Cleaning indiscriminately

The method is suitable if the contamination is not too significant. To renovate the inside of the boiler and remove limescale, you will need:

- fill the tank only 1/3, heat the water in it to 95 degrees;

- open the drain connection and connect the hose through which the cleaning solution will be supplied to the container;

- the hose must be fixed at any point above the tank and left in this position for several hours;

- drain the working solution and rinse the reservoir with clean water.

To completely remove the remaining solution, you will need 4-5 tank volumes, after which the water heater can be used as usual. The water for flushing should be warm - about 25-35 degrees. It is unacceptable to use for any purpose water from a boiler that has not been washed after using a chemical solution.

Tank cleaning

If there is a smell in the water from the boiler, microorganisms are most likely to blame. The ideal environment for them is humidity and warmth. And this is enough in a storage water heater. They also often accumulate near the heating element, where sediment from poor-quality water remains.

Scale is formed mainly on the heating element and the surrounding area. It is dangerous to human health. If you are going to drink water from the boiler. But even if water is consumed only for domestic needs, one should not delude oneself.

Limescale and metal have different coefficients of expansion. Therefore, the heating element wears out due to constant on and off cycles. Scale also interferes with effectively transferring heat to water, reducing the useful power of the water heater.

The upper part of the heating element is most likely covered with dirt, which can be easily removed by hand. There will be a layer of scale (calcium, lime) under it. You will have to tinker with him.

The outer layer of dirt is best removed with a wire brush. knife, etc. But do this carefully so as not to damage the metal of the tube. It is not that too fragile, but still ... When the main contamination is removed, you can continue cleaning with special tools.

Nowadays it is not difficult to buy a descaler. Any of them is suitable for heating elements. But the magnesium anode can only be cleaned by hand. To do this, use the same wire brush or sandpaper.

You can finish cleaning the wet heating element with a folk remedy. Put it in a container and estimate how much water you need to completely cover it. Measure the required volume and add to it:

- Vinegar: 100 ml per 1 liter of water;

- Soda: 50 grams per 1 liter of water.

Leave the heating element to soak for a day.

If there is dirt inside the tank, it can be removed mechanically. That is, wipe it off with your hands. For this, the following are suitable:

- Soda;

- Vinegar;

- Lemon acid;

- Detergent.

Cleaning a removed tank is a safer and more economical way than pouring solutions into it and heating it. You will need very little active ingredient and a regular sponge or dish brush with a long handle. But at the same time, remember a few rules:

- If the inside of your boiler is painted with enamel - do not use hard or metal brushes or sponges;

- Perform all work with gloves;

- If there is a thick deposit of scale, you will have to install the water heater in place, pour the active substance into the boiler and warm it up;

- If corrosion appears on the inner walls, the best option is to clean it with emery and paint over the tank with enamel.

In the first version, the device is disassembled, the heating element is removed, and it is descaled using chemicals or mechanical intervention. The tank is flushed with a special substance.Citric acid solution is the simplest example, however, this is not the most effective option. Further, the design of the device is cleaned of drug residues, assembled, and checked by starting an idle cycle.

The CIP method is the most relevant solution for boilers with a large volume, since their dismantling is difficult and impractical. In this case, for cleaning, the device works as usual, but special substances are added to the water to remove scale, as well as protect the metal components during operation.

With collection

The method is relevant if the scale layer is already too thick and it will not be possible to dissolve it chemically. Before starting work, prepare:

slotted and Phillips screwdrivers;

wrench;

sandpaper;

screwdriver;

cleaning agent.

It is most convenient to dismantle the water heater with an assistant. Do not forget about precautions: use gloves when applying chemicals to surfaces, and special masks to protect the respiratory system from acid fumes.

Disconnecting the device from the power supply and draining the remaining water as follows:

- first of all, close the tap, which is responsible for supplying water to the room;

- the valve that stops the supply of cold water to the water heater is closed;

- a hose is connected to the hot water pipe through which the remaining water is drained.

