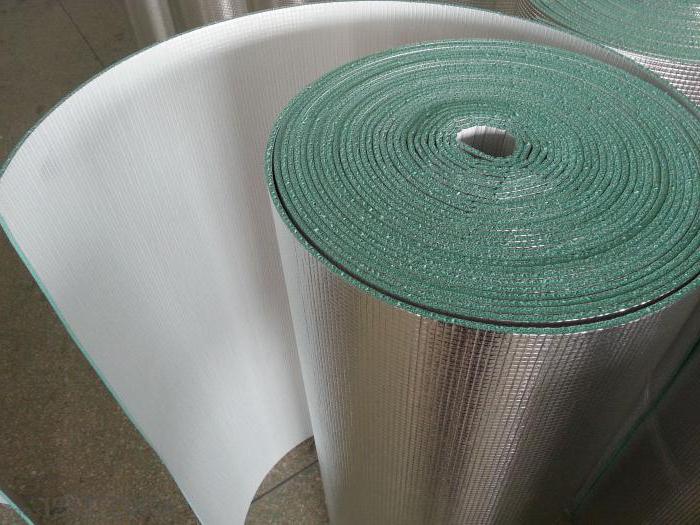

The reflective insulation on the polyethylene foam pad is penofol.

In the previous article about insulation for a garage, we calculated the total cost of work for each modern material. As a result, mineral wool insulation turned out to be the most profitable. If there were reflective insulation with one-side foil as an internal hydro-barrier, then the amount of stored heat would be even greater. By the way, there is a mineral wool with a layer of foil on sale. For example, at a thickness of 10 cm, the foiled material will be as effective as a 15 cm layer of ordinary mineral wool. In our article today, we will tell you how heat is retained through reflective insulation. We will tell you about the types of this material and manufacturer reviews regarding their use.

Where different types of foil insulation are used: "BestIzol"

If you are interested in reflective insulation, then you can consider several varieties of similar materials, among others, you should highlight "BestIzol", which is a steam, heat and sound insulation with a high level of reflectivity.

This insulation consists of closed cell polyethylene film and aluminized foil. Polyethylene foam is used with a thickness that depends on its brand and varies from 2 to 10 mm. As for aluminum foil, its thickness can reach 14 microns, while the minimum value is 7.

Today, this reflective insulation is presented for sale in several varieties, among others, type "A", type "B" and type "C" should be distinguished. The first option is insulation based on polyethylene foam with one-sided foil. The second solution has double-sided foiling, while the third has a foil layer on one side, and on the other, an adhesive with an anti-adhesive material is applied to the surface.

This insulation is effective not only for residential buildings, but also for insulating ships, vans, refrigerators, metal structures and ventilation ducts. This material is very lightweight and durable, so it can be embedded in metal structures and fixed to control elements or frame. This eliminates the additional costs of temporary structures and insulation grids.

What to Consider When Choosing Heat Reflective Film

First of all, you should decide on the place of its application. So, to create a heat-reflecting screen behind the battery, you need to remember that the thermal conductivity of aluminum is very high. In order not to heat the wall behind the battery, but to reflect the heat into the room, there must be an insulating layer between the film and the wall. The ideal choice in this case is foamed polyethylene films.

They are also great for organizing warm floors, allowing you to minimize the thickness of the cake - you don't have to lay a thick layer of insulation for interfloor floors, limiting yourself only to a heat-reflecting film. For such floors, it is better to choose films with aluminum foil. Its thickness from 10 microns will maximize the distribution of heat, removing possible cold streaks when laying pipes. The sprayed layer does worse with the leveling of the general thermal field.

But if you need to insulate the bath, it is the metallized films that show an excellent result. They do not corrode and reflect 60% of infrared radiation. Only canvas-based films are laid on the insulation, and any options can be mounted on "bare" walls.

Additional area of use of "BestIzol"

The above reflective insulation has a fairly wide range of uses. It can be applied by installing behind heating radiators, which allows them to increase their efficiency by 30% maximum. If you install such a sheet behind a heating radiator, then more heat will be reflected into the room. The radiation will work to heat the room.

