High temperature fans are used in many systems for different purposes. It can be ventilation of baths and saunas, as well as stoves and fireplaces. The purpose of a high-temperature fan depends on its design and assigned functions. High-temperature fans (they are also called heat-resistant) can be of axial or centrifugal design. The working environment of such fans can be hot and aggressive. Most often they are used in ventilation ducts, but there are designs of heat-resistant fans that are used without air ducts.

Applications for high-temperature fans

The scope of application of high-temperature fans covers not only domestic use, but also industrial premises, use in technological processes and much more. Thanks to high-temperature fans, you can provide:

- ventilation of premises such as a sauna or a bathhouse,

- hot air movement in air heating systems,

- organize the removal of hot air from fireplaces and stoves,

- remove combustion products from industrial areas (posts) for welding and cutting metal or other materials,

- provide reliable ventilation in electrical installations and much more.

High-temperature fans can be installed: on the ceiling, on the wall, on the suspended ceiling, on special brackets and hangers, as well as on internal walls to provide ventilation with air discharge directly outside the room (outside) or into the duct system. Also, high-temperature fans can be used as a heat exchanger between adjacent rooms. There are special fireplace heating systems in which hot air is removed from the fireplace to air heating systems or directly to the required room. In such systems, high-temperature fireplace fans are used. At the same time, high-temperature (heat-resistant) duct fans have a high performance and an operating temperature range of at least -5 to +140 ° C. Some models of heat-resistant fans can operate at significantly higher temperatures. The operation of high-temperature fans can be intermittent or continuous. Therefore, such fans can be used both for ventilation of household and for ventilation of commercial, sanitary, industrial and other premises.

Spot coolers

Adjustable spot cooler (Adjustable Spot Cooler)

|

|

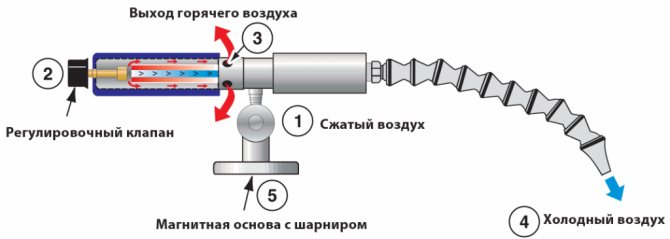

Adjustable spot cooler

instrument

- an economical and efficient solution for various tasks on local cooling in production conditions, for example - cooling the tool with compressed air through a vortex tube. This device allows you to easily and quickly change the temperature of the outgoing air flow using a regulator. The spot cooler can produce air flow with temperatures from -34 ° C to room temperature.

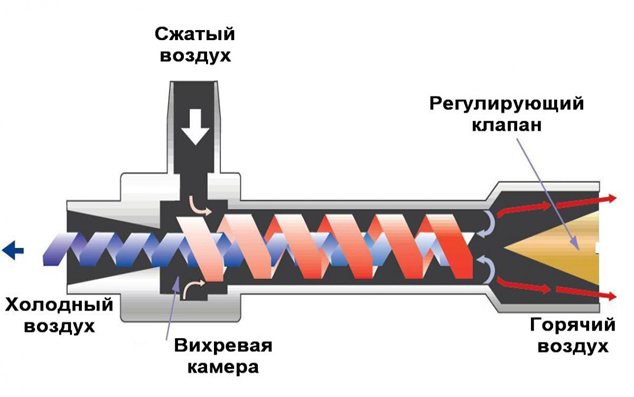

The adjustable spot cooler is designed on the basis of a vortex tube. Using compressed air as an energy source, the vortex tubes generate two streams of air, hot and cold.

In their work, vortex tubes use the vortex effect (Ranque-Hilsch effect) - the effect of separating a gas or liquid when swirling in a cylindrical or conical chamber into two fractions.At the periphery, a swirling flow with a higher temperature is formed, and in the center - a swirling cooled flow, and the rotation in the center occurs in the opposite direction than at the periphery.

In operation, the vortex tube uses compressed air with a pressure of 5.5 - 6.9 bar. Getting into the cylindrical chamber, the compressed air flow spins along the walls of the chamber up to 1,000,000 rpm. In this case, the air flow is divided into 2 fractions. A fraction of warm air leaves the vortex tube chamber on one side, and a fraction of cold air on the other.

| Compressed air tool cooler features | Application |

|

|

The magnetic base with the hinge allows the spot cooler to be quickly installed on magnetic surfaces and easily repositioned if needed. The flexible tube maintains its position and always directs the air flow in the desired direction. The spot cooler contains no moving parts and therefore does not require constant maintenance. This device has a low noise performance (75 dB).

The air flow temperature is easily set to the desired value using a thermometer.

