Natural gas heating equipment is very popular today - it can be used to heat rooms of any size. In residential buildings connected to a centralized gas network, boilers equipped with electric ignition are usually installed. Such a device greatly simplifies the use of the unit - you no longer need to use matches to “turn it on”. It is enough to press the electric ignition button and the gas boiler will start producing heat energy. A special device instantly generates sparks, causing a flame to appear.

The principle of ignition

Electric igniters, which are equipped with most modern models of gas boilers, include the following elements: diode, resistor, capacitor, transformer, candle, switch. This convenient and practical invention facilitates the operation of the unit, speeding up its start-up and set-up. With the help of a compact device, you can kindle a flame in a burner not only quickly, but also safely, without the use of matches and lighters, which tend to run out and deteriorate. The flame appears immediately after pressing a button or turning a lever.

It is customary to distinguish between several types of electric ignition for gas boilers - mechanical, automatic and semi-automatic. If the unit is equipped with a mechanical ignition, to turn it on, you must not only activate the burner by turning the switch, but also press a special button. The device will generate a spark and ignite a flame. If the electric ignition is automatic, then the equipment turns on when you turn the knob - you do not need to use additional devices. To be able to use auto-ignition, the heat-generating device must be connected to the mains (an earthed socket must be nearby). If the electric ignition of the gas boiler is out of order, it is worth calling a repairman for heating equipment at home, this can be done on the website https://24master.com.ua/.

Selecting a non-volatile boiler

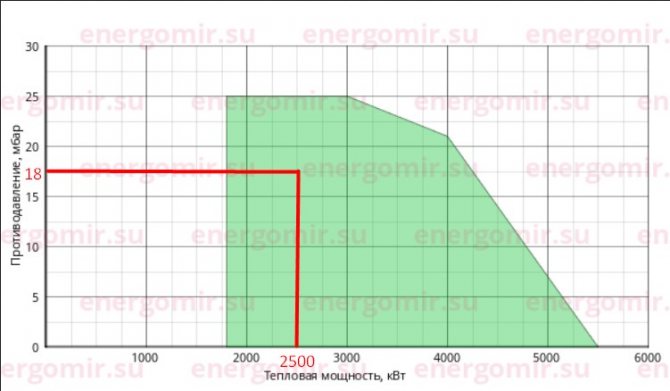

The boiler is chosen according to its power so that it is enough to heat an apartment or house

The choice depends on the purpose of the object and the financial capabilities of the buyer. There are other parameters that you pay attention to before purchasing the unit.

Technical characteristics are taken into account:

- Power. If the indicator exceeds the heating requirement of the room, excess fuel is consumed. For double-circuit boilers, 25% is added to the area of the house for the needs of hot water supply.

- The number of contours. Depends on the purpose of the building. In medium-sized residential buildings, double-circuit units are installed, and single-circuit units are suitable for auxiliary buildings. If the cottage is large, a water heater is additionally mounted to the boiler.

- Heat exchanger material. Steel models save money, but cast iron is chosen for long-term operation.

- Gas consumption. The models have different combustion rates and different efficiency.

- Temperature limit of operation. Gas units heat water up to +80 - 90 ° С.

- Coordination and management system. Automation ensures independent operation of the unit without human intervention.

The design and dimensions of the unit are selected depending on the user's preferences. There are a large number of standard sizes, but the appearance does not affect the quality of functioning.

Rating

The wall model Proterm is enough for a house with an area of up to 200 sq. m

Most of the offered boilers are manufactured abroad. The leading place is given to Germany, Italy, Slovakia, Belgium, South Korea.

Popular quality models:

- Protherm Cheetah. Wall-mounted model of a two-circuit unit with a power of 23.3 kW. The efficiency is at the level of 90.3%, heats the house up to 200 m2. The compact unit weighs 31 kg.

- Ferroli Domina N F24. Non-volatile model with a power of 23.5 kW. Double-circuit equipment with a closed chamber. Heats the area up to 180 m2, efficiency - 93%.

