Published: 14.04.2012 Heading: Materials and technologies, Construction Hits: 6453

Thermal insulation and waterproofing of the foundation and basement

Modern basements in a private house are no longer associated with gloomy dungeons or damp cold cellars. Using every millimeter of usable area, the owners often equip laundries, workshops, gyms, etc. in the basement. To feel comfortable in such a room, you need to protect it from moisture and heat loss.

Basement - not cheap pleasure. According to experts, its proper arrangement increases the cost of building a house by about 30%. Additional costs begin with a pit: it needs to be dug to a depth of freezing of the soil - at least 150-160 cm. Waterproofing and insulation of underground square meters will also cost a pretty penny. Especially if the basement is located below the pound water level. In this case, waterproofing using welded panels or multi-layer carpets is required. This is a very expensive and time consuming solution and makes the basement unnecessary.

If additional space is needed, it is cheaper to build an extension or an attic rather than burrowing into the ground. But if the costly article did not frighten the owners and the basement in the house is planned, you need to bring it to mind so that it does not turn into a problem area.

The basement walls, in essence, represent the foundation of the house, therefore, the further fate of the dwelling depends on their durability. They say that a drop wears away a stone, and moisture absorbed into the pores of concrete or brick expands when it freezes and breaks the wall materials. In addition, excess moisture causes corrosion of the reinforcement in the concrete.

If there is no waterproofing in the basement, its walls will be wet and damp, mold will appear and plaster will peel off.

Especially relevant is the waterproofing of underground premises for owners of country houses and summer cottages located in the most prestigious places - near water bodies. In such areas, groundwater can come to the surface.

Mineral wool

This material belongs to non-combustible, fibrous insulation. It is made from basalt, which is melted, stretched into fibers, and then pressed using a binder (resin), resulting in slabs or mats (rolls) used for thermal insulation: roofs, floors, ceilings, ventilated facades. Mineral wool is also used in the production of three-layer building panels for layered masonry. It can be used in ordinary living quarters, as well as for thermal insulation of buildings with high temperature and humidity loads (saunas, baths).

The advantages of basalt or as it is called "stone" wool are:

- Non-flammability. Even at a temperature of 1000 ° the fibers retain their structure and do not melt.

- Chemical resistance. Mineral wool is a passive material that does not come into contact with chemicals and does not corrode metal.

- Biostability. Mold, decay, fungus, rodents are not dangerous for basalt insulation.

- Compressive strength, resistance to stress, retention of geometry (dimensions, shape).

Famous waddings: HITROCK, IZOBEL, ROCKWOOL, PAROC, TECHNONICOL, IZOVER.

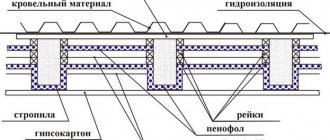

Features of vapor barrier in a frame house

The vapor barrier layer is not a simple film, but a whole system for protecting the insulation from excessive moisture. The problem is that a wet insulation loses its positive qualities.This can be avoided only by laying a high-quality vapor barrier layer, which will protect the floors from moisture condensation in their thickness. Thinking about how to insulate the floor in a wooden house from below, consider these nuances.

The vapor barrier material has a special membrane through which moisture can circulate and does not condense on the inner side of the layers laid in the "cake" of the floor. When laying, it is important to observe the main rule: the front part should be directed towards the room. Upside down material will have the opposite effect: moisture will condense even more, leading to the immediate formation of mold and mildew.

Glass wool

Just like the basalt counterpart, it belongs to fibrous insulation. However, it has its own differences. Glass wool is softer due to the increased fiber length. The material is suitable only for non-loadable structures, for example, it has proven itself remarkably in pitched roof systems, and is actively used in interior partitions.

The material is produced from waste glass industry, which undergoes high temperature processing (melting), after which a long fiber is formed from it. Advantageous characteristics of glass wool: incombustibility, chemical resistance, absence of corrosive agents, immunity to biological damage.

Mineral and glass wool additionally provide effective sound insulation. They are delivered to the consumer in the form of plates or rolls. Well-known manufacturers: IZOVER, URSA, KNAUF.

Foundation protection

In order for a house to have a reliable and solid foundation in the long term, it is not enough just to design and calculate it correctly. A mandatory set of measures is required to protect against such external factors that have a destructive effect on the main supporting structures of the building. The main ones are ground and atmospheric waters, as well as temperature drops. That is why waterproofing and foundation insulation are always relevant.

Concrete, which is part of a monolithic base, has an unpleasant characteristic: from moisture on its surface, it, playing the role of a sponge, begins to absorb water in significant volumes. Therefore, in order to preserve the frame made of reinforcement, as well as to maintain the optimal microclimate parameters in the basement and basement floors, the foundation is waterproofed. SNiP, regulating this process, presupposes a certain procedure for its implementation. There is no need to say that this process is mandatory.

As for insulation, with its help you can not only protect the building from sudden temperature changes, but also get the opportunity for a longer preservation of heat inside it. In turn, waterproofing the foundation (SNiP 2.02.01-83) using special materials and compositions makes it possible to protect it from the harmful effects of moisture.

