By purchasing a gas boiler, each owner expects that this boiler will provide him with uninterrupted operation throughout the entire heating season. The boiler is the equipment that is mercilessly exploited, and therefore it is necessary to ensure a long duration of its service life by all possible means.

So, in what ways is it possible to increase the service life of the boiler, as well as guarantee its normal operation.

Selection of heating equipment

When choosing heating equipment, key importance should be given to its power and materials of manufacture in order to avoid buying an expensive boiler, which does not have obvious advantages, and, at the same time, does not reach the required power, and therefore is forced to work at the limit of possibilities. Parameters such as the size of the house, the level of pressure in the gas pipeline, the thermal insulation of the walls, etc. should serve as a guideline. It is they who form the value of heat loss, based on which they select the power of the boiler.

Due to the nature of the material, cast iron boilers are the most durable. Therefore, if you want a boiler with the longest possible service life, you should pay attention to these representatives.

Types of boilers by the method of removal of combustion products

The fuel is burned in a special chamber, which can have a different design. For each type of boilers, the furnace has its own characteristics, on which the efficiency and conditions of use of the unit depend, namely, the place of its installation.

Turbocharged

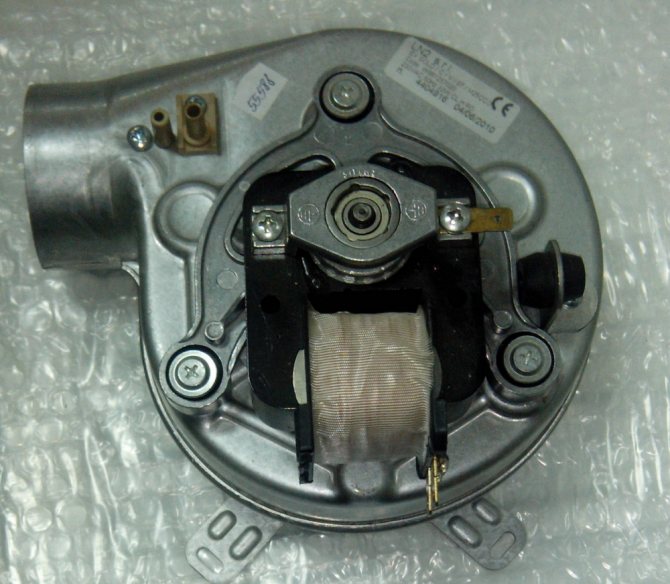

Any boiler needs oxygen to operate. In such units, a forced draft fan is responsible for the air flow. Compared to other boilers, turbocharged ones require a special chimney, consisting of two pipes: air enters through one, and smoke is removed through the second.

Often, units of this type are used in conditions of insufficient free space, where it is not possible to equip a classic chimney. A distinctive feature is that turbocharged boilers are produced with low power - up to 35 kW, which is explained by the presence of a copper chamber, which requires gentle operation.

Atmospheric

This type of boiler is suitable for houses with a chimney over 130 mm in diameter. The chamber is open here, and combustion products are removed naturally. Often this type of instrument is called "atmospheric".

The flue pipe of the Baxi boiler has a diameter of 121–122 mm, therefore an aluminum corrugation with a diameter of 125 mm can be used as a pipe. This element is not afraid of high temperatures (up to + 400 ° C) and easily stretches up to 3 meters. An alternative option is to install a stainless steel chimney, but this will cost a little more. The design of the atmospheric unit does not provide for the installation of a turbine.

Competent installation

In general, you need to remember that any work with gas equipment must be coordinated with the local gas service. And the work on installation, replacement and repair itself must be carried out by specialists who have the necessary permits and approvals.