Using the type "A" type "BestIzol", you can insulate pipes of small diameter. The material is wrapped around the products, but for a hot pipeline, in order to achieve maximum effect, it is necessary to use 20 mm shroud rings made of the same material. As an alternative solution, an asbestos cord or fluoroplastic is used. In this case, the effect of a thermos is formed between the insulation and the pipes. However, in this case it is recommended to purchase "BestIzol" type "B".

How to use BestIzol

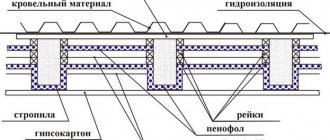

The above-described reflective insulation, the use of which is almost unlimited, is also used for roof purlins. For this, the material is laid from the cornice to the cornice, and it must be carried through the ridge. It can sag 20 mm between purlins. Fastening is carried out with construction brackets, which are installed at a distance of 150 mm from each other. At the same time, ventilation, which is provided for by the building structure, is preserved. Double-sided insulation is suitable for this.

If it is used to insulate the attic, then it will be necessary to ensure that there is an air gap between the insulation or and the ceiling. To do this, you should purchase reflective insulation with one-sided foil, which should be directed outward. Additionally, slats are laid, the distance between which will be 250 mm.

Reflective Heat / Sound insulation (lavsan) "ISODOM PL"

The option with internal insulation, when the room resembles a creogenic chamber with shiny walls, disappears immediately. What remains is external insulation with an air gap and internal insulation with a fake wall.

In the first case, on the outside of the wall, it is necessary to place penofol so that a few centimeters of air space remain between it and the wall. A small layer of heat insulator will remain, the effectiveness of which is equal to that of traditional heat insulators.

From a technical point of view, it is not difficult to create a hinged system with penofol. But only such a system will be ineffective.

Where to use "Penofol"

Traditional insulation can be supplemented with Penofol. It forms the basis of the structure in the construction of low-rise frame buildings, increasing the thermal resistance of the walls, because their volume increases. Using this insulation, you can reduce heat loss, because it has high reflectivity and is a reliable vapor barrier.

Reflective insulation "Penofol" complements the massive insulation and allows you to reduce its volume, increasing the service life. You can use the material for insulation:

- attics;

- roofs;

- attics.

It is used for insulation of floors and their insulation, as well as insulation of walls, ventilation ducts and pipes.

Installation ↑

The construction of an appropriate thermal insulation system based on foil-clad heaters can be compared to the installation of an unclasped thermal insulator. The only, perhaps, that distinguishes, will be gluing the borders of neighboring products with aluminum tape, which gives the connections a relative tightness.

What advice can you give to those who are going to buy foil-clad thermal insulation products? Products of such well-known brands as penofol, isolon, Rockwool, Isover, Xotpipe, Paroc, Linerock and a number of others are known and distributed in Russia.These reputable brands, which produce thermal insulation materials based on basalt wool in a wide variety, also have products with reflective foil insulation in their range. For those looking for rubber-based products, we recommend K-Flex reflective insulation.

How to use "Penofol" for the roof

The maximum effect when using "Penofol" for the roof can be achieved by providing an air space of 2 cm on both sides of the insulation. Aluminum conducts electricity well, so wiring must be protected. Before installing the material, it is important to take care of the reliability of the wiring. The insulation used will reflect up to 97% of the heat flux. The inner layer of the roof insulation must be made airtight.

The reflective layer must be directed towards the heat source. In order to achieve complete tightness and waterproofing, the joints must be glued with foil tape. The basic rule is that foil acts as an excellent conductor of electrical current. To fix the material from the inside, you should prepare self-tapping screws or a stapler. For this, it is most convenient to purchase 5 mm sheets. If you have to work in a house or apartment, then you must use one-sided material. But in the case when the walls are very cooled, additional insulation with expanded polystyrene or cotton wool should be carried out.

