Home / Gas boilers

Back to

Published: 03.06.2019

Reading time: 3 minutes

2

1320

Owners of private houses are often interested in how much gas a gas boiler consumes per month. You can find out the numbers through the correct calculations. More on how to measure gas consumption and how to reduce this level later in the article.

- 1 Approximate gas consumption 1.1 What affects gas consumption

- 1.2 How to reduce gas consumption

- 2.1 Approximate calculation of energy consumption

What is the power supply for a gas boiler?

With the advent of closed combustion chambers, gas units became dependent on electrical networks. Electricity consumption in such boilers is determined by the composition and amount of electronics in its insides.

And it is already allowed to install them not only in an isolated boiler room, but also in kitchens and bathrooms. From a security point of view, they have a high level of protection.

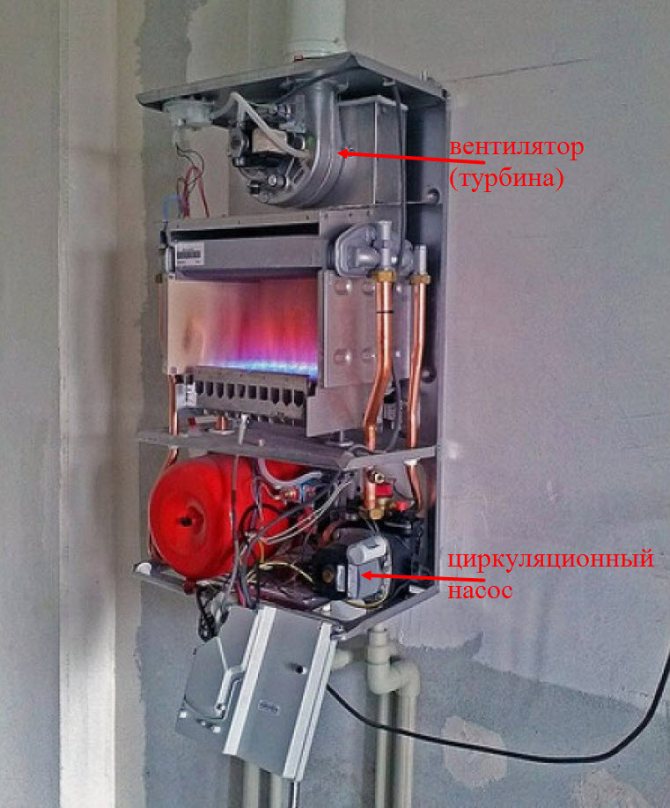

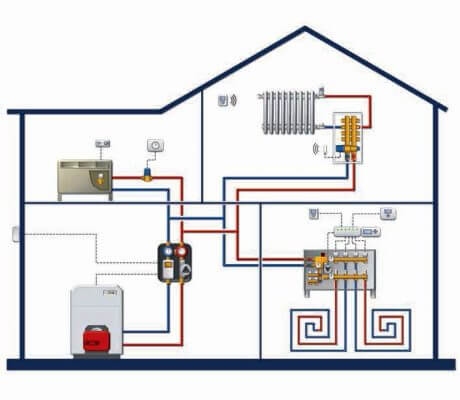

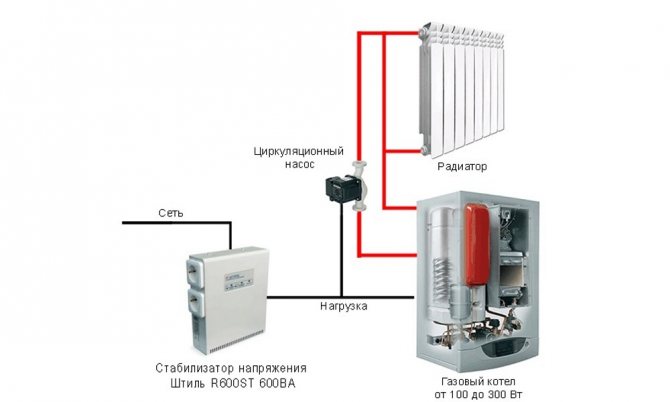

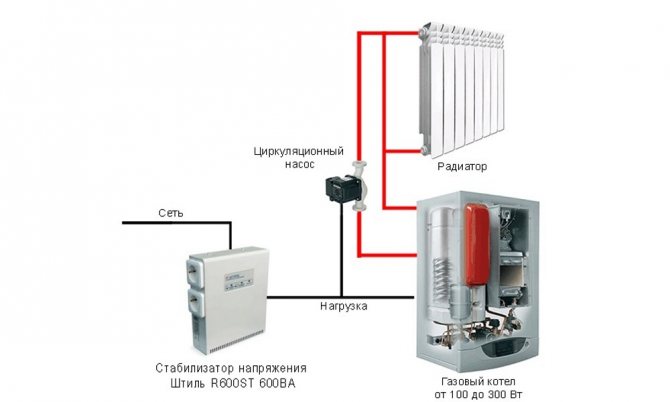

The arrows mark the main electrical consumers of the wall-mounted gas boiler - the air blower and the built-in circulation pump. In systems with a floor-standing boiler, the pump is installed separately, and in general, not one, but several pumps can be used in the heating system, and all of them will consume electricity

Let's list what exactly requires energy consumption:

- electric ignition;

- circulation pump;

- a fan in a closed combustion chamber;

- automation (gas supply adjustment, as well as traction sensors, gas pressure, water pressure, etc.).

