a rule, the procedure is limited to two steps:

- Installing jets with smaller holes (or replacing the entire burner).

- Gas pressure setting according to passport data.

Important! No matter how simple it may seem to set up a boiler for liquefied gas, it should be done by specialists.

The video below shows the setup process for the most popular models.

Viessmann Vitopend 100 (Viesman Vitopend 100).

Baxi ECO-5 Compact 18F.

Pressure

For boilers operating on liquefied gas, the ability to operate at low pressure is of fundamental importance.

The continuous supply of bottled gas will be carried out at a pressure of 3-4 Mbar. Therefore, when selecting a boiler, you should pay attention to this parameter.

Correct use of gas cylinders

Tanks for storage and transportation of liquefied gas must undergo an annual calibration if they are used constantly, if only during the heating season - once every 2 years.

Cylinders must not be installed both in basements and in basements. Where the cylinder will be installed, a solid floor must be installed, without cavities, and free space.This requirement is due to the fact that the gas is heavier than air, and in case of insufficient tightness of the system, its accumulation leads to the possibility of an explosion. If there are no other rooms, then the basement should be properly equipped: install a concrete floor, and also eliminate free space in the walls, if any.

Containers should not be used in an inclined position or lying down. Only vertically, having previously secured it to the wall using a special clamp. The clamp prevents the container from accidentally falling. In order for the cylinder to be checked or quickly replaced, it must be installed separately from the main equipment. Next to the used product, for better practicality, you can mount the fasteners for spare containers.

The outdoor cabinet contains four gas cylinders with a capacity of 50 liters and a gas cylinder installation. When the cabinet is closed, accidental drop of cylinders is excluded

More information about cylinder cabinets is described in the video below.

Gas equipment in cars and private houses is identical, and when operating it, you should be guided by the basic rule - do not fill the bottle completely. For products that are more than 90% filled, the service life is sharply reduced, and the possibility of explosion also increases.

Gas cylinders should not be left in direct sunlight - gradual heating of the outer surface of the product can also lead to an explosion.

Applying a heating system in a house built on the use of gas cylinders, one should not forget about periodic maintenance. Typically, users try to do maintenance before the heating season, or immediately after its end.

Disadvantages of gas heating on cylinders

Like any other heating method, this one also has its drawbacks:

- if the cylinder is on the street, in case of severe frost, the system may turn off - the condensate will freeze and prevent gas from escaping;

- do not place cylinders in unventilated rooms;

- since the gas is heavier than air, if it leaks, it can go down (into the basement, underground), and with a strong concentration, serious consequences will arise.

Thus, heating with gas cylinders can be very dangerous if certain conditions are not met. Therefore, they need to be stored only in ventilated rooms, under which there is no basement. It is even advisable to place them in a separate extension on the site. The room must be warm so that the system does not turn off in frost. If it is cool in the extension, then you will have to make an insulated metal or plastic box for the cylinders. For insulation, the walls are sheathed with foam plastic 5 centimeters thick. Ventilation holes must be made in the box lid.

How to calculate a heating system on gas cylinders

In order to understand the practicality and economy of this heating system, preliminary calculations should be made and an important question should be answered: for how long does one cylinder last?

The sequence of the calculation, based on the average readings:

- The boiler output must correspond to 1 kW of energy per 10 m2 of the room. For a private house with a total area of up to 100 m2, you need to purchase a gas boiler with a capacity of at least 10 kW. The installation of heating radiators, instead of ordinary multi-section batteries, will facilitate faster heat transfer throughout the entire area of the house.

- For the above-described gas boiler, at least 0.86 kg / h of liquefied gas will be required, given the fact that the boiler efficiency must be at least 90%.

- The heating season usually takes no more than 6 months, sometimes 7 (if April is too cold). 7 months - 5040 hours. Of course, the boiler will not work with the same power all this time; for greater efficiency, the operating modes should be alternated.

- 1 cylinder with a capacity of 50 liters holds 21.2 kg of liquefied gas.A calculation is made: 5040 is multiplied by 0.86 kg / h and the resulting value is divided by 21.2 kg of gas. The final value (rounded down) is 204 cylinders for the entire heating season. This figure will be even higher if, instead of cylinders with a capacity of 50 liters, products of 27 liters are used.

