What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant with which the heating system is filled. The single-circuit boiler does not produce water for hot water supply. In premises where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments, and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh a little more than 40 kilograms. Wall-mounted single-circuit boiler organically fits into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

A single-circuit gas boiler does not have any complex elements and mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler is with a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of the floor heating device, which has a low power.

What is a double-circuit boiler

This heating device not only heats up the heating medium, but is also intended for preparing hot water. A double-circuit boiler has a more complex device than its single-circuit counterpart. The most complex device has a two-circuit heating device, which is equipped with a three-way valve.

There are two-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating the water in the heating system, and the second heats the water for water supply. The most rational design is provided by double-circuit heating devices, which are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermal heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But the more popular models are boilers with separate heat exchangers.

Double-circuit gas boilers are good because they solve all the problems associated with the preparation of hot water by heating the room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented by:

- the second heat exchanger (if the boiler design provides it);

- 3-way valve (if the heat exchanger is not bithermal);

- inlet and outlet for the DHW pipeline.

Boiler with built-in boiler: main advantages

The purchase of a gas boiler with a boiler will be the best solution when using several points of water analysis, it will provide a sufficient number of advantages.

3 main advantages:

- A positive and significant advantage is water heating at night, when the water pressure in the water supply is weak;

- To get started, a separate connection to the water supply and heating system is not required, but simply toss water, gas and electricity to the boiler;

- All variants of gas-type boilers are compact, since all the constituent elements of the boiler are assembled in one body.

All these indicators are possessed by the Vaillant and Nova boiler water heaters. They are the most popular brands on the boiler market.

Pros and cons of a double-circuit boiler

A double-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler, you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also, the external attractiveness of double-circuit heating devices should be attributed to the indisputable advantages. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce the cost of utilities. Double-circuit boilers allow you to perfectly adjust the temperature inside the room, as well as adjust the temperature of the water in the DHW pipe.

These heating devices are not without several drawbacks, the list of which includes:

- turning off heating at the time of parsing hot water;

- relatively low productivity in the preparation of hot water.

What power does a wall-mounted double-circuit gas boiler with a boiler have?

The power of the gas burner in the boiler determines the rate of water supply to the flow-through wall heater. The heating rate also depends on the design of the heat exchanger. The peculiarity of heating the liquid lies in its prolonged contact with the heat exchanger, and that is why in order to warm the coolant to the required temperature, a lot of heat is needed. And to increase the heating performance, it is necessary to increase the power of the gas burner in the boiler and increase the gas consumption.

If you need to heat water up to 40 degrees, then you will need to adjust the burner. Its oriented power should be about 20 kW. If your boiler is not designed for such an indicator, then you will not be able to get a warm stream of water as a result, and you can forget about taking a warm bath or shower.

Most gas models have a power of 20 to 30 kW, it is important to decide for what purpose you will use it, because 10 kW will be enough for the heating system. For boilers of this type, special modulated burners have been created.

It is very important to know that every gas boiler, even if it has a weak power, has a limit value.

Exceeding the norm can lead to the fact that the burner will turn off and on. Such a defect will very soon lead to equipment breakdown or an increase in gas consumption. This problem leads to the fact that the purchase will not only be unjustified, but also unprofitable.

Read about how to calculate gas consumption per unit area of the house in the article:.

And it is for this reason that a boiler is built in double-circuit boilers, which collects hot water, and then gives it back in large quantities while taking a bath or shower. Thus, the layer-by-layer heating of water is optimal, it enables the normal operation of the equipment and does not lead to burner breakdown.

What is an indirect heating boiler

Today more and more people are using indirect heating boilers. This useful device allows you to more efficiently use the heat of a gas boiler.In winter, when the heating system is turned on, the indirect heating boiler works from this system, and in the summer, when the boiler does not work for heating, such a boiler works from an electric heating element or the boiler is switched to summer mode (if the settings allow).

