What are pellets

Pellets are an energy carrier obtained from the remains of natural raw materials by a technological method, which is in the form of granules. Fuel cells come in different fractions, with a diameter of 0.4 to 1 cm and a body length of 0.315 to 5 cm. Typically, a production line is designed to produce pellets from a specific material, so several types of such fuel enter the market.

Why are briquettes better?

Their main advantage over firewood is an affordable price and high heat transfer. For example, the heat transfer of firewood with a humidity of 20% is about 3000 kcal / kg, and a briquette - 5000 kcal / kg. Compared with wood, the moisture level of briquettes is 3-4 times lower, this is achieved due to the fact that they are almost completely dried. High density provides excellent heat transfer, they also emit less soot, ash and do not pollute the chimney, burn evenly, which is achieved due to a uniform and homogeneous structure.

Pressed products take up less space, are compact, and if we compare what is better for heating - firewood or fuel briquettes, then it is worth considering the disadvantages of each type of fuel.

Artificial firewood is sensitive to moisture, has a higher cost and very often the quality does not meet the standards.

It is very difficult to distinguish between a visually good briquette and a low-quality one, since outwardly it is simply impossible to determine its composition. Waste from soft wood, low-quality wood can be added to briquettes, which, as a result, significantly reduces heat transfer.

What are the pellets for the boiler

The type of granule depends on the material from which it is obtained. From this pellet has its own name:

- Woody;

- Coal;

- Peat;

- From the remains of vegetation;

- Thatched;

- Corn;

- From bird droppings (chicken);

- On the basis of waste paper;

- From solid household waste.

Wood pellets for boiler

The most popular and consumed product. For the manufacture of pellets of this type, both coniferous and deciduous tree species are used. Any waste obtained in the process of woodworking is suitable as raw material:

- Sawdust;

- Shavings;

- Sawdust;

- Pieces of scraps;

- Croaker.

"White" pellets made of wood without bark inclusions have the lowest ash content, which is why they are highly valued. "Gray" wood pellets, which contain bark, are mainly used for powerful boilers. They are relatively inexpensive, their ash content is higher.

Coal dust granules

Unlike wood pellets, where particles are retained by natural resins, carbon granules are pressed in a special way, with the addition of a binder. The method is called spiral pressing.

The result is a solid fuel suitable for use in any pellet boiler. One of the advantages of such a material, in addition to its high calorific value, is good transportable qualities - coal pellets are not prone to shredding during transportation.

Peat boiler pellets

Peat pellets contain pure peat and retain their shape due to internal binders that are activated when squeezed. They are fragile, so their diameter cannot be small and reaches a size of 12 mm. This type has a high energy consumption, economy in use. For example, if you burn a ton of material, the heat will be released exactly as much as when burning 475 cubic meters of natural gas, 1.5 tons of wood or 500 liters of diesel fuel.

Pellets from plant residues

Another name for such fuel is agropellets.They look brown in color, the raw material is agricultural waste, namely, buckwheat husks and sunflower husks.

Due to the fact that the initial material contains particles of sand, earth, dust and other non-combustible components, the agropellet has a high ash content. Its use is justified only for heating industrial enterprises. The price here is much lower if you take other material for comparison.

Straw pellets

In terms of density, calorific value is equal to wood pellets. They are cheaper than them, but have a high ash content up to 5.5%. After pressing, the pellet is resistant to moisture penetration, which has a positive effect on the fuel's ability not to deteriorate during storage.

Pellets from corn stalks

Although corn stalks can be classified as products of the agrosphere, pellets from them are fundamentally different from agropellets due to their relatively low ash content, which is only 2.6%. Additional advantages include a very long burning time, high density and caloric content. Due to its low weight, such a product is easy to pack, load and transport.

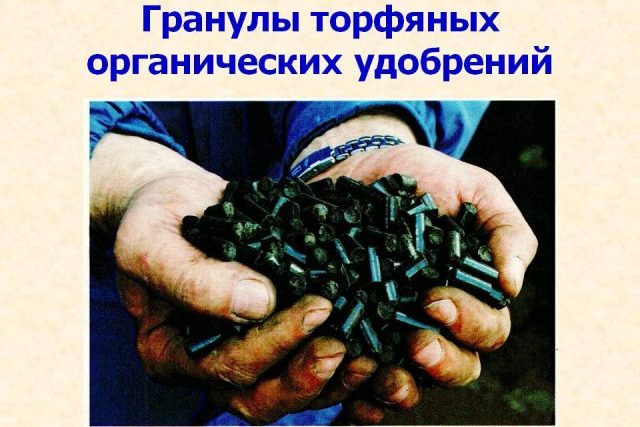

Pellets based on chicken manure

Possible option of dual use of pellets from poultry manure - as fuel and granular fertilizers. Due to the high humidity, the raw materials are first dried in special rooms, and then crushed and pressed.

