Gas boilers Beretta have proven themselves as a source of thermal energy in autonomous heating systems. The units are equipped with a function of self-monitoring of the processes occurring in the units and parts during the operation of the boilers. Equipment malfunctions can be detected by light signals.

Let's analyze the typical malfunctions of the Beretta gas boiler and their elimination. Let's consider in what cases it will be possible to solve the problem on our own. We will find out when for repair operations you will have to call a foreman from the gas service.

We will tell you how to determine the error in the operation of the equipment, about which it independently warns the owner. Let us show you what the combinations of letters and numbers mean in the event of a malfunction on the built-in display or indicators. With this information, you can decide how best to proceed.

The main malfunctions of gas boilers Beretta

The design of Beretta boilers is a reliable and durable engineering solution that takes into account all the loads and effects on the parts and assemblies of the unit.

The most probable malfunctions occur in the most critical nodes experiencing maximum temperature or dynamic loads.

According to experts, the most common malfunctions include:

- Lack of flame on the burner, causing blocking of the boiler. This problem occurs most often, since it can be caused by various reasons, from clogging of the burner nozzles to the cessation of gas supply to the mains.

- Failure of the control board - burnout of parts or failure due to the ingress of condensation. This is one of the most frustrating problems for the user, since replacing the control board is a very expensive procedure.

- Boiler shutdown due to exceeding the admissible flue gas pressure. Here, the reasons can be both clogging with soot or the appearance of ice at the exit from the chimney, as well as an increase in wind, which creates excessive pressure in the chimney.

- Failure of any self-diagnosis sensor. The boiler control system recognizes such situations as an equal error and immediately takes appropriate action.

- Low water pressure in the supply pipe of the heating circuit. If make-up does not help to solve the problem, then a leak or failure of the expansion tank is possible.

IMPORTANT!

The listed problems are among the most common, but this does not mean that they are obligatory - during operation, any accidents are possible, and the described situations may not appear at all.

Device

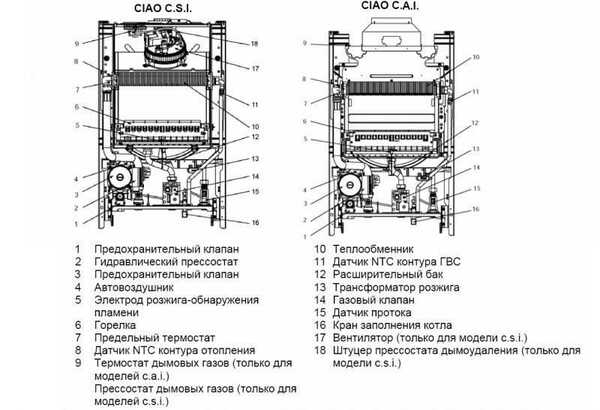

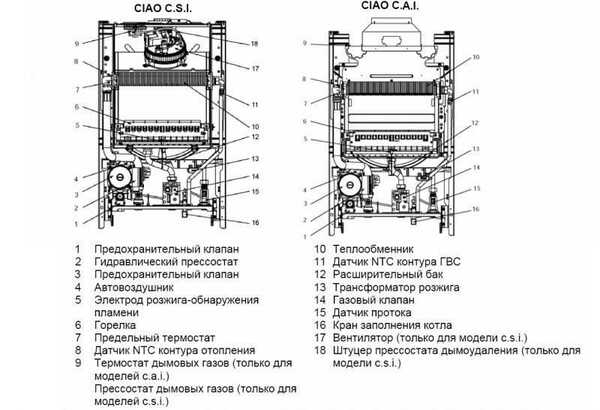

The main structural elements of the gas boiler Beretta CIAO 24 CSI are:

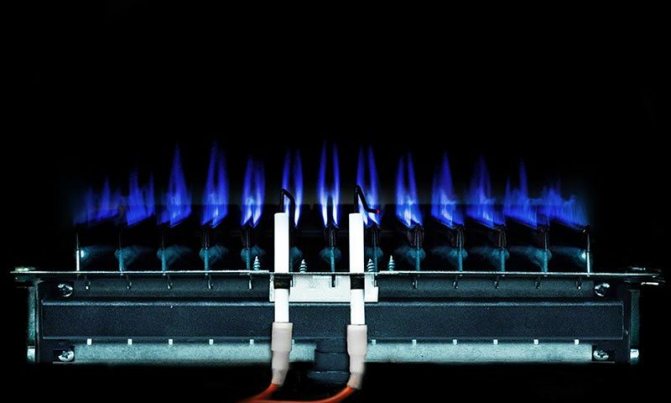

- Modulating gas burner.