An electric ignition gas boiler ignites automatically from an electric spark. There is no ignition wick, which constantly burns in other ignition systems, at all, gas is not wasted in vain for its combustion.

At the moment of the appearance of an electric spark, some kind of electricity is spent, but the moment itself lasts a fraction of a second. In this case, electricity is consumed minuscule, gas savings due to the missing igniter covers these costs. The only negative is that in the absence of electricity, the boiler equipment cannot be started.

If the power supply to the network suddenly disappears, the gas cutoff will be triggered. When the power comes on, the electric ignition will restart the heating system again without human intervention.

The circulating pump - so it raises the power consumption dramatically! But it is possible to minimize the costs when operating a gas boiler if you use thermostats in all rooms, integrating them into the general circuit of the pump power supply and the operation of the boiler.

The programmer also significantly increases the economic result. The thermostat only helps to maintain a stable set temperature, and the programmer is able to set the day / night mode, changes by day of the week, etc.

Modern automation of a gas boiler needs electricity and represents the most complex electronic devices that, without human intervention, regulate the fuel supply and the strength of the flame of gas burners, control the temperature, diagnose breakdowns

A fan (turbine) in a closed combustion chamber also consumes electricity, but less than a circular pump. The costs are justified by the improved smoke extraction. A boiler with a coaxial chimney does not burn oxygen in the room, does not allow carbon monoxide to pass outside and makes less noise.

Automation in a gas boiler increases its final cost, but with it control of the heating system is reduced to setting the desired temperature and pressing just one button.

Electricity is needed to operate the gas controller and many sensors.Its consumption depends on how complex the automation is, but in general we are talking about low-cost energy consumption.

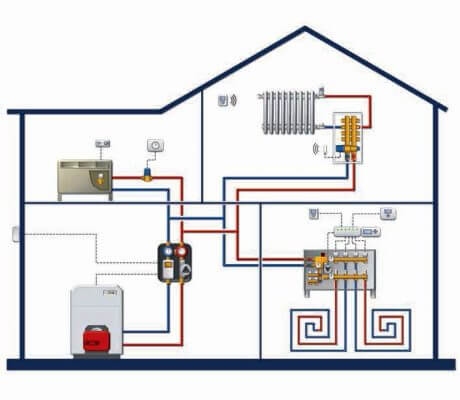

Automatic temperature control in a house with underfloor heating

In a house with underfloor heating it is necessary to have three automatic control systems temperature: 1 - underfloor heating according to the air temperature in the room, but with the limitation of the floor temperature; 2 - radiators for indoor air temperature; 3 - boiler weather control according to the outside air temperature.

As known, underfloor heating can be either "comfortable" or "heating".

"Comfortable" warm floor

slightly warms up the surface and provides a pleasant sensation when a person is on the floor. The main supply of heat to the room is provided by radiators. For a comfortable warm floor, it is necessary to maintain a constant temperature of the coolant.

"Heating" warm floor,

in addition to comfort, it provides complete heating of the room.

In the conditions of the Russian climate, the relatively low heat output of the warm floor makes it suitable most often only for comfortable heating.

An air temperature sensor in the thermostat housing and a sensor in the floor provide room temperature control and protect the floor from overheating

In a home with a comfortable underfloor heating for temperature control it is necessary to have three automatic control systems.

One system that regulates the work of the warm floor, should be controlled by the room temperature until the floor surface temperature reaches a comfortable level. That is, in the off-season, the house will be heated with warm floor heating.

If the floor temperature has reached the upper limit, and the air temperature in the rooms decreases, then the automatic radiator control system... Radiators will warm up the air in the room, add their own heat to the heat that will constantly come from the warm floor.

The mode of heating the coolant by the boiler must be regulated by one more automatic weather control system that reacts to the outside temperature.

Considering that the underfloor heating system has a high inertia (heats up slowly and cools slowly), it is recommended to use weather automation to control its operation. Then the temperature of the heating medium supplied to the system will be adapted to the outside temperature. Due to this, together with a change in the outside temperature, the temperature of the heating medium circulating in the floor changes.

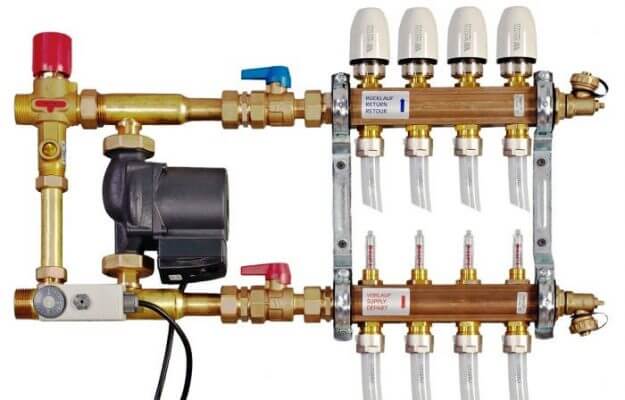

Mixing unit with a circulation pump - on the left. On the right, a collector of underfloor heating pipes is connected to the mixing unit. The manifold is equipped with servo-driven control valves. The valve is controlled by a thermostat through a servo-actuator, which regulates the supply of heat carrier to the underfloor heating circuit, depending on the temperature of the floor surface and the temperature of the air in the room.