- Baxi Slim 1.300 iN. Floor-standing construction with cast iron heat exchanger. It is possible to connect an external boiler and a floor heating system. A built-in outdoor temperature meter is provided, which facilitates the operation of the automation. Heats up to 365 m2.

- Ariston GENUS Premium EVO 24 FF. Wall-mounted double-circuit model with display and front panel controls. Gas consumption is not more than 2.5 m3 per day. Stainless steel heat exchanger, it is possible to connect a pump and a forced fan.

- Navien GA 35 KN. The device is of low weight and dimensions, equipped with connecting pipes on both sides. Convenient control, instructions in Russian. The unit works quietly, the internal elements function reliably and for a long time.

Models of well-known manufacturers take into account the conditions of the Russian climate and work efficiently.

Why Ignition May Not Work

Electric ignition is considered one of the most vulnerable elements of a gas boiler, since it is he who fails more often than other components. The reasons for the breakdown can be mistakes made during the operation of the device, wear of parts or mechanical damage. Having discovered that the ignition does not work, the first step is to make sure that it is connected to the mains, and there is voltage in it. If everything is in order with the power source, and the device is still not functioning, the reason may be a malfunction of the power supply or a button, damage to the wire. To diagnose a breakdown, you will need a tester, it allows you to check the presence of conductivity.

How to fix the ignition yourself

Self-repair of household appliances or its components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to fix the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to water or grease, power surge, or carelessness. The main symptom of a device malfunction is the absence of a spark. If there is a spark, but the flame cannot be ignited, it is necessary to clean the contact areas of the burner and candles. If the electric ignition unit is broken, the current-carrying paths and the resistance of the windings should be checked. When repairing the ignition, new parts may be required.

Diagnostics at the service center

Repair of electric ignition of a gas boiler is included in the list of services of many service centers specializing in maintenance of household appliances and heating equipment. Turning to qualified specialists, you can count on the fact that the device malfunctions will be eliminated as quickly as possible. Reliable service centers that value their own reputation provide customers with a long-term warranty for equipment repairs.

To determine the cause of a malfunction in the electric ignition of a gas boiler, the foremen use modern diagnostic devices. During the repair, specialists use exclusively high-quality original components. In addition, the SC offers to call the master at home. This service eliminates the need to deliver the overall unit to the workshop yourself. Repair of a gas boiler may involve replacing the ignition unit, restoring the control unit, eliminating the leak, installing a new valve. An experienced specialist will be happy to answer all the client's questions regarding the rules for operating the equipment, and also tell you how to avoid breakdowns in the future. Service centers offer advice or order this or that service at any time of the day.This can be done by phone or through the website.

The principle of operation of a gas burner

There are several different types of gas burners, but the principle of operation is the same.

The burner is a metal hollow tube with several holes (nozzles). It is supplied with gas, which is burned in air, which is forced into the combustion chamber.

As a result, a mixture of combustion products is formed (carbon monoxide, carbon dioxide, water vapor, soot - pure carbon), which is removed to the outside. The gas is evenly distributed thanks to the nozzle system, and the air is forced by natural draft (forced draft in industrial furnaces).

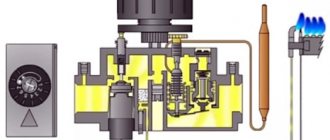

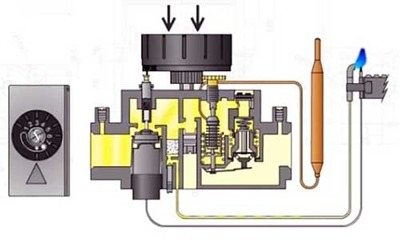

It can be schematically represented as follows.