In the next step, you can start opening the tank. The bottom panel of the device is removed, the wiring is disconnected, after photographing the location of the wires in order to connect them accurately during assembly. The elements holding the heating element are unscrewed and removed: first, the bar bolts are unscrewed, and after removing the remaining water, the heating element is taken out. If there is too much scale, and it interferes with the removal of the heating element, it is permissible to scrape it off first with a knife, and then pull out the part.

The heating element that is now in the hands can be cleaned in 2 ways:

- Mechanical - used with a loose layer of scale. Most of the plaque is removed with a knife, and the rest is scraped off with sandpaper. However, the heating element must not be polished too much, as there is a risk of damaging it. Scale needs to be removed while it is still damp, as it will be less susceptible after drying.

- Chemical - the scale is scraped off with a knife, and after the heating element is placed in a solution to remove such deposits. There he remains for several hours.

Principle of operation

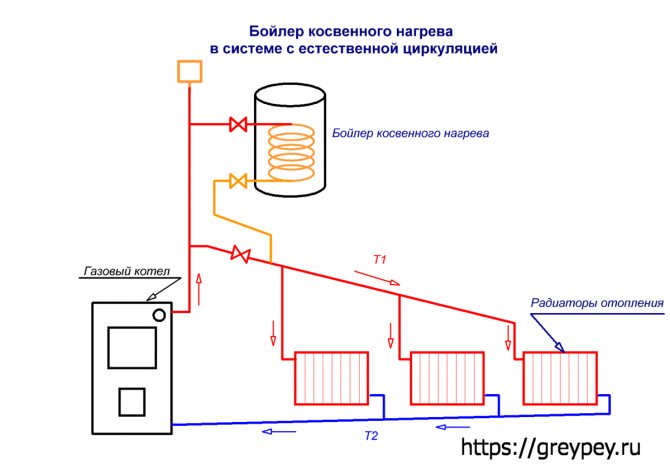

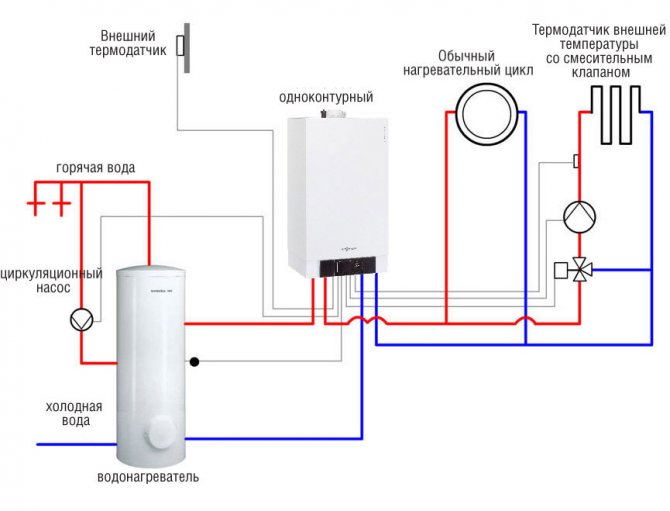

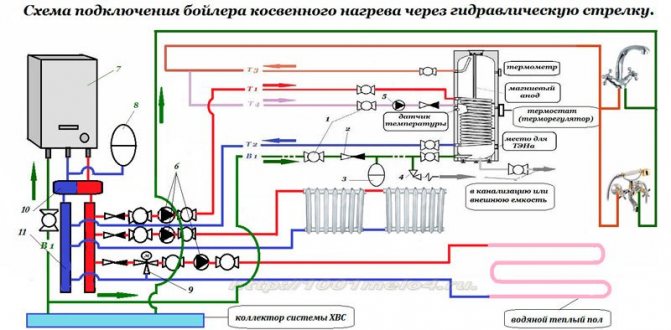

Single-circuit gas boilers with an indirect boiler operate in two main connection schemes. The principle of operation of the first is as follows:

- The three-way valve dominates here. A pump is installed directly into the outlet of the gas boiler, which circulates and builds up pressure. The next step is to install a three-way valve, which is connected to the boiler thermostat. When heating tap water or other coolant, its flow is directed to the heating system, and priority is given to the ingress of hot medium into the boiler coil. This is done using an additional, second pump. And it turns out that in this case the hot water supply and the heating system are connected in parallel, and they can form two circuits, in this closed chain. And after the boiler, an additional pump is installed, which helps to regulate the operation of the thermostat. The principle of starting and stopping the process is also controlled by a thermostat, namely, with strong heating, a forced shutdown of the fuel supply occurs, when the coolant cools down, the fuel is passed through again, and the burner is automatically ignited.

- If there is no double circuit and priority is not given to heating hot water, the boiler is mounted in a common system, installed in a convenient place, and water is heated on a par with all radiators.

You will be interested >> Advantages of a double-circuit floor-standing gas boiler

Professional cleaning

Any used agent, which contains alkalis and acids, can completely remove old scale and rust.

When cleaning water heaters, the following means are used very often:

- salt;

- silite;

- filtero;

- master boiler;

- topperr 3031;

- bagi Kumkumit;

- eon Bio.

Before using these drugs, you must carefully read the instructions. If the concentration of the substance is too high, the water heater may fail.

When is it time to clean the boiler?

As a rule, the water heater gives “warning signs” 2-3 years after installation. During this time, a layer of lime accumulates on the heating element.

The fact that the boiler needs cleaning may be indicated by:

- increase in energy consumption and water heating time;

- there was a hiss during the operation of the device;

- the water has lost its transparency, it seems rusty;

- the water smells like hydrogen sulfide;

- floating scale particles are visible in the water;

- the tank cover has started to heat up.

If in the area where you live, the water hardness is higher than 350 mg / l, then it is recommended to clean the inner surface of the water heater once a year. Sometimes the water is very hard, so additional cleaning is required at intervals of 5-6 months.

Causes of dirt deposits

Scale appears as a result of heating water containing calcium and magnesium. When heated, they fall out on the surface in the form of a soft and porous sediment. Over time, it accumulates particles of clay and sand, hardens and becomes a ceramic dense and difficult to remove deposit called scale.

The largest scale deposits in a boiler with heating elements are formed on heating surfaces. They have strong insulating properties. Such an element, covered with scale, reduces heat transfer, which reduces the efficiency and increases the excessive consumption of the energy carrier.

Studies have shown that scale deposits of 3 mm reduce heat transfer by up to 30%, isolate the heating element from water, followed by overheating. According to consumers, scale in the boiler is the most common cause of an emergency stop.

We offer you to familiarize yourself with Dry carbonic baths: indications and contraindications, medicinal properties, what are the benefits of mineral, dry-air, Reabox. Reviews and price

The temperature of the metal surface washed by water and having a scale of 5 cm is 3 times higher than that of clean water and significantly exceeds the permissible limit for operating conditions, "weakens" the metal and reduces the operating time of Thermex equipment and other European and domestic analogues. As a result, cracks appear in the tank with an emergency exit of water into the room.

How to clean an indirect heating boiler at home.

Over time, one way or another, you have to carry out cleaning procedures. The appearance of a rotten smell, a weakening of the pressure - all these are sure signs that problems in the serviceability of the equipment are beginning to appear, and in order to minimize them and, if possible, correct them, it is necessary to carry out preventive measures. The correct solution would be to flush the boiler. Use the required chemicals. In this way, you remove the original cause of the breakdown and raise the overall quality level. Systematic inspection of equipment and regular procedures for cleaning the boiler from rust, trapped debris and scale will ensure the longest possible service life. You can carry out cleansing procedures both in a specialized service and at home. If the need arises, cleaning can be done by your own efforts, without calling the master.

