Gas boiler with built-in boiler has a long service life and excellent performance

Every day there are more consumers who want to organize an autonomous heating system. The monetary costs that were when buying heating equipment and installing it will soon pay off on energy savings and the ability to adjust the power of the system. The best system for houses and apartments would be the option with a gas boiler with a boiler.

Boiler with built-in boiler: main advantages

The purchase of a gas boiler with a boiler will be the optimal solution when using several points of water analysis, it will provide a sufficient number of advantages.

3 main advantages:

- A positive and significant advantage is water heating at night, when the water pressure in the water supply is weak;

- To get started, you do not need a separate connection to the water supply and heating system, but just throw water, gas and electricity to the boiler;

- All variants of gas-type boilers are compact, since all the constituent elements of the boiler are assembled in one body.

All these indicators are possessed by the Vaillant and Nova boiler water heaters. They are the most popular brands on the boiler market.

Buying a boiler with a boiler in the "Termona-Rus" store

Before buying a gas boiler with a built-in or a separate boiler, we recommend that you seek professional advice. They will help you choose the type of boiler and boiler, their capacity, volume, additional options, control methods. It is also better to trust the installation to professionals who will carry out the work in accordance with safety requirements. Everything related to gas heating equipment requires a careful approach.

Our catalog contains a number of models of gas boilers with the ability to connect boilers. You can get detailed information about their specification and application from the instructions (in Russian) or from our managers by phone and in person.

How to connect a boiler and a double-circuit boiler

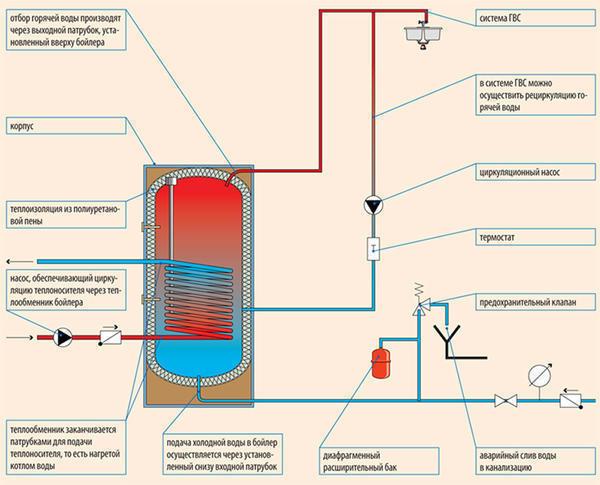

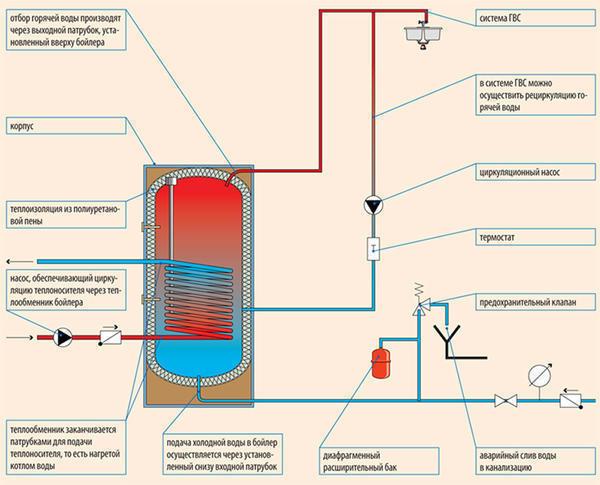

A boiler for a gas boiler is presented in the form of a storage tank, in the middle of which there is a heat exchanger.

This model inherently seems to be a two-circuit, since it has the ability to connect for heating and hot water systems.

The built-in flow-through heater is a double-circuit model.

About how double-circuit boilers are arranged, the principle of their operation, as well as how to choose, you will learn from our article:.

You can consider the option of connecting a double-circuit boiler to a separate boiler. Such an installation will relate to a technique with a layer-by-layer type of heating. In addition, at specialized points you can see boilers both double-circuit and with layer-by-layer heating, they are combined by a gas boiler and can be either a complete set or separate.

The choice will depend on which option is best for you. It can be a separate or a holistic model that is easy to transport and install. If you are the owner of a single-circuit boiler, then you can give preference to a boiler with layer-by-layer heating, which includes an instantaneous heater. In the event that you want to save space in the room, then purchase a single-circuit type gas installation with an indirect heating boiler.