The principle of operation of a gas burner (diagram)

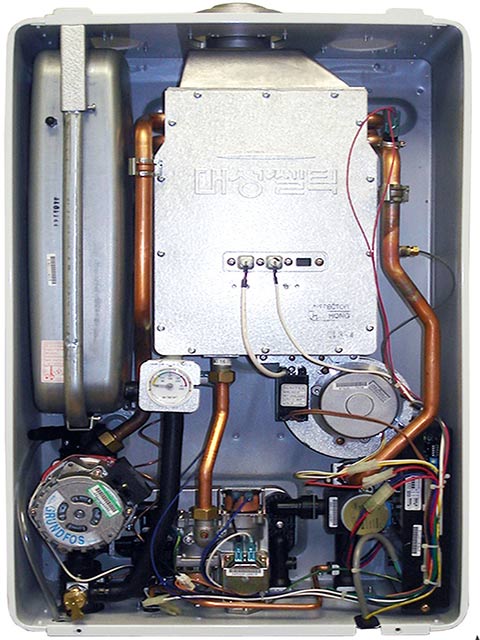

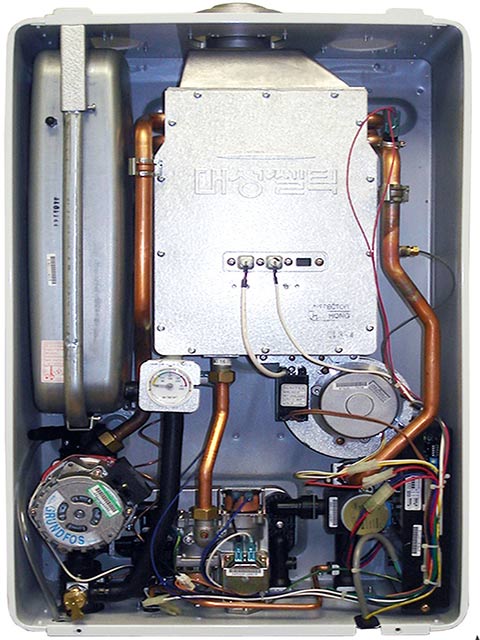

And in a real gas boiler, the burner looks like this.

Thus, if the gas boiler does not ignite, this means that any of the combustion conditions are not met:

- Gas is not supplied.

- There is no draft (no air is supplied).

- Combustion products are not removed (as a result, they accumulate and do not allow the flame to ignite, which is why it goes out immediately after ignition).

Double-circuit boilers.

Double-circuit boilers, in addition to heating functions, play the role of titanium or a water heater. Double-circuit boilers are of two types:

- Type 1 has a boiler for hot water storage. The water in such a boiler retains its temperature long enough after the boiler is turned off;

- Type 2 with a flow-through heating system, in which water does not accumulate, but heats up, passing through the boiler fire or the primary coolant. In this case, accordingly, there is no supply of hot water.

By the type of chimney system, gas heating boilers can also be divided into types:

- smoke and combustion products are removed due to natural draft, and there is a need to build a chimney. The rooms where boilers are installed with such a system for removing furnace gases must have good ventilation, because they consume room air;

- chimneys with forced draft. In such exhaust systems, combustion air comes from a special coaxial chimney consisting of two pipes. The outer pipe brings air to the combustion zone, and the combustion products are removed through the inner pipe. With the help of this design, heating of the air entering the combustion zone is achieved, as well as cooling of the outer walls of the chimney, which in turn reduces its fire hazard.

The ignition system of a gas boiler can be either electronic or piezoelectric.

The main causes of problems with a gas boiler

You can start repairing equipment only after the cause of the malfunction has been accurately determined. Then you can determine whether it is possible to fix it yourself or you will have to call the wizard.

External causes of boiler malfunction

The reasons for the fading of the boiler burner can be caused by external factors:

- deterioration of the natural draft of the chimney or its overturning;

- lowering the gas pressure in the pipeline;

- gas meter malfunctions;

- clogged gas filter;

- power outages;

- lack of supply air;

- a draft in the house, creating a short-term excess of supply air;

- heating system malfunctions.

Very rarely, sharp gusts of wind can overturn the draft in vertical external chimneys or exhaust shafts arranged in the thickness of the wall, due to which the gas boiler can go out.

Malfunctions inside the boiler

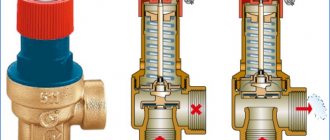

Modern gas boilers are equipped with a minimum set of safety automatics that shut off the gas supply according to the following features:

- Drop in gas pressure in the line.

- Insufficient chimney draft.

- Attenuation of the burner from external influences.