How often the boilers need to be flushed.

Manufacturers always leave instructions for use in the operating manual. In particular, there is always a clause that explains all the nuances in carrying out cleaning procedures. BKN must be cleaned on average once a year if no serious breakdowns are observed that affect the serviceability of the equipment. It can smell like rotten eggs when warm and hot water is used. Also, a decrease in temperature for heating water, the appearance of rust can be a sign. If you find any of these signs, then you urgently need to stop further operation of the equipment and carry out maintenance. The frequency of cleaning procedures is influenced by the following circumstances: Output quality.

Frequency of equipment operation.

In the case of tanks used in industry, things are a little different. Unlike using BKN at home, when using water heaters in industry, it is recommended to carry out cleaning procedures at least twice a year: Before the start of the season and immediately after Serious equipment breakdowns are best left to specialists. Call the wizard to fix the problems. However, cleaning procedures can be carried out with your own hands. You need to check the tank for all sorts of debris and foreign objects, establish the consequences of operation in the form of scale and rust. If you have a need for minor repairs and you are confident in your abilities, then you will need the simplest set of tools for repairing plumbing.

How to empty a boiler

The instructions for use indicate the need for cleaning procedures at least once every 6 months. This is guaranteed to protect the equipment from most breakdowns and seriously reduce the chances of lime scale appearing, thereby extending the life and improving the quality of work. The preventive maintenance manual clearly indicates the sequence of actions to be taken: 1. Shut off the low temperature water supply. 2. Open the hot water tap. 3. On the outlet piping, the relief valve must be open to remove all liquid from the equipment. 4. After all the contents of the boiler have been taken out, you can proceed directly to cleaning the equipment with your own hands and without the help of specialists. 5. You need to remove all foreign particles that have accumulated on the bottom of the equipment during operation. At the same time, it is advisable to check the general technical condition of the tank and all the parts in it. Various procedures for cleaning a water heater are not particularly difficult to perform. You can use a hose with water after disconnecting the tank from the power supply. If the specified cleaning method did not solve your problem and calcium deposits are visible on the equipment, then there is a need to purchase means for cleaning BKN. You can purchase ready-made chemicals at specialty hardware stores or household chemicals stores. You can also make your own flushing fluid using some of the ingredients that almost everyone has. You will need vinegar or citric acid. Pour the agent into the tank and in most cases this will be enough, you can completely clean the agent without taking it out of service. It is only necessary to turn off the water supply for a while and follow the flushing instructions: 1. Shut off the water supply. 2. Empty the tank by a third. 3. Connect the hose to the drain pipe. 4. Use chemicals. 5. Place a funnel over the end of the hose. Before removing the cleaning agent, raise the hose so that it is not below the water level. After using chemistry, you must fill the container with water and let it stand for about half an hour.After that, it is necessary to start the boiler and heat the heat exchanger to approximately 40-45C, then wait an hour. Then you need to fill the tank with water twice in a row and empty it. It is recommended to press the system after flushing procedures. Conditions of increased pressure are created in the tank, exceeding the operating level. This is done in order to check the equipment for all sorts of malfunctions. The procedures must be carried out by disconnecting the boilers by the hydrostatic method of pressure = 1.5 from the working pressure, but exceeding 0.2 MPa (2 kgf / cm at (2Ati)) at the bottom. t-ke Sis-we.

Requirements for the location of such a boiler

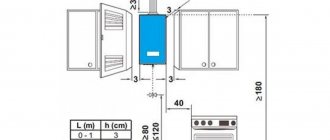

Single-circuit gas boilers are subdivided into floor-standing and wall-mounted, and, depending on the model purchased, there will be special requirements for the room:

- For wall-mounted single-circuit gas installations, it is necessary: the presence of at least one window in the room where the boiler itself will be located;

- you need to mount a chimney;

- the boiler is best located near the boiler.