Differences between single and double-circuit boilers

A single-circuit gas boiler with a boiler can only heat the room - it does not have a built-in system, which is necessary to provide hot water supply. But if you connect a remote boiler with a heat exchanger to it, then it will be able to heat water for domestic needs.

Double-circuit boilers have a more complex device, respectively, and they are more expensive. They serve to heat water not only in the heating system, but also in the water supply system. In order to increase the amount of heated coolant, a boiler can be connected to such boilers.

What power does a wall-mounted double-circuit gas boiler with a boiler have?

The power of the gas burner in the boiler determines the rate of water supply to the flow-through wall heater. The heating rate also depends on the design of the heat exchanger. The peculiarity of heating the liquid lies in its prolonged contact with the heat exchanger, and that is why in order to warm up the coolant to the required temperature, a lot of heat is needed. And to increase the heating performance, it is necessary to increase the power of the gas burner in the boiler and increase the gas consumption.

If you need to heat water up to 40 degrees, then you will need to adjust the burner. Its oriented power should be about 20 kW. If your boiler is not designed for such an indicator, then you will not be able to get a warm stream of water as a result, and you can forget about taking a warm bath or shower.

Most gas models have a power of 20 to 30 kW, it is important to decide for what purpose you will use it, because 10 kW will be enough for the heating system. For boilers of this type, special modulated burners have been created.

It is very important to know that every gas boiler, even if it has a weak power, has a limit value.

Exceeding the norm can lead to the fact that the burner will turn off and on. Such a defect will very soon lead to equipment breakdown or an increase in gas consumption. This problem leads to the fact that the purchase will not only be unjustified, but also unprofitable.

Read about how to calculate the gas consumption per unit area of the house in the article:.

And it is for this reason that a boiler is built in double-circuit boilers, which collects hot water, and then gives it back in large quantities while taking a bath or shower. Thus, the layer-by-layer heating of water is optimal, it enables the normal operation of the equipment and does not lead to burner breakdown.

The advantages of double-circuit boilers and their use

Double-circuit boilers are more functional, but also more expensive. Before buying, you should decide how the equipment will be used.

The following models of double-circuit boilers are currently on the market:

- with a flow-through water heat exchanger;

- with a built-in boiler for 40-60 liters;

- with a built-in boiler for a volume of 80-500 liters.

The choice of a boiler is influenced not only by the price and installation method, but also by the needs of the residents of the house for hot water.

Hinged boilers with a flow-through water heat exchanger have the following features:

- simultaneously heat rooms with a total area of up to 300 "squares", and also provide two water points;

- small size allows you to build equipment into a wall niche;

- low cost;

- simple and inexpensive installation;

- uncomplicated management;

- the presence of self-diagnostic elements.

Gas heating boilers with a boiler with a volume of 40-60 liters have a number of advantages:

- able to heat a house with an area of up to 300 "squares" and provide a simultaneous supply of water directly to 4 water points;

- Ease of Management;

- the presence of a self-diagnosis system.

Boilers with a boiler for 80-500 liters are of three types.The first and second of them include devices equipped with everything you need, having small dimensions and allowing you to fully control the system. Boilers of the third type require the installation of additional equipment and various components. As a result, you will need to spend a lot of money on the purchase of all the required elements and the work of qualified specialists.

The device of a gas boiler with a boiler, a detailed video:

The main features that a layer-by-layer heating boiler has

In models with a double-circuit layer-by-layer heating, water enters already in a heated state, this allows the boiler to very quickly bring the water to the required temperature.

There are a number of advantages that these installations have:

- Hot water enters the upper layer of the boiler after 5 minutes from the start of operation. Indirectly heated boilers run for a longer time, as they need to take time for convection from a heat source.

- Since there is no heat exchanger inside, the tank collects more water that can be used in everyday life. The performance of such a boiler is much higher than models with an indirect type of heating.

In most situations, people do not realize what a boiler is needed for in a boiler. The answer is that such an organization can provide a more comfortable use of warm water. In addition, such a device guarantees the constant availability of hot water in the house, even when several water supply points are opened. Not a single loop boiler is able to cope with such a task. In addition, floor-standing models are similar to a refrigerator and can hold up to 100 liters of liquid, and this is enough to provide a large family with warm water. Floor standing models are compact and also a great alternative to large units if you don't have a lot of space in your home.

