The device of heating electric boilers

The operation of the heating elements of boilers is based on the passage of the coolant through a container with installed tubular heating elements. Due to the high resistance of the spiral inside the tube, an increased amount of thermal energy is released when the current flows along the spiral. It also goes into heating the coolant passing through the heating elements.

Automation of heating elements of boilers allows you to control their operation, temperature control and automatic switching on and off.

Pros and cons of using heating elements for home heating

The main disadvantage of this heating method, as in the case of other electrical appliances, is the cost of operating costs. Electricity is still the most expensive source of heat (unless, of course, you have the opportunity to use free energy from the sun or wind, and you are connected to the mains power grid). Another disadvantage is the impossibility of repair in the event of a spiral failure. However, there are some positive aspects, which in some cases may become a priority.

- Environmental friendliness of the heating system. When using electric heating devices, there is no need to store and store any kind of fuel, and there are no harmful combustion products that enter the environment;

- Possibility of autonomous installation of a heating system in the absence of access to other heat resources (for example, gas);

- Small dimensions and a large selection of models in terms of power and functionality;

- The ability to automate the heating process: installation of heating elements with a thermostat;

- Low purchase and installation costs. There are models for which the cost does not exceed 1000 rubles. And the installation of heating elements in heating radiators can be done independently.

And finally, a few tips for self-installation of tubular electric heaters. How to properly embed the heating element into the heating system? First of all, you need to choose the right model by measuring the diameters of the radiators where the heating element is supposed to be installed and making power calculations. Then carefully read the instructions for the device, which should indicate whether additional sealing is required or not. This is one of the most important points, since contact of the conductor with a heat-conducting liquid will lead to the fact that your radiators are energized, and this is dangerous for residents. If the manufacturer indicates the need for additional sealing, then it must be done. In addition, it is unacceptable to use electric heating devices without grounding.

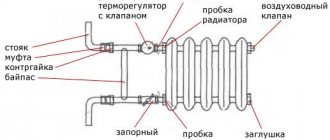

The location of heating elements in a cast-iron heating battery

Installation of heating elements in cast-iron heating batteries has a number of features. They are associated with the diameter of the nozzle and the direction of the thread. In general, the procedure for installing heating with heating elements in an existing system is as follows: disconnect the heating system from the heat source, drain the water, install the heating element, fill in the coolant, check the system's performance. When using heating radiators with heating elements with thermostats in the heating system, it is also necessary to check their operability after installation. It is also advisable to install water sensors and check the tilt angles of the radiators. Since air locks can significantly affect the operation of the entire system and disable the heating element.

Disadvantages of heating elements of boilers

Indirect heating of the coolant in the heating element tank of the boiler, significantly increases the heating time. It takes more than 10-15 minutes to warm up such a boiler.

This is a subjective drawback, which is perfectly compensated by the safety and clean operation of the heating elements of the boilers.

However, due to indirect heating, 10-15% of the heat released by heating elements is lost even at the heating stage. This negatively affects the efficiency of such boilers.

The weak point of the heating elements of the boiler are the heating elements themselves. Being constantly in an aggressive environment, they rust, corrode and salt deposits. A simple metal heater will require replacement in 5-6 years.

Popular models of electrode boilers

Galan are single-circuit floor-standing electrode boilers designed for operation in a single-phase network.

Galan Hearth

Recommended for heating small areas (up to 110 sq. M.).

| power, kWt | 2-6 |

| Weight, kg | 0,9-1,1 |

| Length, mm | 275-335 |

| Diameter, mm | 35 |

| Area, sq.m | 50-110 |

| Required volume of coolant, l | 20-70 |

Average cost from 3600 rubles. up to 4000 rubles, depending on the model.

Advantages: fast heating of the heating medium, energy saving, low cost.

Disadvantages: it is difficult to select the required specific resistance of the coolant, the need for periodic cleaning of the electrodes.

Galan Geyser

A series of boilers "Galan" of the middle level, with a heating area up to 200 sq.m.

| power, kWt | 9/15 |

| Weight, kg | 5/5,3 |

| Length, mm | 360/410 |

| Diameter, mm | 130 |

| Area, sq.m | 120/200 |

| Required volume of coolant, l | 50-200 |

Average cost from 6900 rubles to 7300 rubles.

Advantages: Compactness, low cost,

Disadvantages: for efficient operation of the boiler, preliminary thermal insulation of the room and accurate heat calculation of the required power are desirable.

Types of heating elements of heaters

However, in addition to metal tubular heating elements, there are more expensive and durable counterparts. Today on sale you can find electric boilers with the following types of heating elements:

- Metal alloy with cupronickel and nichrome;

- Heating elements made of ceramics;

- Heating elements made of composite materials.

The most expensive ceramic heating element has the longest service life.

How to choose heating heating elements

Heating element for heating with plates

How to choose the right ten for the heating system? There are many manufacturers currently offering similar products. However, not always the quality and technical parameters correspond to the required ones.