- equipment of a separate room;

You will be interested >> The principle of operation of the gas boiler Navien

How to descale a boiler

Not all scale can be removed with reagents; therefore, there are other ways to remove deposits. In the absence of the necessary maintenance, calcium deposits appear on the equipment. The procedures can be performed at home using a special pump, or in the service, in which case the equipment must be disassembled. All necessary equipment for dry cleaning is divided into two types: household. industrial. A flushing pump, regardless of its type, is quite expensive, in this regard, buying it to clean one water heater becomes unprofitable from a financial point of view. However, it is not possible to achieve the same, simply pouring a chemical reagent into the container. The pump is necessary for high-quality flushing of the coil. For maintenance, you can use the following reagents: 1. Sulfamic acid - often used in the manufacture of tools for prompt cleaning of equipment from scale. It should be noted that the dissolution of this substance will require a water temperature of at least 60C. At the same time, the product is cheap and is sold in special granules. On average, buying one bag will cost you about 200 rubles. 2. Citric acid is a popular and effective folk remedy. Recommended for use in less advanced cases, i.e. in case of moderate scale. Substitution with vinegar is allowed if necessary. The main prerequisite for effective flushing is regular maintenance. To ensure the prevention of limescale, it is recommended to carry out a similar procedure twice a year. Among the advantages is the safe impact on the surface of the equipment. In fact, there is no risk of damaging the surface. For best results, follow the instructions for use. Pay particular attention to the recommended mixing ratio.

Boiler flushing

There are several ways to descale the boiler. It cannot be said which one is more effective - it all depends on the quality of the water and the substances it contains. You may have to try them all. Also, these methods will help flush the indirect heating boiler.

You will need a large amount of citric acid, one 20 gram sachet per liter of boiler volume. For example, a 50-liter water heater will require 0.8 kg of citric acid.

Actually, the procedure:

- Dilute citric acid 1 to 3 with water;

- Pour the resulting mixture into the boiler through the water supply hose;

- Connect the hose to the water pipe;

- Turn on the boiler and wait until it is completely filled;

- Set the maximum temperature and wait until the water heats up;

- Drain the water.

Method number 2 - vinegar

For cleaning, you need vinegar or 70% vinegar essence. If you are using regular 9% vinegar, you will need 100 ml for every liter of boiler volume.

If you are using 70% essence, then you need 13 ml for each liter of boiler volume. For a 50-liter one, you need to take 650 ml of essence. But before use, dilute it in 2-25 liters of plain water.

Step-by-step description of the process:

- Pour vinegar or essence solution through the water supply hose;

- Connect the hose to the water supply and fill the boiler completely;

- Turn it on at maximum temperature;

- Wait until it is fully heated and leave it there for 30-35 minutes;

- Drain the water.

To descale the water heater, you need 25 grams of baking soda (NaHCO3) per liter of tank volume. It must be completely diluted in water in a ratio of 1 to 12 at a temperature not exceeding 55 degrees. If the baking soda gets hotter, it will decompose.

Latest publications:

- All the pros and cons of inverter compressors in refrigerators, their features and types

- The principle of operation of air conditioners for cooling and heating, device, features of ALL types

- Air conditioner operating modes, description, translation into Russian, features

- 10 reasons: why the riser is hot, but the heating radiator is barely warm

- 11 reasons: Why the air conditioner does not heat, blows poorly, heats poorly

Using:

- Pour the soda solution into the boiler through the water supply hose;

- Turn on the water heater, wait until it is full;

- Set the temperature on the regulator to 55 degrees and wait for the water to heat up;

- After the water has warmed up, leave the boiler on for an hour;

- Drain the water.

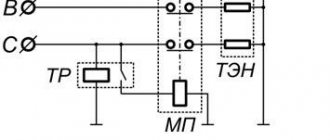

There are two options for attaching heating elements. Some are screwed into the tank, others are held by nuts. Sometimes the nuts can be hidden behind plastic plugs or a cover plate on the clips.

