Here you will find out:

- What is a gas burner

- Classification of gas burners

- Other differences

- Gas burners for universal boilers

- Homemade units

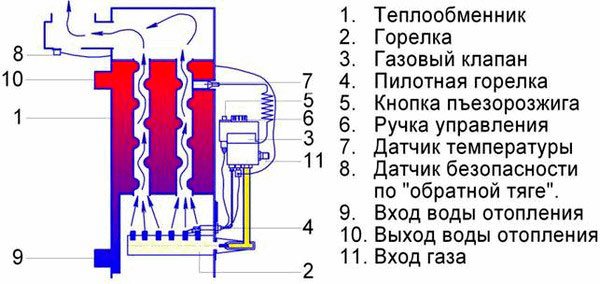

The heart of any gas boiler is a burner with a heat exchanger installed above it. The burner burns the gaseous fuel by generating heat. In turn, the heat is absorbed by the heat exchanger and sent to the heating system. It is the burners that the current review will be devoted to.

We will tell you what a gas burner for a solid fuel boiler is, and also give information about the types of burners for gas boilers.

What is a gas burner

The gas burner is one of the most important components of any boiler. She is responsible for creating a stable flame. It is here that the combustion of the supplied fuel takes place. The resulting heat rises up to the heat exchanger, where it almost completely passes into the coolant. Combustion products, together with heat residues, are discharged into the atmosphere in one way or another.

The device of a gas burner for a boiler is extremely simple - it includes several main components:

Low emission of nitrogen oxides and carbon monoxide gases during combustion makes the boiler almost flawless in environmental terms.

- Nozzle - gas is emitted from here;

- Ignition system - provides gas ignition;

- Automation system - controls the temperature;

- Flame detector - monitors the presence of fire.

To put it simply, this is how it looks. And how different types of gas burners differ from each other in different models of boilers, you will learn a little later.

A modern gas burner for a heating boiler is a device that has certain requirements. First of all, the noiselessness of work is important. I immediately recall some models of Soviet instantaneous water heaters, where the flame rustled with the force of a hurricane. Modern samples burn relatively quietly (attention is also paid to quiet ignition, without pops and explosions). An additional influence on the noise level is exerted by the design of the combustion chambers.

Long service life - if you remember the old gas units, they served for quite a long time (in those days, everything was done for centuries). Today, there are no such technologies anymore, so burners in boilers often break down. There is only one way out - to buy units from trusted brands, where components of normal quality are used. As for any Chinese junk from unknown manufacturers, everything is obvious here - you shouldn't take it.

The same applies to cheap Russian-made boilers - short-lived burners are often installed in them.

Complete combustion of the gas is another important requirement. A burner for a gas boiler must burn the fuel completely, with minimal emission of carbon monoxide and other related components. However, everything here depends not only on it - the other components also influence the quality of combustion. We must not forget about the proper discharge of gas, for which you need to have a clean chimney with good draft at your disposal. As for the principle of operation of a gas burner, it is simple:

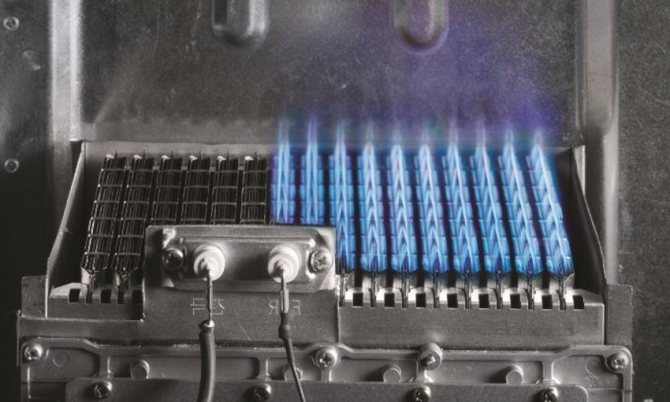

In the burner, the combustion gas is combined with air. At high temperatures, a chemical reaction occurs to form carbon dioxide and water.

