Home »Heating and water supply» Features of installing a gas boiler in the basement of the house

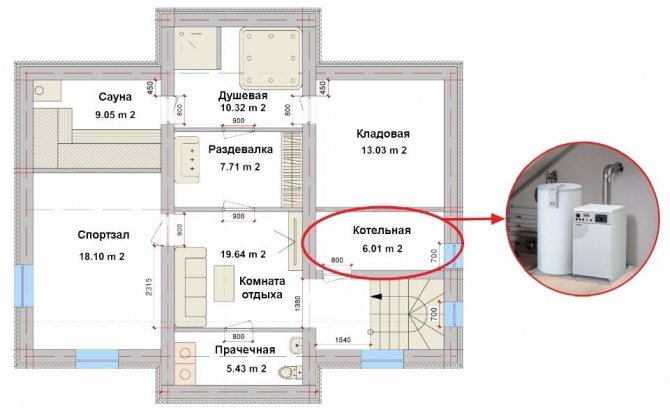

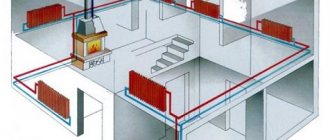

Owners of private houses, looking for a suitable heating option, often opt for gas equipment. But the unit itself, the elements of its piping and the chimney take up too much space in the room, therefore, if there is such an opportunity, they choose the option of placing the gas boiler in the basement of the house. This saves living space and increases the safety of using the heating system.

…

- 1 Installation conditions for gas boilers in the basement

- 2 Pros and cons of a gas boiler room in the basement

- 3 Boiler room equipment in the basement

Can the boiler be installed in the basement?

A gas boiler in the basement today is installed by many country homeowners. But there are also exceptions. So, the boiler should not be placed if the system operates on the basis of liquefied petroleum gas produced from oil. For many years, state standards prohibited boiler rooms from being located in the basement of a private house because LPG systems were used everywhere.

You can place the heating system in the basement. if you comply with the necessary requirements.

After the general transition to natural gas and special boilers took place, the requirements for the ban were lifted. Now, in the basement and on the basement floor, it is allowed to install no more than 4 gas boilers (water heating or heating type), the total capacity of which does not exceed 200 kW. If necessary, it is allowed to install a gas boiler even in attics.

Do not forget that before installing a gas boiler in your house, you need to approve a boiler room project. This must be done before you put the boiler on and start the system, because in the future, serious problems with the fire inspection are possible, where it may be necessary to rebuild or dismantle the boiler room. In addition, this approach will allow you to protect yourself from the fact that careless inspectors will demand a bribe. If the project is brought in advance, then the officials make certain adjustments to it without any problems, which must be taken into account and corrected in practice.

Output

The installation of a boiler room in the basement of a residential building is a perfectly acceptable solution. The room is brought in accordance with the requirements of GOST and the equipment is installed. For a more complete experience, we recommend the video in this article.

It has long been known that living quarters are not the best place to locate a gas boiler. In this case, the best solution seems to be to place this very gas boiler in the basement of the house. But what are the requirements for a boiler room? How to make sure that all SNIPs and state standards are observed?

What should be the premises?

Having decided to make a boiler room on the basement of the house, it is necessary to take into account some of the requirements that are usually imposed on such premises. Regardless of the location of the future boiler room, the following standards and requirements apply:

- The height of the room should be more than 200 cm. The ideal option is 250 cm.

- The premises must be separated from the living rooms. Installation of gas equipment in a room adjacent to the living room is prohibited.

- 1 boiler (of any type) in the boiler room must have at least 4 m2 of space. In addition, the system should be located more than 1 m from the wall.

- It is necessary to provide full access to any part of the gas boiler from any side, so that, if necessary, it can be quickly turned off or repaired.

- The boiler room must have a window facing the street. The window size cannot be less than ¼ m2.The best option is 0.03 m2 per m3 of the room.

- The doorway in the boiler room must be comfortable and safe (at least 80 cm wide).

- The flooring must be made of cement screed in order for the floor to be solid. It is not recommended to lay linoleum, laminate or other combustible materials. The ideal option is tiling the floor and covering it with special refractory materials.

- Wall and ceiling surfaces should also be made of fireproof materials and finished with tiles or plaster. If there are materials near the firebox that can potentially burn or deteriorate under the influence of temperature, they must be covered with shields with insulation material.

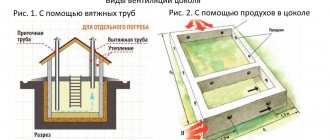

- At the entrance door to the boiler room, it is required to provide for the presence of a ventilation hole, which is usually located at the very bottom of the door leaf.