Such pellets contain many non-flammable inclusions, they are not suitable for work in private boilers due to their high ash content. It is most practical to use the product as a fertilizer - the droppings absorb moisture well and gradually release it to the plant roots.

Paper pellets for boiler

To obtain granules from waste paper, a more complex technological process is used. Unlike any other raw material, paper needs to be moistened first before pressing.

What is more profitable to buy: pellets or birch firewood of annual drying

To count, you need to know the following. Any firewood: birch, spruce, aspen with the same moisture content has approximately the same calorific value. Although there is an opinion that aspen firewood gives little heat - this is a delusion, the difference in the calorific value of different types of wood does not exceed 3% (the smallest in aspen, the largest in pine among those common in the middle lane). This opinion is due to the fact that aspen has the lightest wood and, with the same volume, it actually gives less heat than birch, which has the densest wood. Firewood is measured in solid and foldable cubic meters. A dense cubic meter is an abstract cube made of wood with 1 meter edges, i.e. wood without air gaps. A folded cubic meter is the geometric volume of a real cubic woodpile with 1 meter edges, i.e. there is air between the logs. In practice, you can also encounter the so-called. bulk cubic meter is the volume of logs in the back or in a dumped unstacked heap. Firewood sellers often use ignorance of buyers and, referring to the existing prices, they sell a stacked or bulk cubic meter of firewood at a price of a solid one.

Conversion factors (approximate):

tight / fold = 1.0 / 1.3 tight / bulk = 1.0 / 1.7

The moisture content of well-dried wood is about 20% (relative humidity). The calorific value of birch at this moisture content is approximately 3600 kcal / kg.

The density of birch at 20% humidity is approximately 550 kg / dense meter.

Total: 1 solid cubic meter of birch firewood = 550 kg = 1980 Mcal 1 fold cubic meter = 423 kg = 1523 Mcal 1 bulk meter = 323 kg = 1163 Mcal

Those. 1 ton of pellets (4200 Mcal) is equal in calorific value to 2.12 cubic meters of birch firewood; 2.76 storage cubic meters; 3.61 bulk cubic meters.

For spruce and pine firewood, add about 20% to these data, and about 30% for aspen firewood (due to their lower density).

To accurately calculate the ratio of the cost of heat contained in firewood and pellets, substitute the price of firewood in your locality (just keep in mind that firewood from freshly cut wood has a moisture content of about 50% and a calorific value of about 1930 kcal / kg, i.e. almost 2 times less than dry wood

and reduce the service life of the boiler

).

And one more point: the efficiency of a good pellet boiler is 93%, a Russian stove is 25-40%, a wood boiler is 40-80%, so when comparing a wood and pellet boiler, feel free to multiply the results by 2 in favor of a pellet boiler.

Here is an approximate calculation in Belarus for January 2014, after calling several companies, the following came out: 1 cubic meter of birch firewood of natural moisture (alder and oak is more expensive) costs 550,000 rubles.

When calculating, we get: 1 folded cubic meter of firewood of natural moisture (50%) = 0.65 tons x 1930 kcal / kg = 1.255 Gcal. = 550,000 rubles. 1 ton of pellets x 4200 kcal / kg = 4.2 Gcal = 1,300,000 rubles. (pellets of our production in bags).

Total: 1 Gigacalorie of heat from wood costs 438,247 rubles, 1 Gigacalorie of heat from pellets costs 309,523 rubles. The ratio is 1.4: 1 in favor of pellets, i.e. heating with pellets is one and a half times more profitable than wood.