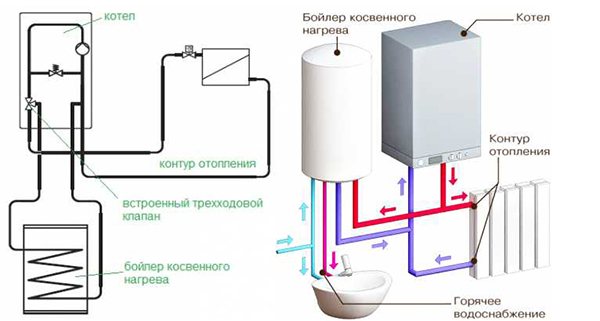

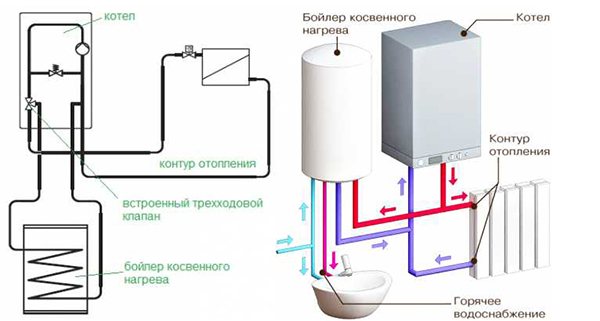

The heating of water in an indirect heating boiler does not occur in a direct way, but as if in an accompanying way. Inside such a boiler there is a rather large coil, inside which the coolant circulates from the heating system. Thus, the gas boiler heats the water in the indirect coil, which circulates through the pump in the heating system, and the heat exchanger heats the water in the boiler. Such heating of water for the hot water main is recognized as the most cost-effective.

The casing of this boiler is mainly made of steel sheet, and the inside of it is made of stainless steel. Between the outer and inner parts of the indirect heating boiler there is a special material that hardly conducts heat. The design of such a boiler is very similar to that of a thermos.

As a rule, an indirect heating boiler is installed near the heating boiler. The heated coolant must pass through the boiler first. The water in such a boiler will always be hot, and several hot water extraction points can be connected to this boiler at once. Hot water is heated in an indirect heating boiler without affecting the operation of the heating system.

In most cases, such a boiler is equipped with a highly efficient heat exchanger made of special steel. More expensive indirect heating boilers are equipped with heat exchangers made of brass. The heat exchanger of the boiler has the shape of a long spiral, which allows you to very quickly heat the water to the temperature that the water in the heating system currently has.

How to connect an apparatus for a boiler with two circuits

The boiler is selected, having decided on its type, location and volume relative to the capacity of the water heater. In drives of indirect and combined type, it is recommended to provide additional protection against scale inside the coil.

Attention! It is forbidden to connect the boiler before putting the boiler into operation gas service.

Connection diagram

Connection diagram depends on the type of tank:

Direct heating device

The inlet pipe of the accumulator is connected to the inlet of cold water supply. Outlet pipe - to the entrance to the second boiler circuit.

Cold water flows directly into the boiler, where it heats up up to 60 ° C under the influence of heating elements.

From the boiler, the liquid is sent to the boiler, losing along the way several degrees of temperature. Passing through the second heat exchanger of the heating device, water recovers losses and goes into the DHW system through the boiler outlet valve.

Indirect and combined heating

Have two additional pipes from the coils. They are connected to the primary boiler circuit. The scheme of work assumes that the heated coolant of the heating system will first of all pass through the storage coil, and only then go to the radiators.

Due to this, the main gradient of heating tap water is provided by a coil. Cold water entered directly into the drive, heated liquid diverted to the DHW circuit of the boiler.

When cycling, that is, periodically turning the burner on and off by the boiler automatics operating with an indirect heating boiler, it is recommended to change the tank wiring diagram. The cycle of the boiler indicates that the water in the storage tank does not warm up to the required 60 ° C.

The pipes of the DHW circuit of the water heater are muffled, the water from the boiler is immediately sent to consumers. Liquid heating rate depends solely on power heating systems, it is impossible to operate this scheme in the summer.

Photo 3.Connection diagram of a boiler for indirect water heating for a double-circuit gas boiler.

Materials and tools

Internal elements of boilers are made made of copper, steel or cast iron. Heating elements and coils are made of copper or steel. The steel walls of the tank are corroded, the service life does not exceed 15 years. Cast iron walls are twice as massive and expensive, but they work properly up to 90 years old.

