Steel radiators have been known to many since Soviet times, when ribbed appliances were installed in apartments with central heating and which gave heat at a decent level. Today, steel heaters have not gone anywhere, but on the contrary, they have developed and are actively used in heating systems. Let's understand in detail.

The main types of radiators

Steel radiators... They are mainly used for heating residential buildings. The appearance is quite aesthetic, the price is above average, decent heat dissipation is why they choose steel radiators for private houses.

Bimetallic radiators... They are widely used in the construction industry. The quality-to-price ratio is acceptable. A distinctive feature is the use of a steel tube in an aluminum casing. Can be used in central heating.

Cast iron radiators... The oldest type of heating radiators. Their form is simple and strict, the facade is smooth, and the design is restrained. They heat up for a long time, but are ideal for systems with central heating. They are durable, inexpensive, last about 50 years.

Aluminum radiators... They stand out for their beautiful external appearance. However, this type of radiator for heating is not the best option for use in living space where there is a central heating system. But in a living space with an autonomous heating system, this type of radiator is considered quite famous. In addition to their elegant external appearance, they are distinguished by reliability and a long service life - about 25 years.

Copper-aluminum radiators... They have high heat dissipation. They are often installed in apartments, offices and similar premises. Resistant to corrosion.

Connection options

Radiator connection options

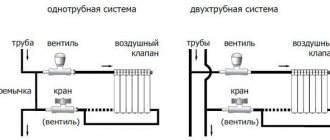

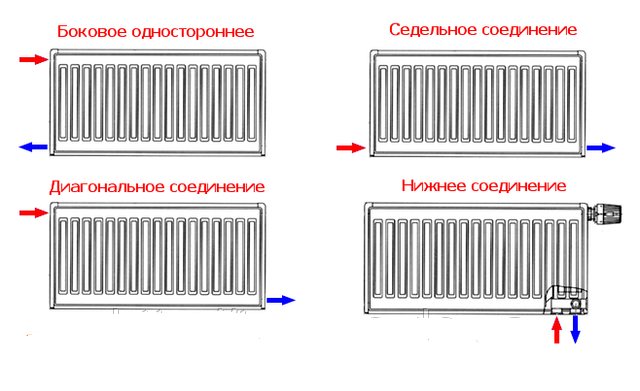

There are several connection options, including bottom, diagonal, and side. Each of them has its own characteristics, therefore, when choosing, you need to focus on the type of heating system, the area of the room, as well as other factors. It is best to contact a specialist who will install the battery in accordance with the rules and standard standards.

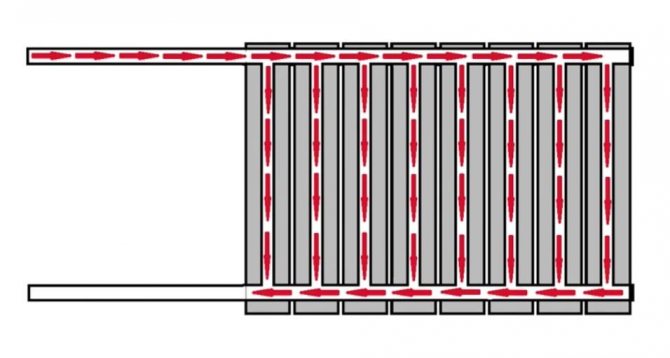

Diagonal

This type of connection is suitable for one-pipe systems. This method allows you to distribute hot water as efficiently as possible. When there are more than twelve sections in one radiator, special nozzles must be used so that the flow passes deep into the heating device. To clarify the exact number of sections, you need to calculate the power using a calculator in order to eliminate possible errors. This scheme allows the heat carrier to pass diagonally through the entire volume and evenly heat all sections.