- Bithermal (combined) heat exchanger.

- Three-speed circulation pump.

- Turbocharger fan, positioned for condensation.

- Gas valve.

- Three-way valve.

- Control board combined with a self-diagnosis sensor system.

- Housing with control panel and LCD display.

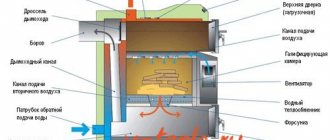

The operation of the boiler consists in the simultaneous heating of the coolant and hot water in a combined heat exchanger. At the outlet, the heating agent enters a three-way valve, where it acquires the temperature set by the operating mode and enters the heating circuit.

The process is monitored by a sensor system that sends a signal to the control board when a problem occurs.

How to run self-test

The self-diagnosis system is a network of sensors located on all important and critical parts and assemblies of the boiler..

They do not need to be started, since they operate in a continuous mode, from the moment of switching on to stopping the operation of the unit.

Therefore, the start of the self-diagnosis of the gas boiler as a separate function is not possible.... Moreover, if it occurs to someone to stop the operation of the system, then no result will work - it is impossible to stop the process by standard methods, and the disconnection of the sensors is regarded by the control board as the same error causing the boiler to block.

The self-diagnosis system is an integral part of the gas boiler operation process, which ensures the safety of the equipment and notifies the owner or repairman about the localization of the defective unit.

Error codes and their decoding

Consider the main error codes (pictures) of Beretta boilers:

| The code | Decoding |

| A01 | Boiler shutdown due to lack of flame on the burner |

| A02 | Boiler blocked by thermostat signal (overheating) |

| A03 | Exceeding the permissible flue gas pressure |

| A04 | Low pressure of the heating agent in the heating circuit |

| A05 | DHW temperature sensor failure |

| A06 | Heating circuit temperature sensor failure |

| A07 | Thermal relay does not open |

| A11 | Parasitic flame (a flame is detected when the burner is off) |

| A24 | Fan failure |

| ADJ | The setting of the upper and lower limits of the boiler output is required. |

| E33 | Incorrect phase and neutral connection of the power supply |

| E35 | Pressure switch failure |

| E37 | False flame, chimney problems |

| E38 | Smoke sensor short circuit |

| E39 | Broken smoke sensor contacts |

| E40 | Unstable supply voltage |

| E42 | Short circuit of the pressure sensor of the direct line of the heating circuit |

| E43-44 | Opening of contacts or short circuit of the pressure sensor on the return line of the heating circuit |

| E46 | Overheating of the coolant |

| E48 | The fan is peddling |

NOTE!

Errors of type "A" require a restart of the boiler, and errors of group "E" disappear after the cause is eliminated without the need to restart.

Common breakdowns of Beretta boilers

According to the gas workers involved in the repair and adjustment of Beretta gas boilers, there are several main malfunctions that most often occur in the equipment of this brand:

- There is no flame on the burner, as a result of which the equipment is blocked. This problem can be caused by several reasons, ranging from a blockage to a lack of gas supply.

- Breakdown of the control board. It occurs due to the accumulation of condensation on the board, which leads to its failure. Also, a breakdown of the board can occur due to burnout of parts on it.

- Increase in flue gas pressure. Ice in the chimney of a gas boiler, clogging with soot, and increased wind force can lead to such a failure. As a result, the equipment is blocked.

- Breakdown of the self-diagnosis sensor. Also leads to equipment shutdown by the control system.

- Low water pressure when supplied to the heating circuit. The most common cause is a leak or a problem with the expansion vessel.

The statistics collected by experts does not mean that such problems will occur in every Beretta boiler.

Perhaps the problems will not appear at all for a long time, or completely different failures will arise for other reasons. Each malfunction or failure in Beretta gas boilers has its own code designation, which is displayed by the control system on the LCD display.

It is necessary to pay attention to malfunctions and malfunctions during the operation of the Beretta gas boiler and eliminate them in a timely manner in order to avoid more serious breakdowns.