When installing a boiler, detachable pipe connections are provided. For this you need:

- tape measure, pencil, chalk;

- hammer drill with a set of drills (for making holes for piping, wall mounting elements);

- adjustable wrenches and wrenches (models with ratchets are recommended);

- Screwdriver Set;

- pliers;

- nippers;

- joint sealant (flax, FUM tape, plumbing thread);

- sealants;

- shut-off valves, tees;

- fitting;

- pipes.

If it is not possible to arrange detachable connections, apply polypropylene pipeswelded in place.

Phased installation and quality control

All work is carried out with the equipment turned off and the liquid removed from the system.

- Marking the bindings with a pencil or chalk. Drilling mounting holes.

- Checking the load-bearing capacity of the wall... Relevant for mounted models. The fasteners supplied with the drive are installed on the wall, loaded with bags of cement or sand at the rate of a double reserve.

If the wall material can withstand the load 100 Kg, then you can hang up a boiler with a volume of up to 50 liters.

- Placement of the container on the wall or on the floor.

- Plumbing insert.

- Installation of overpressure valves along the water flow.

- Installation of an expansion tank.

- Filling with water and checking the tightness of the connections. If, after an hour of downtime, the system filled with water did not leak, then the density of the joints is satisfactory.

- Connection of equipment to the network, check of work.

Pros and cons of a single-circuit boiler and BKN

A boiler that prepares hot water by indirect heating is often used in conjunction with a single-circuit heating device. This tandem has both advantages and disadvantages. The main advantage of such a boiler is that this device practically does not require any maintenance and financial costs throughout the entire period of operation. The indirect heating boiler does not overload the power grid with excessive load, which is very important for those regions where voltage drops are observed.

An indirect heating boiler that works in conjunction with a single-circuit gas boiler is very convenient to use. Such a boiler rationally consumes water, since it does not require draining a large amount of water until the moment when hot water flows. Such a boiler heats water very quickly, and several mixers can be connected to this device, which can be located in different places of the house or apartment.

The heat exchanger of the indirect heating boiler operates under conditions that completely eliminate the formation of scale. Also, the design prevents the formation of harmful microorganisms inside the device. The indirect heating boiler does not require periodic cleaning and can operate for more than ten years without any maintenance.

The heat exchanger of the indirectly heated boiler is specially protected against corrosion. This protection very effectively protects these elements of the boiler from stray currents that occur in the water mains.

Indirect heating boilers have several minor drawbacks, the list of which includes:

- higher cost than their electric counterparts;

- indirect heating boilers are larger than conventional boilers;

Using a single-circuit boiler and a conventional boiler

Along with indirect heating boilers with single-circuit gas boilers, conventional boilers are also used.Conventional electric boilers are slightly cheaper than indirect heating boilers, but they are significantly inferior to them in many parameters. A conventional electric boiler heats water much longer and this device needs regular maintenance.

It is advisable to clean the electric boiler from scale once a year, and also periodically change the anode, which protects the electric heater. An electric boiler also needs a reliable power supply, and an independent electrical line must be laid to this device. Also, this water heater seriously loads the power grid - in general. Therefore, it is better to use an electric boiler in those rooms where the electrical wiring has a margin of safety.

How to connect a boiler and a double-circuit boiler

A boiler for a gas boiler is presented in the form of a storage tank, in the middle of which there is a heat exchanger.

This model is inherently dual-circuit, as it has the ability to connect to heating and hot water systems.

The built-in flow-through heater is a double-circuit model.

About how double-circuit boilers are arranged, the principle of their operation, as well as how to choose, you will learn from our article:.

You can consider the option of connecting a double-circuit boiler to a separate boiler. Such an installation will relate to a technique with a layer-by-layer type of heating. In addition, at specialized points you can see boilers both double-circuit and with layer-by-layer heating, they are combined by a gas boiler and can be either a complete set or separate.

The choice will depend on which option is best for you. It can be a separate or a holistic model that is easy to transport and install. If you are the owner of a single-circuit boiler, then you can give preference to a boiler with layer-by-layer heating, which includes an instantaneous heater. In the event that you want to save space in the room, then purchase a single-circuit type gas installation with an indirect heating boiler.