An extended set of automation allows you to control the temperature of the coolant, adjust the intensity of combustion, and so on.The more complex the device, the more elements it contains that are susceptible to malfunctions. Because of them, the fuel supply is blocked and you should look for the reason why the gas boiler does not ignite.

Here is a list of possible malfunctions:

- The burner ignites but goes out after a few seconds. This could be due to soot contamination of the photocell of the flame monitor. It is necessary to clean the element and try to ignite again.

- Failure of the draft sensor blocks the flow of gas into the burner. You can try to clean the sensor, if this does not help, then replace it.

- A failed thermocouple that controls the safety valve will prevent the burner from operating when the control wheel is released during ignition. The defective element must be replaced.

- The gas supply is also blocked if the coolant pressure sensor is faulty. As a temporary solution, its contacts can be included directly, but subsequently a new item can be installed.

- A "dead" display may indicate that the controller fuse has blown, replacing it will help. The same effect happens when the phasing of the electrical network is incorrect, it can be treated simply: you need to pull the plug out of the socket and insert it back, turning it over.

Electric ignition of a gas boiler

Unlike piezo ignition, electric ignition is part of an automatic gas equipment control system. The user does not need to press any button. The boiler starts up automatically. Agree, it's very convenient. Another advantage of this type of ignition is real energy savings.

Gas boiler CELTIC (Korea) with a smooth electric ignition system and a flame control function.

In other systems, the igniter must maintain the flame continuously. In automatic systems with electric ignition, this is not necessary. But there are also disadvantages. If piezo ignition is absolutely autonomous, then electric ignition, in accordance with its name, requires connection to electricity. And if there are problems with electricity at the installation site of the gas boiler and there is no uninterruptible power supply system, it will not be possible to start the boiler equipment in another way. We'll have to wait for the light to come on. However, you shouldn't worry about safety. If you turn off the electricity, protection is triggered, blocking the access of the energy carrier. When electricity appears, the electric ignition is triggered automatically, restarting the heating system.

What you can do yourself

The sequence of the first steps is the same in all cases:

- The boiler is disconnected from the power supply and the gas valve is closed completely.

- A visual inspection is carried out - for possible clogging, mechanical damage.

- If the combustion chamber is open, you can simply light a match or lighter and hold the flame near the holes through which air is supplied to the burner. If the rod is not clogged, the tongue will immediately deflect towards the holes, and the flame will burn evenly. If the flame deflects slightly, then there is a large blockage.

- You can also draw conclusions about the operation of the boiler. If it hums quite strongly, and the color of the flame is closer to colorless, then the thrust is too strong - it must be reduced.

Similar problems can arise at the very beginning of the boiler operation - in case of incorrect installation, with deviations from the diagram below.

If there is no result, do not go into the transformer.

If there is no ignition in the gas boiler, the reason may be in the system itself or in shut off the gas supply, clogged filter... If the equipment is powered by electricity, there may be no voltage in the network. It is not recommended to fix breakdowns on your own without appropriate skills. Better to see a specialist.

Hello! We have questions about the operation of the "Baksi" boiler, model MAIN Four 24.First: when starting up, the burner flame is very powerful, the water in the system heats up very quickly. In just seconds, the temperature rises by 10 degrees and the burner turns off. This is normal? Second: several times a day explosions occur in the combustion chamber, which are accompanied by loud bangs, and sometimes the release of a flame. What could it be? The chimney has no blockages. Opening or closing the transom has no effect on the situation.

If the boiler does not start at all

It may also be that the boiler does not turn on - i.e. there is no flame initially.

The reasons for this may be:

- The simplest is low voltage or other power problems. What to do: you should again check the connection, the integrity of the electrical wiring, the serviceability of the outlet.

- The electronic control system does not work. Then it is necessary to call a service technician, since it is almost impossible to eliminate such faults on your own.

- Burner nozzles are clogged - they can be cleaned neatly at home. The cause of the blockage is incomplete combustion of the gas and soot deposits. Normally, the flame is blue, and clogging can be identified by the abundance of red, orange and yellow tints in the flame. How to eliminate the cause is shown here.