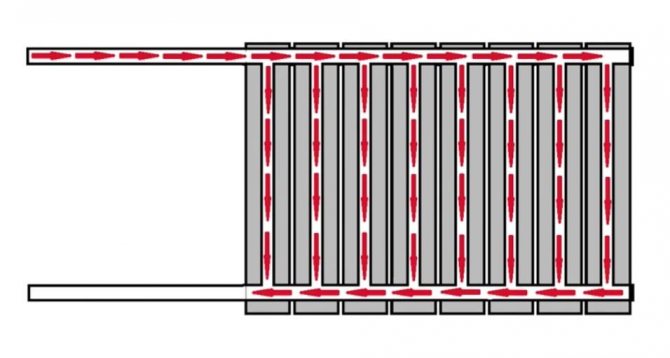

Lower

Devices with this connection method are called universal. Their main advantage is complete invisibility and the ability to harmoniously fit the unit into the interior and space of any type. This is possible through the use of angle and straight fittings, also called radiator binoculars in plumbing parlance. The complete set of the units includes a thermostatic valve, a thermal head and much more. Although they are not more expensive compared to other types of radiators, they are not a bad option for most modern homes and apartments.

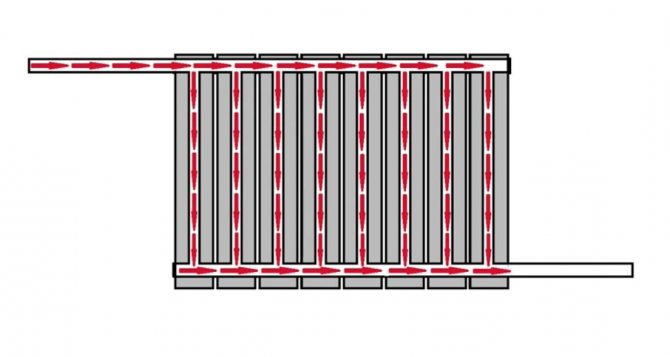

Lateral

With lateral connection, the potential of the radiator is fully exploited

Devices with a side connection method are the most popular among buyers, and not only because of the low price.Such radiators are switched in several ways, most often a one-sided side circuit is used, thanks to which the potential of the device is used to the fullest. Side diagonal connection is used only for units with a large number of sections, this option negatively affects the aesthetics, but provides an ideal level of heat transfer and heating.

Panel view

Steel panel radiators are often called convectors. Consists of one / several heating panels, convector fins, connection pipes, channels for the heating medium, grate.

Quite an economical choice for use in a private house, it is widely used for rooms with autonomous heating.