- The boiler detects a discrepancy between the temperature in the heating circuit and the parameters set by the users;

- The gas valve opens, gas begins to flow into the burner;

- At the same time, the ignition system is triggered;

- The gas is ignited and a flame is formed.

At the same time, the control of the presence of a flame begins to work - if the fire suddenly goes out, the automation will cut off the supply of blue fuel. As soon as the temperature in the heating system reaches the set limit, the gas supply will be shut off.

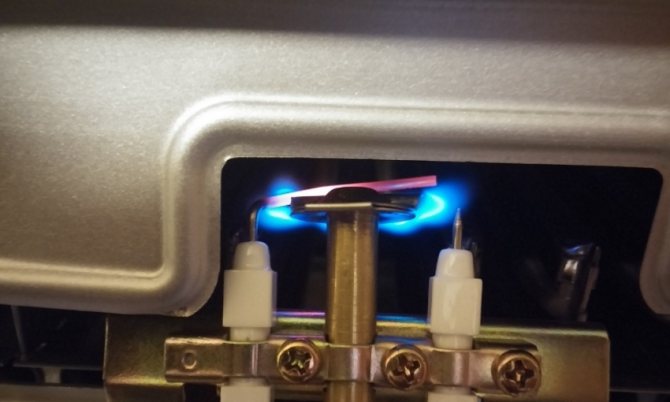

Flame control is implemented differently in gas burners. Somewhere there is a simple thermoelement, and advanced boilers with electronics-based automation are endowed with ionization control systems.

Ways to designate GG

All gas burners are marked in accordance with the current regulations and standards. The following are some examples of symbols that identify the performance and options of the machine.

The type of device is marked with letters. And the letter "G" indicates that the device is a burner.

If GM is indicated, it means that it is allowed to use the device in boilers operating on gas and fuel oil.

DS - evidence that the burner has an elongated gas sector.

Р - designation of the rotary model.

P - the device uses a nozzle, its rotor rotates to the right side.

L - the rotor rotates in the reverse vector (like an hour hand)

From the direction of rotation of the indicated rotor, the installation site of the burner itself in the combustion sector is determined.

Classification of gas burners

For a long time, the market was dominated by the simplest boilers, devoid of complex electronics and advanced automation. They needed full-fledged chimneys and had to be installed in rooms with good ventilation. Today, there are units on sale that can be operated in almost any conditions. Traditional models are sold along with them. They all differ in the design of gas burners.

Atmospheric gas burners

The use of atmospheric gas burners greatly simplifies the design of heating equipment. They work due to the natural flow of oxygen, and full-fledged chimneys are used to remove combustion products. Since oxygen is taken from the room, there must be good ventilation in it. Let's take a look at the main advantages of atmospheric boilers:

- Simplicity of design - has a direct impact on the cost of equipment;

- Low noise level - there are no additional fans, only the flame is buzzing;

- Higher reliability - a completely understandable pattern is triggered here that equipment with a minimum of parts breaks down much less and less often;

- Energy independence - thanks to this, the equipment can work in buildings in which there is no electrification.

There are also some disadvantages:

- Not the highest efficiency - you have to put up with this drawback. More advanced gas boilers with closed burners are more economical and efficient;

- The need for a full-fledged chimney leading to the roof is an additional cost in houses under construction;

- The installation of a boiler with an atmospheric gas burner should be carried out in a specially designated room, where there is ventilation and a window - sometimes it is problematic to follow these requirements.

It is also necessary to note the possibility of incomplete combustion of gas fuel.

"Turbocharged" burners

We have come close to the most modern heating equipment equipped with closed-type gas burners. Such boilers are often called "turbocharged". They are equipped with compact chimneys, often extending directly behind the opposite wall. This is very convenient, especially when the building is under construction - no need to worry about arranging the chimney and ventilation ducts.