Such calculations are very superficial, because no user will constantly keep a gas boiler at full power. But, based on these values, which should also be multiplied by the price for gas (add transportation and filling of cylinders), you can decide whether to install a gas cylinder heating system.

Reasons for choosing heating with gas from cylinders

Heating with gas cylinders is quite common, mainly for the reason that gas is relatively inexpensive (especially in comparison with electricity), and with low fuel consumption, a significant amount of heat is generated (read also: “Gas consumption for heating a house - gas consumption by a boiler by examples "). In addition, the connection of such a heating system can be carried out at any time, including after using a different type of boilers.

If you first use, for example, wood-burning equipment, then you can always buy and install a gas boiler using bottled gas. But in order to connect to the gas main, you will have to do some work, including those related to the house.

Despite the fact that there are cheaper heat sources, gas is still the most common fuel. This is also influenced by the fact that a gas boiler from a cylinder can work in any area and building, therefore this method of heating is indispensable if there is no access to other sources of energy.

An example of heating a house with gas cylinders in the video:

Is it possible to reduce gas consumption

This is not only possible, but necessary. Since a few simple elements in a gas cylinder system help to significantly reduce gas consumption.

- Install special sensors that signal the presence of gas in the room. This allows you to identify the leak in time (which leads not only to an explosion, but also to excessive consumption) and eliminate it.

- Without fail, the gas heating system should be automated. Only with the use of automation elements can a lower fuel consumption be achieved.

- Use only high-quality and genuine fuel, no additives. If there are impurities in the gas, then its consumption increases significantly.

- Monitor the temperature in the room where the LPG equipment is installed. It, like the rest of the rooms, should be heated. Insufficient temperature in the furnace can be the reason for the failure of the gas boiler.

In addition to the above measures, the outside of the house should be insulated. High-quality insulation will help to achieve a minimum gas consumption and a more comfortable temperature in the house.

Heating with bottled gas

Main gas for many residents of country houses remains a dream. A gas storage tank is a very expensive pleasure, just like a pilot boiler. It is also not always possible to connect the heating system to electricity. A few years ago, it was profitable to heat a house with diesel fuel, but prices for it have increased significantly and the savings have come to naught. An economical waste boiler remains, but you will not leave it unattended. Here are almost all the options for heating systems. The stove can not be taken into account, it cannot be autonomous a priori. Geothermal heating, heat pump, solar panels are expensive and difficult to maintain and install systems.

By the method of elimination, we come to heating with gas cylinders. Such a system is autonomous to some extent: it all depends on the time of absence of the owners of the house. In principle, the issue can be solved by connecting several cylinders. But in winter, you can leave her unattended for a week or two.

Heating a house with an area of 120 m2 per month costs about 6-8 thousand rubles.The initial costs for the entire system (boiler, reducers, hoses, combs and cylinders) are forty to sixty thousand rubles.

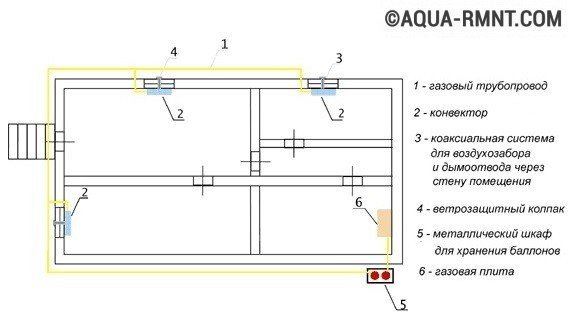

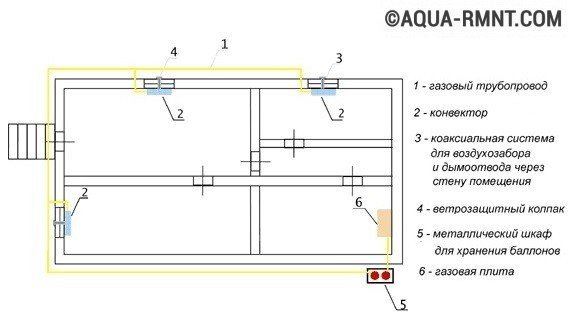

We heat the house with convectors

The heating system can be based not only on boilers, but also on convectors. Most often, they are selected depending on the area of the room at the rate of 1.0 kW of power per 10 m2. True, if you heat the house not in winter, but, starting from early spring to late autumn, you can get by with a lower value. But, if the house is intended for permanent residence, it is better to calculate the heat loss for each room. Then, even in severe frost, the system will cope with the work.