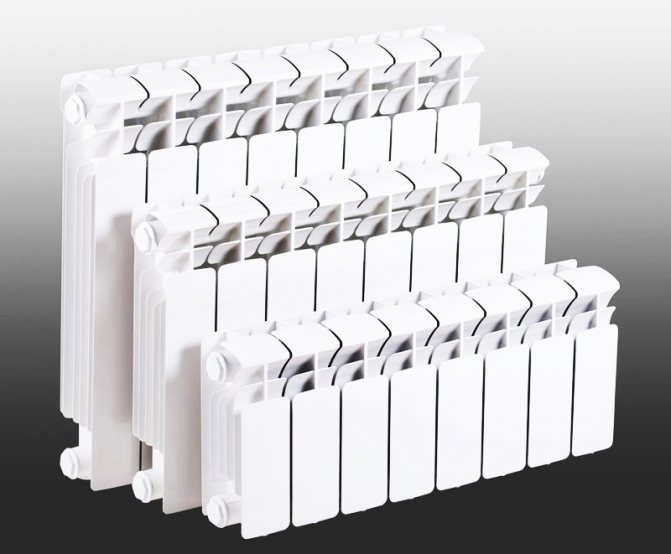

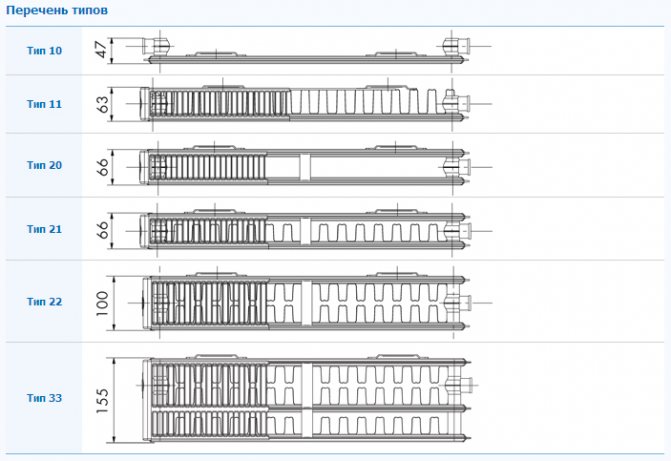

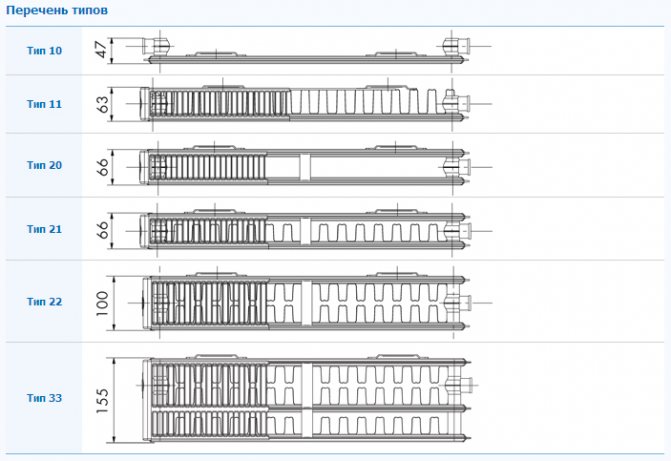

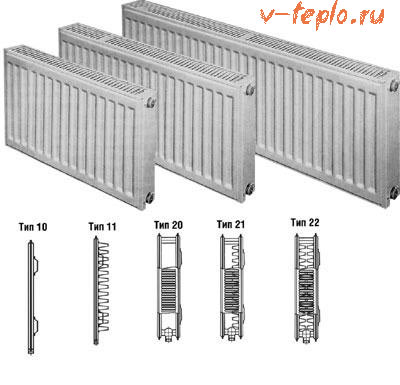

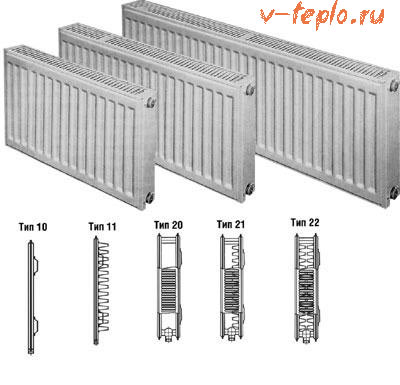

Types of steel batteries

It is divided into types depending on the number of heating panels, convectors. 11 type - consists of one row of panels, convector, does not have a grate on top. They are often used to equip corridors and toilets. 22 type - has two panels, convectors, casing. With a relatively small size, it has good heat output. Type 33 - three panels, convectors, the casing is closed.

Selection

Heat dissipation varies between 200 and 1800 Watt and more. Depends on the size of the radiator, brand and model. Their inertia is small. They heat up quickly and give off heat to the room. Working pressure is about 7-10 atmospheres. They are highly susceptible to corrosion. Withstand water temperatures up to 120 degrees. The length is about three meters, the height is from 25 to 85 centimeters. The thickness of the steel depends on the manufacturer, usually from 1.1 to 1.2 mm. Durable due to their material, the thicker the walls, the longer the radiator will last. Their installation is quite simple and convenient.

