In order for solid fuel to ignite and continue to burn (be it firewood, wood waste, coal or peat), oxygen must be supplied to the combustion chamber. To obtain the desired temperature of the coolant in solid fuel boilers, more and more sophisticated automation is used with the use of fans and smoke exhausters. However, there is a compact mechanical device - a draft regulator, which maintains the set temperature in the heating system with quite acceptable accuracy without using electricity.

The principle of operation and functions of draft regulators for solid fuel boilers

The control of the boiler damper or the door of the furnace blower by the operator (fireman) changed the amount of oxygen in the furnace and changed the temperature of the coolant in one direction or another (due to more or less intense combustion). The operating principle of a mechanical device capable of doing this job is also quite simple.

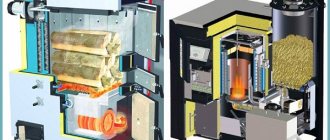

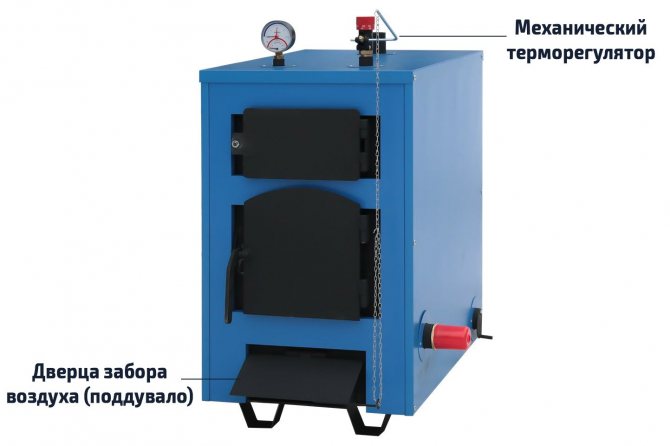

This is what a standard mechanical top-positioned tag adjuster looks like. There are also side models.

Such a thermostat consists of the following parts:

- sleeve with a heat-sensitive element;

- mechanical amplifier for temperature change;

- calibrated knob setting temperature;

- spring, the compression of which will determine the level of the task;

- a lever with a chain that controls the ash pan door (blower).

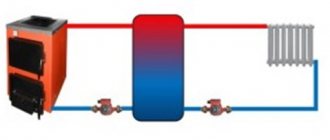

The setting of the coolant temperature is set by the regulator knob, which compresses the spring with the required force. The difference between it and the strength of the cold thermosensitive element is large, so the lever mechanism opens the damper by a chain to a certain large angle. A lot of air enters the firebox, intensive combustion occurs. As it heats up, the linear dimensions of the sensitive element increase, the difference between the set and operating temperatures becomes zero. The ash pan door, smoothly lowering, takes a position corresponding to the given one and then reacts to temperature deviations.

The functions of the draft regulator include the following tasks:

- stable maintenance of the set temperature of the coolant in the control range, preventing it from boiling;

- control of the power and efficiency of the boiler due to the supply of oxygen, achieving complete combustion of the fuel, which reduces its consumption.

Important. Not all solid fuel units are initially equipped with a mechanical draft regulator, so the user is tempted to use a safety valve as a draft regulator, which relieves excess pressure when the coolant boils. Such savings will result in the fact that in the event of a real emergency, it will work late or not work at all, which will entail serious repairs at least.

Benefits

The installation of a chimney draft stabilizer gives a number of positive points:

- the safety of operation of the chimney system increases, due to the stabilization of the flow of fuel gases;

- the service life of the chimney increases due to the reduction of peak loads from hot combustion products;

- the amount of harmful substances released into the atmosphere is reduced;

- thanks to the constantly ajar damper, air circulation increases;

- the regulator is capable of operating on forced and natural draft;

- stabilization of fuel combustion;

- maintaining a constant temperature of combustion products in the chimney, as a result of which it does not overheat;

- protection from strong gusts of wind;

- exhaust gases do not enter the room;

- it becomes possible for low-temperature heating devices to work with old chimney systems;

- external heat loss is reduced.

Note! And, one more, of the essential points. In addition to stabilizing the operating modes, up to 10-15% of fuel is saved.

Feedback on the use of mechanical draft regulators: advantages and disadvantages

The owners of solid fuel boilers speak favorably about the device of various manufacturers and recognize its usefulness in creating comfortable conditions in a private country house.

Table 1. Advantages and disadvantages of mechanical thermostats for solid fuel boilers.

| Benefits | disadvantages |

| Low cost for the provided comfort | The declared characteristics are fully fulfilled in compliance with the instructions, no shortcomings have been identified. |

| Complete independence from power supply, complex electronics and automation | |

| Accessibility for understanding the installation and use of the device for untrained consumers | |

| With proper installation and operation, it will last for a long time | |

| Due to the simplicity of the design, usually high quality workmanship |

If the boiler package does not include a draft regulator, then when purchasing separately it is necessary to choose from those recommended for this unit. However, the only negative point is that not all solid fuel boilers are equipped with a threaded socket, which is necessary for using a thermostat.

This is how the seat for the lateral draft thermostat looks like.

DIY chimney draft stabilizer

The industry produces various models of devices for regulating the draft in the chimney. But it is not always possible to buy them. There are two options for stabilizers that you can make yourself:

- damper;

- "fungus".