A metal cylinder storage cabinet can be installed in the house, but for safety reasons it is better to place it against an outer wall

The convector is installed permanently on the wall of a room or other room. In addition to it, you will need fittings for wiring, a reducer, at least two cylinders with a propane valve and a metal cabinet for storing them. For gas storage, containers with a volume of five to fifty liters are produced. The latter, of course, are most suitable for heating a house. The reducer must be of high quality and operate stably in the operating pressure range at an external temperature of up to minus twenty-five degrees Celsius.

You can find information on the principle of operation and design of gas convectors in our material:.

The cylinder cabinet can be placed against the outer wall of the house, in the kitchen or on the terrace. The first option is preferable both from the point of view of safety and for the sake of saving space. From the convector to the cylinder, the wiring is carried out with one-piece bent steel pipes (½ "or ¾"). There should be no threaded connections or corners on them. In the places of branching, fragments of pipes are welded.

The cylinder cabinet must not be installed in rooms with an underfloor or cavities. Propane is heavier than air and will accumulate if leaked. An explosive concentration can be reached within a few days.

A cabinet for storing gas cylinders is a mandatory safety requirement. It is better to install it either near the outer wall of the house, or in a warm boiler room with a concrete floor and thick walls.

Experts advise placing cylinders in special rooms - boiler rooms. They should have a concrete floor and thick walls. This is to ensure the safety of the occupants. And for the efficiency of using this fuel to be higher, the temperature in the boiler room should be +20 C.

What kind of boiler is needed and how long does one cylinder last?

Most boilers can operate on both mains and liquefied gas. Depending on the type of fuel, one of the two burners that come with the kit is installed.

When choosing a boiler, it is better to give preference to those that have a lower lower threshold for the working gas pressure. This will maximize the use of the balloon. With correctly selected settings, the heating system consumes one in three to four days.

Heating an insulated house with an area of 130 m2 and hot water supply requires 3-4 cylinders per week. At the same time, the temperature in the house is maintained around the clock +21 ... + 23 ° С, and outside from minus 18 ° С to minus 23 ° С. This is about 9,000 rubles a month.

How to reduce gas consumption?

Fuel consumption can be reduced by the same methods as in any other:

- install automation;

- install propane sensors in a room with cylinders, which will allow timely detection of a leak;

- insulate the house if this has not been done;

- observe the temperature regime in the room with cylinders, because at minus 25 ° C and below the system can render;

- purchase gas from trusted suppliers, since low-quality fuel at low temperatures simply will not catch fire.

If the above measures are observed, the gas consumption is reduced by 20-40%, therefore, the cylinder will last four days.

An example of programmer settings: in a frame insulated house (135 m2) from 23:00 to 6:00 the temperature is maintained at around +14 ° C, from 6:00 to 9:00 it increases to +21 ° C, from 9:00 to 16 : 00 while everything at work and at school is reduced to +12, and from 16:00 to 23:00 in the house +23 ° С. On weekends from 23:00 to 8:00 - +14 ° С, from 8:00 to 23:00 again +23 ° С. With such settings, about 6-7 cylinders are consumed per month. However, vacations and holidays significantly increase consumption in December-January. On average, during the heating season per month (taking into account hot water supply and a gas stove), 9-11 cylinders are needed.

At the same time, two or more cylinders can be connected to the system, however, it must be borne in mind that the pressure in the cylinders is high. Safety first

One way to reduce gas consumption is to install a Gas Saver. But is the economist so good? You will find useful information about its structure and principle of operation, as well as reviews in our article:.