Connection types

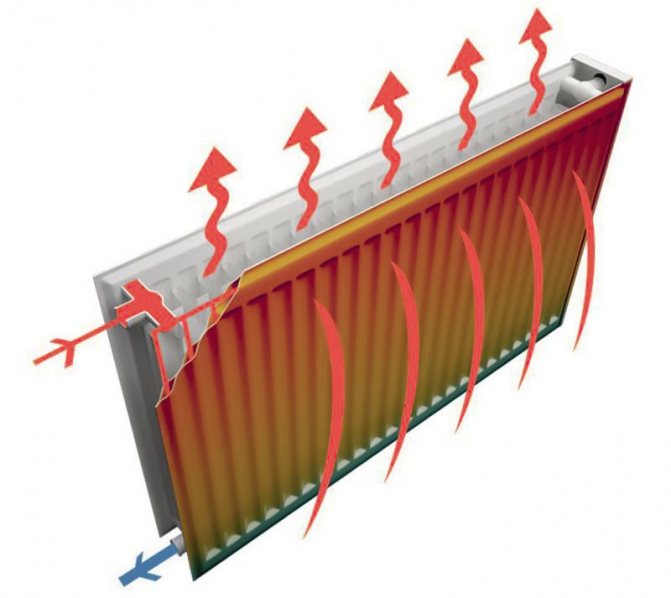

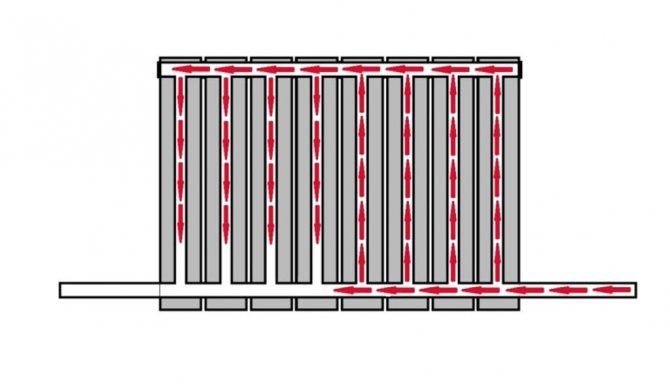

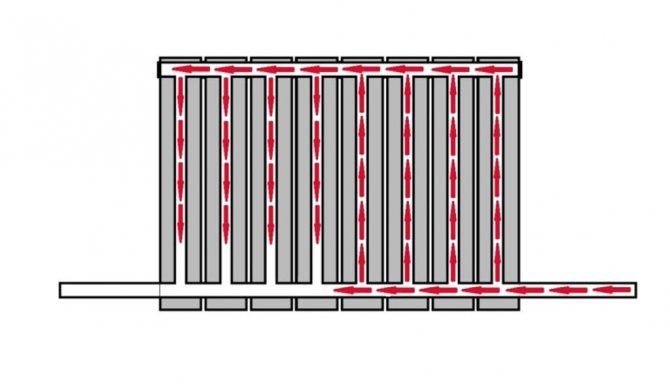

Lower... The coolant flows into the lower part of the radiator. Warm coolants are lighter than cool ones, as a result of which it rises upward, displacing the cooled coolant. Then the cooled one is lowered into the lower horizontal radiator manifold. Heat costs will be approximately 15-20% depending on various factors.

Upper... The coolant moves along the upper part of the radiator, but must go down because of the plug, then go up along the pastel section and flow out of the radiator from the other side. Thus, the coolant flows through the entire structure of the radiator, and it heats up completely.

Lateral... With this inclusion, the coolant enters the upper part of the radiator, after which it descends downward along the vertical channel of the radiator and through the lower collector comes out through the side from which the radiator was connected. However, any coolant moves along the path of less resistance. A huge fraction of the coolant will flow through the 1st sections. As a result, the more sections the radiator has, the lower the heating temperature will be in the last sections. This will affect the joint heat loss of the radiator.

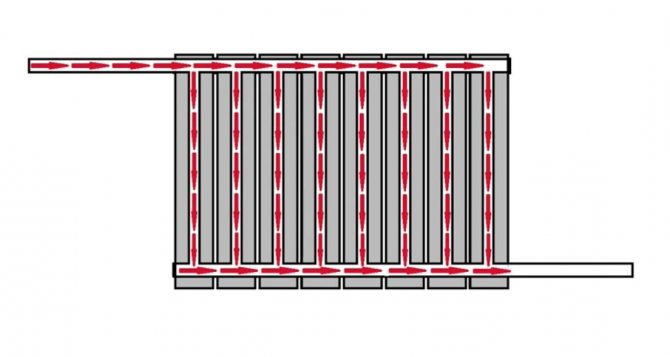

Diagonal connection... The heating medium is supplied through the upper part of the radiator, which is horizontal to the floor. Then it flows downwards along vertical pipes, falls into the bottom of the radiator and goes out in the other direction. So the radiator heats up completely, each section heats up approximately identically well.