A heating boiler with a closed combustion chamber is a heating unit in which a gas burner is enclosed in a special chamber.Oxygen is supplied here from the outside, through a special coaxial chimney. Through it, combustion products are removed. A powerful fan with automatically controlled speed controls all flows. If desired, the "turbocharged" boiler can be mounted in an absolutely sealed room, devoid of ventilation and windows.

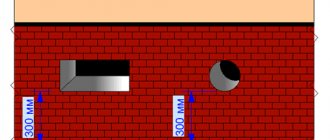

A coaxial chimney is a kind of "pipe in pipe" design. It serves for intake of outside air and for removal of combustion products. Such a chimney is displayed at an arbitrary point of the nearest wall, but not closer than half a meter to the nearest windows (more stringent requirements may be imposed).

Advantages of gas boilers with closed burners:

- Can be installed in any room - in kitchens, basements, bathrooms (even in the bedroom);

- Increased safety - gas burns in an isolated chamber. Even if it goes out, and the automation does not react to it, the gas-air mixture will be removed outside the apartment / house;

- Increased efficiency - gas boilers with closed burners are indeed more efficient, but this does not apply to all models;

- More efficient temperature control - for this, a fan speed control system is used here;

- High environmental friendliness - the fuel burns almost completely.

Unfortunately, there were some drawbacks:

Increased safety and efficiency come at the price of higher noise levels and higher maintenance bills.

- Increased complexity - gas burners for heating boilers have a more complex design, which makes it difficult to carry out repair work;

- Slightly reduced reliability - the more parts, the lower the reliability of the system (the cheapest samples and Chinese models often fail);

- High price - in order to buy a "turbocharged" boiler, you will have to pay a round sum (they cost 10-15% more than their atmospheric counterparts);

- Increased noise level - the fan installed in the system emits a hum (the noise level depends on the specific model);

- Lack of non-volatility - when the light is turned off, the equipment will stop working. The problem is solved by installing an uninterruptible power supply.

Despite this, the use of these boilers for heating houses and apartments is becoming a certain trend.

Closed-type burners are equipped with so-called condensing boilers, which are characterized by increased efficiency due to the extraction of heat from the combustion products.

Views

By the way oxygen is supplied to the combustion chamber

They are divided into two groups:

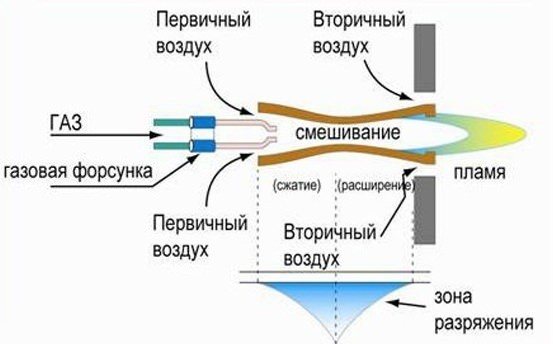

Atmospheric

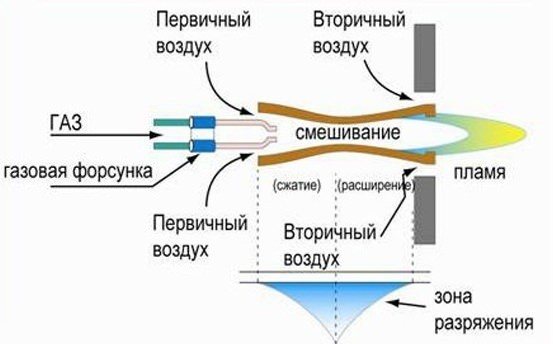

The gas is mixed with air coming directly from the room where the boiler is installed. The principle of an elementary ejector is applied here. The gas is directed through specially shaped nozzles located inside the channel. They have access to ordinary air. A little further away there are several slots through which the prepared mixture of gas and air will come out.