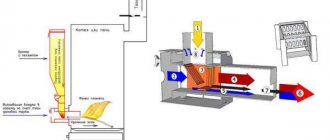

Damper

It is an ordinary damper, partially or completely overlapping the pipe section. The simplest option is a cross damper (as in classic Russian stoves or fireplaces).

Another option is the drive inside the case. The circle is attached to a transverse rod, through which the position of the damper is set inside the pipe. A significant disadvantage of both devices is manual adjustment, which requires almost constant monitoring of the boiler operating mode.

"Fungus"

It is made in the form of a tapered insert in the main pipe. Outwardly it looks like an umbrella. A thermal sensor is installed inside the structure, which controls the temperature of the gas flow. In the event of reverse thrust or an unstable mode, the waste products of combustion accumulate under the "umbrella". There is a general increase in the thermal background. The sensor is triggered and sends a signal to the natural gas supply regulator. The boiler shuts down.

How to choose the right mechanism

The possibility of installing a mechanical thermostat is indicated by the presence of a sleeve welded into the boiler drum from the side, front or top, in addition, the ash pan door must open upwards. For units in which the blower door opens to the side, there are still no serial regulators. The space around the case should allow the device to be easily mounted and adjusted.

The selected device must meet the following requirements:

- The internal thread of the sleeve defines the external thread of the regulator.

- The design and power of the lever mechanism should allow unhindered fully raise and lower the blower door, so look at what force the mechanism is designed for and compare it with the weight of the blower door.

- Most regulators operate reliably in the 60 ° -90 ° C range.

The choice of model and brand of device depends on the user's preference and the purchase budget. Experience shows that it is enough to take any of the well-known thermostats, all of them are quite accurate, of high quality and reliable (in view of the simplicity of the design as a whole).

Types of regulators and features of choice

If the basic configuration of the solid fuel heater is not equipped with a draft regulator, the device will have to be installed independently.

A prerequisite for this is

:

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are produced that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

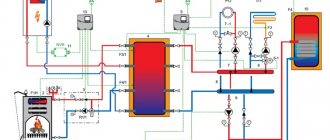

On the left is the boiler with the possibility of installing a regulator, on the right - with manual control

When choosing a model, pay attention to the following parameters

:

- the effort that the drive develops (the value is indicated in the passport, it should be enough to lift the ash pan door);

- temperature range of heating the coolant (60-90 ° С);

- working stroke of the actuator (it should be enough to fully open and close the damper);

- type of threaded connection on the body - it must correspond to the thread in the sleeve of the boiler unit (usually 3/4 ″).

The design of the draft regulator can provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the boiler water jacket. With these models, the immersion sleeve is removable.

Related article: Hydraulic flushing, how and why

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of more and more complex systems for automatic control of heat and hot water production processes. They are more accurate and do not require user participation in most operations. However, such systems are becoming more and more dependent on electricity and more expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. It works reliably in the range of 35˚-95˚С, operating temperatures from –20 ° C to + 150 ° C. It can be used with various antifreezes, and the thermostatic element can be replaced. Requires heating when used in low temperature environments. Installed in any position, does not need service. Fits into a 3/4 in. Pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuels, due to its extreme simplicity, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device is mounted vertically and horizontally, the scale of temperature levels allows this. The temperature control range of the heating agent is 30–90 ° C, the maximum operating temperature is + 120 ° C. Coupling with internal thread G3 / 4 ”. Device weight 0.42 kg, manufacturer - Czech Republic.

Cost: from 1500 rubles.

Honeywell FR 124

High quality mechanical thermostat from Germany, compatible with many domestic and foreign boilers. The water temperature control range is from +30 to + 90 ° С, the maximum operating temperature is +115 ° С. Chain load from 100 to 600 grams, lifting stroke up to 60 mm. Standard installation in threaded sleeve G 3/4 ". The peculiarity of this regulator is the presence of a removable immersion sleeve, for replacement of which it is not required to drain the water from the boiler. Device weight 0.47 kg,

Cost: from 1900 rubles.

Self-assembly of the stabilizer

To make a stabilizer you will need:

- semiautomatic argon welding machine;

- argon gas cylinder;

- grinding discs;

- stainless steel AISI 304 or 321 with a thickness of 8-10 mm;

- steel bar with a diameter of 8-10 mm for the axle, screws, nuts and washers.

Fasten the pipe joint by welding so that the inner diameter is 115 mm. Weld seams must be thoroughly cleaned outside and inside, and a cutout must be made for the valve, which is 15% of the chimney cross-section.

A retainer is installed in the area of the damper, and the rotary axis, which is equipped with a rotary valve handle, protrudes from the pipe by 120-150 mm. From the upper and lower edges, at a distance of 25-30 mm, roll the sides to connect with adjacent pipes.

It is best to install the stabilizer in the burst of the chimney. To fix the device at the top and bottom, clamps with a width of 50-60 mm are used.

We offer you to watch a video of a homemade traction stabilizer.

Prices: summary table

| Model | Regulation range | Max sensor temperature | Weight, kg | Cost, rub. |

| ESBE ATA 212, Sweden | 35–95 ° C | 150 ° C | 0,38 | 2 800 |

| Regulus RT4, Czech Republic | 30–90 ° C | 120 ° C | 0,42 | 1 500 |

| Honeywell FR 124, Germany | 30–90 ° C | 115 ° C; | 0,47 | 1 900 |