Each room with a "warm floor" is at least one circuit (one pipe loop). All these circuits must somehow be combined into one and connected to a boiler or other heat source. Both ends of the pipe of each underfloor heating circuit are connected to a manifold.

To control the temperature of the underfloor heating, it is necessary to select and install a manifold equipped with servo drives on the control valves.

A servo is a device that, when an electric current is supplied to it from a thermostat, acts on a valve, opens or closes it. The servo works like a switch, opening or closing the valve completely. The temperature of the underfloor heating surface will be maintained with an accuracy of +/- 0.5 - 1 ° C.

Gas boiler electricity consumption in figures

Usually, everyone is primarily interested in gas consumption.And the question of how much electricity a typical gas boiler consumes seems to fade into the background. Let's deal with it.

A volatile gas boiler is connected to an alternating current network with standard characteristics: 220 V and 50 Hz. For the stable operation of the unit, it is important that the voltage does not drop beyond the 195 V mark. At lower voltages, electrical components will go wild and start to shut down.

Minimum electricity consumption

The need for electricity at different stages of work is different. The minimum electrical consumption of a gas boiler is 65 W. This is in the phase of operation of the circular pump, and at the time of electric ignition - 120 W, i.e. almost twice as high. If the fan is on, then it also consumes electricity - another 30-35 watts.

Convenience of starting the boiler, saving gas and safety due to the absence of a constantly burning igniter are the main advantages of a gas boiler with electric ignition, despite the fact that electric ignition requires electricity consumption

We draw conclusions. Electric ignition requires 120 W, then, with the pump and fan running, the power consumption will be:

65 + 30 (35) = 105 (110) W

This is the minimum daily power consumption. It does not take into account the consumption of electricity by other elements of the heating unit - the same automation. Let it be insignificant, but the final result will increase.

And it should also be noted that the figures are based on a single-circuit apparatus, i.e. only heating without hot water supply is taken into account. If we take the same thermal power, but a double-circuit boiler, the power consumption will be higher.

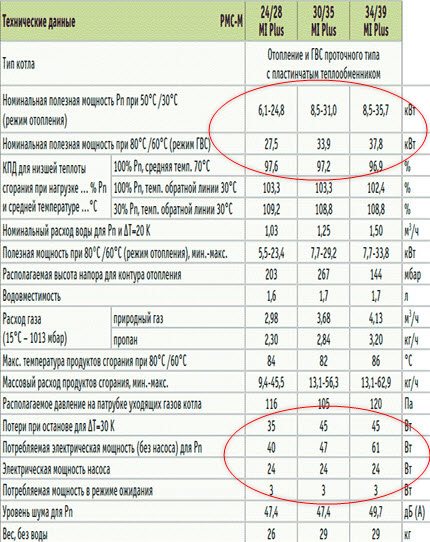

What does the technical passport of a gas boiler say?

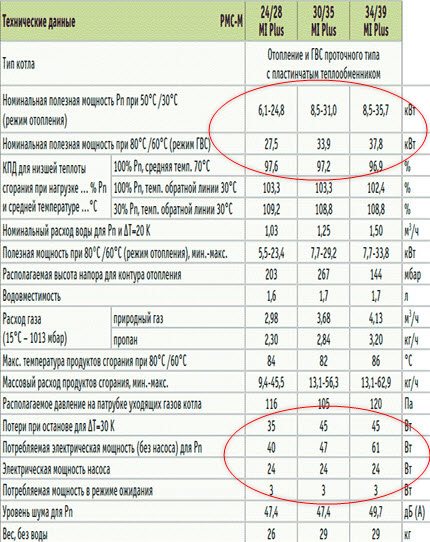

In the characteristics of any gas boiler there is information about power consumption. After examining the technical documentation for the products of Bosch, Baxi, Vaillant, Ariston and others, we see that the electric power of the floor units is in the range from 100 to 200 W, and of the floor units - from 15 to 160 W.

But since in heating systems with floor-standing boilers, separately installed circulation pumps are often used. It is important not to forget about them and take into account additional power consumption.

And here is a visual comparison of power consumption in the presence of hot water supply (double-circuit boiler) and without hot water supply (single-circuit boiler): a floor-standing single-circuit with a power of 30 kW consumes 15 W, a double-circuit also with a power of 30 kW - already 150 W.

From the technical data it can be seen that the greater the thermal power of the gas boiler, the higher its demand for electrical energy.

Different manufacturers ambiguously describe their power consumption in the characteristics of gas boilers.

It can be one general line, or it can be detailed:

- electricity consumption by the pump;

- electric power without pump;

- stopping losses;

- standby consumption.

Consumption for all items is indicated in W.

Calculation of power consumption by example

To calculate the kilowatts of electricity consumed by a gas boiler, we make a classic calculation of energy consumption - the same as for other electrical appliances. We are based on the electrical power of the boiler indicated in the technical data sheet. The manufacturer sets this parameter with a maximum value that actually exceeds the average actual indicator.

Example.

Let's say we have a single-circuit gas boiler Baxi Luna 31.310 Fi, its useful thermal power is 31 kW, power consumption is 165 W.

We calculate the daily consumption of electrical energy for the preparation of the heat carrier. We multiply the power consumption by the number of hours of operation of the boiler.