Therefore, before purchasing, you need to pay attention to the following performance characteristics of the heater:

- Rated and maximum power. If a heating element is needed in a heating boiler, its power must be enough for the system to work. The simplest calculation method is for 10 sq. M. houses need 1 kW of thermal energy;

- Power supply type. For models with a power of up to 3 kW, you can use a 220 V home network. If it is planned to install a ten for a heating system of greater power, a three-phase 380 V network should be installed.This may be due to difficulties in the preparation of documentation;

- The presence of a thermostat. For a radiator electric heating system, this is the main selection factor. If you buy a ten without the ability to adjust the power, it will constantly work at maximum mode. Thus, the cost of electricity will rise sharply;

- Cost. The average price of a 2 kW model starts at 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. They are often made to order.

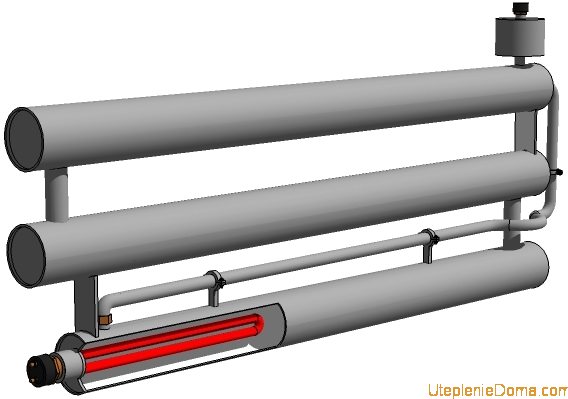

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a ribbed heating element for the heating boiler. It differs from the usual ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heating elements in heating radiators of a larger diameter. Reviews about them speak of increased heat transfer even with a minimum operating mode. But their overall dimensions do not always make it possible to install in a battery. Therefore, most often they purchase simple tubular-type heaters. To increase the efficiency, you can buy a block of heating elements with a thermostat.It differs from traditional ones by the presence of several heating elements on one base.

Boiler heating element example

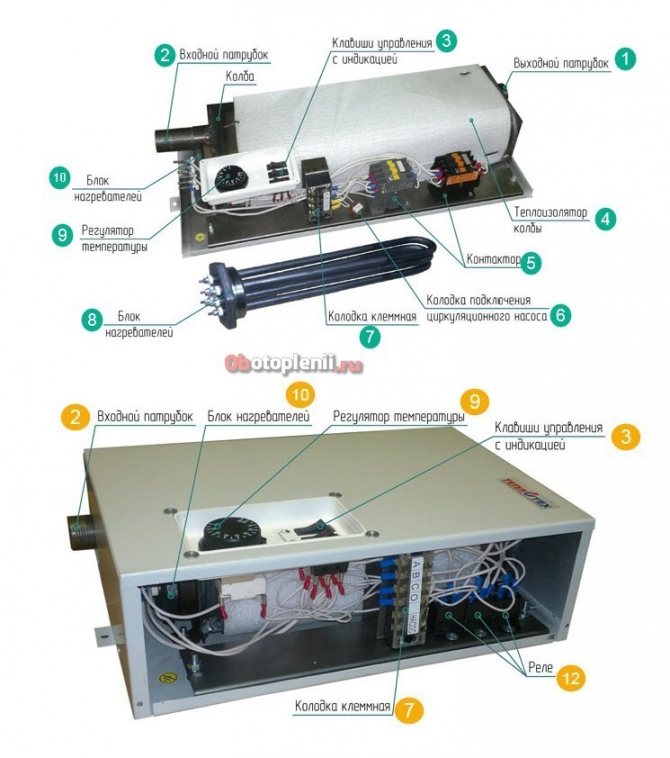

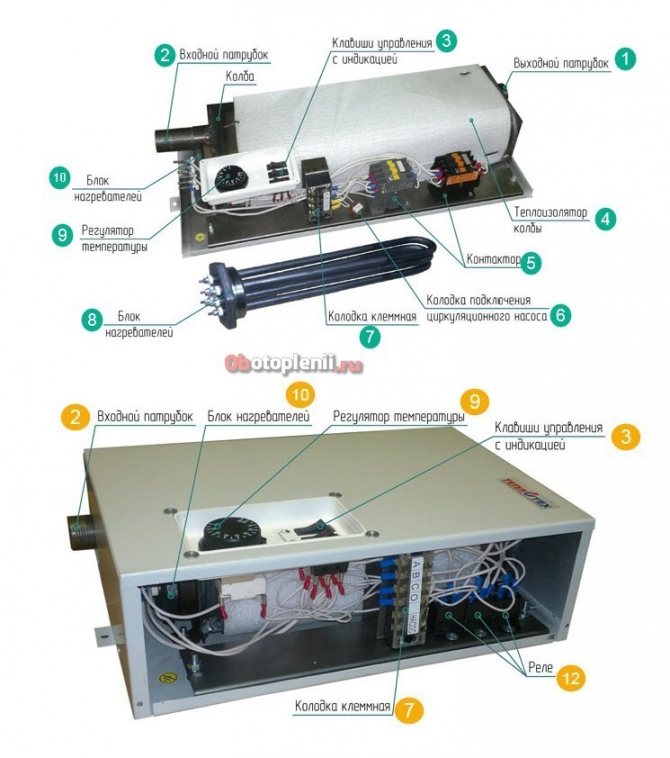

Let's look at an example of a popular manufacturer of heating elements for boilers, the Teplotekh plant, boilers of the EVP brand (electric water heaters).