Expanded polystyrene

Along with fibrous insulation, expanded polystyrene plates are often used in construction. It is produced by mixing polystyrene pellets at a high temperature and then extruding through an extruder (hence the name extruded polystyrene foam). The result is slabs / blocks having a porous structure with closed cells. Expanded polystyrene:

- Waterproof.

- Long lasting.

- Resistant to mortar and adhesive mixtures.

- Easily withstands temperature loads.

- Differs in low weight.

Depending on the density of the material, it is used at various stages of the construction of a house, for example: the device of fixed formwork, insulation of facades, foundations, basements, as well as internal walls (in particular balconies, loggias).

Thermal insulation manufacturers: Penoplex, TECHNONICOL, Tepleks, URSA, Penosteks.

Self-waterproofing and insulation of the foundation

To do this work with your own hands is quite within the power of someone who understands at least something in construction. To carry out the work correctly and reliably, a novice master should follow a certain sequence of actions. First, you need to prepare the surface of the foundation, clean it of dust and dirt, removing everything that may interfere with the adhesion of the insulating material to the base. Sharp elements are also eliminated in the process. Then the surface is treated with a primer solution. After it has dried, the main insulating component is applied. If we are talking about the use of the material to be welded, for example, linocrome, then in this case the lower part of the rolled roll is heated with a burner, while the foundation is also heated. The insulator, slowly rolling out, is pressed against the surface.

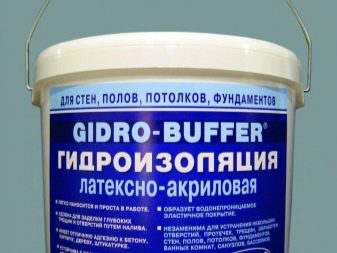

Waterproofing

Waterproofing materials effectively protect building structures from moisture and climatic factors. By eliminating contact with water, the durability of all building elements is ensured, from the foundation to the roof. The main types of waterproofing materials include:

- Rolls. The covering material is a base (fiberglass, cardboard, etc.) impregnated with an insulating moisture substance. For example: roofing material, waterproofing, brizol, etc. Usually used on horizontal surfaces: floors, floors, foundations, roofs.

- Mastics. These are plastic adhesives that include dispersion fillers. After application to the surface, they form a waterproof / water-repellent layer. An example is bituminous mastics. Such waterproofing is used to cover the entire area of the base or to process seams, joints.

- Waterproofing coating. Dry mixtures that form a solution when combined with water. Such compositions, like mastics, are applied to the surface to be treated to obtain a durable waterproofing layer.

- Penetrating (water repelling) liquids. After application, for example on concrete or brick, the liquid penetrates into the structure of the base, filling all microcracks. After drying, a reliable water-repellent barrier is created.

- Films and membranes. A striking example of the well-known waterproofing is the usual polyethylene or polypropylene film. Membranes have a more complex structure, consisting of two layers separated by a reinforcing mesh. Such material is more resistant to mechanical, chemical and thermal stress.

Materials (edit)

Insulating properties today have many substances, which are used in the arrangement of the floor.

Many experts recommend using isospan for such purposes, but besides it, there are several groups of waterproofing materials:

- Waterproofing paints. The main component of such solutions is bitumen, which is mixed with various polymers. Application is carried out with a regular brush, which allows you to cover with it even in hard-to-reach surfaces. To obtain a quality result, the surface must be carefully prepared before processing. Therefore, this approach has not found widespread use.

- Insulating fillings. The product is a liquid that is simply poured over the base. It is made from asphalt concrete and bituminous components. Experts recommend using fillings on concrete surfaces, since they practically do not crack and do not diverge, like wood boards.

- Loose substances. This type of material consists of granules that are not able to absorb liquid. The substance is not only a high-quality waterproofing agent, but also not a bad heat insulator.Therefore, the use of bulk mixes eliminates the introduction of mineral wool or other heat-insulating material.

Vapor barrier

Vapor barrier materials are a protective barrier that separates the zones of cold and warm air. If you exclude their use, then temperature drops will cause the formation of condensation, which in turn will destroy the insulation and other elements of the building structure. As a vapor barrier, special roll materials are used - films or membranes. They are pulled over the insulation, thereby eliminating the possibility of the formation and accumulation of moisture. Scope of application from facades to internal partitions, ceilings, roofs. Among the well-known manufacturers, IZOVEK can be distinguished.

Do not forget that hydro, steam and thermal insulation materials are a guarantee of the durability of your home.

Backfill insulators

Bulk materials are usually a mixture of bentonite and water-repellent granules. In fact, it is an alternative to insulating wool. This coating has a minimum level of moisture absorption and excellent thermal insulation characteristics. Sometimes a loose insulator is used not only to protect against moisture, but also as a heater.

You should be aware of the following nuances before starting work on filling the insulator:

- The preliminary finishing of the subfloor is carried out only with bentonites filled with water. Such a connection will lead to the formation of a kind of liquid waterproof gel-like layer.

- The resulting moisture-repellent material is poured over the rough base.

- Freezing takes place in a few days.

The advantage of this technology is that the material can also be poured in wooden houses between the logs at the base. The thickness of the layer can correspond to the level of the lag.