Peat briquettes for heating: customer reviews

Because they contain a small amount of sulfur, no harmful pollutants are generated when the material is burned. Briquettes for heating have good reviews, which say that, thanks to easy ignition, they burn for a long time.

Loading briquettes into the firebox is much safer and easier than using conventional fuel. In the process of burning briquettes, no sparks are formed. This also indicates an increased level of security.

The consumption of this material for heating is much less, which means that it can significantly save on heating costs. Due to the efficient combustion in the furnace, less ash is formed, in addition, it can be perfectly used in the future as a potash fertilizer. Fuel briquettes have one more positive quality - they exclude the possibility of spontaneous combustion.

Peat briquettes allow you to have the following advantages:

- High heat dissipation;

- Ease of use;

- Long burning.

Affordable cost and high efficiency can be called the main advantages of fuel peat briquettes.

Features and types of peat

Peat is an organic breed, which is the result of the biochemical process of decay of marsh plants with excessive moisture and oxygen deficiency.

Peat contains plant fibers, humic acids and various trace elements.

If you look at peat as a fuel, given its main characteristics, then it can be safely called young coal. In terms of basic parameters, they are similar, however, peat extraction does not imply the creation of a complex developed infrastructure, because of this, its cost is much lower in comparison with coal.

The main feature of peat is ash content. It refers to the amount of combustible products that remain after burning a kilogram of fuel. This parameter is measured as a percentage.

The less ash remains after combustion, the higher the quality of the fuel.

The ash content of peat also depends on the origin. Based on this, three types of this breed can be named.

| Peat type | Features of the |

| Lowland | Consists of a large amount of rotted wood residues. It has a very high ash content (for some species it can reach 50%) and a low thermal capacity. Because of these characteristics, it is often used in the preparation of natural fertilizers for clay soils. |

| Horse | It is based on the remains of marsh vegetation and sphang mosses. Has a low ash content of 1-5%. This peat is most often used for domestic purposes, it is he who is most often used as the main raw material in the production of fuel. |

| Transition | This is a cross between lowland and high moor peat. |

Of course, peat as a fuel is not used in its pure form. After extraction, the natural material undergoes special processing, which allows rational and efficient use of all its properties.

Therefore, the following types of peat can be distinguished, depending on the characteristics of its processing.

| Peat type | Features of the |

| Shredded / milled peat | It is a placer that is intended to be burned in suspension. |

| Semi-briquette / lump peat | Characterized by a low degree of compaction, this fuel product is produced directly at the site of the developed deposit. |

| Peat briquette | It is a high-calorie product with a significant degree of compaction. Due to the characteristics obtained as a result of processing, it is able to replace coal. A ton of peat briquettes in terms of the amount of heat emitted is equal to 1.6 tonnes of brown coal and 4 m³ of firewood.Peat briquettes are stable in their thermotechnical characteristics, which makes it possible to make accurate calculations of the fuel requirement of a particular object. |

The manufacturers of fuel briquettes Ruf, Pini Kay, Nestro and Nilsson can be found in detail on this page.

Heating briquettes: what customers say

Modern peat briquettes for heating are nowadays a profitable alternative to ordinary wood for stoves. At the same time, you do not have to worry about preparing firewood for the winter, chopping it, storing it and then using it.

Feedback from people who have already started using the new type of fuel testifies to its positive qualities.

This economical and safe, both environmentally and in terms of fire, type of fuel is already in full use in Europe. With the help of it it is very convenient to heat both city and country cottages and houses. Thanks to a well-thought-out and streamlined production, briquettes made of sawdust and peat are not easily transported, give a good return and ease of use.

Reviews indicate that:

- There is no corrosive smoke during the combustion of briquettes;

- Heat transfer is much higher than that of firewood;

- More profitable than firewood or coal;

- Light weight of the material.

The disadvantages of many include the need to provide suitable storage conditions, where the briquettes would not get damp and rot.

Positive properties of coal briquettes

The use of this type of raw material is absolutely safe, since no carbon monoxide is emitted during combustion. It is no coincidence that coal briquettes for heating are widely used in home and country heating based on various types of systems: boilers, stoves. The distinctive features of raw materials include:

- high density;

- low moisture content;

- control of fuel consumption and maintenance of the combustion process;

- due to the complete combustion of the product, all the thermal energy is released into the room, respectively, it will be possible to warm up the house much faster;

- ease of transportation, during which the material is not crushed;

- during combustion, only ash is formed, which can be easily removed.

