Production conditions of various scales are characterized by the occurrence of the following factors that complicate the performance of duties for workers in shops: polluted air and dust, unfavorable temperature indicators.

However, in addition to the difficulty of work and the threat to human health safety, many factors can adversely affect the course of work processes in the room. That is why industrial ventilation plays one of the key roles in ensuring the safety and efficiency of the work process at the enterprise.

Types of industrial ventilation

Air exchange in industrial locations can be done in different ways. Depending on the organization of the device, there are three types of industrial ventilation:

- Natural

- Mechanical (artificial)

- Mixed

Each type has its own characteristics and disadvantages, which should be considered when organizing the system in production.

Equipment for industrial ventilation systems

The range of ventilation equipment on the pages of our catalog is represented by several product groups:

- Fans;

- Air handling units;

- Components and accessories for ventilation systems, including valves, air vents, diffusers, grilles, etc.

- Automation for controlling the operation of ventilation equipment.

You can buy the product you are interested in online through the shopping cart. We deliver products not only in Moscow, but also in other regions of the country.

Natural ventilation in production

The natural system functions due to the physical properties of pressure and temperature fluctuations in the room and outside.

It differs in turn:

- Organized

- Unorganized

Disorganized is considered when the air enters the room through leaking gaps in the building structure,

if there are no equipped ventilation devices.

Organized ventilation system for industrial premises performed by means of exhaust shafts, channels, vents, etc.,

with which you can control the amount and strength of the incoming air flow. An umbrella or a special device - a deflector - is often installed over the shafts of ventilation systems to increase traction.

More about the purpose of ventilation

Any ventilation system has 4 main purposes of operation:

- Providing full air circulation in the room, organizing a constant flow of clean air.

- Providing a comfortable indoor climate, including maintaining the correct temperature and humidity.

- Removal from the premises of concentrated harmful substances contained in the air.

- Eliminate or reduce the possibility of fires and explosions.

Any product that is manufactured at any enterprise requires certain storage conditions. This ensures the preservation of the original appearance of the products. In this case, it is recommended to install supply and exhaust ventilation.

Industrial supply and exhaust ventilation

solves many important tasks:

- Elimination of excess moisture.

- Maintaining the optimal room temperature.

- Removal of dust particles harmful to the body and much more.

For workers, this device is able to provide full working conditions that meet all sanitary standards.

Ventilation created artificially (mechanical) in production

This type provides the intake and removal of air flows using fans.The organization of a mechanical system requires an investment of large energy resources and economic costs. Despite this, it has a number of advantages:

- Allows air intake from the required location

- It is possible to influence the physical properties: cool or heat the air flow, increase or decrease the humidity level

- It is possible to supply air directly to the workplace or exhaust with subsequent filtration

Purification of polluted air from premises is a prerequisite for production. This factor is strictly controlled by environmental organizations.

A mechanical system, depending on the design, goals, and tasks assigned to it, differs:

- Supply

- Exhaust

- Supply and exhaust

At production sites, the air system is selected based on the needs and specifics of the site of operation.

Supply ventilation in production

Designed to supply the production area with clean air. Installed mainly in places with high operating temperatures and low concentration of harmful substances.

Unclean air is removed through natural ventilation outlets (transoms, ventilation shafts), additionally supported by the air flow of supply ventilation.

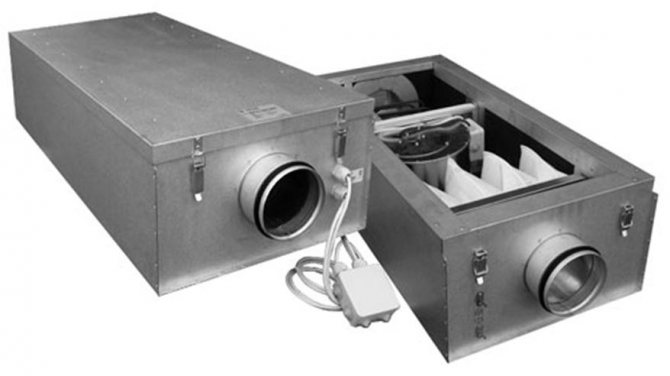

The following air handling units are distinguished by the type of device:

- Monoblock. These devices are easy to operate and maintain, but they are expensive. During installation, the main unit is fixed, to which the air ducts are supplied and the electrical power is connected.

- Typesetting. The devices require special skills to install and are relatively inexpensive in price.

With supply ventilation you can influence the environment

and subject to the necessary processing: heat, dry, humidify, depending on the type of production.

Exhaust ventilation in production

It performs the opposite functions of supply ventilation. Exhaust ventilation system for industrial premises provides air removal.