In the direction from the nozzle to the outlet, the gas-air mixture dilutes the air a little, which creates conditions for supplying a new portion of it.

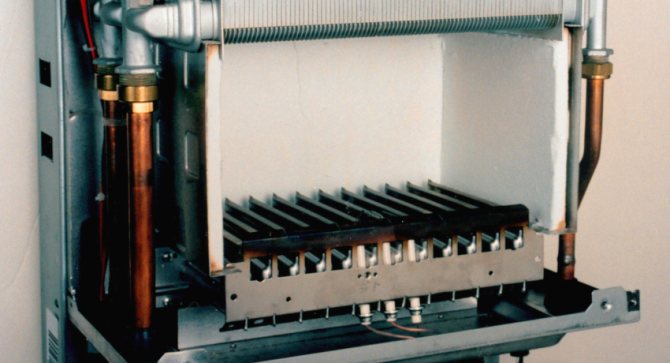

Combustion takes place in a special chamber, where there are several channels installed in parallel with respect to each other. Each of them is equipped with a separate nozzle.

The heated gases after combustion are directed to the top of the heat exchanger, transferring a certain percentage of their energy. They are then released into the environment through the chimney. Due to the fact that as a result of this process, a certain temperature difference occurs, thrust is formed. This creates a regular supply of new portions of oxygen.

atmospheric burner operation diagram

This design has a number of positive qualities:

- It is very simply arrangedand, besides, the components are very cheap.

- The functioning is completely independent of the availability of electrical energy. Here, a much more important role is given to the correct design of the chimney and the total pressure in the domestic gas main.

- Works silently.

- Weighs almost nothing and does not take up space.

- It is very easy to install or replace.

The atmospheric burner also has disadvantages. First of all, you will have to build a chimney without fail. How completely the gas-air mixture will burn completely depends on the composition of the air and the quality of assembly of all systems of the heating boiler.