The spot cooler is perfect for cooling parts, gases, air in cases where standard solutions such as liquid spray nozzles cannot be used. EXAIR manufactures single point or two point coolers.

Single point systems (model 3825)

They contain a flexible tube with one air outlet and are ideal for cooling small areas and surfaces such as seams, drilled holes, heated plastic parts.

Two-point systems (model 3925)

equipped with a double flexible tube with two air holes. These coolers are recommended for cooling larger areas and surfaces.

| Pressure, bar | Air consumption, l / min | Noise level, dB |

| 6,9 | 425 | 72 |

| 6,9 | 708 | 73 |

| 6,9 | 850 | 74 |

The power of the air flow and its temperature are regulated in a wide range using a control valve. The flow characteristics and cooling capacity of spot coolers are determined by an internal component called a generator.

The generator directly affects the flow characteristics of the spot cooler, and can be easily replaced with another one. Spot chillers with a 708 l / min generator have a cooling capacity of 1,700 Btu / h. (429 kcal / hour).

For lower cooling capacities, a generator with an air flow of 425 l / min is suitable. This generator provides a cooling capacity of 1000 BTU / hour or 252 kcal / hour. The generator with a flow rate of 850 l / min, provides a cooling capacity of 2000 BTU / hour or 504 kcal / hour.

In addition, spot coolers can be equipped with a compressed air valve or a solenoid valve to control the operation of the device and more efficient use of compressed air.

| vendor code | Name | Description |

| BP3725 | AdjustableSpotCoolerOnly | Adjustable spot cooler without base, tube, additional generators |

| BP3825J | Adjustable Spot Cooler System (one cold outlet) | Adjustable spot chiller with magnetic base, tube with one air outlet, generators (15-H, 30-H) |

| BP3825 | Adjustable Spot Cooler System including compressed air filter model 9004 and filter mounting bracket model 900396 | Adjustable spot cooler with magnetic base, single air outlet tube, generators (15-H, 30-H), compressed air filter |

| BP3925J | Adjustable Spot Cooler System (two cold outlets) | Adjustable spot cooler with magnetic base, double tube with 2 air outlets, generators (15-H, 30-H) |

| BP3925 | Adjustable Spot Cooler System including compressed air filter model 9004 and filter mounting bracket model 900396 | Adjustable spot cooler with magnetic base, double tube with 2 air outlets, generators (15-H, 30-H) and compressed air filter |

To order NPT models, simply remove the BP letters from the part number designation.

Mini cooler (Mini Cooler)

Mini tool cooler with cold air

- an economical and efficient solution for various local cooling tasks in the production of small areas or parts.

The mini compressed air tool cooler is very effective for very high speed operations (drilling, cutting, etc.). During such operations, the resulting frictional force often leads to fire, heating, melting and other processes associated with heating. The EXAIR Mini Chiller produces an air flow of -7 ° C. Acting locally, the mini cooler prevents excessive heat build-up and heat generation.

This device has low noise performance (75 dB), contains no moving parts and therefore does not require regular maintenance.

| Features of the | Application |

|

|

|

The mini cooler is designed on the basis of a vortex tube. Using compressed air as an energy source, the vortex tubes generate two streams of air, hot and cold. In their work, vortex tubes use the vortex effect (Ranque-Hilsch effect) - the effect of separating a gas or liquid when swirling in a cylindrical or conical chamber into two fractions. At the periphery, a swirling flow with a higher temperature is formed, and in the center - a swirling cooled flow, and the rotation in the center occurs in the opposite direction than at the periphery.

In operation, the vortex tube uses compressed air with a pressure of 5.5 - 6.9 bar. Entering the cylindrical chamber, the compressed air flow spins up along the chamber walls up to 1,000,000 rpm. In this case, the air flow is divided into 2 fractions. A fraction of warm air leaves the vortex tube chamber on one side, and a fraction of cold air on the other.

To order NPT models, simply remove the BP letters from the part number designation.

| vendor code | Name | Description |

| BP3704 | Mini Cooler Only (4 SCFM / 113 SLPM) | Mini cooler without magn. base (113 l / min), flexible tube and filter |

| BP3804J | Mini Cooler System without compressed air filter, single point hose kit | Mini cooler with magnetic base and flexible tube |

| BP3804 | Mini Cooler System including compressed air filter model 9003 and filter mounting bracket model 900395, single point hose kit | Mini cooler with magnetic base and flexible tube with one air outlet, compressed air filter |

| BP3304J | Mini Cooler System without compressed air filter, dual point hose kit | Mini cooler with magnetic base and double flexible tube with 2 air outlets, no filter |

| BP3304 | Mini Cooler System including compressed air filter model 9003 and filter mounting bracket model 900395, dual point hose kit | Mini cooler with magnetic base and double flexible tube with 2 air outlets, with compressed air filter |