Let's say the heating does not turn off around the clock:

165 W × 24 hours = 3960 W × h or 3.96 kW × h is the maximum daily energy consumption

Now we calculate how much electricity in kilowatt-hours a gas heating boiler consumes per month. We multiply the number of consumed kilowatts per day by the number of days in a month (30 days):

3.96 kWh x 30 days = 118.8 kWh is the maximum monthly electricity consumption.

A volatile boiler does not need a natural air flow, as it has forced ventilation. Its control system is fully automated, and frost protection is turned on in the energy saving mode - the boiler periodically turns on to warm up, and the circulation pump drives the water in the system

And finally, you need to get the electricity consumption for the year or for the heating season. Since we are talking about a single-circuit boiler and, accordingly, heating without hot water supply, we take the duration of the heating season equal to 7 months.

Then: 118.8 kW × h × 7 = 831.6 kW × h - the maximum electricity consumption for the entire heating season.

For a double-circuit boiler, 12 months must be taken into account - although in an economical mode, the boiler works in the summer months.

Thermostatic valve on the radiator reduces gas consumption

Thermostatic valve - a thermostat for a radiator reduces gas consumption for heating. Installing a thermostat on a radiator is a mandatory requirement of building codes.

Weather regulation changes the temperature of the heating water in the heating system depending on the outside temperature.

The room thermostat regulates, adjusts the temperature of the heating water depending on the temperature in one room, where it is installed.

A room thermostat is always installed in the largest room of a house or apartment. The temperature in other rooms will differ from that which is required in one direction or another. For example, in order to save gas, it is beneficial to keep the temperature in rarely visited rooms lower.

The temperature in other rooms can be regulated using thermostats installed at the heating water inlet to the radiator. A thermostatic valve or an electronic radiator thermostat is used as radiator thermostats.

Thermostatic valve regulates the flow of heating water through the radiator so that the room temperature remains constant, set on the scale of the thermostatic head. The control head of the thermostatic valve contains a bellows filled with liquid or gas. When the temperature in the room changes, the temperature of the liquid (gas) changes. As a result of thermal expansion of the liquid (gas), the bellows changes its position and acts on the valve stem of the valve on the radiator pipe.

On sale you can find thermostatic valves with remote temperature sensor... Such devices provide a more stable temperature in the room, since the influence of a nearby radiator and window is excluded.

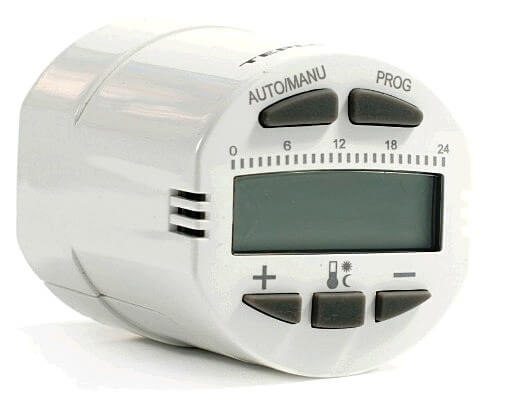

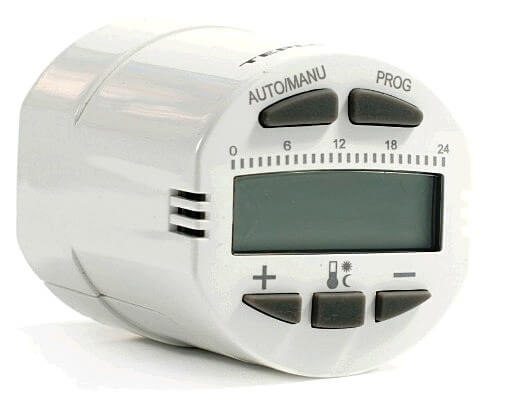

Electronic radiator thermostat

Electronic programmable thermostat for heating radiator. Powered by AA batteries, 2 pcs. Adjustment temperature from 5 ° C to 35 ° C. Hysteresis ± 0.5 ° C. LCD display.

The electronic radiator thermostat, like the head of the thermostatic valve, is mounted on a control valve on the pipe to the radiator. Compared to a thermostatic valve, it has many more control functions.

The radiator thermostat consists of a built-in or remote temperature sensor and a servo-actuator that opens and closes the valve on the radiator.

In the programmable radiator thermostat, you can select the temperature mode for daytime and nighttime, for different days of the week. This allows for greater comfort and gas saving... For owners of a country house, a programmable thermostat will maintain an economical heat mode on weekdays, and will switch to warming up mode before arrival.

An electronic programmable radiator thermostat can provide:

- Indoor temperature indication.

- Battery discharge indication.

- System malfunction indication.

- Operating mode indication.

- Installation of an economical and comfortable temperature regime.

- Setting a schedule for alternating between comfort and economy mode for each day of the week.

- Childproof lock function.

- Room ventilation function.

- Function of protecting the valve from acidification.

- System frost protection function.

How to reduce energy costs?

We will proceed from the fact that, firstly, the electricity consumption directly depends on the heat output of the heating boiler. And, secondly, most of the electricity consumed is taken by the circulation pump, which drives the coolant in the pipes so that the pipes and heating radiators warm up measuredly.