Fan burners

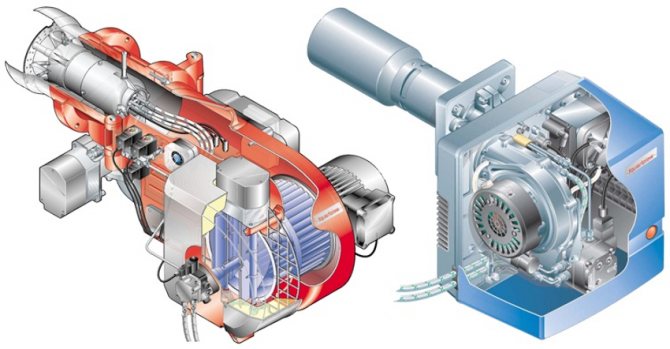

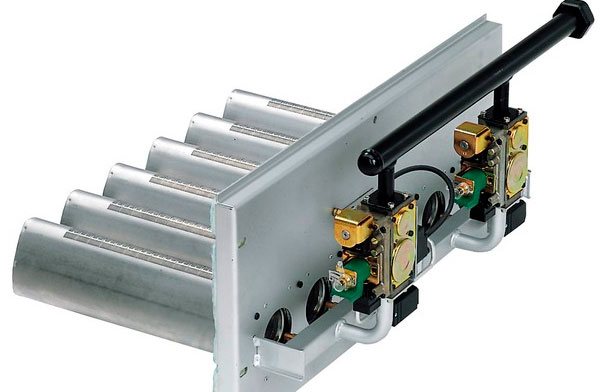

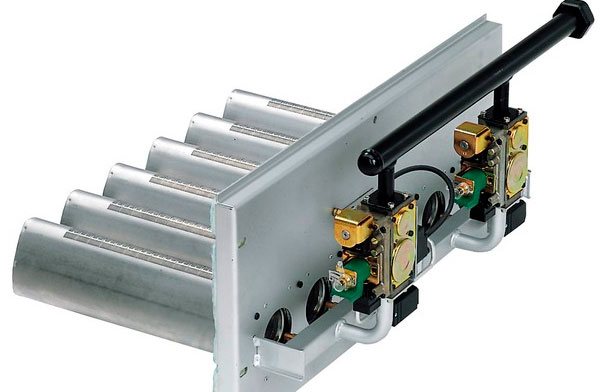

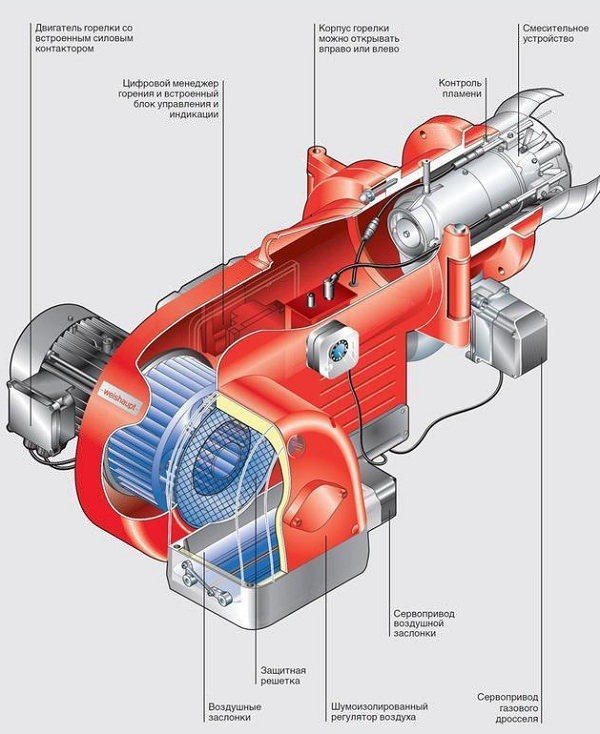

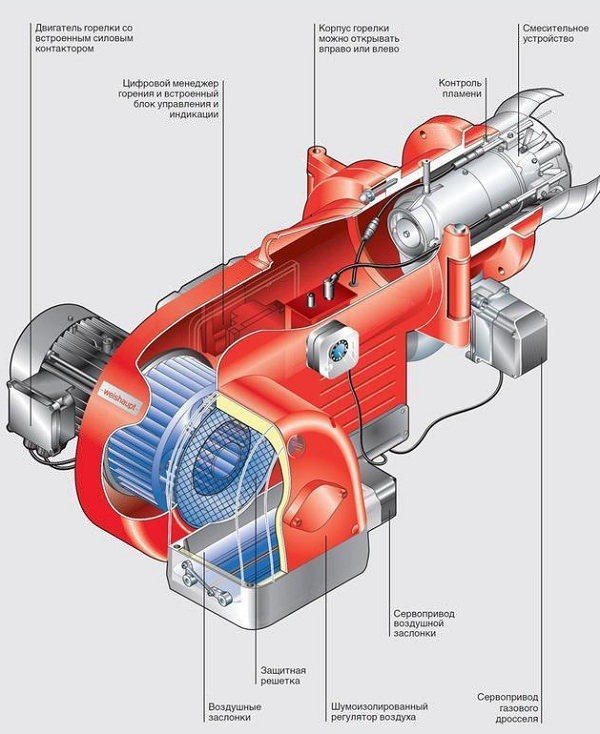

They are more complex, the same can be said about their management. However, with their help, you can achieve absolute control over the entire automatic system of this process. In this case, the air, which is mixed with the gas, comes from the street, and it is sent to the combustion chamber forcibly due to a special fan.

If necessary, the fan speed can be changed depending on the pressure in the system. Exhaust gases are also forced outside the premises.

You can adjust the air or gas supply slightly so that the exhaust is less hot at the exit. Accordingly, this will allow a greater amount of heat to be transferred to the coolant, which, in turn, increases the efficiency of the boiler.