Fault identification occurs thanks to a self-diagnosis system that allows you to instantly identify problems when they occur and take appropriate action.

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs during the operation of the Beretta boiler.

Let's consider the most common errors and possible ways to fix them.:

- A01. Blockage due to lack of flame. There may be several reasons - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are heavily clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the extract air pressure, add fluids to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, accumulation of soot. Weather factors are possible - strong gusty wind.

- A 04. The drop in coolant pressure may be caused by a lack of fluid. Check the system for leaks, if found, repair.

- A05. Malfunctions of the DHW line thermistor are eliminated by replacing the sensor.

- A06. A defective heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent, do not work if the phase wire is incorrectly connected.

- E46. Exceeding the permissible temperature of the coolant indicates problems in the circulation of the liquid. CHECK the operating mode of the circulation pump.

- The bell symbol (bell, p) flashes. This is a signal from the chimney pressure sensor, indicating that there is an obstruction to the exit of smoke, the formation of ice or frost at the exit of the chimney.

IMPORTANT!

The Beretta boiler error is reset by pressing the shutdown button and restarting the boiler after 5-6 seconds.

Beretta CIAO 24 CSI

The Beretta brand is the property of one of the leaders of the European heating industry - the Italian company Riello, whose age is approaching its 100th anniversary.

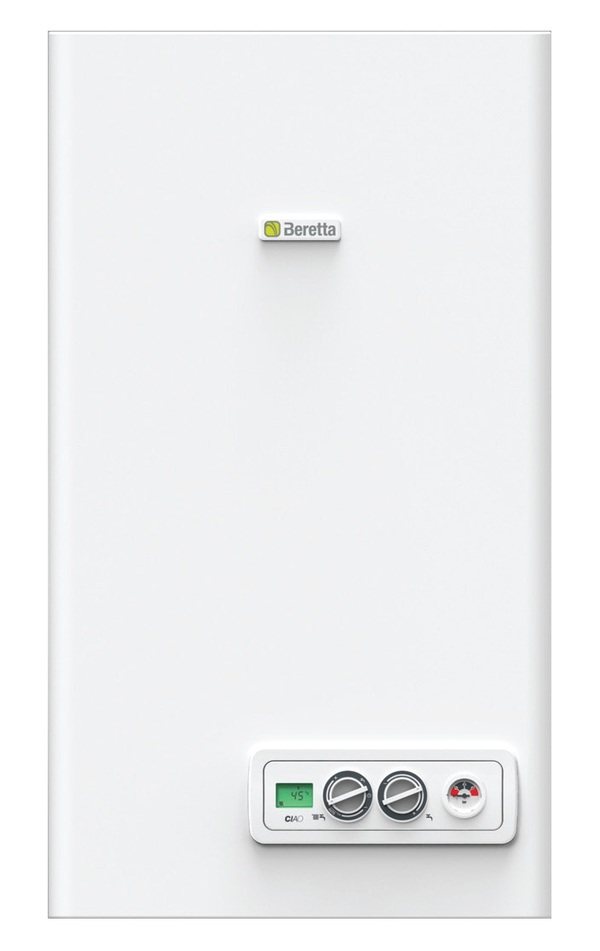

Beretta boilers are manufactured using modern technologies and fully comply with European safety, economy and efficiency requirements. The CIAO 24 CSI model is made in accordance with the most promising technical developments and is able to meet the needs of a modern residential building.

The units are manufactured in a wall-mounted design, have a compact and visually attractive body, which allows them to be installed directly in the kitchen and not have a separate room for the boiler room.

User's manual

Operation of Beretta boilers is carried out in automatic mode, which does not require constant human participation.

The user is only required to adjust the heating mode according to his own feelings, transfer the boiler to winter or summer mode (turn off or start the heating circuit), maintain the cleanliness of the case and periodic maintenance (by the service personnel).

All serious problems are solved only by calling the wizard - elimination of constantly occurring errors or incomprehensible phenomena that occur with the boiler in operating mode.

In addition, the user independently fills the system with water (or make-up as needed).

The process consists in supplying liquid through the make-up valve and filling the system until the water pressure reaches 1-1.5 bar. This is below the working pressure, but when heated, the water will expand and, due to the increase in volume, the pressure will reach the desired value.

Download instruction

Download instructions for gas boilers Beretta.