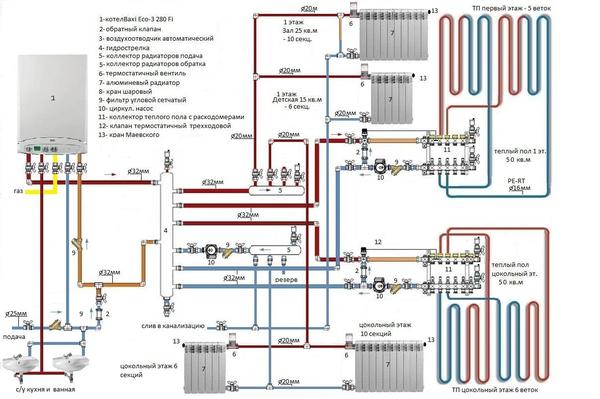

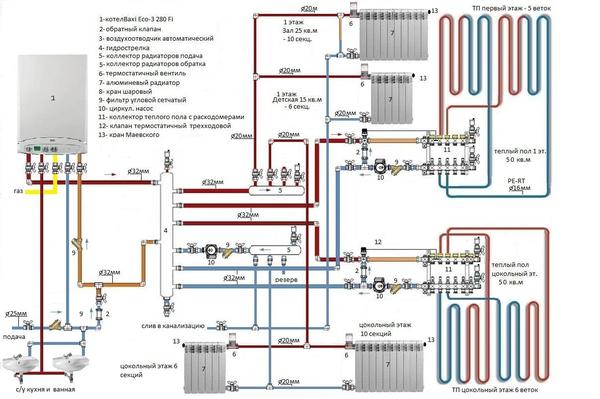

To ensure stable and safe operation of the boiler, first of all, it is necessary to carry out the correct installation of the heating system. Commissioning work should be carried out to adjust the operation of the boiler in such a way that it is not influenced by various external factors. Commissioning is a mandatory operation, since, otherwise, the boiler will function at factory settings, which are not always suitable for a specific heating system.

The commissioning work, which has a serious impact on the boiler's service life, includes, among others, the correct setting of the burner to the gas pressure. If the gas pressure rises above the level that is required for optimal burner operation, the service life of the coolant and the flue exhaust fan will accordingly decrease, and a safety alarm may also be triggered for no reason.

Device

Baksi gas boilers consist of the following units:

- Gas burner open or closed.

- Turbocharger fan (for closed burner models).

- Heat exchanger (primary and secondary if the boiler is double-circuit).

- Three-way valve.

- Circulation pump.

- Gas valve.

- Sensor system connected to the control board.

- Housing with connections for gas and water lines.

Some models have additional elements that provide climate control or advanced system management capabilities.

You can look at the device below in the photo.

Annual maintenance

In accordance with the Decree of July 21, 2008 "On the procedure for supplying gas to meet the household needs of citizens", heating equipment must be subjected to regular maintenance. service. Many large manufacturers of gas equipment directly indicate in the warranty card that the boiler warranty is valid subject to regular maintenance.

The following works should be included in the regular maintenance:

- cleaning the combustion chamber;

- cleaning the burner;

- expansion tank control;

- pressure control;

- checking the heat exchanger;

- inspection of pipes and connections;

- checking the circulation pump;

- checking the correct operation of fuses and safety systems, etc.

As you already understood, regular maintenance also affects the life of the boiler.

Advantages and disadvantages of Baxi gas boilers

Gas equipment has the following advantages:

- Availability of service centers in many cities;

- Large model range at an affordable cost;

- Fast delivery and replacement of spare parts;

The disadvantages include:

- Short lifespan of the electronic board. It is recommended to purchase a voltage regulator;

- It is necessary to install filters so that only purified water without impurities gets into the system;

Today, the most reliable are gas boilers from Baxi. The service life of the equipment is long if used correctly.

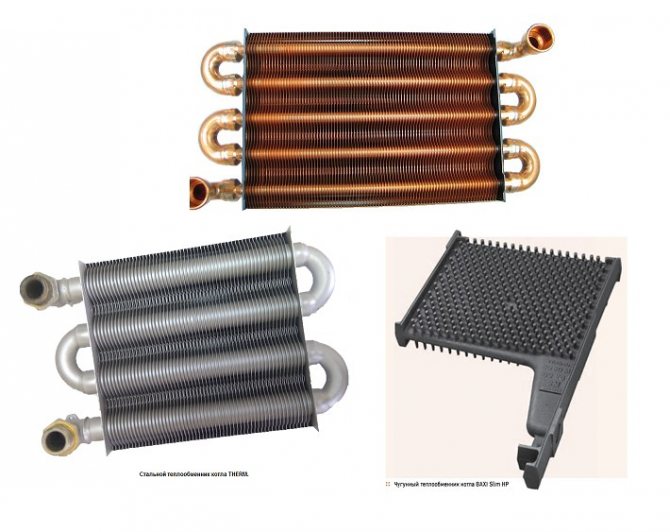

Factors affecting the duration of the boiler operation

- Hard water. If hard water circulates in the system, that is, water saturated with salt and various minerals, then scale will form, then limescale, rendering the entire system unusable. In industry, water hardness is measured under special laboratory conditions. You can check the level of hardness in normal home conditions using a litmus indicator (sold in pharmacies and household stores). Also, the material of the heat exchanger influences the level of plaque deposits. Plate heat exchangers made of steel are quite cheap, but, at the same time, are highly susceptible to scale deposits. But more expensive tubular copper heat exchangers are very slowly covered with limescale. The elimination of salt deposits is the responsibility of a service specialist who performs maintenance and repairs of the boiler, routine maintenance, but, of course, it is better not to bring it up to this.