Here it is most convenient to use a coaxial chimney, which includes several pipes of different diameters in its design. They are inserted into each other. Due to the fact that fan burners force air to the fuel, it is best to think over that they are suitable for several types of fuel at once, for example, gas, diesel fuel, gasoline, and so on.

fan burner design

There are also quite a few advantages of a fan burner:

- Fuel mixture and combustion are under the full control of the operator.

- Boiler power also regulated.

- Consumption fuel consumption is greatly reduced.

- Efficiency higher than atmospheric.

- They can be installed even in such houses or apartments.where the chimney is simply absent.

- The burner does not have to be readjusted for a different type of fuel.

Despite such a large number of positive characteristics, there are also disadvantages:

- Such a burner will be quite expensive.

- It depends on the availability of electricityif not, then the gas is automatically turned off.

- Use and maintain the burner it is possible only by calling specialists.

By type of flame regulation

Low temperature burner

Which works due to the tongues of flame, heated to fairly low temperatures... In most cases, such systems are used in many types of boilers - from Soviet-made designs to the latest models. Just like the atmospheric burner, the low temperature burner is virtually noiseless and is also versatile.

Single stage

It is capable of functioning in only one mode, and the temperature of the coolant is controlled only by turning off and on the burner itself. The two-stage is either running at full capacity or at 40%.

After heating the coolant to a predetermined temperature, the burner begins to economically consume fuel. This makes it possible to maintain the temperature at a stable level, where there is no need to use the burner operating at full capacity.

Modulating burners

which are able to work with almost any power, due to which the temperature control is carried out in a very smooth mode.

In principle, there are quite a few varieties of gas burner designs for heating boilers, but they are not very common:

- Diffusion - in this burner, the combustion of fuel occurs without mixing with air oxygen.

- Injection - here the air is fed directly into the furnace, where natural gas itself is added to it, after which the mixture is ignited.

- Premix burner - here mixing takes place at a point just in front of the outlet.

- Recuperative - before mixing gas and air, they first warm up. Air and gas reach a certain temperature, after which they mix with each other.

Other differences

Consider the division of gas burners by type of ignition. The easiest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two drawbacks here - increased gas consumption and low safety (the igniter may go out). Primary ignition is carried out with matches or with the help of a piezoelectric element that gives a spark.

Natural gas from the mainline gives an even combustion, without forming excessive soot on the walls of the chimney.

Electronic ignition of the burner provides for the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the electrical network. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Together with such ignition, modules for ionization control of the presence of a flame are often installed.

There is also a split according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied with optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without alterations. There are burners that can work on propane - this requires setting up the system and installing a jet. The flame from the combustion of propane gives off a yellow color, there is an increased deposition of soot on the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