The boiler is usually always on at night from 23:00 to 06:00. Use a multi-tariff electricity meter, there are reduced prices at night

Let us name a number of specific proposals for those who would still like to reduce energy costs:

- Stop selection on the non-volatile unit. Most likely, it will be a floor version. In terms of functionality and comfort, alas, it is unable to compete with its volatile counterparts.

- Buy a volatile device, but low power. Here, of course, there is a significant limitation - one cannot ignore the number of heated square meters. If, for example, it is necessary to heat 180-200 m² of a private house, then a gas boiler with a capacity of 20-24 kW is needed. And nothing less.

- Carefully study the assortment lines of different brands. Each model has its own nuances and, perhaps, for some of them you will see the most attractive figures for power consumption in the technical specifications.

- Analyze what makes up the total cost of electricity. Perhaps the share of these costs attributable to a gas boiler is negligible, and attention should be turned to other objects that really consume excessive electricity.

- And how do you like the use of alternative energy - for example, solar panels or collectors on the roof of the house?

And yet, in the pursuit of saving electricity, do not bring your own actions to the point of absurdity. Do not forget that gas units consume little electricity, since their main fuel resource is not electricity, but natural or liquefied gas.

Types of non-volatile boilers

Single-circuit and double-circuit

Passing through the heating element, the water temperature rises. This is how it works single-circuit boiler (circuit - the trajectory along which the water moves). Double-circuit boiler works on a similar principle, except that the heated water passes through a system of sensors that measure the temperature and send information to the control panel.

If the temperature exceeds the norm, the gas pressure is reduced to balance it. If the temperature readings turn out to be critical, the system will turn off the boiler for a whileto avoid overheating, then turn it on again.

Floor and wall

Certain systems are too heavy or too bulky to fit on walls, so install them can only be on the floor.

Another reason - a portable pump that can vibrate, thereby weakening the point of contact with the wall. As a rule, only large boilers for large-scale enterprises and warehouses.

UPS for a gas boiler and its power consumption

In the event of a loss of electricity in the network, the gas unit will switch to an emergency worker, which threatens to break down expensive components. And the UPS (uninterruptible power supply) will come to the rescue in such situations.

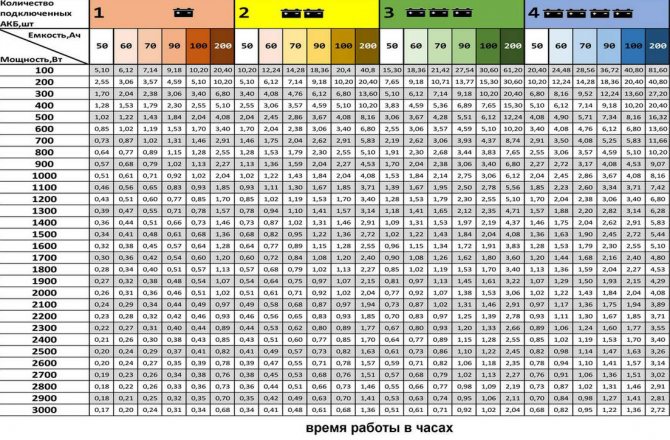

How long a gas boiler can work in the absence of electricity in the network depends on the capacity of the battery pack. Choose either a UPS with a built-in battery, or a UPS with the ability to connect the required number of battery sections to it

Line-interactive type - the most in demand UPS, according to numerous customer reviews. They include a voltage stabilizer, which is able to respond to voltage drops in the network within 10%, if this value is exceeded, a switch to power supply from a rechargeable battery follows.

Off-line type Are uninterruptible power supplies without a voltage stabilizer. They help out in case of a sudden power outage, but do not protect against fluctuations in the mains voltage.

On-line type - the most advanced UPS. They smoothly switch from mains power to battery power and vice versa. The only drawback is that not everyone can afford their price.

At the moment the gas boiler starts up, electricity consumption increases by at least two, or even three to four times. Let it be a short moment, lasting a second or two, we still take a UPS for a gas heating boiler to the maximum and with a power reserve. For a gas boiler with an electric power of 100 W, a UPS with a power of at least 300 W is needed (with a margin of up to 450-500 W).

As for the capacity of the storage battery, for example, one battery with a capacity of 50 Ah will be enough with a power consumption of 100 W for 4-5 hours of operation. To provide 9-10 hours of operation, you need to have two such batteries, etc.

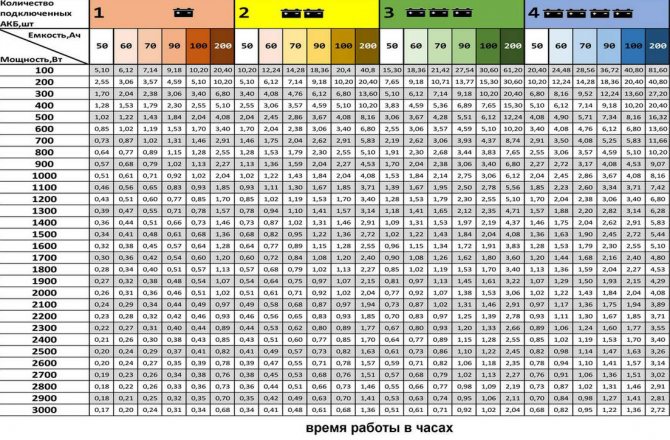

This table shows the autonomous operation of a gas boiler in hours, depending on the electricity consumption of the gas boiler (electric power in W), the capacity of the storage battery (capacity, Ah) and the number of simultaneously connected batteries (one, two, three or four)

And finally, will the UPS consume power for its own needs? It all depends on the efficiency. If we take the efficiency = 80%, then for our 300 W UPS the consumption together with the load will be:

300 W / 0.8 = 375 W, where 300 W is the load, the remaining 75 W is the consumption of the UPS itself.

The given example of calculation is conditional and is applicable for simple uninterruptible power supplies, namely for the moment when the mains voltage surges become above a certain level - more than 10%. When the network is standard 220 V, the UPS consumes practically nothing.