- Low gas pressure. In principle, low pressure does not have a significant effect on the service life of the boiler. According to the norms, the gas pressure in the mains should be in the range from 120 to 300 millimeters of water column. It turns out that even with a minimum pressure value, the boiler must operate at the power level that is stated in the passport. This means that the pressure level below 120 millimeters of water column will entail a decrease in the maximum power of the equipment.The boiler itself will function as long as the security system is able to detect a flame.

- The heating system itself. There should be no leaks in the heating system, since their presence (also in conjunction with hard water) will cause clogging of the heat exchanger.

- Temperature conditions. When using the second hot water circuit, it should be set at 42 - 45 ° C: this mode, firstly, will avoid excessive salt deposition on the pipe walls, and, secondly, this temperature is quite sufficient for all household needs (wash dishes, take a shower, etc.)

- Non-freezing coolants. Antifreeze can be used as a coolant. However, given that this is a chemical compound, it can interact differently with the heating system, depending on the material of the radiators (it can be cast iron, steel or aluminum). Therefore, using antifreeze, it is necessary to pay considerable attention to the state of the coolant and remove it from the system in time.

- Power supply. In order for the boiler to function in accordance with the technical regulations, it must be grounded. The stable voltage of the boiler should vary within 220 V + - 10-15%. Therefore, the best solution is to install a voltage regulator. Grounding + voltage stabilizer = longer boiler life.

Types of gas boilers Baxi

Gas equipment can be divided:

- By installation method.

- By functionality.

- By way of carbon monoxide removal.

Let's consider each type in more detail.

Methods for installing gas boilers Baxi

There are two types of equipment: floor-standing and wall-mounted. The first is used for heating large rooms with an area of over 250 sq.m. Gas boilers have a long service life due to the cast iron heat exchanger. Such equipment has a high efficiency of about 100%.

Floor standing boilers are available in two models:

- Baxi Power Hit from 80 to 650 kW;

- Baxi Slim from 22 to 110 kW.

Wall mounted gas boilers are installed on the wall and are used for heating small areas. The lineup includes 44 equipment.

By functionality

Gas boilers Baxi are single-circuit and double-circuit. The former have only 1 heat exchanger and are used to heat the house. If at the moment there is no need to heat water, then such gas equipment is perfect. As an alternative to a double-circuit boiler, you can use a boiler.

The second type of heating units is considered the most popular. This equipment heats the room and heats water for household needs. The cost of a double-circuit boiler is slightly higher than the cost of a single-circuit, but the advantages are much greater. The equipment can be used only for heating or only for heating water. During summer, only one hot water function can be used. This principle of operation is ensured by two independent heat exchangers.

Boiler accessories

Of course, to increase the service life of the boiler, its economical operation, it is advisable to use additional accessories. For example, a temperature regulator in the control room will provide greater comfort in the operation of the heating system, and will also reduce gas costs by 15 - 20%. Mechanical or electronic thermostat can be selected. Mechanical is more reliable, cheaper and easier to use, however, it does not always determine the exact temperature, and also requires an inconvenient cable connection. Electronic thermostats are very modern and comfortable, which makes them expensive.

Thus, it is not so difficult to increase the viability of heating equipment. It is necessary to competently approach the issue of selection and installation, timely carry out maintenance and know some of the specific features of the functioning of the heating system.And then your boiler will serve for many years reliably and uninterruptedly.

Baxi boiler models and their characteristics

Let's consider several popular models:

- Gas boiler Baxi Eco 4 and Compact. This equipment has an additional heat exchanger for water heating. The main difference is the use of heat from the heating circuit by the steel circuit for DHW. Thus, the load on the main heat exchanger is reduced by 60% and the service life of the equipment is increased. The second model has common elements, but they are assembled more compactly. The gas boiler is smaller. The power can be 14-24 kW.

- Gas boiler Baxi Main 4 and Baxi Main 5. These models are the best sellers. Such boilers are equipped with a bithermal circuit made in the form of a coaxial pipe, and plates are arranged on the surface to increase heat transfer. Heating of the room and water takes place in the same circuit of the equipment, but in different compartments. The dimensions of such boilers are much smaller than other double-circuit ones. The equipment is of the Coaxial type. The power of the devices is 14-24 kW.