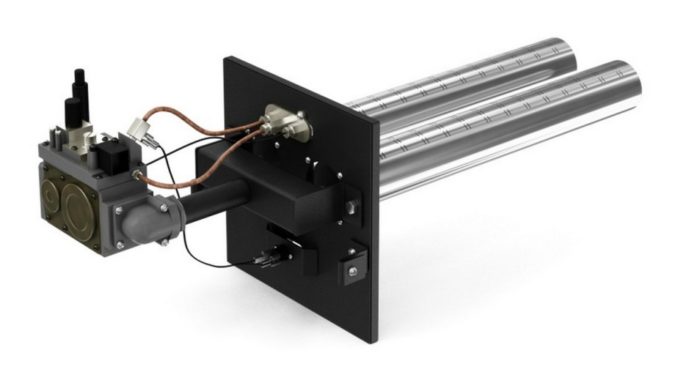

Gas burners for universal boilers

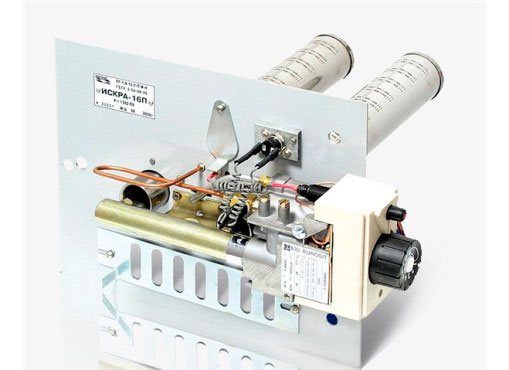

A gas burner for a solid fuel heating boiler is a rather complex unit. It was created to transfer heating equipment from one type of fuel to another. That is, you can purchase a solid-fuel (universal) unit for working on wood, and when a gas main appears, transfer it to work with natural gas.

It is best to entrust the maintenance of even the simplest gas burner to a master - the services of a specialist will come out cheaper than buying a new unit.

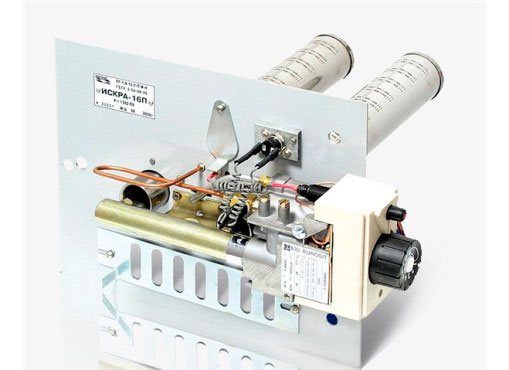

The automatic gas burner for a solid fuel boiler is built according to a fan circuit. Gas is supplied here, mixed with air, after which the finished fuel-air mixture is sent to the nozzle. Here it is ignited, forming a high-temperature flame torch. On board the burner there is a powerful fan, an automation system, a reducer and a gas filter. The unit requires electricity to operate. The product itself has a modular design (removable).

A typical example is a gas burner for a Cooper boiler. The boiler itself is a pellet boiler, but you can connect a replaceable burner to it and convert it to natural or liquefied gas.

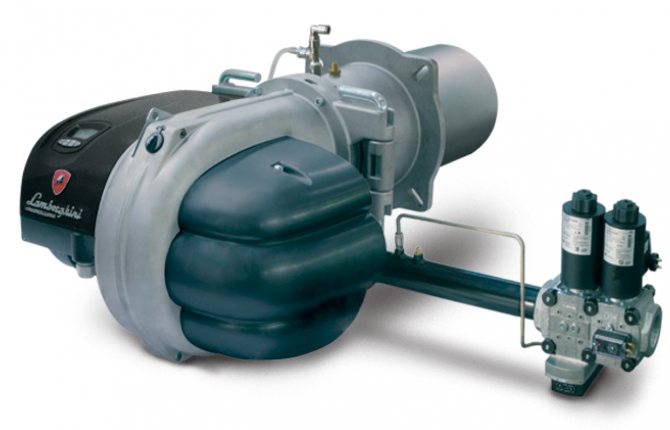

Combined universal burners

Designed to operate on two types of fuel - gas and diesel. Expensive, but they will pay off in the future. can be heated both with main gas and diesel fuel. When using two different types of fuel in boilers, combined burners are used. The most common combination options are considered to be a gas burner with a liquid fuel, and a gas burner with a universal one.The universal ones are the most economical to use, they often work on waste oils, vegetable and animals, on diesel fuel. The use of such burners helps to solve the problem of waste oil disposal. Nozzles for boilers are single-stage and two-stage, with and without heating, they are mainly used on high-power hot water and steam boilers.

Homemade units

Some craftsmen make gas burners for boilers with their own hands (for solid fuel boilers). It should be warned that this is unsafe. Yes, and no one will connect such a structure to the gas main. Most often, such "crafts" are made on the basis of any expired gas units. Remember that a homemade gas burner for heating your home is far from the best option. It is best to purchase the simplest gas-fired non-volatile boiler and convert it to bottled gas.