It is better to entrust detailed calculations for calculating UPS power, battery capacity and additional electricity costs in connection with the installation of a UPS in the heating network.

Weather regulation of temperature reduces gas consumption

All building structures of the house have the property of thermal inertia. For example, when the outside air temperature changes, the outer walls slowly heat up and do not cool down immediately. That is, a change in the outside temperature leads to a change in the indoor temperature with some delay.

When regulating with a room thermostat, the temperature of the heating medium in the system will not change until it starts, for example, to rise in the room due to warming outside. Only after this, the temperature of the coolant will begin to decrease, but due to the thermal inertia of walls, radiators and other structures, the heat release will continue for some time, and the temperature in the room will be higher than the set one all this time.

For this reason, the accuracy of maintaining the room temperature with a room thermostat will not be very high. The range of temperature fluctuations in the house will be greater than the value that is set by the thermostat hysteresis setting.

If the temperature of the heating medium is changed simultaneously with fluctuations in the outside temperature, then the accuracy of regulation of the air temperature in the room can be increased, which will increase comfort and reduce the gas consumption for heating.

Weather control of the room temperature can be done in one of three ways:

- By connecting only the outdoor temperature sensor to the boiler, without connecting a room thermostat.

- Connecting a temperature sensor and a two-position thermostat to the boiler.

- By connecting a temperature sensor to a room thermostat, if its design provides for such a possibility.

The best temperature stability, which means comfort and energy savings, can be achieved by using the third method of weather regulation.

The first option, with only an outside temperature sensor connected to the boiler, provides a minimum cost - no need to purchase a thermostat.

Connecting an outside temperature sensor and a two-position room thermostat to the boiler is the best option for weather regulation.

A boiler with an outside temperature sensor will react to changes in weather conditions, and the room thermostat will adjust the temperature of the heating medium, depending on the air temperature in the room. The fact is that the temperature in the room depends not only on the heat that comes from the heating system. The temperature in the house changes if, for example, a window is open or the sun is shining through the window, electrical appliances are working, or there are many people in the room. The room thermostat will react to all this, adjusting the temperature in the heating system.

Outside air temperature sensor for gas boiler Protherm

For Protherm boilers, the plant produces an NTC type outdoor temperature sensor with code S010075. The sensor is placed outside, on the facade of the house protected from the sun. The sensor is mounted on a bracket, at some distance from the wall so that the wall temperature does not affect the sensor. The sensor is connected to the boiler with a two-core copper wire with a cross section of at least 0.75 mm2.

Dependence of resistance on temperature for a thermistor of an outdoor temperature sensor of a gas boiler Proterm. Order number: 0020040797.

There is experience of using as an outside temperature sensor, NTC thermistor B57164-K 222-J, 2.2 kOhm, 5%, from Epcos. You can buy it in the online store. In parallel with the thermistor, you must connect a conventional resistor with a resistance of 2.2 kOhm. This is necessary so that the dependence of the resistance of the outdoor sensor on temperature approximately corresponds to the data indicated in the table.

For weather protection, the thermistor is placed in a suitable box. The cost of such a self-made sensor with a thermistor is much lower than that of a factory sensor.

How to find out how many kilowatts per day a gas apparatus consumes

To find out how much electricity a gas boiler consumes, you need to make a regular calculation of energy consumption - it is used for any electrical appliances.

For the calculation, you need the value of the electric power of the boiler. Its value is indicated in the technical documentation, it is measured in watts (W or W) and kilowatts. Usually they indicate the maximum value of kilowatts consumed by the device - it is significantly higher than the average.

Let's say we have a Baxi Eco Four 24 double-circuit heater, its heating capacity is 24 kW, and the electric one is 130 W. To calculate the daily electricity consumption, you need to multiply the consumed power by the number of hours during which the consumption occurs.

If energy is consumed around the clock: 130 W x 24 h = 3120 W * h

This is the maximum consumption of the Baxi Eco Four 24 model per day. Dividing the result by 1000, we get 3.12 kWh. To find out how many kW * h the device consumes per month - namely, in these units the consumed electrical power is indicated in the receipts for payment - you need to multiply the number of kilowatts consumed per day by 30:

3.12 kWh x 30 (days) = 93.6 kWh

This is the maximum value of the consumed electrical power. It is clear that to calculate consumption for a year, you need to multiply the result by the number of months in a year during which the device operates.

For single-circuit models, their number is limited by the heating season - about 5. For dual-circuit devices set to summer economy mode, consumption is calculated taking into account the summer months.

What electricity is spent on

In heating equipment connected to power grids, the lion's share of electricity is consumed:

- Circulation pump. He "eats" electricity more than others and consumes energy up to 200 watts per hour. Like any electric motor, the pump requires impeccable voltage parameters. Any inconsistencies with the standards lead to a decrease in power indicators - it starts to work noisily and may break down in general.