Before removing the heating element, place a large container, basin or bucket under it. It is not known how much dirt may be in it. Remember also that the heating element is connected to the power supply, so do not make sudden movements. Disconnect the terminals carefully and note their location.

The need to flush the boiler can be determined by the following criteria:

- the appearance of unpleasant odors from hot water;

- the water has acquired excessive hardness and has become uncomfortable for water procedures;

- turbid water comes from the taps, which indicates the accumulation of contaminants in the mixers with mechanical impurities, sand, dirt, various tiny particles;

- the difference in temperatures at the inlet and outlet of the boiler is less than 15 degrees.

Of course, you can call a service technician, but it costs money, although a high-quality flushing is easy to do on your own at home.

Before flushing, the broiler must be opened to determine the type of contamination and dried. Washing is carried out directly with a strong jet of water (pressure of about 5 bar). If there are many deposits, special reagents are used. It is permissible to use an acid that dissolves calcium well. After completion of the work, it is necessary to carry out disinfection using chlorine-containing preparations.

We suggest that you familiarize yourself with How to make bubble bath yourself, expert advice

To perform high-quality full flushing, it is recommended to use sewer drains and large volumes of water.

To ensure the long-term operation of indirect heating boilers, it is imperative to pay attention to the chemical composition of the used water.Timely disinfection, softening and removal of impurities helps to extend the life of broilers.

How to flush a water heater to eliminate an unpleasant odor

After a couple of years of regular use, a characteristic smell resembling rotten eggs (hydrogen sulfide) may appear. The aroma appears only when the water is heated to high temperatures. It will no longer be enough just to rinse the equipment and clean the surfaces to eliminate the unpleasant stench. The stench occurs due to a malfunction of the BKN, therefore, first of all, it is necessary to find out the cause of the breakdown. There can be several reasons for this smell: 1. Bacteria. Water temperature in the range of 30-40C creates ideal conditions for the development of various microorganisms. To cope with this problem, it is necessary to heat the water to about 70C at least once or twice a month. In the presence of a built-in electr. Heating element up to 90-100C. 2. Magnesium anode. Although this device is a prevention against the appearance of scale, over time, the core begins to rot, which as a result leads to an unpleasant odor. The way out of this situation will be to replace the anode. Use any detergent to remove odor. After refilling the container with water, turn on the water heater at full capacity for about an hour. This procedure is guaranteed to eliminate the odor, provided that you have eliminated the cause.

How to clean without disassembling

In the case when it is not possible to disassemble the heating device, and lime deposits have penetrated not only the heating element, but also the walls of the boiler, other measures can be taken using various means.

It is worth saying that there are many different means for cleaning a water heater. Among them are the following:

Folk

The simplest remedies are citric acid and ordinary table vinegar (consumption is about 250 milliliters per 10 liters), which allow not only to remove scale from the water heater, but also help to eliminate the unpleasant odor. And the important point is that the indicated funds are always at home, so you can clean the boiler at any time.

Professional

As for professional products, you can buy them in the store. It is written on them for how long they need to be placed in the boiler. It is important to remember that the water in the water heater should be at the time of cleaning with the agent to the very top. Otherwise, the heating device will only be half clean. You can also use electric kettle cleaner because the principle of operation is exactly the same. You can read an article about cleaning products for an electric kettle here.

We also advise you to read: How to clean the shower stall from soap stains and limescale

Mechanical

In this case, mechanical cleaning of the boiler directly with your own hands implies the use of a brush with a hard metal pile, or you can use a knife to clean off scale on the heating element, if it is presented as a tubular electric heater. But you need to clean it very carefully, since the heating element is very easy to damage.