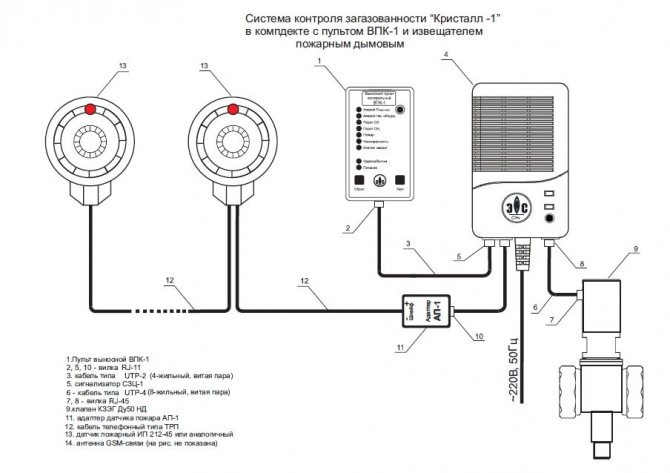

- A mandatory requirement is a device in the boiler room ventilation of the supply and exhaust type.

- Also, the requirements for the installation of a boiler room on the basement provide for restricting access to the premises for persons who are not involved in repair work or maintenance of the equipment installed there. Access of children and pets to the boiler room is prohibited.

All the requirements that have been described above are designed, first of all, to ensure a high level of security for living in a private house. In addition, they allow you to operate the heating equipment in an optimal way. If these requirements are neglected, then the risks of an accident, fire and other emergencies are seriously increased. The boiler room, in most cases, is a small room in area, therefore, when conditions are favorable for the outbreak of fire, it appears there quite quickly.

Wall and floor coverings must be non-combustible.

The requirements for the volume of the boiler room only apply if the boiler has an open firebox. If the boiler's furnace is closed, then the volume of the boiler room can be any. More than 90% of modern boilers have a sealed furnace, however, if you are using an old unit, then the volume of the room should be as follows: 7.5 m3, 13.5 m3, 15 m3 with a heating capacity of boilers up to 30, 30-60 and 60-200 kW, respectively.

To determine the volume of the room, we multiply the area of the boiler room in the basement by the distance from floor to ceiling. In the manual for gas equipment, there is always an indication of the heat output of the boiler. A modern gas boiler in the basement of the house can be placed at any volume of the room. If the boiler room will be located in the basement, basement or ground floor of a building, it is necessary to provide for an exit to the street. In the event that it is supposed to make another entrance from the house, the door there must be finished with fire-fighting materials.

When the building has already been built, and it was not possible to find a suitable room for the boiler room, it is not recommended to allocate living rooms for these needs. The best option in this case is the construction of a separate building. At the same time, you need to take into account some of the rules and restrictions that have been described above.

Fire safety requirements for solid fuel boilers

Rules for solid fuel heating systems:

- the supply of coal, firewood, peat, sawdust, pellets for equipping with a capacity of 1.16 MW and the process of extracting slag, if its volume is more than 150 kg / h, is mechanized (belt conveyors);

- recommended compacted soil for fuel storage areas;

- warehouse capacity: 2 - 14 daily stocks under item 13.12 SP 89;

- stacks are placed 5 m to the fence, 2 m - to the railway tracks, 1.5 m - to the road;

- in warm objects, wet cleaning is allowed (water wash);

- the volume of bunkers: for coal - a reserve for 3 hours; for peat - by 1.5.

Communications

The room equipped for the boiler room must have all the required communications for optimal operation of the system.The boiler room of a private house must fully meet fairly stringent requirements: it is necessary to bring not only gas and water supply there, but also a sewage system with electricity. In addition, when making communications, the following requirements should be observed:

- It is necessary to install a single-phase power network with a standard rated voltage and a maximum current of 20 A. Also, grounding and an automatic device must be installed. In addition, do not forget about high-quality insulation on the wires.

- If one boiler is installed, then the installation of one shut-off unit, which is placed on the gas main, is enough. When there are 2 or more boilers, each one needs to install its own shut-off unit.

- The water supply in the boiler room must work in the same system with the hot water supply of the building and the heating system. In this case, the boiler room becomes a room in which you can install not only a boiler, but also perform any work.

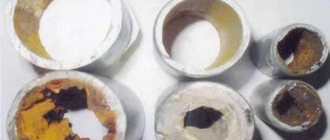

- In water supply systems, ventilation, as well as in chimneys and boilers, it is required to provide a device for eliminating condensate and other moisture. This is a very important point for an instant water drain system.

- State standards clearly regulate the communication indicators for boiler rooms on the basement floor, so it is advisable to familiarize yourself with them before starting work.

The choice of heating devices

Optimal system operation is impossible without the required communications for the equipment. Installing a boiler room in a private house is a complex process, for the implementation of which it is necessary to take care of the supply of gas, water supply, sewerage and electricity.

First of all, you need to take care of conducting a single-phase electrical network, which has a standard rated voltage and a maximum current of 20 A. Another important condition is high-quality wire insulation, grounding and installation of the machine.