Design

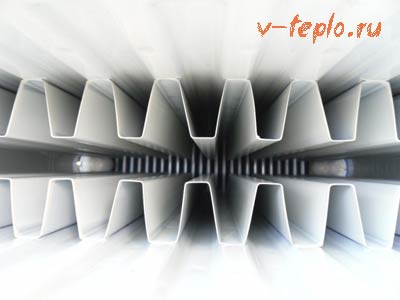

Radiators consist of 1, 2 or 3 panels. To create each of them, metal stamped plates are used. The plates themselves are welded together along the contour. Vertical channels inside the plates are formed during stamping. These channels become the main route along which the coolant flows.

Finished plates are connected using roller welding. Use special pipes if more than one panel is installed. It is allowed to fix plate convectors between panels to increase heat transfer. The gaps on the sides are closed by casing grilles when the panel is not alone.

The heat dissipation of the devices is increased due to the finning. The second number in the marking will tell you how many edges there are inside the structure. The first digit indicates the number of panels themselves.

- 10 - no ribs.

- 11 - supplied with 1 row of edges.

- 22 - in two rows.

- 33 - 3 rows.

The panels are available in different lengths and heights. The minimum height is 30 cm, the length is the same, and the minimum width is 4.5 cm.

The thermal power depends on the standard sizes. The accompanying documentation lists the specifications for a particular model. In some models, heat transfer reaches 75 percent, only due to convection.

Advantages and disadvantages

- environmentally friendly, do not harm (thanks to this they can be used in clinics, schools, etc.);

- small volume of coolant and energy consumption;

- high heat transfer;

- aesthetic appearance;

- convenient to mount;

Disadvantages:

- drafts may occur, dust may rise due to convection;

- high risk of damage due to water hammer, use in high-rise buildings is not possible;

- paint may peel off;

- the appearance of corrosion when draining water from the radiator.

- lose in price to many radiators

Tips and Operations

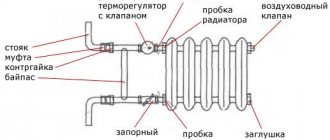

Even the highest quality device can fail if not properly maintained and safety instructions are not followed. During the operation of panel radiators of any type, the following rules are observed:

- radiators with a manual or mechanical thermostat are considered the most practical;

- to prevent accidents and flooding, it is necessary to install ball valves that shut off the flow of the heat carrier;

- in order for the system to work efficiently, air is periodically pumped out from the inside.

It is not so difficult to choose steel panels for home heating; before that, you should familiarize yourself with all the available options in order to make the right choice, and seek advice from specialists.

Tubular view

They look like a standard construction of pipes and steel through which high temperature water flows. Their production costs higher, so the price is more expensive than that of panel radiators. Quite low pH of water - from 8 to 9. Withstands pressures from 9 to 14 bar. The thermal power is 1300 to 1500 Watt.

Tubular steel radiators have similar pros and cons as panel radiators. However, there are two different indicators: they can withstand more pressure and are more expensive.

Steel panels: good or bad

Most steel radiators are affordable. Steel is cheap in itself, and this is a fact, and the simplicity of its processing only plays into the hands of the consumer.

This feature applies mainly to panel radiators. Tubular steel radiators, for example, are difficult to manufacture and therefore more expensive.

Steel has good heat dissipation. It is lower than that of aluminum, but on a five-point scale it can be estimated at 5 (aluminum will have 5+).

From the point of view of environmental friendliness, steel radiators have no equal: in accordance with sanitary and environmental requirements, they can be used in almost any facility (even in hospitals and kindergartens).

Steel heaters are not devoid of disadvantages, but all their disadvantages are very controversial.

For example, the chemical properties of steel are such that corrosion is its true companion. This fact, in the opinion of ordinary people, “puts an end to steel radiators (at least - on their use in centralized heating systems). In accordance with their logic, autonomous heating can be filled with non-freezing liquids and independently control the quality of the coolant. But let us turn to the opinion of a specialist.

Konstantin Vitaliev

The steel panel radiator can be used absolutely in any modern heating systems. Closed (independent) heating systems are used in modern apartment buildings.This means that the coolant in the heating circuit of an apartment building is heated through a heat exchanger installed in the ITP (individual heating unit). The heat exchanger, in turn, is heated by the heat carrier from the external boiler room. Thus, the heating system of the building is insulated and uses only its own heat carrier, the quality of which is easier to monitor.