Boiler features

Boilers are used to organize hot water supply for consumers' needs through taps. Having such a device in their home, its residents will not depend on the presence of hot water in the tap.

Boilers can use different types of energy:

- household gas;

- electricity;

- thermal energy generated during the operation of the boiler.

Regardless of what type of device is chosen by the consumer, its installation must be coordinated with competent organizations and entrusted to specialists, so that subsequently there will be no problems. It is very important to make the correct connection of the equipment - in this case, a double-circuit gas boiler with a boiler can be highly efficient and provide hot water, which will be supplied not only to the heating system, but also through several taps simultaneously (

What are double-circuit floor-standing gas boilers

Modern gas floor standing double-circuit boilers have an excellent design and operate almost silently, so they can be installed in any room that meets the requirements.

A gas double-circuit floor-standing boiler is a unit that combines the functionality of two devices at once - in fact, the boiler itself and an instantaneous water heater. In it, the coolant and hot water never mix with each other - they are immediately distributed to separate circuits.

The technical device of such boilers varies depending on the specific model, but the standard design is almost always the same:

- gas burner and ignition element;

- starting and main igniters;

- system for gas and smoke removal;

- combustion chamber and heat exchanger.

Optionally, the double-circuit floor-standing gas boiler has other components: an expansion tank, a blower fan, a circulation pump, an automatic control module, electronic sensors and safety valves to optimize operation, as well as monitor the safety of the equipment.

It is advisable to install gas double-circuit floor boilers in relatively small residential buildings (50–400 m2), where hot water supply does not require laying a long pipeline (7–8 m). Otherwise, heating of running water will take too long, which entails excessive consumption of fuel.

Also, an essential point is the number of people living in the house, because, as a rule, in the presence of two circuits, priority is given to water supply. In practice, this means that if you simultaneously use several points for drawing off hot water, then the volume of its production (even with excess capacity) will always be insufficient. Therefore, the total number of rooms with hot water consumption points (bathroom, kitchen, laundry) should not exceed three.

Principle of operation

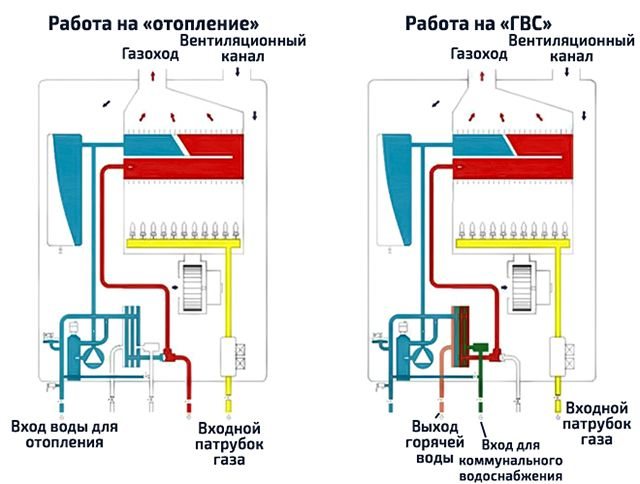

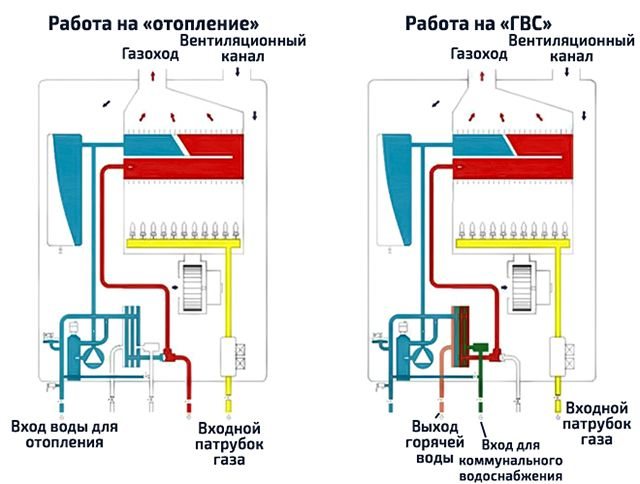

A clear principle of operation of double-circuit boilers with the priority of hot water supply (DHW).