The boiler starts up automatically when the required temperature of the coolant in the system is set.

Do not pour water into a hot boiler due to the risk of destruction of the heat exchanger... Wait until the boiler cools down, and only then pour water.

The device and principle of operation of Beretta boilers

Floor models

The Beret company produces floor-standing, wall-mounted and condensing wall-mounted models of gas boilers.Floor standing units are presented in the Novella and Fabula series.

The control panel is located in the upper part of the case, the buttons are closed by a hinged cover. On the left are the buttons for turning on, resetting the burner lockout, a temperature controller and a thermometer. To the right is a flue gas limit thermostat and a manual reset draft sensor. At the bottom there are LED indicators for network and blocking.

In the upper right part of the body there is a sleeve for installing sensors. Below the base is an atmospheric two-stage gas burner with two gas valves. A sectional cast-iron heat exchanger is installed above it.

Novella models 174 RAI to 279 RAI have two heat exchangers of equal capacity, connected together and having one chimney. The circulation pump is mounted on top of the burner. To the left is the gas fittings. In the lower left corner there is a valve for draining the heat exchanger from the boiler.

Wall models

The wall-mounted Beretta City 24 CSI has a control panel in the lower right corner of the cabinet. It has a switch for the "Summer" and "Winter" modes. The Beretta Ciao (Chao) 24 CSI model has a backlit screen that shows the temperature of the coolant and hot water, and also displays error codes in case of malfunctions.

The Beretta Super Exclusive device has a separate manometer for monitoring the water pressure level in the system. The secondary plate heat exchanger is separately taken out to provide hot water supply. A thin expansion tank is attached to the right wall.

Closed combustion chamber, completely isolated from the room. The flue gas fan is located at the top and is connected to the flue gas flange. There is an electrically operated three-way valve under the pump.

Does not start (does not light up) - reasons and solution

The failure of the boiler at startup can be caused by various reasons, which can be determined either by the corresponding error code, or by checking the status of the boiler independently. The simplest option is the absence of gas in the main line.

This problem is external, it can only be solved by contacting the gas service.... The gas supply valve on the unit itself may be closed. There is one more reason for failure in ignition - polarity reversal of the power wires. It is shown on the display as code E33.

The solution to the issue is to reconnect the wires... Such a situation may arise even after a certain period of normal operation of the boiler, if any work was performed on the power supply panel and the phase and neutral were reversed by mistake.

If you cannot find the reason for the failure to ignite the boiler, you should contact a service workshop.

Installation features

The user needs to know about the main requirements for installing the device:

- Do not place the device in a living room.

- In the utility room, the boiler is placed in any convenient place. In the kitchen, do not mount the unit over the dining table or over the stove.

- The distance specified in the instructions is maintained between the wall, surrounding objects and the apparatus.

- The body and chimney become very hot during operation. If the apparatus is placed near a heat-sensitive surface, the area must be insulated.

- Before entering the boiler, a shut-off valve must be installed on the gas pipeline. This device is not included in the package. If the water quality is poor, it is recommended to install a filter.

At the end of the work, it is necessary to check the tightness of all connections. After that, they start checking the equipment.

How to check the sensors

All sensors of the Beretta boiler are part of the self-diagnosis system. They not only perform control functions, but are themselves objects of observation.

This means that in the event of failure, short circuit or wire breakage of any sensor, the corresponding error code will immediately appear on the display of the boiler control panel. The system polls the sensors automatically at the moment of switching on, no special actions are required from the user.

Most of them are thermistors that respond to changes in the temperature regime or the indicators go beyond the limits set by the operating mode. The design of the elements is simple, replacement, if necessary, is not difficult and does not take much time.

It is not recommended to change any elements of the boiler yourself, you need to call the master from the service center.

What do the indicator signals mean?

In some models of Beretta gas boilers, for example Beretta City, the appearance of malfunctions in the operation of the units can be judged by the signals of the red, yellow and green indicators.

The indicators are two or three LEDs located on the central panel that start flashing at different intensities when a particular fault occurs.

In some models of Beretta gas boilers, errors and malfunctions are indicated by light indicators located on the control panel.