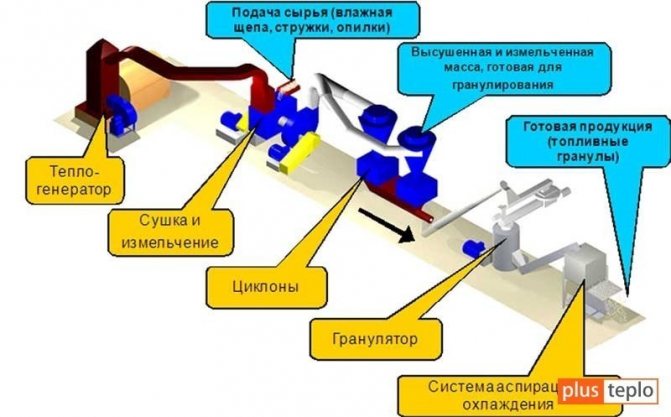

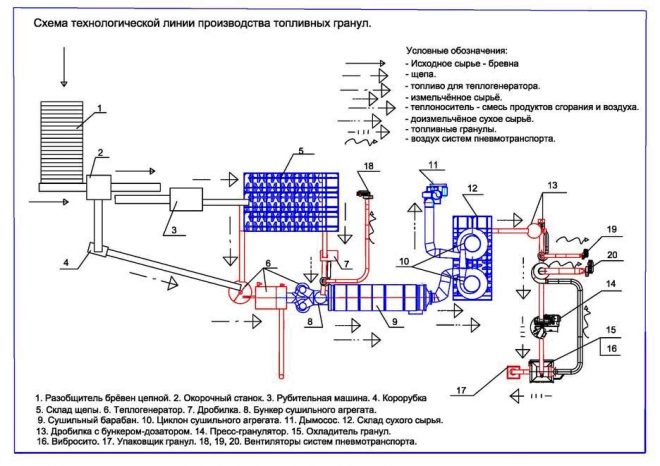

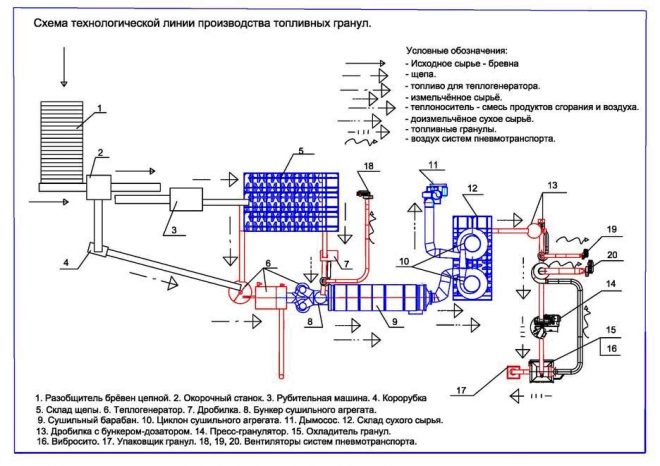

How pellets are made

When making pellets for a boiler, the raw materials must go through a certain technological process on the production line. The main stages of this process, using the example of obtaining wood pellets, are as follows:

- Crushing into coarse fraction - at this stage, woody parts of different sizes lead to a state of homogeneous mass by a crushing plant;

- Grinding into a fine fraction using a hammer mill - the particle size of the resulting raw material should not exceed 6 millimeters;

- Drying to the state of material moisture content in the range of 8.0 - 10.0% in belt and drum drying installations;

- Pressing in a pellet mill. At this stage, the mass is heated to a temperature of 120 degrees Celsius and pressed through the matrix;

- Cooling (if necessary) and packaging of the finished product.

In the manufacture of agricultural pellets from sunflower husk, the stage of raw material crushing is excluded from the technological process.

Heating pellet production: main stages

You can make this type of fuel yourself. The main thing is to understand the production technology itself. In total, there are 7 main stages of professional manufacturing.

Stages of creating fuel pellets:

- Grinding material for production;

- Drying;

- Re-grinding;

- Moisturizing the composition;

- Compression of raw materials and addition of water;

- Cooling;

- Packing, labeling and sales.

Grinding is carried out on a special crusher. Then the raw material is dried and re-grinded. After that, the moisture content of the material should be 8-12%. At high humidity, the material undergoes another drying, and when dry, it is moistened.

After that, the material must be compressed. For this, special machines are used. Their design may differ depending on the type of matrix: round or flat.

The principle of operation of devices with different matrices does not differ. The raw material is pressed through special holes in the matrix.

The force and temperature during pressing determine the quality of the initial product. The resulting granules must be cooled. For this, special conditioners are used. After this stage, the fuel is packaged and sent for sale.

Selection of pellets for boiler plants

Industrial boilers are usually designed for heavy loads and are not as demanding on raw materials as their domestic counterparts. In order for the boiler to effectively provide heating of the house on the pellet, in addition to its type, you need to pay attention to the following technical indicators, which must be indicated by the manufacturer:

- Product moisture - for normal ignition and maintaining combustion should be within 8%, over 14% - the material is not suitable for use;

- Heat transfer during combustion - it is better if it is around 4.5 and above kcal / kg, like wood pellets, but 4.3 kcal / kg is also acceptable;

- Ash content of the product - has an upper tolerance threshold within 1%, if this limit is reduced to 0.5%, then the boiler can be cleaned no more than once a month.