- Gas boiler Baxi Four Tech. The equipment is equipped with plastic tubes, due to which the cost is significantly reduced. The heat exchanger is made of stainless steel and copper. The DHW circuit uses the heat of the main one to heat water. Despite all the nuances, such a unit has a rather high price.

What factors should be considered

In addition to the class and price segment, other aspects also affect the duration of operation of gas equipment.

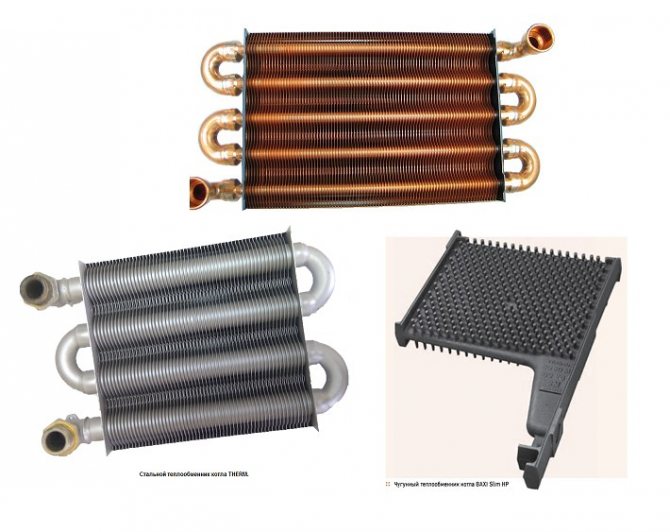

Heat exchanger material

Why is the service life of a wall-mounted appliance shorter than a floor-standing appliance? Perhaps the type of accommodation matters? No, it's just that floor-standing units are equipped with cast iron or steel heat exchangers. For the same period of operation, the percentage of wear they have is much lower than that of copper radiators, which are installed in hinged boilers.

Copper is thinner than steel, and during operation it is susceptible to oxidation and corrosion. The backlashes in the heat exchanger can be soldered, but the unit will not last long. Average term of work is from 5 to 10 years maximum. Practice shows that copper radiators serve no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of the tap water.

Wall-mounted appliances are less powerful than floor-standing appliances. This leads to constant operation at maximum power and rapid wear.

The type of heat exchanger also matters. The ordinary coil can be descaled by yourself, and the boiler will continue to work. Bithermal radiators cannot be cleaned, and replacing a unit is almost equal to the cost of a new device.

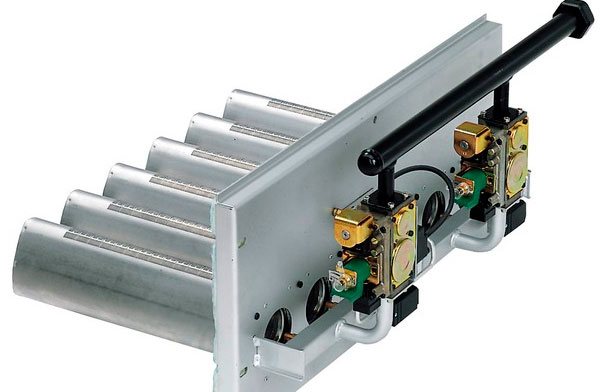

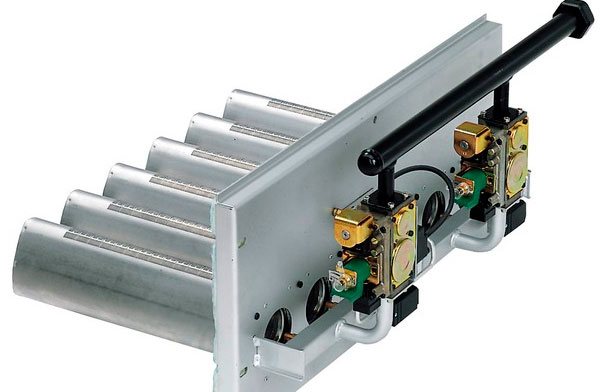

Burner type

Gas appliances have two types of burners:

- Atmospheric - they take air from the room to maintain the flame. Combustion products are removed naturally by means of draft.

- Pressurized or forced (turbocharged chambers) - clean air is taken from the street through a coaxial chimney. The flame power can be adjusted, the smoke is removed by a fan.

What does the operating time have to do with it? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases the efficiency and reduces the load on its units.

In appliances with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation, heating temperature, so the units fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnostics and require a network connection. Instability in the network, power surges lead to damage to the elements. We recommend installing a voltage regulator.

