This amount in various oil factories can reach tens of tons per week.

Hull disposal has always been a problem: due to the low bulk density, transporting waste to landfill is expensive. During storage, it can easily ignite and smolder, spreading an unpleasant odor. A certain amount of it is used as fertilizer and for loosening the soil.

However, sunflower husks have such an invaluable property as high calorific value on combustion

... It is this quality that makes it one of the most efficient types of fuel, which is produced in the form

fuel briquettes and granules (pellets)

... Granulation is one of the most common methods of processing husk, as a result of which the moisture content of the product is reached up to 12% and the compression of the initial volume is 5-10 times.

Advantages of sunflower husk pellets over other fuels:

- Heat transfer is 17000-19000 kJ per kilogram

... This is more than the average values of wood and about the same as some types of coal give off heat during combustion.

- 2 tons of sunflower husk pellets emit as much heat as 3.2 tons of wood fuel, 957 m3 of gas, 1000 liters of diesel fuel or 1370 liters of fuel oil.

- Burning pellets is energy efficient, usually the amount of non-combustible residues (ash content) does not exceed 3%

.

- When burning no harmful substances are emitted

.

- There are no pores in the granules, which prevents them from spontaneously igniting.

- Sunflower husk - cheap raw materials

which oil factories are interested in selling in order not to bear disposal costs.

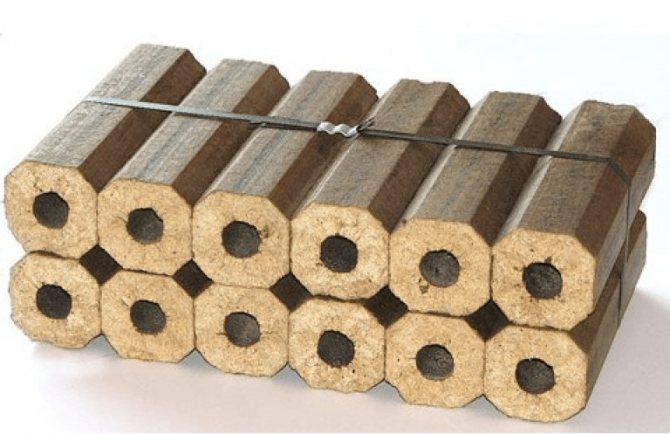

Reviews about Pini-Kay briquettes

Pini-Kay fuel briquettes, reviews of which in most cases are only positive, differ in that they do not stain the surface that comes into contact with them during transportation and storage. High density can also be distinguished, which is equivalent to 1200 kg / cubic meter.

Ash content can reach 3%, which is one of the lowest indicators. If we additionally talk about density, then it is 2.5 times higher than this parameter inherent in wood. The bulk density of the material is 1000 kg / cubic meter. These figures are of interest to consumers quite often, buyers compare this figure with the bulk density, which is 300 kg / m3. This indicator, according to the owners of heating equipment, makes it easy to transport material over impressive distances. Due to the ideal shape, as well as small dimensions, it is possible to tightly stack briquettes on pallets, pouring, if necessary, through special sleeves. This makes it possible to fully automate the process of loading and unloading, as well as further combustion of this type of fuel.

Fuel briquettes "Pini-Kay", reviews of which you will know after reading the article, should be stored separately from other substances and materials. If the conditions are observed, the products can be stored indefinitely until the time of use. The temperature in the covered warehouse should be equal to the limit from +5 to +40 degrees. In this case, the relative humidity can vary from 30 to 80%. Interaction of products with water and aggressive substances should be excluded. Consumers claim that in order to extend the shelf life, it is necessary to exclude exposure to ultraviolet radiation.

Sunflower husk pelleting technology

In the production of pellets from sunflower husks, an algorithm is used that is common for fuel pellets.

Required husk moisture - up to 14.5%

... Under normal storage conditions, it is already dry enough for granulation.

1. Grinding of raw materials on a crusher to a fine fraction.

2. The crushed raw material goes to the storage hopper before granulation.

3. The mass evenly enters the granulator, where it is moistened with water in the mixer-conditioner, after which it is fed into the pressing chamber, from the matrix of which the granules subsequently come out.

4. Since the granules are compressed at high temperatures, they are conveyed to a cooling column by means of a conveyor, where they are cooled and sieved to separate non-granular particles.

5. Next, the pellets enter the storage bin or are immediately packed into bags or big bags using a weighing machine.

Reviews about RUF briquettes

Fuel briquettes RUF, reviews of which correspond to the characteristics of the material, are easily decomposed. Owners of fireplaces, boilers, and stoves note that when using a different type of fuel, they have to turn into a stoker, ensuring that the fuel is put on every hour. In order to ensure smoldering, it is necessary to reduce the thrust by closing the blower. When melting the equipment, insignificant draft must be guaranteed, then a cold plug will be formed in the chimney, and the briquette will not smoke.