In addition to all of the above, the pellets should be visually inspected for cracks.

High-quality material has a shiny surface, does not crumble and breaks with difficulty. When the granules are dipped into water, they should eventually turn into a soggy mass, if this did not happen, it is likely that a chemical adhesive component was used in their manufacture, which is unacceptable. The presence of coarse sediment of small stones and sand also indicates a poor quality of the product.

Where do pellets burn?

Heating boilers for pellets belong to the class of solid fuel boilers. They have a robust housing with a combustion chamber and heat exchanger. Combustion of fuel pellets leads to the release of hot combustion products, which passing through the heat exchanger give it (and it is the heat carrier) heat.

Pellet heating boiler

"Born" back in 1947, pellet boilers have grown significantly in terms of efficiency and "intellectual" development. Pellet boilers today are fully automated systems capable of "relieving" a person from the duties of a stoker for quite a long time (up to a month or more). It all depends on the size of the bunker or warehouse for storing pellets. The self-cleaning function allows you not to "interfere" with the life of a high-quality boiler during the entire heating period.

Pellet boiler construction

An important factor in the distribution of fuel pellet boilers is their high environmental friendliness. After all, pellets are recycled wood, and the process of their combustion occurs with minimal release of harmful by-products. In fact, this is a waste-free "production".

Pellets are an "ecological" product

Pellet boilers, having a high efficiency, a long period of operation, autonomy (from a person), also have a high cost. But the cost of pellets in a few years compensates for the investment in the boiler. The consumption of pellets for heating can be determined from the ratio: to obtain 5 kW of heat, it is necessary to burn 1 kg of pellets. A house with an area of 100 square meters will require 20-25 kg of pellets for its heating.

If necessary, such boilers can be heated with wood, coal, wood chips, straw waste, etc.

Pellet fireplace

The "reverse" application is also possible. If you have a ready-made stove or fireplace, you can heat them with pellets. Recalling the analysis of the properties of fuel pellets, it can be argued that a pellet stove will have a higher efficiency than when working with wood.

Pros and cons of fuel pellets for the boiler

The obvious advantages of granular fuels are that they are easy to transport and store. In addition, granules have:

- High heat transfer, which is 2.5 times more than that of wood;

- Low ash content, which allows you to spend less time on boiler plant maintenance;

- Low percentage of humidity, which has a positive effect on the functioning of the heating system, increasing its service life;

- High density - a smaller amount of such fuel is capable of producing as many calories of heat as another energy carrier with a large volume.

The most significant disadvantage of fuel pellets is that they can only work in special boilers that have an automatic supply of energy to the burner. The price of such equipment is much higher than the cost of ordinary solid fuel boilers.

Storage conditions

When choosing a more profitable fuel, you should also not forget that you need to create favorable conditions for storing stocks of any selected type of fuel.Usually, fuel is purchased in large quantities, for the entire cold season. For example, coal is always accompanied by dirt. Because of this problem, in order to use coal, the boiler room needs to be equipped with an additional room where the coal supply can be stored. But, in spite of this, coal dust still gets into living quarters, and can settle on furniture.

When choosing pellets, the problem with cleanliness is much easier than with coal. Basically, this type of fuel is packed in bags weighing from 40 to 600 kilograms. Wood dust is observed only when the fuel is poured into the boiler. But it can also be minimized even more by installing a stronger device, in which a furnace of a much larger volume will be produced, because the fewer the number of loads in the boiler, the less dust.

For example, there is an option with one loading of pallets, it may be enough for a whole month of constant operation of the heating system. This fact allows you to keep pellets right in the living room, you just have to organize a partition for them.

Based on all of the above, it is impossible to specifically answer the question of what is better and more profitable than coal or pellets. The conclusion can be made by each consumer separately for himself, guided by his personal priorities. If a person's priority is to save money, then coal will certainly do. If in preference the consumer is also inclined towards ecology, ease of maintenance, as well as the cleanliness of his home, pellets are more suitable for such people.

Fire fuel

If you need to create a special atmosphere with the help of a beautiful flame in the fireplace, then a wood fire is ideal, the flame from which is much larger and very beautiful. It should be borne in mind that birch firewood will burn best of all due to the oils contained in the wood.

Birch belongs to hard tree species, respectively, the density of firewood is higher, which has a positive effect on heat transfer.

When heating a fireplace with briquettes, it is better to place them vertically, then the flames rush up. Briquettes, unlike firewood, burn longer and more evenly, and this is ideal for a long-burning boiler and is inferior to using them for an open fire.