Features of operation

The service life of heating equipment initially depends on the right choice.To do this, it is necessary to select a boiler taking into account the characteristics of the room in which it will operate and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Pros and cons

In general, the advantages of gas heating boilers include such equipment properties as full automation, long service life, fuel availability and high efficiency. But the boiler also has disadvantages. Among them it is necessary to highlight:

- exactingness to operating conditions;

- the need for permission to install a heater in Gaztekhnadzor;

- lack of economic benefit when heating premises with an area of less than 100 m2;

- smoking burner when equipment is worn out.

In Russia, one more factor is added to the listed factors: pressure drops in the gas distribution system. This can shorten the service life of the unit: if the gas flow is weak, the burner will start burning itself. Therefore, it is recommended to purchase gas heating boilers adapted to Russian conditions.

Classification of devices

The basic criterion for choosing a boiler is its ability to heat the designated area. In order for the device to work not at maximum loads, you need to choose an economical gas boiler with a small power reserve.

Experts recommend when choosing to be guided by the approximate value of 1 kW, which is designed for heating 30 sq. M. In this case, an insulated house with double-glazed windows and an insulated front door is taken as a reference point. In the absence of any of the elements, add 10-15% to the calculated value.

Such an indicator is conditional, but with its help it will be possible to select the necessary equipment.

It is worth choosing according to the accommodation option, because there are two large groups:

- floor-standing boilers;

- wall-mounted boilers.

Floor standing

The first option is in demand for heated premises with an area of more than 200 m 2. These units are used not only for direct heating of housing, but also for creating a special indoor climate. It should be noted that the efficiency of such a gas boiler will be lower than that of their wall-mounted counterparts. However, this is offset by a significantly longer service life, which, with proper grooming, reaches several decades.

Operating principle

The operation of the boiler consists in heating the coolant entering the primary heat exchanger using a circulation pump... At the outlet, the hot air passes through a three-way valve, where it mixes in a predetermined proportion with a colder return flow, as a result of which the temperature of the coolant acquires the required value and is sent to the heating system.

Hot water is heated in a secondary indirect heat exchanger... The heat source for it is the hot OM, which has not yet entered the three-way valve.

The operation of all nodes is constantly monitored by a system of sensors that transmit a signal to the control board.

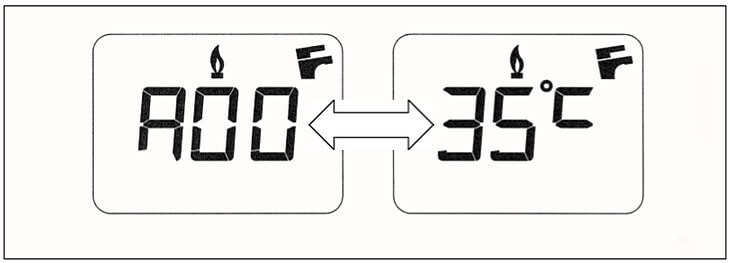

When changing the nominal mode, the display shows an error code related to a specific unit or part of the boiler.

Download instruction

You can download the instruction here.

How to set up correctly

The boilers are set up according to certain rules detailed in the user manual.

The point of the whole procedure is to set the minimum and maximum gas pressure, determine the parameters of the heating water and hot water supply. All actions are performed during initial start-up or after routine repairs (maintenance).

During the operation of the boiler, the current regulation of the heating water temperature is performed, which does not affect the general settings of the unit..

IMPORTANT!

Self-tuning of the parameters is not recommended, since such actions must be performed by employees of the service center. Most organizations have a negative attitude towards independent action and may refuse warranty service.

Features of the

It's all about the counting technique used by the manufacturers. Maintaining the operation of a conventional boiler takes up to 6% of the energy, condensing - up to 11%. The remaining heat is transferred to the water, and the manufacturer takes it as 100% by default. Therefore, in order to establish the exact efficiency of condensing equipment, it is necessary to subtract 11 from the indicator indicated in the technical passport.

As a rule, the resulting ratio is 97-98%. This is much higher than that of heating boilers operating on solid or liquid fuels. In terms of efficiency, only electric boilers can compete with gas boilers.

Gas and oil boilers have a similar device, the only difference is the burner. If you replace it, then the heater can be converted to work with a different type of fuel. But it is not recommended to do this on your own, especially when it comes to converting a diesel boiler into a gas boiler: for this, it is imperative to obtain a permit from Gaztekhnadzor.

There are things without which it is difficult to imagine our everyday existence. One of the most essential heating devices in a private house is a gas boiler.