At the same time, it is possible to melt the device without preheating the air duct. Using RUF fuel briquettes, reviews of which it will be useful to read before visiting the store, you can warm up the room in a shorter time than using traditional firewood.

Features and disadvantages of husk pellets

From our own practice, we know that not every granulator is suitable for pelleting sunflower husks, since this fuel material is compared to sawdust characterized by increased oiliness

... If the pellet mill manages to obtain high-quality pellets from wood, pellets from husk from the same matrix may have an uneven surface and insufficient density. This material requires

high compression matrices

.

Seed husk granules have higher ash content

than wood. This disadvantage is of most concern to users of pellet boilers on the forums. The ash content of the husk is usually estimated at 1-3%, although according to some reviews

can reach 5-7%

... Surprisingly, sunflower seed husks grown in different soils can leave a different amount of incombustible residues due to the different mineral composition of the soil.

Due to the higher ash content, the owners have to better watch your boilers

: several times more often to clean the ash pan, check if the chimney is not clogged. However, at a price such pellets are one and a half times cheaper than their wood counterparts. Therefore, consumer choice often depends on the level of laziness or on the cost of delivery. Territorially, sunflower pellets are more available in the southern and central parts of Russia.

Moreover, even sunflower husk ash is not waste

: it has been successfully used to fertilize the soil. Rural homeowners stockpile it to use in summer gardening.

Burning time reviews

If you decide to purchase fuel briquettes, it is recommended to read reviews about them even before going to the store. It is important to take into account that these products, as consumers note, are characterized by a significant burning time, which is especially evident when compared with traditional firewood. Thus, laying in heating equipment can be done 3 times less often. Combustion occurs with minimal smoke generation, material does not spark or fire. In this case, it is noted that a constant temperature is ensured throughout the entire combustion period.After combustion, coal is formed, which is also true for ordinary firewood. In the future, the combustion product can be used for grilling or cooking kebabs.

Sunflower husk pellets prices

Average price of sunflower husk pellets - 3000-4500 rubles

per ton. Wholesale prices are much lower, you can find offers from 1500 rubles. Industrial enterprises buy such fuel in bulk, this is typical for European countries. In Europe, this product costs about

105 euros

per ton.

Additional features of RUF briquettes

In shape, these products resemble bricks, in the manufacture of which minimum requirements are imposed on the qualifications of personnel and the organization of production, which favorably affects the cost of the product. Among the minuses, one can single out the least resistance among all other briquettes to moisture and external mechanical stress. Therefore, for this brand of fuel, high-quality packaging is required; if it is damaged, long-term transportation and storage becomes impossible. This is especially true for the CIS roads, the level of which does not correspond to the European level.

Characteristics of sunflower husk pellets

As already mentioned, the characteristics can be heterogeneous depending on the area of sunflower growing and the method of preparing the raw materials, as well as on the technology used.

Let us give characteristics of sunflower husk pellets

- a consignment from Ukraine, certified according to the international standard EN plus.

- Humidity: 9.71%

- Ash content: 1.31%

- Sulfur content: 0.03%

- Density: 1.054 grams per cm3

- Total energy value: 21.43 mJ / kg, 5118 kcal / kg, 5.95 kW / h

- Energy value in operation: 19.35 mJ / kg, 4622 kcal / kg, 5.38 kW / h

Reviews of reed briquettes

If you are interested in reed briquettes - who burned, reviews and other information - you can read all this below. Buyers claim that 1 kilogram of material will be enough for 7 hours of continuous burning. In this case, the heat transfer will be 6550 kcal / kg. Owners of boiler equipment say that the device will have to be cleaned only once every two years. The resulting ash, like coal, can be used as an environmentally friendly fertilizer.

You can ensure autonomy by using this type of fuel, since the equipment will not depend on the companies supplying electricity and gas. There is no dependence on external conditions such as damage to pipelines, power lines, theft, etc. Consumers do not face the need for long-term approval, which is carried out before connecting electrical or gas equipment.

Reed fuel briquettes, reviews of which resonate with positive characteristics, have a high density. In the production process, a technology is used that involves screw pressing. As a result, it is possible to achieve a density in the range from 1.1 to 1.2 t / m3. The surface consists of a sufficiently strong crust, which excludes damage and rupture of the briquette during transportation and storage. Transportation can be carried out by laying the products in two tiers, since the material almost does not form crumbs. The existing crust is able to reduce the penetration of moisture inside, which makes the use of briquettes more comfortable.

Production of briquettes in production

To get a clear idea of how to independently make briquettes, including for the Buleryan oven. first you need to know how they are made in the factory.