To understand the general principle of operation of double-circuit gas boilers, consider how each circuit functions separately:

- heating - constantly "drives" the heated coolant through itself, which transfers heat through the radiators to the surrounding space in the rooms;

- water heating - it is activated when the three-way valve is turned on, which redirects part of the coolant to heat tap water.

Thus, during periods of active use of running water, the heating of the house is very limited (in the presence of a three-way valve) or completely switched off (when working according to the principle of "DHW priority"). Due to this, the temperature of the running water remains stable, regardless of the pressure force, the number of open taps (within acceptable limits) and the pressure in the gas line.

When the hot water tap is closed, the three-way valve switches back to the heating circuit. If the coolant has already had time to cool down, the system again begins to generate heat energy to resume heating, and if everything is fine with the temperature, it goes into standby mode (background heating).

The device is based on the example of the domestic double-circuit model Conord KSts-g-30N: the minimum number of components, simple materials, uncomplicated non-volatile automation.

How to choose a room thermostat and save up to 30% per month on heating

The main classification of gas boilers

Gas boilers are classified according to several criteria:

- in terms of functionality, single and double-circuit (with a built-in boiler or instantaneous water heater) are distinguished;

- by the type of coolant (water or water plus antifreeze);

- by the type of combustion chamber, they can be chimney or turbocharged;

- according to the ignition method, there are models on the market with both automatic electric ignition and manual piezo ignition;

- by the type of traction - with natural or forced;

- according to the method of placement, you can choose between a parapet, floor-standing and wall-mounted boiler;

- according to the material of the heat exchanger - steel, cast iron, copper, stainless steel or silumin. The latter two are used in condensing gas boilers;

- by electrical dependence, respectively, electrically dependent (with and without a self-starting function) and electrically independent boilers are distinguished.

Traditional domestic boilers heat the heating medium only due to the combustion fuel. However, if we are talking about condensation models, then they additionally use the thermal energy released during the condensation of water vapor - one of the constituents of flue gases. Such equipment has an average efficiency of 10-20% higher than that of traditional systems, which means a decrease in fuel costs by the same amount.

A boiler with a cast iron heat exchanger weighs twice as much as its steel comrade. It is more expensive, more durable and takes much longer to cool down. True, it has one significant drawback - fragility. It must be transported and installed with care, since cracks may appear on the heat exchanger upon impact

Such a number of criteria provides buyers with a wide assortment in which it is easy for an ignorant person to get lost. However, before you finally decide on the model of equipment, it is better to study the entire list. This will allow you to choose the best option at a reasonable price.

Differences between "double-circuit" and "single-circuit"

A double-circuit gas boiler allows you to avoid unnecessary costs associated with the purchase and installation of equipment for hot water supply. Two heat exchangers, independently of two of each other, heat the heat carrier in the heating system and water for sanitary needs. This is especially true for buildings under construction, or for those who, due to circumstances, decided to completely replace the heating and hot water supply systems - it's time to optimize.

A double-circuit boiler allows you to reduce construction costs. Installation and maintenance of a boiler with a DHW circuit will be cheaper than for two separate systems

Floor-standing gas boilers, like wall-mounted ones, can be paired with an instantaneous water heater or an external or built-in boiler. The latter can be sixty-one hundred liters in volume, and some models are equipped with 150-liter containers. Wall-mounted boilers cannot boast of such characteristics. A large water heater is relevant for houses with a large number of consumption points.

Most models of wall-mounted gas boilers are available with a capacity of up to 60 kW. Much less common are specimens that can provide heating for buildings with an area of 800-900 square meters. But floor-standing gas boilers are produced with a capacity of four to several hundred kilowatts. Agree, there is much more room for choice. Therefore, for large buildings, in which there is the possibility of equipping a separate boiler room, it is better to buy a floor-standing gas heating boiler.

Floor standing heating boiler, as a rule, requires installation in a separate boiler room. In this room, it is advisable to install a sensor that, in the event of a gas leak, will immediately turn off the fuel supply line.

Double-circuit floor-standing gas boilers with an instantaneous water heater provide hot water consumption up to 33 liters per minute. This figure can be increased by additionally installing a storage boiler. The most powerful floor-standing boilers are equipped with independent circuits that provide heating of the heating medium for the underfloor heating and water for the pool.