How to flush the boiler so that there are no bacteria

You don't need any special products to get rid of various bacteria. You can use the most common soap solution for processing. If necessary, you can use absolutely any detergent for washing, which does not contain acids. A good option and a replacement for expensive products will be a dish detergent. The time-tested way to eliminate legionella bacteria is to run the boiler at its highest power. It is advisable to carry out this procedure every six months. Most of the various bacteria and pathogenic microorganisms die at high temperatures and are washed out with water.Timely maintenance of the water heater guarantees you a long service life of the equipment.

Examples of applications

Back to

Cleaning technology

To clean the heater from dirt and limescale, it is imperative to follow the algorithm of actions, since the appropriate cleaning technology is provided. It lies in the fact that you need to carry out:

We also advise you to read: Smell in the toilet: how to remove the smell of cat litter, how to get rid of the smell of cigarettes in the toilet, the smell from the sewer in the bathroom

Draining

Before starting cleaning work, it is imperative to drain the water from the water tank. How to do this procedure correctly is noted in the instructions. This is due to the fact that the available models of the heating device differ and, accordingly, the water can be drained in different ways. The same applies to flushing the indirect heating boiler.

Dismantling the boiler

Disassembly of the boiler must be carried out in accordance with the instructions provided by the manufacturers, noting them in the instructions. It indicates the disassembly process, consisting of the following actions:

- without fail disconnect the boiler from the network;

- then close the common water supply tap;

- then you need to turn off the cold water;

- after that, at the closest mixer, you need to open the tap and drain hot water;

- next, you need to connect the drain fitting with the tube, directing it into the sewer, opening the tap after;

- then it is necessary to dismantle the boiler from the wall;

- after using screwdrivers, you will need to unscrew the bolts and remove the front cover of the water heater;

- then the thermostat holder is removed;

Cleaning the heating element

It is advisable that the scale is fresh, because it is much easier to clean it off than deposits that are old in nature. Several ways to clean the heating element can be presented for consideration, since it is on it that most of the scale is formed. These are such as:

- Buy more special descaling products from the store. It is better to use products to remove deposits in the kettle. The thing is that the principle of operation in this case is the same for both heating devices.

- It can be cleaned with a stiff brush or sandpaper, but you will need to do this cleaning very carefully.

- You can also use citric acid or vinegar. To do this, take a deep container, pour water into it and add the indicated components. After that, place the heating element in the resulting acidic solution overnight. If the deposits are strongly set, then you can warm up the acid solution for 30 minutes over low heat.

Cleaning the water tank

It is imperative to clean the heating tank, as scale and other dirt can form on the walls. To rinse the water tank, place an empty bucket under the tank and rinse the inside of the tank through the hole. For greater convenience, it is recommended to dismantle the boiler from the wall.

We also advise you to read: How to clean the toilet from urinary stones

Eliminate odors

After disassembling and cleaning the tank and heating element, the water tank smells unpleasant, then often the reason for this may be:

- deposition of impurities from water,

- preventive measures have not been taken for a long time,

- the water was always heated at 60, which promoted the formation of bacteria.

Also, the heating device was not periodically cleaned, for example, the boiler was never cleaned by heating water with the addition of vinegar or citric acid. Therefore, a smell can come from the tank, which simply stinks strongly.

Boiler assembly

The assembly of the water heater is accordingly carried out in stages, as it was disassembled, but only the other way around. It is important not to miss a single detail and do everything consistently. It is also important to remember that it is imperative to correctly install the grounding wire in order to avoid getting an electric shock. And do not forget that all parts must be completely dry during assembly. There must certainly be a dry shadow.

Descaling

Limescale is the most common problem with any heating appliance. But in most cases, almost no one pays attention to water hardness, which subsequently becomes the cause of boiler breakdown. After all, the presence of various impurities in ordinary water at a temperature of 75 contributes to the formation of scale on the heating element and directly on the walls of the device for heating water.

To remove the accumulated lime deposits, it is recommended to use special household chemicals or to use folk methods. Among them are the following:

- lemon acid;

- table vinegar;

- soda with vinegar.

Using these products, you can not only get rid of scale, but also disinfect.