The need to attach a boiler room to a house from a bar arises in different situations for different reasons.

- Firstly, in the project you like, the original layout does not provide for such a room.

- Secondly, the house was planned as a non-residential, summer cottage, and later heating was needed.

- Thirdly, the project of a log house was deliberately selected so that there were no fire-hazardous boilers in the residential area.

One way or another, there is only one way out of all sorts of situations, including those described, - to attach a boiler room to a log house. This event may seem simple only at first glance, and does not require detailed study. It would seem that it could be simpler - he added the walls by 2 meters, covered them with a roof, installed a boiler and brought pipes into the house. However, if this issue is faced in practice, a lot of problems arise.

The main problems of the boiler house attached to the log house

In order not to overlook anything and return to this material, if necessary, like a cheat sheet, all information will be arranged "on the shelves":

- Fire safety. The boiler room is a high-risk room. Given this problem, what material to choose for the walls of the extension? If it is wood, how to protect it from fire?

- House shrinkage. The problem is relevant only for those cases when the extension begins to be built during the period of the most intense shrinkage of the timber. The structures of the boiler room and the pipes connecting it to the house should not interfere with shrinkage, and even more so suffer from it.

- Boiler room level. To equip the most efficient heating system, the boiler must be located below the level of the radiators, that is, in fact, below the basement of the house.

- Foundation. How to make, from what, and is it needed at all for such a structure as an attached boiler room?

- Physical binding of the extension to the house. So that communications are not broken at the point of passage through the border of the extension with the house, the first must somehow be "attached" to the second. In addition to pipes, an aesthetic moment should also be considered here - the gap between the boiler room and the house will not suit anyone in the future.

- Warming. Not every boiler will be able to heat even a small extension by itself, and it will not always work at full capacity. How to solve the problem with the possibility of water freezing in this room?

- Other problems. What dimensions should the extension be made, on which side the door should be, whether it is necessary to have a window and so on.

All these questions are given short and clear answers below. To form the information below, not only official data from generally accepted norms and rules were used, but also the experience of real people who already use a boiler house attached to a house from a bar.

Installation of modular boiler rooms

← previous articleTechnical conditions for gas (TU for gas) Technical conditions for gas is a document that allows owners of a boiler house to connect it to the central gas supply system ... the boiler room will work. The composition of the included auxiliary elements is related to whether the boiler room will be gas, liquid or solid fuel, two ...

Author: Alliansteplo

Date: 04/14/2015

The installation of modular boiler houses is carried out at the supplier - the boiler houses are delivered to the connection point already assembled, with a configured operating mode, therefore, their connection to the heated facility is carried out within a few days.The only thing left for specialists to do is to put the modular boiler room on the foundation prepared in advance.

For quick and easy connection, all block boiler houses are equipped with special systems:

- heating and fuel supply pipelines equipped with outlets;

- power supply cable equipped with a receiving device;

- drainage pipeline.

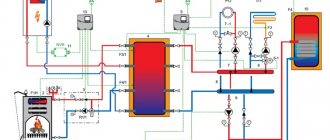

The installation of boiler rooms at the plant includes the equipment of the unit with the equipment necessary for the operation of the system. Inside the block boiler room are installed several boilers (their number varies depending on the needs of the customer) connected to a common fuel line. The boiler room is supplied with water from the water supply network or from a water carrier, if there is no water supply at the place of deployment.

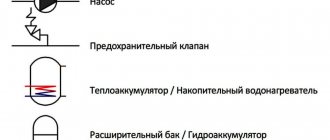

In addition to boilers, the installation of turnkey block boiler houses implies installation of heat exchangers, whose task is to transfer heat energy to the heating system. Traditionally, pressure gauges are located at the inlet and outlet of heat exchangers to monitor the pressure. To pump hot water from boilers to the heating system, circulating pumps, usually in the amount of two pieces: working and standby, so that in the event of a breakdown of the working pump, the standby one will automatically turn on. All heat exchangers and pumps are additionally equipped filters for water purification.

If a block boiler room operates from the mains, its system is additionally equipped with emergency power supply unit - usually a diesel generator. Its task is to maintain the efficiency of the boiler room in the event of power outages. When installing a modular boiler room, it is provided ventilation systemdesigned to cool the generator. Ventilation of a block boiler room includes:

- ventilation openings with windproof shutters;

- heat heaters;

- gas concentration sensors;

- internal temperature regulators;

- exhaust fans, shut-off and safety valves, etc.

Control the entire block boiler house comes from a special point, which ensures the most uninterrupted, reliable and safe operation of all systems. In most modular boiler houses, the automation does not imply regular operator intervention: the boiler room can operate independently in accordance with the set parameters.

And the last point in the installation of a modular boiler room - chimney installation... The pipes are usually made of stainless steel and are led out horizontally through the side wall, joining the outer chimney pipe. The height of the pipes can be adjusted depending on the operating conditions of the modular boiler house.

Himself block made of insulated sandwich panels.