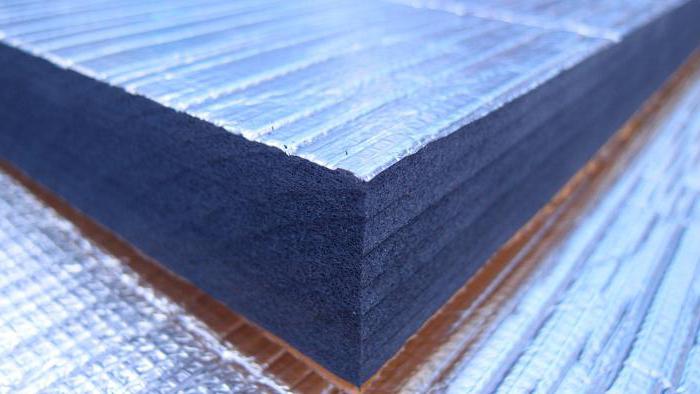

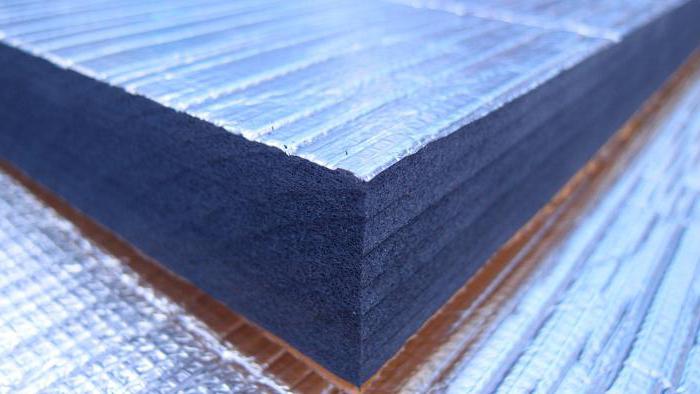

Appointment of insulation VPE lavsan

The reflective HPE insulation is made of foamed polyethylene and has a silvery surface. This material is practical, ready to serve for a long time, affordable and versatile. It is used for noise and heat insulation of premises for various purposes. With its help, it is possible to achieve partial damping of vibration. The products are placed under the decorative coating of the floor, ceiling and walls, and they can be used even in those conditions where high humidity will remain during operation.

How to use HPE insulation

HPE reflective insulation can be mounted on surfaces with any configuration. The material is effective in low-rise construction, and the canvases are attached end-to-end, while overlap must be eliminated. The joints must be sealed with a special foil tape with an adhesive layer. You can use a composite of polyethylene and aluminum for this.

The connecting element is characterized by strength, moisture resistance and the ability to reflect infrared and ultraviolet radiation. The service life can reach the time of using the foil layer itself. By using HPE reflective insulation, you can reduce heating costs and achieve significant energy savings.

Insulation can be installed under parquet, laminate or other floor coverings, as well as in a floor heating system under a gypsum or cement screed. Reflective insulation 10 mm is the thickest version of this coating. The minimum thickness is 2 mm, while the width remains the same and equal to 1 m. But the length varies from 10 to 100 m. For a 10-mm thickness, the price of one square meter will be 58.13 rubles.

Film Ondutis R Termo - when it is important to keep warm

Heat-reflecting film Ondutis R Termo is perfect for reducing heating costs. Due to its characteristics, it provides up to 80% heat reflection. As a result, instead of heating the walls, thermal energy is used exclusively for heating the premises.

The low weight of the Ondutis R Termo vapor barrier (70 m2 / g) allows it to be used for insulating light frame structures, and the vapor permeability of up to 10 g / m2 per day provides maximum protection of the insulation from steam even in a Russian bath. At the same time, the film does not lose its properties at temperature drops from -40 to +120 degrees.

How and where are different types of reflective insulation used?

All types of heat-reflecting insulation can be classified into three types, each of which is designated by its own letter. For example, Type "A" is a polyethylene foam material with foil on one side. This insulation is versatile and can be installed on any surface. It is glued with special glue or nailed to a wooden surface with staples or nails.

The one-sided coating speaks for itself, because this solution can be used in most cases for interior work, installing it with foil inside the room. Type "B" is also foamed polyethylene, but its thickness reaches 5 mm. The coating is here on both sides, it is foil-coated and expands the area of use. This material can be used for refrigerating chambers, which should not let heat through on one side, and not let out cold on the other. This reflective insulation can be used for walls, if you need to maintain the same temperature in different rooms.

The last type of such insulation is Type "C". If we compare it with type "A", then it has a self-adhesive base, but otherwise it is almost no different. Convenience of work is an additional advantage.