- Protective automatics. It spends a little electricity - about 15-30 watts. He is afraid of power surges - because of them, the controller may break down, which will provoke a shutdown of the equipment.

- Burners. They are extremely demanding on current characteristics. A three-pole connection is required so that the fire is recognized by the ionization electrode and the burner does not stop working. Gas burner devices are distinguished by a long starting current of the fan - there is an increase in starting power. The fan motor is sensitive to the parameters of the electrical network - at the smallest deviations from the correct sinusoid, it is unstable.

Conclusions and useful video on the topic

How to choose a gas boiler (the video contains information about volatile boilers and their components that require electricity to operate):

How much electricity does a gas boiler consume (the author of the video makes a measurement with a wattmeter):

Autonomous power supply for a gas boiler (experience of a home "craftsman"):

When buying a gas boiler, put the task of reducing energy consumption to one of the last places. Electricity bills are incomparably lower than the obvious plus - savings of up to 30% of consumed gas.

The main thing is that in your area there are no problems with a sudden power outage for a long time. Well, and, undoubtedly, the boiler automation provides more opportunities for setting and monitoring the unit during its operation.

Please leave comments in the block below, ask questions, post photos on the topic of the article. Share how much energy your gas unit consumes during operation. It is possible that your advice on saving and operating the boiler will be useful to site visitors.

How to calculate fuel consumption

For heating a private house or apartment, calculations are used, which are based on two parameters: the power of the heating equipment and the area of the room. An average calculation is taken - 1 kW per 10 m².

Many articles have been written on this topic, but few people specify that the unit of measurement for kilowatts is heat power, not electrical power. This is confusing to many users.

It would be more logical to measure the work on natural gas in cubic meters (m³ per hour), and on liquefied gas - in kilograms (kg / h).

On average, 0.112 cubic meters per hour of main gas is consumed per 1 kilowatt of thermal power.

For example, let's take the AOGV unit with a capacity of 17.4 kW. The passport data indicates the consumption of main fuel 1.87 cubic meters, liquefied gas - 1.3 kg / h. These values are valid for continuous operation, but if the device constantly runs into wear, then parts will quickly fail. When choosing, throw in plus 20% to the indicated power.

"AOGV" in our example will be installed in a room of 140 m². Now take a look at the rates (roughly):

- Natural fuel: 3.9 rubles per cubic meter.

- On bottled gas, the calculation is based on the volume of the container. For 50 liters - 600 rubles. The cylinder is not completely filled with propane, about 80% (21 kg). This means: 600/21 = 28.6 rubles. You can add shipping costs here.

The calculation per day for the trunk connection will be as follows:

Day (24 hours) x 1.87 (cubic meters / h) / 2 = 22.4 cubic meters. To find out the cost: 22.4 x 3.9 (tariff) = 87.5 rubles.

22.4 (daily consumption) x 30 (number of days) = 672 m³.

Why install a UPS

The UPS has two main functions:

- It stabilizes the parameters of the applied voltage to the norms allowed by the standards.

- Converts the direct current supplied by the battery to alternating current.

An additional function of the UPS is to recharge the battery from the mains, it happens as needed.

How to choose a UPS

When choosing a UPS, you need to take into account the requirements of the circulation pump, burners and automation for the quality of the supplied voltage. Off-line UPS or UPS used in computers are absolutely not suitable. First of all, because of the quasi-sinusoidal waveform of the voltage they output. They are also not suitable in terms of capacity - it is not enough to ensure long-term operation of the equipment.

The best UPS are double converters (on-line UPS). The principle of their work:

- AC voltage of the mains is first converted to DC;

- Thanks to the electronic inverter, the DC voltage (obtained from the mains or from the battery) is again converted into AC, but with a perfect sinusoidal shape and stable characteristics.

A double-conversion UPS allows you to supply the gas heater with ideal power.

How long will the charge last

When choosing a UPS, the battery capacity is important, in addition, you need to rely on the experience of operating the boiler in a specific area - for what maximum time the electricity can be turned off. For 8 hours of continuous operation of burners consuming 200 W, a battery with a capacity of about 100 A * h is needed. For reliability, consumers often stock up on generators.

UPS location rules:

- Do not place the UPS near a heat source. At a temperature of about 35 ° C, the operating time is reduced by 1.5 times.

- The battery heats up when charging, so you need to ensure that it is cooled - leave a sufficient distance for air circulation.

How to find out how many kilowatts per day a gas apparatus consumes

To find out how much electricity a gas boiler consumes, you need to make a regular calculation of energy consumption - it is used for any electrical appliances.

For the calculation, you need the value of the electric power of the boiler. Its value is indicated in the technical documentation, it is measured in watts (W or W) and kilowatts. Usually they indicate the maximum value of kilowatts consumed by the device - it is significantly higher than the average.

Let's say we have a Baxi Eco Four 24 double-circuit heater, its heating capacity is 24 kW, and the electric one is 130 W. To calculate the daily electricity consumption, you need to multiply the consumed power by the number of hours during which the consumption occurs.