Any of the available methods precedes the preparatory stage, during which the raw materials are crushed and dried.

The raw material is sawdust and some larger pieces of wood waste. Drying is carried out until the moisture readings are close to 8-10 percent.It is interesting that all kinds of agro-industrial wastes (for example, husk or seed husks) and coal dust can also be used as raw materials for Eurowood.

Briquetting

The next production process is sawdust pressing, or briquetting. Today this can be done in two different ways:

- Extrusion method;

- Forming briquettes on a special hydraulic press.

In both cases, as a result of the powerful squeezing of the crushed wood, lignin, a special natural substance, begins to be released from it. It is he who becomes a binder for the friable mass of raw materials. The difference between the processes lies only in the different methods of squeezing. In one case, a hydraulic press is used, capable of developing a force of up to 300-600 bar.

From the force of this compression, the shredded wood heats up, and this contributes to the formation of a hard rectangular briquette.

With another method, extrusion, the wood raw material is poured into a special hopper of the unit, and, by analogy with a meat grinder, the screw moves into a conical working channel, which narrows. It is there that the compression is carried out, during which the screw press develops an incredibly powerful force of up to one thousand bar.

As soon as it is ready, firewood made from sawdust in the form of hexagons comes out of the extruder. Before that, they undergo heat treatment, and are cut with a special knife to exact dimensions.

SUNFLOWER HOOD AS A RENEWABLE ENERGY SOURCE

SUNFLOWER HOOD AS A RENEWABLE SOURCE OF ENERGY LEGALIZED BY REGULATORY DOCUMENT

Head sector prom. safety and labor protection, Ph.D. Barmashev V.A. , head. department of production of vegetable oils, Ph.D. V.N. Markov, head. department of standardization F.P. Nosovitskaya VNIIZH, St. Petersburg Tel. F.P. Nosovitskaya

Currently, there is an increased interest in the use of renewable energy sources all over the world. The European Community program has set the task to triple the production of energy from renewable sources of biofuel within the next ten years. In Western Europe, as well as in some CIS countries, programs have already been adopted and approved at the legislative level, which oblige to generate at least up to a quarter of all necessary energy using renewable energy sources. As an alternative to fossil fuels, fuels are used from wood waste in the form of bark, chips and sawdust, as well as buckwheat and sunflower husks, corn cobs, straw, etc. First of all, this is due to the need to protect the environment, as well as the tendency to switch to energy-saving and resource-saving technologies. This report will focus on the use of sunflower husk as an alternative fuel. This type of fuel can be used for boiler houses and thermal power plants, in furnaces and fireplaces, for the production of heat and electricity, for heating industrial, domestic and residential premises. In fact, the burning of husk as an alternative fuel at the enterprises of the fat-and-oil industry in Russia takes as long as the industry itself has existed. The calorific value of 1 ton of dry matter of sunflower husk is equivalent to 17.2 MJ. According to this indicator, husk is superior to firewood - 14.6-15.9 MJ / kg and brown coal - 12.5 MJ / kg, and the coefficient of conversion of husk to conventional fuel reaches 0.63 units. When hulls are burned, the amount of carbon dioxide emitted does not exceed that formed during the natural decomposition of wood, and the amount of other harmful emissions is negligible. The ash formed during the burning of husk can be used as fertilizer. Due to the low bulk density of the original husk, transporting it to other objects is not economically efficient.At a number of enterprises in the industry, work has begun on briquetting and pelleting husk, and fuel pellets are supplied not only to the domestic, but also to the foreign market. When granulating, the starting material is compacted 5-10 times. Granular fuel also has a number of advantages, among which it should be noted the consistency of quality characteristics, ease of storage, the ability to use in systems with automatic fuel supply. As a result, the issue of not only the stability of energy supply is solved, but also the problem of environmentally friendly disposal of industrial waste. The absence of a sectoral regulatory document providing for the use of sunflower husk as fuel made it difficult to promote it on the market as a product. In accordance with the federal law "On the protection of atmospheric air" (Article 15, Clause 3.5 and Clause 7, Article 18), there was a question about the legality of its use as a fuel, and actually its combustion as a method of disposal. At the request of a number of Russian oil and fat enterprises, VNIIZh and TC 238 "Vegetable oils and products of their processing" developed TU 9147-468-00334534-2007 "Sunflower husk for technical purposes". The developed technical specifications provide for the production of three types of sunflower husk: non-granulated, granulated and briquetted. The set of standardized physical and chemical indicators laid down in the TU allows the husk to be used both as a fuel and for other purposes, for example, as a fertilizer and an improver of soil properties. The section "Safety Requirements" contains data on the hazard class and the ignition temperature of the husk, as well as the maximum permissible concentration of sunflower husk aerosol in the air of the working area. Appendices to the TU contain information on the average component composition of the ash obtained after burning sunflower husk and data for calculating the TOC of dust of sunflower husk ash in the air. The developed technical specifications convert the husk into a marketable product, the value of which is determined by market relations.