All these positive properties explain the popularity of such material as coal briquettes for heating. Reviews often mention the availability of the material.

Production of peat briquettes: what they are made of

In fact, heating pressed briquettes are a combustible pressed material that has passed a pre-processing stage. An improvement in the energy qualities downward occurs due to the admixture of various additives.

New fuel briquettes, including peat briquettes, are much more efficient than conventional fuels. Using a special technology for processing the source material, manufacturers receive an energy carrier characterized by excellent qualities.

This type of fuel is made by pressing or extrusion from the following raw materials:

- Various agricultural and wood waste;

- Peat;

- Coal dust.

To achieve a high density of the product for heating and to exclude the use of artificial binders, production is carried out using high pressure, in the range of 30 - 100 MPa, the indicator of which depends on the technology. As a result of the use of a press, the density of the briquettes increases significantly, and the moisture content of the material decreases, which contributes to an increase in the level of heat capacity.

Forms of fuel briquettes

View gallery

This heating raw material is available in several varieties. So, round briquettes are made in the form of a cylinder, have a diameter of 60-90 mm and a length of up to 350 mm. High pressure mechanical or hydraulic presses are used for their production. Fuel briquettes in the form of bricks are also made from sawdust, wood chips, while no harmful chemicals are added to them.Pini-key briquettes are made in the shape of a polyhedron, which have a dark crust and a hole in the center. These varieties are not only pressed, but also fired, due to which they become stronger and more resistant to moisture. Such Eurowoods look modern, but at the same time they are more expensive. As a rule, they are bought for heating fireplaces, since the pini-key burns very beautifully.

Solid fuel for boilers in briquettes: negative reviews

However, as often happens, all good things have their downside, and the same goes for peat briquettes for heating. Good quality material, made in compliance with all crushing, pressing and drying technologies, ignites from a small amount of brushwood and paper. They burn even after that powerfully and evenly, giving off a lot of heat and heat. That is why, in the event of careless handling of the product, lovers of bath procedures, using previously ordinary logs, quickly render their stoves unusable by improperly burning briquettes.

Quality charcoal briquettes work even better and burn hotter than even sawdust bricks. Therefore, they cannot be used in steel stoves intended exclusively for wood.

The emergence of a huge number of irresponsible left-wing manufacturers on the market has tarnished the reputation of all types of briquettes. They are produced cheap, but absolutely do not meet the requirements of this product. They make them from just about anything, do not dry, do not mold, and generally do not bear any responsibility for their goods. The products crumble, turning into dust even at the stage of loading them into the furnace. And, of course, such fuel does not provide enough heat and produces a lot of ash.

In this regard, the consumer has developed prejudiceyatoenegative opinion:

- Briquettes are very expensive;

- They burn badly and give enough heat;

- Smolder for a long time;

- A huge amount of ash remains;

- Fuel does not hold its shape, crumbles and is very dusty;

- Gives soot;

- The sauna stove burns out especially quickly, either, and sometimes it is simply not possible to light it up and heat it qualitatively, and the required temperature is not provided for the steam room and the firebox.

As a consequence, it is necessary to choose only high-quality peat briquettes, made by the responsible (Nestro), "Prometheus" or "Smiga", who have the appropriate certificate.

Features of the firebox

View gallery

As we have already said, ease of use and affordability are the main indicators that distinguish briquettes for heating. Reviews about them focus on the high quality of combustion. The heating process is also simple, especially if wood briquettes are used - they are simply put into the oven. When creating peat products, they first get rid of moisture, after which they are crushed.

During briquetting, the material is compressed, as a result of which the substances contained in the wood are released, binding the material into a single piece. At high temperatures, moisture evaporates from the wood, however, if this is too intense, so-called steam pockets can form. That is, the material will expand, which means that the briquette will collapse.

What are peat briquettes (video)

Is there a new generation fuel alternative to traditional firewood? What is its calorie content? Is it possible to make equipment for the production of peat briquettes with your own hands? How much does a cube of briquettes weigh? All these issues are actively discussed on the forums and indicate that interest in peat briquettes is growing and their popularity is increasing.