If there is one boiler on the basement floor, then one shut-off unit will be sufficient. It is installed on the gas main. When installing two boilers for each unit, you will have to use a separate shut-off unit.

Care should be taken to connect the water supply to the general hot water supply and heating system. This will allow you to use the boiler room if you need to perform other work.

Condensation collects in the water supply system, ventilation, chimney and boiler, therefore it is necessary to use a device that removes excess moisture. This issue cannot be ignored, since state standards contain regulated indicators for boiler rooms in the basement.

Wall-hung boiler installation

If you want to install a gas boiler for a private house with your own hands, then the first step is to choose the type of equipment: a floor-standing or wall-mounted boiler. Each of them has its own advantages and disadvantages.

The fixing of the boiler to the wall should be as reliable as possible.

Next, we will talk about installing a wall-mounted boiler:

- Choosing a place for installation. It is necessary to provide for the moment that for other equipment the distance from the boiler wall should exceed 20 cm. In addition, a small indent of 30-50 mm will have to be made from the wall (depending on the boiler power). It is allowed to mount the boiler on the wall above other equipment located on the basement of the house if there are several units in the boiler room.

- Before installation, it is imperative to check whether all the necessary elements for work on site: installation project, instructions, mounting brackets, screws, etc.

- A plate with all the technical characteristics of the unit must be placed on the boiler lid. Before installation, it is necessary to check the indicated figures with those shown in the instructions and on the packaging. If everything matches, then you can start editing.

- If the walls on the basement of the house are made of wood or any other material that is exposed to fire, then a shield made of insulating material with a thickness of 3 mm or more must be installed between the wall and the unit. In addition, it is required to provide a distance from the boiler to the wall of 50 mm.

- Next, the brackets are attached. It is best to fix the brackets with dowels. The instructions always indicate the scheme according to which it is best to do this. It should be noted that the wall-mounted boiler is recommended to be mounted according to the rules at a height of 80–150 cm above the floor.

- Then the mounting strips are attached to the boiler. Fastening can be done in different ways (everything will depend on the specifics of the unit and the manufacturer). As a rule, ordinary bolts or self-tapping screws are used. In this case, there will be no incomprehensible details.

- Before hanging the boiler on the brackets, it is necessary to rinse all the pipes of the unit with cold water in order to remove particles from them that have entered the system during the production and transportation of the equipment.

- The boiler must be hung on the pre-installed brackets using the fixing bar. This is done as indicated in the instructions provided by the manufacturer. The boiler must be placed horizontally, otherwise operational problems may occur.

- We find a pipe that supplies water to the heat exchanger, after which we mount a special filter on it to prevent the boiler from clogging up during operation. The filter on both sides must be equipped with ball valves, with the help of which, if necessary, you can quickly repair and service the equipment.

- Gas-type boilers are connected and put into operation only by licensed employees of the relevant companies, so you cannot do this yourself.

The boiler room of a country house may have several boilers at once, if, for example, the house is multi-storey or large, or heating of neighboring outbuildings is required (garage, barn, etc.). In this case, the requirements change slightly.

Floor standing boiler installation

Before starting the installation of the unit, it is required to arrange a foundation cushion or support frame for it. The boiler room in the basement, by and large, can be finished as you like. In addition, at the same time, a place is being prepared for connecting the pipeline and chimney.

If your experience is not enough to carry out installation work, trust the specialists.

- The boiler is being installed in a previously prepared place. Many units are equipped with comfortable screw feet, with which it is necessary to set the boiler horizontally.

- After a simple installation of the boiler, it is necessary to connect it to the return and supply pipes, which will lead to the circulation system of the unit. If the gas boiler is double-circuit, then it is necessary to bring a water pipe to the heat exchanger and perform flexible piping of the system. In addition, a cleaning filter must be installed on the return pipe to prevent rust from entering the equipment.

- Further, the boiler is connected to the gas supply system and the chimney. In most cases, these works are performed by professionals, and not by their own hands, because at this stage there are many technological features of the equipment that must be foreseen during installation.

- As soon as all installation work is completed, it is recommended to once again check the tightness of all seams and joints of the boiler. Usually, a soapy solution is used for this, which is applied to the joints.

As in the case of a wall-mounted boiler, all connection and commissioning work should only be carried out by professionals. This is the guarantee that all the necessary requirements will be met.

Exhaust from the boiler room

Solid fuel plants are equipped with flue gas cleaning systems (ash collectors).The flues must be free from ash deposits. When using wood fuel, "wet" spark arresters are installed. Each boiler is equipped with draft units (smoke exhausters, fans).

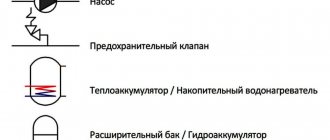

Supply ventilation should provide 3 times air changes in 1 hour and sufficient oxygen supply for the burners. For each kW, 8 cm² of the cross-sectional area of the ventilation duct is required or 30 cm² if air is taken from the building system.