A blinking green light can mean the following:

- 1 time / 3.5 sec - the equipment is switched to standby mode, the fire is extinguished;

- 1 time / 0.5 sec - the boiler is stopped due to a breakdown;

- 1 time / 0.1 sec - the unit is switched to the automatic control system;

- the indicator is on and does not blink - the boiler is working normally, the fire is on.

The Beretta City may stop on its own due to a breakdown in case of receiving a signal from the pressure and smoke exhaust sensors.

The boiler can stop working for 10 minutes, during which the correct parameters must be restored. During this time, the system will automatically scan. A detailed guide on how to check the readings of the sensors of the Beretta gas boiler should already be laid down in the self-diagnosis system.

The indicators on the panel of the Beretta boiler can give signals in different combinations and with different intensities. The type of light signal depends on what kind of error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator is on and does not blink - if, after the suspension, the operation of the boiler is not adjusted, the unit goes into emergency mode;

- indicator blinking - activation of the limit temperature sensor. Sometimes the error can be eliminated using the mode switch.

Simultaneous flashing of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator comes on and lights up continuously when the preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified technician to repair the Beretta gas boiler.

To eliminate all the above-described problems with Beretta gas boilers, it is strongly recommended to use the services of the masters of authorized service centers and organizations with which an agreement has been concluded for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to even more serious damage, which will result in costly repairs and a long shutdown of the autonomous heating system.

The pump does not work - what to do

If a failure of the circulation pump is noticed, it is necessary to stop the operation of the system and call the wizard.

There can be several reasons for failure, from power supply problems to mechanical problems.... The first reason is determined by testing and checking the condition of the pump motor.

The second reason can be detected by checking the condition of the moving parts of the pump, the absence of difficulties when rotating or moving parts of the mechanism, breakdowns or wear of gears and other elements.

The decision to repair or replace the pump is made based on the result of an examination of the performance and condition of the unit parts... If the forecast for repair work is favorable, the pump is restored, otherwise a complete replacement is required.

How to turn on the boiler

Installation, inspection and first connection is carried out by a gas expert

The gas heating boiler Beretta is installed and tested by a specialist. The first ignition is performed in his presence.

The following parameters are checked first:

- availability of electricity, water and gas;

- chimney and air intake functionality;

- gas pressure in the gas pipeline;

- tightness of the gas pipeline;

- the presence of a safety device.

After checking, fire up the boiler. The procedure is as follows:

- turn on the power supply;

- open the gas valve on the incoming gas pipeline;

- set the temperature regulator to +20 C;

- turn the selector knob to the required position - summer, winter, heating water for hot water supply.

The boiler turns off when the regulator is moved to the off position. In this case, the device is not disconnected from the mains, the gas supply remains possible. If the user will be absent for a long time, it is better to turn off the device completely: turn the main switch to the off position, turn off the water and gas supply and disconnect from the mains.

The first ignition is carried out at an air temperature above 0 C.

How to flush the heat exchanger

Beretta boilers are equipped with either separate or bithermic (combined) heat exchangers. In the first case, flushing gives a greater effect, the second type of heat exchangers is difficult to flush due to the design features.

There are two ways to flush:

- Mechanical... Requires disconnection of the heat exchanger from the boiler. The results of this rinsing are not particularly successful, since it is extremely difficult to mechanically clean the inner surfaces.

- Chemical... It does not require dismantling the heat exchanger, but is performed using a special device It has a fairly high efficiency, is able to remove scale and extend the service life of the unit.

For flushing, special reagents are used that dissolve scale and remove it from the inner cavity of the heat exchanger tubes. The procedure should be performed every 2-3 years, depending on the quality of the water. To perform the work, you need to invite a specialist from the service center.

Specifications

Consider the parameters of the wall-mounted gas boiler Beretta CIAO 24 CSI:

| Parameters | The values |

| Boiler type | Wall heating |

| Fuel type | Natural or LPG |

| Efficiency | 92,8 % |

| Functions | Heating and hot water supply |

| Power | 24 kWt |

| Mounting method | Suspended, on a load-bearing wall or supporting structure |

| Heat carrier temperature | 40-80° |

| DHW temperature | 35-60° |

| Heat exchanger type | Bithermal (combined) |

| Gas consumption | Up to 2.73 m 3 / hour |

| Dimensions (edit) | 715 × 405 × 248 mm |

| Power supply | Single-phase 220 V 50 Hz |

| Weight | 28 kg |