If energy is consumed around the clock: 130 W x 24 h = 3120 W * h

This is the maximum consumption of the Baxi Eco Four 24 model per day. Dividing the result by 1000, we get 3.12 kWh. To find out how many kW * h the device consumes per month - namely, in these units the consumed electrical power is indicated in the receipts for payment - you need to multiply the number of kilowatts consumed per day by 30:

3.12 kWh x 30 (days) = 93.6 kWh

This is the maximum value of the consumed electrical power. It is clear that to calculate consumption for a year, you need to multiply the result by the number of months in a year during which the device operates.

For single-circuit models, their number is limited by the heating season - about 5. For dual-circuit devices set to summer economy mode, consumption is calculated taking into account the summer months.

What electricity is spent on

In heating equipment connected to power grids, the lion's share of electricity is consumed:

- Circulation pump. He "eats" electricity more than others and consumes energy up to 200 watts per hour.Like any electric motor, the pump requires impeccable voltage parameters. Any inconsistencies with the standards lead to a decrease in power indicators - it starts to work noisily and may break down in general.

- Protective automatics. It spends a little electricity - about 15-30 watts. He is afraid of power surges - because of them, the controller may break down, which will provoke a shutdown of the equipment.

- Burners. They are extremely demanding on current characteristics. A three-pole connection is required so that the fire is recognized by the ionization electrode and the burner does not stop working. Gas burner devices are distinguished by a long starting current of the fan - there is an increase in starting power. The fan motor is sensitive to the parameters of the electrical network - at the smallest deviations from the correct sinusoid, it is unstable.

Why install a UPS

The UPS has two main functions:

- It stabilizes the parameters of the applied voltage to the norms allowed by the standards.

- Converts the direct current supplied by the battery to alternating current.

An additional function of the UPS is to recharge the battery from the mains, it happens as needed.

How to choose a UPS

When choosing a UPS, you need to take into account the requirements of the circulation pump, burners and automation for the quality of the supplied voltage. Off-line UPS or UPS used in computers are absolutely not suitable. First of all, because of the quasi-sinusoidal waveform of the voltage they output. They are also not suitable in terms of capacity - it is not enough to ensure long-term operation of the equipment.

The best UPS are double converters (on-line UPS). The principle of their work:

- AC voltage of the mains is first converted to DC;

- Thanks to the electronic inverter, the DC voltage (obtained from the mains or from the battery) is again converted into AC, but with a perfect sinusoidal shape and stable characteristics.

A double-conversion UPS allows you to supply the gas heater with ideal power.

How long will the charge last

When choosing a UPS, the battery capacity is important, in addition, you need to rely on the experience of operating the boiler in a specific area - for what maximum time the electricity can be turned off. For 8 hours of continuous operation of burners consuming 200 W, a battery with a capacity of about 100 A * h is needed. For reliability, consumers often stock up on generators.

Determine how much electricity an electric boiler consumes

It is impossible to choose the right heating device without a series of calculations and a clear definition of the functional purpose of the boiler. First you need to find out how many circuits the water heating unit requires. It will be used only for space heating or also used for preparing hot water in the second circuit (DHW). These data will help determine how much an electric heating boiler consumes per month.

We offer you to familiarize yourself with the Breneran heating stove - features and reviews

After confirming the choice: a single-circuit or double-circuit boiler is necessary for the house, proceed to fixing the following parameters:

- area of heated rooms;

- voltage available to power the boiler;

- the volume of the coolant in the heating circuit;

- the duration of the operating season;

- the mode of stay of residents in the house;

- working hours at maximum load (peak hours of comfortable stay of residents);

- operating time during the heating season;

- performance and efficiency.

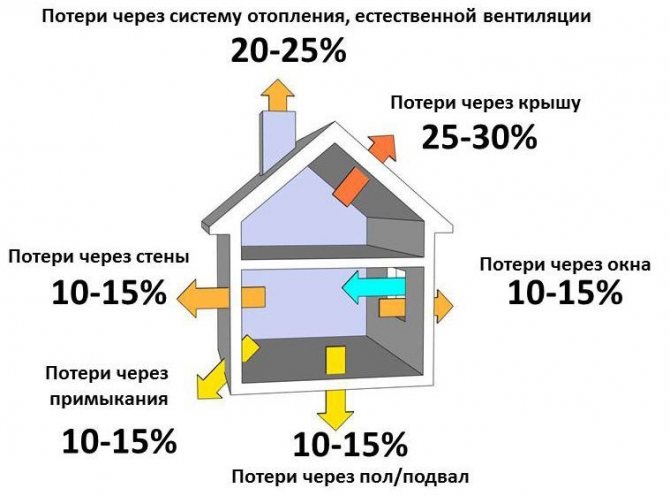

Directly for calculations, the average temperatures for a particular region are taken during the winter, corrections are introduced for the insulation of the house, for the thermal conductivity of the building materials from which the building is made, as well as the type of thermal insulation used to exclude heat loss through the ceilings.

It is impossible to choose the right heating device without a series of calculations and a clear definition of the functional purpose of the boiler. First you need to find out how many circuits the water heating unit requires. It will be used only for space heating or also used for preparing hot water in the second circuit (DHW). These data will help determine how much an electric heating boiler consumes per month.

Directly for calculations, the average temperatures for a particular region are taken during the winter, corrections are introduced for the insulation of the house, for the thermal conductivity of the building materials from which the building is made, as well as the type of thermal insulation used to exclude heat loss through the ceilings.