Types of fuel briquettes

There are two classifications of briquettes. The first is related to the raw materials for them. Production of fuel briquettes from wood obviously. However, wood is different. On sale there are:

- Birch fuel briquettes... Their calorific value is 4600 kilocalories per kilogram. We have to keep track of the amount of impurity in the bark blocks. Birch has resins in it. They give soot when burning briquettes, as well as when burning ordinary logs.

- Aspen blocks have a calorific value of about 5,000 kilocalories per kilogram. In addition, aspen blocks are the lightest, as well as the wood fired on them. Aspen material is also distinguished by its ability to clean the chimney and gives ash content, which is minimal for pressed blocks.

- Coniferous briquettes. Their calorific value is approximately 4000 kilocalories per kilogram. In the blocks there is a solid admixture of needles. It is saturated with resins. When burned, they "pour out" into tar, which settles on the walls of the stove and chimney, as if on the walls of a black bath. On the one hand, tar disinfects, and on the other hand, it clogs up the working space and gives the firebox a nondescript look. In addition, coniferous briquettes have maximum ash content.

- Coniferous birch. They have mixed properties. Which of them prevail can be seen from the proportions. Some blocks contain more birch dust, while others contain more coniferous shavings.

- Coniferous-aspen. Like coniferous-birch, they differ in “floating parameters. So, the calorific value of briquettes can be 3900 or 4300 kilocalories per kilogram.

- Linden briquettes. Their thermal conductivity is 4800 kilocalories per kilogram. The ash content of the blocks is minimal.

Fuel briquettes from sawdust compete with blocks from agricultural waste.The same cellulose is used as in wood, but in the form of sunflower husk and straw.

Such blocks are about half less than wooden ones, and the efficiency is the same. The humidity of the category briquettes is also at the standard level. Only the ash content differs. It is a couple of percent higher.

In addition to fuel briquettes based on cellulose, there are blocks in all its types:

-From coal. Their heat transfer is two units higher than that of the best woody ones. The picture is darkened by the high ash content of coal blocks. Against 0.7%, wood briquettes are set at 12%. If we are talking about a product made of brown coal, the ash content reaches 30%.

At the same time, heat transfer drops to that of a tree. There is also a minus in the high heat transfer of anthracite blocks. They are suitable for boilers and ovens with high combustion temperatures. Such a minority and they are expensive. For wood and peat briquettes, any firebox is suitable.

-From peat. The ash content of these blocks is 20%, and the heat transfer is at the level of pressed “bricks” of coniferous wood. An additional disadvantage of peat briquettes is high humidity. It reaches 18%, leading to an abundance of condensation.

The second classification of briquettes is related to the form of their release. It does not affect the quality parameters of the fuel. Appearance is due solely to the method of pressing.

So, blocks of wood are hexagonal or tetrahedral, cylindrical, in the form of tablets. Agrobriquettes are often in the form of a cylinder. The charcoal and peat blocks resemble sausages, pads or tablets.

There are standards for different block shapes. Fuel briquettes RUF, for example, brick-like. These are created at an operating pressure of 30-60 units. Fuel briquettes RUF, by the way, the most popular in Russia.

Reviews about briquettes "Nestro"

Fuel briquettes "Nestro", reviews of which will become known to you, if you read the information below, has a wide area of use. They are used when it is necessary to operate industrial equipment, as well as in railway transport. The bars can have an 8-sided shape with a hole that is located inside. The length of the product is 250 millimeters, while the cross-section is square, and has a side within 65 millimeters. The diameter of the circle is equivalent to 70 millimeters, and the hole has a diameter of 20 mm. The moisture content of the product on delivery should not exceed 9%, while the maximum value varies within 7%. The ash content is minimal and amounts to 0.5%.

Consumers like the presence of a technological hole inside the product, which contributes to more intense combustion, while forced ventilation is not required. This makes it possible to use fuel in equipment that is characterized by low thrust. The products are manufactured using the technology of shock-mechanical pressing of husks and sawdust. The main difference between such briquettes is the lack of processing under the influence of temperature during pressing. If there is a need to use briquettes of a certain shape, then these requirements can be taken into account by the manufacturer.

Manufacturing is carried out using connecting rod mechanical or hydraulic presses. Fuel quite often has a cylindrical shape, and among the negative and positive characteristics, the same features can be distinguished that are inherent in RUF materials. The cost of such products is relatively low due to the fact that the production process is inexpensive. Consumers note that in terms of technical features, these briquettes are inferior in many qualities to Pini & Kay fuel.