- Weak pressure in the gas pipeline network, drops. You should clarify the data on a possible accident or temporary failure by calling the service company.

This is important to remember

Gas devices are classified as hazardous equipment. Therefore, the main thing to do in case of a problem:

- turn off the boiler;

- check for gas contamination of the room;

- ventilate the room.

Only after that you can figure out what to do if the gas boiler does not light up.

After that, the main thing is to check the traction, and then to study the error code on the display. This will help you understand if you are able to fix the problem yourself or if you have to call the wizard.

So, if the boiler does not ignite, or if its flame is very weak and dies out after a while, then this can mainly be due to mechanical reasons (clogging). And such faults can be eliminated by yourself.

If the reason is different (or it cannot be determined reliably enough), it is preferable to contact a gas equipment service company to call a master.

Hello dear readers. What to do if the piezoelectric element in the gas column does not work? In what situations can you solve the dilemma with your own efforts? And when is it necessary to contact specialists? And how to fix the problem in Amina, Zanussi and other brands?

This material examines the reasons for the failure of a piezoelectric element in a gas apparatus. Cases with models of different brands are reflected. Methods for solving this problem are provided.

Attenuation of the boiler due to causes within the system and their elimination

The most common cause of boiler attenuation is lack of oxygen for the burner. Such a malfunction is inherent in economy class models, which are bought more often than others. Expensive boilers have a special exhaust device that multiplies the air flow, maintaining combustion in all weather and indoor conditions.

Lack of oxygen is a common cause of soot and gas burner damping. The fire goes out, because the missing air flows are captured from all openings, the flame is displaced, the temperature of the thermocouple drops and the protection turns off the burner, as if the temperature had reached the maximum value. Other causes of boiler burner damping:

- In gas boilers with a turbocharger, a built-in electric fan helps to pump air. If it does not work correctly, the burner can also go out. The fan is easy to diagnose - it continues to make noise when it is off.

- A non-working draft sensor is another reason for the damping of the boiler.It should turn on if the temperature in the smoke catcher rises from hot steam, which for some reason did not enter the chimney.

- The burner does not ignite or does not burn well - nozzles are clogged. Clean them with a brush or wire of the appropriate diameter.

- If air enters the gas pipe of the boiler, the operation of the boiler is blocked, and an error is shown on the display. The reason why the gas boiler goes out can be easily eliminated - you need to start the boiler again, first unlocking it according to the instructions.

- During the operation of the boiler, the gap in the igniter may be disturbed or contact with the wire may be broken, or the air filter on the air line may become clogged. It is almost impossible to restore the gap with your own hands - you need the help of a gas worker. But you can clean the filter and check the reliability of the connection of the current-carrying conductor yourself.

- The gas burner may not go out immediately, but after a few minutes. The most common cause is that the ionisation electrode is dirty. Also, the correct gap could be violated in the electrode, or the connecting wire could fall off from constant heating.

- The flame comes off the burner and is extinguished. Usually, the nozzle starts to make noise and whistle. The malfunction is eliminated by adjusting the gas pressure at the ignition electrode. The flame can come off if the draft is very strong - this phenomenon occurs with strong supply and exhaust ventilation.

- If the boiler is installed in a private house, then flame attenuation can occur if the chimney is brought out very high.

- Spontaneous shutdown of the boiler, accompanied by strong noises, occurs due to an inoperative pump or fan (explanation above). An inoperative thermostat causes the water to boil, followed by the separation of the flame.

If the voltage in the network fluctuates and decreases, then the boiler burner may go out - an automatic device is triggered, which recognizes a low voltage. After the power is restored to normal, the protection turns on the boiler again, so for the most part no one notices such cases. However, unstable voltages are detrimental to the performance of electronic protection systems.

And the very obvious reason for the burner damping is the low gas pressure in the main line. This trouble can happen not only due to breakdowns in the external gas transmission line, but also due to internal problems.

- Malfunction in the gas meter. Check visually whether the mechanism is working, whether the numbers jump on the scoreboard. Even if this is the case, the malfunction may be delayed - and often the meter is noisy.