| BP3708 | MiniCoolerOnly | Mini cooler without magn. base, flexible tube and filter |

| BP3808J | Mini Cooler System without compressed air filter | Mini cooler with magnetic base and flexible tube with one air outlet |

| BP3808 | Mini Cooler System including compressed air filter model 9003 and filter mounting bracket model 900395 | Mini cooler with magnetic base and flexible tube with one air outlet, compressed air filter |

| BP3308J | Mini Cooler System without compressed air filter, dual point hose kit | Mini cooler with magnetic base and double flexible tube with 2 air outlets |

| BP3308 | Mini Cooler System including compressed air filter model 9003 and filter mounting bracket model 900395, dual point hose kit | Mini cooler with magnetic base and double flexible tube with 2 air outlets, compressed air filter |

| 5904 | Mini Cooler Hose Kit (One Cold Outlet) | Flexible tube with one air outlet |

| 5905 | Mini Cooler Hose Kit (Two Cold Outlets) | Double flexible tube with 2 air outlets |

Design features of high-temperature fans

Depending on the version (axial or centrifugal), the fan casing can have different overall standard sizes. There are several connection sizes for axial inline high-temperature fans. But it is worth remembering that along its entire length, a high-temperature fan can have the same or different cross-sectional diameters. With different diameters, it is worthwhile to provide additional installation space.The material from which the casing of high-temperature fans is made can be metal (most often aluminum), as well as heat-resistant plastic (often glass-filled polyamide). High-temperature fan motors are manufactured using radial bearings and allow them to be used for at least 30 thousand hours without interruptions and failures. The degree of protection of the electric motor IP44 allows you to install systems that operate in high humidity and dusty conditions. In addition, there are special high-temperature fans, which are more related to other types and types of fans (for example, high-temperature roof fans).

The use of high-temperature fans (heat-resistant) allows hot air to be used or removed from the room without creating special temperature protection systems. Ventilation systems based on high-temperature fans always have small dimensions and high performance, which makes them indispensable in small rooms (kitchens, cooking, bakeries, saunas, baths, as well as production areas with high air temperatures).

Features of the model

Extreme operating conditions require appropriate material for the manufacture of the instrument. The most commonly used metal (aluminum) or heat-resistant plastic. Sometimes the body is made of glass-filled polyamide. E

it is a synthetic material with high strength, low coefficient of friction and unique heat resistance - polyamides operate in the temperature range from -60 to +200 degrees Celsius. In the manufacture of motors for such fans, radial bearings are used, the uninterrupted operation of which exceeds 25 thousand hours. The motor itself has an IP44 protection level. This makes it possible to operate the devices in a high humidity mode.

Small size and high performance make high-temperature fans indispensable in small spaces, but in production areas (welding shops, cutting plants), devices are also in demand. The advantage of this exhaust device, in comparison with other types of fans, is the level of noise insulation. Quiet operation of the cooler is a nice bonus to the functionality of the device.

Heat-resistant fan can withstand colossal loads

Heat-resistant fans have a temperature limit of 200 degrees, but a number of manufacturers (such as JSC) produce models that can withstand colossal loads. The purpose of such devices is to remove gas and air, the temperature of which exceeds 1000 degrees Celsius, and to cool the heated process equipment.

The ability to withstand such temperatures has led to the main field of application of this mechanism - emergency ventilation. The power and performance of these giants allows you to instantly clear the room from smoke and gas, which is necessary in the event of a fire.

The scope of application of heat-resistant fans is quite wide:

- sales areas where grills, ovens are used;

- in canteens for steam and smoke extraction from gas and electric stoves;

- production facilities where welding machines, metal cutting equipment, drying plants, electrical panels, etc. operate.

Installation is carried out at the time of assembly of the air handling unit with a common casing or air heating system.

There are explosion-proof models designed to clean rooms from explosive gases at high temperatures. They are used for ventilation of industrial buildings, residential buildings, but the main operating environment is explosive plants in the chemical, oil refining and gas industries.Such models are made of stainless or carbon steel, which are coated with varnish, paint or chemically resistant substances. In the manufacture of the device, brass elements are also used. This is due to the fact that this metal does not spark.

The set of explosion-proof fans includes the following elements: asynchronous motor, vibration isolator, brass pad (to reduce the likelihood of leakage), temperature controller. In terms of operating temperatures, explosion-proof fans are divided into temperature classes T1-T6, which is equal to indicators over 450 and below 85 degrees, respectively.

One of the high-temperature subspecies is a barbecue fan. Such an exhaust device is installed in the canopy, together with a spark arrestor and a grease filter. The dome itself is connected to the ventilation in the house.