Installation of modular boiler rooms is a fairly simple procedure if it is performed by professionals. The design of the modular boiler house itself minimizes the possibility of making a mistake in the process of its installation on site, and preliminary design work carried out by competent specialists practically guarantees a trouble-free installation and timely launch of the modular boiler house.

For all questions, please call 8 (495) 781-81-55

In order to calculate the cost of a complex of necessary services or buy a boiler plant, send a completed questionnaire.

To calculate the cost of the boiler room, please fill out the questionnaire for the boiler room. The questionnaire can be completed online or downloaded. For any questions you may have: multichannel telephone e-mail

Fill out the questionnaire online

Calculate the cost of the boiler room

You may also be interested in

List of required documentation for obtaining limits and technical specifications for gas To obtain limits and technical specifications for gas consumption, you must: perform a heat engineering calculation in the prescribed form ...

How is heat energy generated by boilers? In other words, how do boiler plants work? Let's look at the principle of generating thermal energy using the example of a hot-water boiler house and at the same time find out which equipment is responsible for what.

Pros and cons of rooftop gas boiler houses Rooftop gas boiler houses appeared in Russia in the early 2000s and are still quite popular today. The main reason for the demand is low heat loss due to the absence of long heating mains, on which an impressive amount of energy is lost.

Boiler house reliability Boiler house reliability is the ability of the system to produce and distribute heat carrier among its consumers under normal operating conditions. The main criterion for reliability is the failure-free operation of the entire boiler house as a whole and each of its elements in particular.

Boiler systems Today it is impossible to imagine life without a boiler system even in the warmest corners of our country. In most apartment buildings, central boiler houses have long deprived us of almost all the problems associated with hot water and heating radiators ...

Foundation and physical anchoring to the house

The foundation is required for a boiler room of any size. It is advisable to perform it so that it is physically tied to the base of the house. Since the boiler room must be below the level of the house, not every technology is suitable for arranging the foundation. The optimal, affordable and proven option is tape.

The walls of the boiler room must be tied to the house. To do this, you can use almost any available fixtures and fittings. It all depends on the wall materials and other conditions.

Features of the choice and installation of doors

If you are not going to attract specialists to install a solid fuel boiler, you will have to prepare yourself for work.

First of all, you need overalls and tools:

- overalls, leggings and welding mask;

- welding machine;

- circular saw with cutting discs for metal;

- building level and square;

- set of open-end wrenches;

- adjustable wrenches;

- screwdriver with a set of different attachments;

- tape measure and marker;

- sealant gun.

To connect the boiler to the heating system, you need to additionally purchase:

- 2 ball valves with a squeegee and double-sided (external and external) thread with a diameter of 50 mm;

- safety group (pressure gauge, safety valve, automatic air vent and a pair of ball valves with a diameter of 15 mm);

- 3 steel couplings with a diameter of 50 mm;

- steel adapters 57-32 mm;

- steel bends with a diameter of 50 mm;

- chimney with gate valve;

- metal pipes for connecting the boiler;

- heat-resistant sealant;

- plumbing reel;

- circulation pump (installed on the return line and provides forced circulation of the coolant in case of natural difficulty).

The most important thing when installing a heat generator is to follow the provisions of the manufacturer's instructions. Before starting installation work, it is necessary to assemble the heating system and check it for leaks, as well as organize ventilation and a smoke exhaust system in the boiler room.

Features of production

Kotlostroyservice - certified modular boiler house 2.5 MW

A block diesel, solid fuel or gas boiler house is not produced at the factory fully assembled. The manufacturer only complements the main unit with heat generators and auxiliary equipment. In the basic configuration, the systems are one or more boilers, water treatment lines, sediments and electromechanical units.

Installations from several manufacturers are in demand on the territory of the Russian Federation.

Rosenergoprom

There are representations in Novosibirsk, Kemerovo region, Yekaterinburg. They produce solid fuel, gas, fuel oil and diesel boilers. Furnaces of devices - manual or mechanical type. They are engaged in the design and installation of systems.

Kotlostroyservice

There are representative offices in many cities, including Moscow, Izhevsk, Voronezh, Novy Urengoy. The production of block modular boiler houses operating on diesel and gas has been established since 1998. The line of free-standing, attached equipment, single and twin boilers is represented by models with a capacity of 100 kW - 5 MW.

Buildkomplekt

Stroytekhkomplekt, model BMK-0.1 "Economy"

Production is concentrated in Yekaterinburg. The enterprise produces mobile and stationary boilers for any type of fuel, provides services for design, installation supervision and commissioning of BMK.

EnergyLeader

A manufacturer with a representative office in 4 cities of the Russian Federation, which produces hot water and steam boilers. Carries out a set of works on their design, commissioning, training of service personnel.

AllianceHeat

Brand from the city of Stary Oskol, performing the construction of turnkey systems with a capacity of 1-60 MW. Provides design services for boiler houses with further commissioning. The units operate on natural gas diesel fuel, fuel oil, and are connected to 220 and 380 V.