Comments (1)

-1 Julia 12/28/2017 9:02 PM I have been buying just such briquettes for many years, they are convenient to use and store. At the same time, there is quite a lot of heat during their combustion. They do not cost so much, considering that they are needed quite a bit.

Quote

0 Daniel 12/23/2017 07:18 AM Really excellent fuel, it burns for a long time and evenly, there is no such intense heat as from wood or coal, but the heat gives excellent and economical in costs. Last winter I bought it, it was enough for me for the whole winter, but for this winter I could not find it anywhere, they were not sold.

Quote

0 Katya 12/08/2017 09:04 PM I have been buying peat briquettes for the second year, it is really profitable to buy them. They burn for a long time, so the consumption is economical. I think this is the best fuel for the money at the moment.

Quote

Refresh comment list RSS feed of comments for this post

Features of the technological process

Fuel briquettes are a modern material that has great prospects. Due to their compactness, environmental friendliness and ease of use, they are becoming more and more popular, and the manufacture of briquettes for heating is a profitable business. This raw material is effective because it burns longer and heats the room longer, because heat is generated continuously. There is practically no smoke when they burn. Briquettes with a through hole in the middle contribute to better fuel combustion. The use of this material is advisable in those countries where climatic conditions are severe.

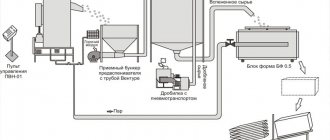

The production of briquettes for heating is carried out on the basis of the following equipment:

- a machine for shredding wood waste;

- press;

- a machine that packs finished products.

There are also automated lines for the production of briquettes, while the variety of equipment allows you to optimize this process, which is simple.

What's the price?

How much do briquettes for heating cost? Eurodrova (namely, wood briquettes) are very popular precisely due to the fact that their purchase will be cheaper. For comparison: 1 m3 of briquettes will require 5 m3 of birch firewood. In this case, the cost will be 5500 rubles against 7000 rubles for ordinary firewood. Why are the savings being made? Firstly, there are no costs for logging, for its delivery to the site, sawing and splitting. Briquettes are created, as already mentioned, from wood waste at the factory (and even with their own hands, if there is anything) and do not require large transportation costs, since they take up little space.

On the other hand, many people say that peat-based fuel briquettes are only good advertising, in fact it is not profitable to buy them. You can give the following table, which will reveal the features of peat products and ordinary birch firewood.

Comparative characteristics

| Peat briquettes | Birch firewood | ||

| Kindling features | Melt equally well with paper or birch bark | ||

| Combustion | They burn slowly, the inner layers do not ignite until the top layer is burned out | Burn well and evenly | |

| Flame | Ugly and small | Decorative flame | |

| Heat | A little heat is released, vigorous combustion is noted if the briquettes are placed vertically | There is a lot of heat when burning | |

| Burning duration | Briquettes burn for a long time - about 2 hours | Firewood burns out in an hour | |

| Storage | Take up little space | Requires a lot of space | |

| Firewood preparation | Ready already, thanks to the standard shape they fit well into the oven | It is required to split, respecting the dimensions of the firebox | |

| Ash amount | After the combustion of briquettes, about 2% ash remains | After burning wood ash about 10% | |

Can you make briquettes yourself?

View gallery

It is quite possible to create briquettes for heating with your own hands, especially if you have access to free sawdust or other woodworking waste. At the same time, you will receive environmentally friendly, and, importantly, cheap raw materials for heating a house or summer cottage. By the way, for the manufacture of Euro wood, you can use not only chips and sawdust, but also husks, straw and many other materials at hand.

Clay can be used as a binder for future briquettes at the rate of: 1 kg of clay - 10 kg of the material itself. To make the resulting briquettes conveniently stored, you should give them a certain shape, for example, using homemade forms from boards.

DIY briquettes for heating are created as follows.

- We take a container, into which we pour the previously prepared consumables, clay and water. The mass should be well molded.

- Pour the resulting solution into the mold.

- We press it thoroughly.

- Dry.

To make the briquettes stronger, you can cover each product with paper, rags, and then press it.