Boiler EVP-18M, 380V

This boiler has a power of 18 kW, which is enough to heat a house with an area of 160 meters. The boiler costs 7800-7900 rubles. The high power of the boiler enables a three-phase supply. However, this complicates its connection in the country houses of individuals.

- This boiler has a large volume of a heating flask, which allows uniform heating of the system coolant without possible overheating.

- The boiler has a stepwise power switching. The switching is controlled by three keys from the control indications of the included power.

- The temperature of the coolant is monitored by a temperature sensor.

- It is possible to connect a temperature sensor in the rooms and limit the heating temperature of the premises.

The boiler thermostat regulates the temperature of the heating medium in the range from 0 to 85 ° C.

© Obotoplenii.ru

Calculation of the power of devices

In order not to overpay for electricity and prevent emergencies, it is necessary to calculate the required power before installing heating elements in the heating system. And to do it "by eye" will not work. Calculations are based on the fact that for heating 10 sq.m. premises require 1 kW of thermal energy. The formula for calculating the power of the heating device is as follows:

Rm = 0.0011 * m (T2-T1) / t,

where Pm is the calculated power, m is the mass of the coolant, T1 is the initial temperature of the coolant before heating, T2 is the temperature of the coolant after heating and t is the time required to heat the system to the optimal temperature T2.

Let's consider the calculation of power using the example of an aluminum radiator in 6 sections. The volume of the coolant of such a radiator is about 3 liters (exactly indicated in the model passport). Let's say we need to heat the radiator by connecting the heating element to the heating battery, in 10 minutes from 20 degrees to 80. Substitute the values into the formula:

Рм = 0.0066 * 3 (80-20) / 10 = 1.118, that is, the power of the heating element should be about 1-1.2 kW.

The heating element is installed in the lower section of the heating batteries.

However, this is only valid if water is used as the heat carrier. If it is necessary to make calculations for oil or antifreeze, then a correction factor is used, which is about 1.5. Simply put, the power of heating elements for heating oil heaters should be increased by about one and a half times. Otherwise, the estimated time to reach the optimum temperature will increase.

Induction electric heating boilers

The operation of these electric heating boilers is based on a physical phenomenon - electromagnetic induction. The coil acts here as a source of thermal energy. An electromotive force arises on the primary winding, acting on its inner part (secondary winding). It provides a constant flow of energy, which is converted into heat and transferred to the coolant.

As a result of the fact that almost the entire body of an electric heating boiler acts as a heater, the heating agent is heated as efficiently as possible. This reduces the likelihood of scale build-up on the internal elements, which increases the life of the boiler.

It is worth noting that an induction electric heating boiler, the price of which is not cheap, has a solid specific gravity, which causes certain difficulties during installation. In addition, the constant vibration noise can cause discomfort when in close proximity to the boiler.

Heating electric boilers

Heating systems are traditional and most commonly used for heating private houses.An electric boiler, the price of which is low and affordable to many, is simple in design. The presence of models with low power will allow you to install a heating boiler in a country house with a small living area without the need to obtain special permits.

Teng is a tube made of metal or ceramic, inside which a heating element is enclosed. The latter is a nichrome thread made in the form of a spiral. Between the heater and the walls of the heating element there is a dielectric with good heat-conducting properties. Such a design ensures high operational safety and a minimal probability of breakdown of the heating element body.

Despite its availability and unpretentiousness in use, before purchasing a heating element electric heating boiler, it is necessary to take into account its disadvantages:

- the appearance of scale on the surface of heating elements, which reduces their performance;

- in the event of an air cushion inside the heating tank, the heating elements quickly burn out and require replacement;

- increased requirements for the composition of the coolant.

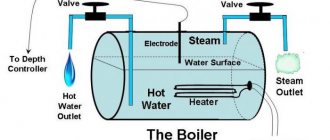

In ionic electric heating boilers, the heating medium is heated not due to the operation of the heating element, but by direct action on it. The process is carried out by exposing the ions of salts dissolved in water to an alternating electric current, which causes them to oscillate. As a result, thermal energy is released, heating the coolant itself.

The advantage of these systems is the compact dimensions of the body of the electric heating boiler and the ability to install it in those places where the maximum amount of heat is needed. In this case, the process of heating the coolant and adjusting its temperature is carried out almost instantly. Due to the absence of a heater as such, scale is not terrible for ionic electric boilers. Please note that over time, the electrodes will wear out and need to be replaced.