Enterprises are required to provide buyers with documents on compliance with GOST, SNiP and PPB, as well as certificates of conformity from Rostekhnadzor.

Overlap and roof

The pitched roof type is compatible with almost any roof of the house, therefore it is the most common configuration. We will consider it.

- The rafters are installed with one end under the slope of the roof of the house, and with the other they are supported on the wall of the veranda. Fixed with metal corners. The main thing is to choose the exact angle of inclination.

- The rafter legs should protrude at least 30 cm beyond the wall boundary. Such a roof overhang will protect the veranda walls from precipitation.

- The issue of roofing is decided in advance. Usually the material that covers the house is chosen. Under the soft roof, solid material is laid on the rafters: plywood, OSB sheets or frequent lathing. Slate or metal tiles are laid on the rafters if the joists are installed with a small step.

- The structure is covered with waterproofing, which is selected individually for the coating material.

- Roofing starts from the bottom of the rafter.

- For insulation, mineral wool is used, which is laid between the rafters. Sew up the ceiling with boards or panels and decorate.

Roofing material is selected based on the financial capabilities of the master. The cheapest today are ordinary slate sheets 175 cm long. Up to 30 sheets of material can go to the roof of one small extension. The exact amount depends on how large the overlap of the panels will be - on average, the sheets are laid with an overlap of 5-10 cm.

Slate can be replaced with other materials - today the market offers many roofing options. The most affordable option for roofing is the use of rolled roofing material. We recommend using it only in cases where protection from moisture or cold is not required from the frame extension.

We offer you to familiarize yourself with the Trencher for a walk-behind tractor

Boilers with gas heaters

The use of gas fuel, the most popular among private home owners, requires a significant number of requirements to be met.

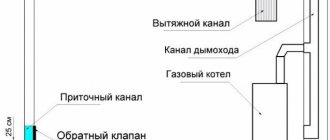

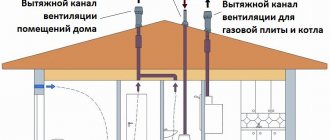

It is necessary to properly attach a gas boiler room to the house because of the high explosiveness of the energy carrier used. It is especially important to pay attention to the following points:

- standard parameters of the volume of the room - 15 cubic meters, and the area - from 6 sq. m;

- the presence of proven natural ventilation;

- the height of the ceilings must be at least 2.5 m;

- area of window openings - from 0.5 m;

- connection to the sewerage system for the drainage of condensate and emergency drains;

- a prerequisite for installing a chimney - it must be higher than the roof ridge. For the convenience of cleaning, the ventilation system is equipped with additional channels.

What technology for construction should be applied

Based on our own experience, we can offer you the most advantageous construction option - frame construction. Why exactly he? It just so happened that this method of construction has a number of advantages over other construction methods. Namely:

- Turnkey construction speed;

- Possibility of parallel finishing;

- Saving on the foundation;

- Warm walls;

- Favorable cost of work and materials.

So, let's briefly find out what you need to focus on in the first place if you plan to add a boiler room to a private house. The very first thing with which to start such a production is to draw up a plan of the facility. It should reflect all the dimensions of the outer walls of the room, and also indicate the configuration of the roof. It is also important to study the condition of the soil in the suburban area and the strength of the main foundation of the existing house.

Further, the technical assignment for the object and the estimate are already being drawn up. All upcoming stages of work must be agreed with the customer without fail - he must be aware of how and from what material the extension of the boiler room to his country house will be made. It is also important to choose a technically correct foundation - it should be combined with the foundation of the main house in its characteristics, otherwise deformations will appear at the joints of structures with each other after each winter.

Extension by a boiler house or a work brigade

If you have never encountered such a turnkey construction before, then you must first get detailed advice from the relevant specialists so that you can make a decision: whether you can implement this object with your own efforts, or will it require the intervention of experienced builders. And this is a very serious and responsible step: it will definitely help you in the implementation of a quality object, regardless of the final decision.

As practice shows, rarely when the customer does everything himself. It is more profitable and easier to attract professionals for this. But the cost of work is different for everyone, since the quality of their result is very different, as well as the guarantees. For example, an ordinary editing team will do the job for you, and then you will never be able to find it. But if a construction company is involved in the business, then the concept of guarantees will be an urgent issue for you and they will be fulfilled in case of any questions.

Experience is also a very important role in all construction. See for yourself: the one who has more practical knowledge - the one who has more efficiency. And a significant amount of work performed is available from a specialized company that is actively engaged in this issue at a practical level. And the usual assembly team, which works by itself, does such construction work very rarely - and therefore does not know many of the nuances of such construction.

By the way, such work can be attributed not only to new construction. This is also the most important stage in the complex of works, with the help of which the reconstruction of the house is realized. Such work is performed when the existing house is rebuilt, and therefore its configuration changes in this process and new areas are added. Next, we will describe the technical part of the boiler house production.