- Gas workers require the installation of monitoring equipment - gas leakage sensors and temperature sensors. They monitor the observance of the regimes around the boiler. The activation of the sensors leads to the shutdown of the boiler.

- Gas line connections are leaking. A gas leak is a low pressure, so the automation immediately reacts and the boiler shuts down. If there is no leak sensor, then this type of malfunction is detected by the smell of gas. To identify the malfunction and fix it, check the joints on the line by applying soap suds - if there is a leak, the foam will bubble.

Methods for troubleshooting geysers

Gas water heaters "Vector" are among the most demanded in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the "Vector" gas column, a spark does not appear and the burner does not ignite. The reasons for the problems are as follows:

- Lack of draft in the chimney. It could just get clogged and need to be cleaned. The column contains a special sensor that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this on your own, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve.A very low head may indicate a problem with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and rinse it under water, and the membrane is best replaced as it gets damaged over time. You can do it yourself.

- Nutrient is not working. The ignition is done with the help of batteries, without which there will be no current, for the appearance of a spark. It is necessary to remove the panel, then take out the block with batteries, pull them out and insert new ones.

Which option should you choose?

To answer this question, it is necessary to take into account many parameters, including financial issues, problems with electricity on the site, basic convenience. If the budget for the purchase of boiler equipment is limited, choose piezo ignition without hesitation. A gas boiler, all other things being equal, with this type of firing will be cheaper. If the budget is not limited, it is better to invest in the convenience and comfort of use.

But don't forget about the power problems. The convenience of electric ignition is completely leveled in the absence of electricity in the house, since you will simply sit without heating.

As for operational safety, both versions of modern boiler equipment are fully equipped with protective systems. Therefore, you should not worry about accidents during the operation of a heating boiler on gas.

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The gas supply valve is closed. Measure - turn it all the way.

- Low water pressure. It can be not only in the main, but also at the entrance to the boiler, where the filter can become clogged.

- The water heats up slightly. Solution: cleaning the heat exchanger (TO). Fastenings, on which plaque has accumulated, can be cleaned with VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour, until the scale disappears completely.

- The burner clogged. Sometimes there is a lot of soot and soot in the jets. You can get rid of it with a thin copper wire.

If the piezo does not work in the Electrolux gas column or in another similar technique, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

Features of electric ignition of boilers with automation

For heating cottages and private houses, boilers with electric start are preferable. Gas equipment with electric ignition is powered by electricity.

Device gas boilers:

- Gas supply fittings.

- Gas burner.

- Heat exchanger.

When the equipment is turned on, the hardware part takes over. Automation starts the armature - gas is supplied to the system, a spark is ignited in the combustion chamber, from which fuel flares up.

The water in the heat exchanger heats up to the set level and the boiler turns off automatically. Fuel is ignited as the coolant cools down.

Gas boilers with electric start on the market various modifications:

- Ordinary heating elements.

- Mini boiler roomsequipped with circulation pumps, expanders, safety groups.

- Double-circuit for heating and preparing hot water.

Advantages and disadvantages of starting with electrodes

When installing boilers of an electric type, there is no need to equip a riser. To the disadvantages of these boilers complete dependence on electricity.

Important! To ensure the normal operation of the equipment, it is required reliable autonomous electrical wiring.

Electric fired boilers have and advantages:

- Exploitation without soot and soot.

- Quiet or nearly silent Work.

- Environmental Safety.

- Saving fuel.

Gas equipment of an electric type is easy, quick and safe to install in any room of a private house.

Lights up and goes out immediately

The reasons for this problem are as follows:

- Weak cravings.The chimney needs cleaning. If there is poor ventilation in the kitchen, then you need to open the vents or make a ventilation valve on the window frame.

- The ignition button is not pressed well. It needs to be held for 20 to 30 seconds.

- The sensor does not work, which removes the combustion products. This can be found out with a multimeter. If the sensor is working, there will be an infinity sign on the screen.

- Mixing streams. Set the controller to a constant normal temperature.

- High pressure in models with low power. Set the water parameters as indicated in the instructions.

- Systematic shutdown of the overheating sensor. Solution: replace it.