Another disadvantage, which is mistakenly attributed to all steel radiators: these products are not designed for high system pressure. Indeed, a heater with a wall thickness of half a millimeter cannot withstand the same pressure as a panel radiator with a wall of 1.25 mm. Therefore, always pay attention to the passport characteristics of the product, and problems will bypass you.

Additional restrictions on the operation of a steel radiator, again, are associated with the electrochemical properties of the steel. It is prohibited to drain the coolant from the system in which steel radiators are installed (except for situations related to accidents or the need for preventive maintenance). If it is not difficult for the owners of autonomous systems to comply with this requirement, then residents of apartment buildings can ignore it at all.

Konstantin Vitaliev

In modern apartment buildings, the coolant has not been drained from the heating system for a long time. Therefore, there is no problem with compliance with the manufacturer's requirements.

Main manufacturers

One of the most famous steel panel radiator manufacturers - Kermi, Germany. The quality of the products is high, and special technologies are used during the creation that increase the heat transfer factor. Thanks to the two innovations “Therm X2” and the setting of the valves, approx. 10% of the energy is saved in advance. The range includes radiators with bottom and side connections. Available with popular types 11, 22 and 33.

Buderus, Germany. They are used mainly for heating houses, other buildings, where the coolant temperature is not more than 110 degrees. Lengths of executions from 400 to 2900 mm, heights from 350 to 850 mm. Upon delivery, the radiators are completely ready for installation. Can be installed in systems with pressures up to approx. 9 bar.

Korado, Czech Republic. Their main part is a pair of plates, which represent a heating surface. The company has a wide range of models, so a person can easily pick up the steel panel heating radiator he needs. Wall thickness over 1.15 mm. It is used as a coolant for water / water substances with a temperature of up to 109 degrees Celsius. You can install the piping in a hidden way.

DeLonghi, Italy. They work silently, there are no open heating parts at all, the rooms are heated evenly. The manufacturer guarantees the safety and reliability of the products.

PURMO, Finland. Finnish steel radiators are gaining more and more popularity in our country. Indeed, due to the affordability of prices, domestic creators are not particularly represented on the heating appliance market. The price / quality pleases buyers, a different choice of sizes and types of radiators makes it possible to choose a heating device for your place of residence, office, or other building. Reviews speak of a long service life, a pleasant appearance, high performance of the device. Also a plus is the fact that the manufacturer makes radiators not only in white, but at least in black, red, and so on. You can choose the color to order. Manufactured from mild steel. 4 types of connection are possible - lateral, saddle, diagonal, bottom.

Among the manufacturers of tubular steel radiators, it is worth noting Charleston, Germany. They have a lateral connection, a columnar structure. Made up of several sections that are connected by welding. They are used in closed systems where the radiator does not come into contact with air. It is not applicable for hot water supply.Can be used not only for residential premises, but also for administrative buildings. The thickness of the steel is standard, about 1.2 mm.

Arbonia, Germany. Their appearance is quite minimalistic, you can also choose a color to order. Radiators do not take up large areas due to their small and narrow dimensions - they are tall, but thin. The modern look is perfect for freshening up the design of your area. It doesn't look like traditional batteries.

How to choose panel heating radiators

It may seem to many buyers that the panel radiators offered on the market are very similar. In fact, they have quite a few differences. Before making a choice, you should pay due attention to the following features:

- Marking

- Number of panels

- Connection method

- Performance

- Set

Marking

All the basic information about the panel type radiators offered on the market can be found by looking at the marking. It usually contains the following designations:

- The first number is the number of panels

- The second digit is the number of planes containing edges

- The first letter of the name (C - Purmo, I - Integral, K - Kompakt, etc.)

- Designation of the type of connection to the pipe line (C - side, V - bottom)

Many manufacturers tend to provide additional useful information, including the height and length of the panels.

Number of panels

The number of panels is a very important indicator, since it primarily affects the power of the product. Radiators of three types have become widespread:

- With one panel (thickness - about 6 cm)

- With two panels (thickness - 10-14 cm)

- With three panels (15-18 cm thick)