- Adjust the igniter. Disconnect the electrode from the igniter so that the spark is in the center of the burner. Inspect and test the tubing connections for leaks.

If the ignition is delayed, clean the burner. It is highly likely that soot and soot has accumulated in it. Also, the problem may lie in the microswitch.

Piezo ignition of a gas boiler

Piezo ignition is functioning on the principle of piezoelectric elements in lighters. When fuel is supplied to the combustion chamber, a spark is emitted and it ignites. The gas burner works constantly, maintaining the set temperature in the room.

When the coolant heats up to the desired level, the gas supply is interrupted. The auxiliary burner continues to operate and the main burner goes out.

When the water temperature drops, the fuel supply resumes and the main burner lights up. The cycle repeats itself.

Benefits boilers with piezo ignition:

- Energy independence.

- Ease of use.

- Affordable cost.

Disadvantage piezo ignition is increased gas consumption.

Reference. Non-volatile boilers only suitable for houses with good traction. The equipment works efficiently if the pressure in the gas line corresponds to the data specified in the technical data sheet.

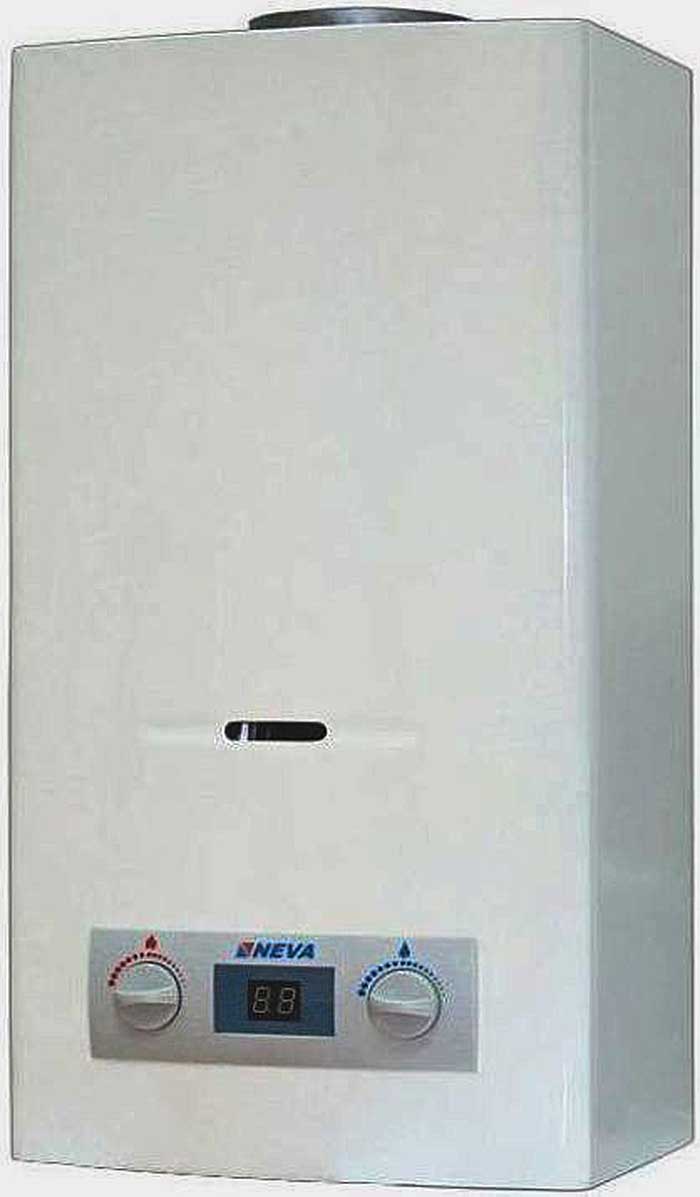

The advantage of domestic speakers

There are many types of malfunctions, so it is easier to find locally made parts. Therefore, speakers made in Russia, such as "Neva", are in great demand.

And the newer model "Neva 4511" consumes even less gas and is completely silent.

A gas water heater called "Oasis" is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a security system that blocks operation in case of overheating of the column.