In production, it is independently used for small movements of the air flow. Depending on the prevalence, exhaust ventilation is distinguished:

- General exchange. Air movement covers the volume of the entire room

- Local. Designed to remove air from a specific workplace

Mainly installed in warehouses, utility rooms, in places where where there is no large concentration of harmful gases and impurities.

In this case, the inflow comes by the method of infiltration through the building frame, windows, transoms.

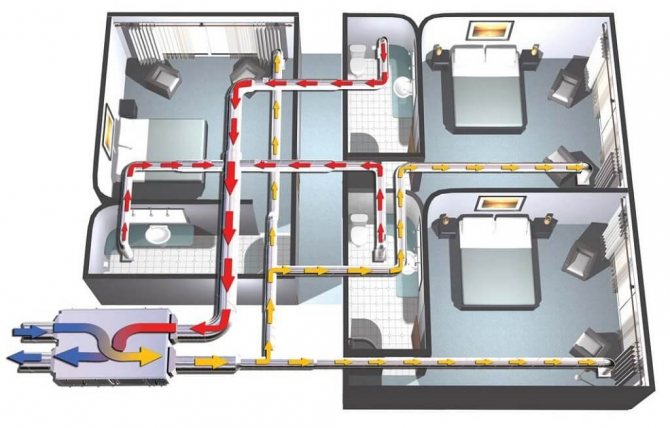

Supply and exhaust ventilation in industrial premises

The main task of the supply and exhaust system is providing production facilities with fresh air flow

and removal of treated, contaminated air. This type of system is the most common in industries with increased requirements for air exchange. It is necessary to correctly calculate when installing flow and exhaust ventilation in factories so that air flows do not enter, unnecessarily, into adjacent rooms and are not removed from there.

Fresh air supply devices are placed on the equipment maintenance side, so that harmful substances or warm vapors do not fall on personnel.

Accurate calculations are required for this type of installation.

What are the limitations of any ventilation system?

Some restrictions include:

- Systems deteriorate over the years due to contamination built up within the system (especially filters).

- Requires constant maintenance.

- Regular and routine testing is necessary to identify problems at an early stage (for timely corrective action).

- Only qualified personnel who are able to make changes to it can make sure that the ventilation system is working effectively.

Below is an example of changes that might affect how the system works:

The hood and branches are added to the existing piping. Local exhaust ventilation pulls air into the system from a new location - this reduces airflow from other locations that are farther away from the exhaust fan. Again, airflow affects all elements. As a result, airflows from other hoods can be connected much faster into the system, and this may be sufficient to adequately remove contaminants.

How to calculate supply and exhaust ventilation

The first step in the design of supply and exhaust ventilation in industrial places is to determine the source of harmful or hazardous substances. Next, it is calculated how much air must be removed from the room and the air flow for the safe work of workers. Ideally, if there is no environmental pollution at the enterprise, then the required air flow is calculated:

L = N x m

Where: L is the amount of air used; N is the number of people working in the room; M is the consumed air per person per hour.

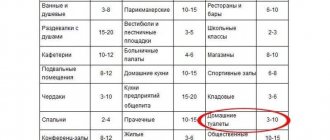

The amount of air consumption per person is regulated by sanitary standards and amounts to: 60 m3 / h per person - unventilated room, 30 m3 / h - ventilated room.

Individual substances have their own concentration standards in production. In order to ensure that the amount of harmful substances does not exceed the permissible values, a clean air flow is supplied to production sites, which is calculated by the formula:

L = Mv / (ypom - yp),

Where: L is the required amount of fresh air to supply m3 / h; Mw - harmful substances entering the room, mg / h; ypom - specific pollution of the entire production area, mg / m3; yп - the amount of this substance in the incoming air flow, mg / m3.

To create the correct air balance, it is necessary to take into account the amount of hazards and local suction in order to accurately calculate how much fresh air should be supplied.

What types of ventilation are there?

Today, two types of industrial systems can be distinguished:

- A local exhaust system that removes hazardous and noxious airborne substances by releasing them outside.

- Fresh air ventilation reduces the concentration of negative components.

- General ventilation cleans the air in the dirtiest places. The system adds a clean stream of air to the room in an amount sufficient to dilute harmful substances to the permitted level. If we are talking about thermal indicators, then they are reduced until such time as to prevent an excess of heat.

Requirements for the ventilation system in production

Systems are regulated by special sanitary standards, which are disclosed in SNiP "Ventilation of special and industrial buildings." The main provisions that should be highlighted:

- Installation in industrial places should be carried out in any production, regardless of the number of workers and pollution. This is necessary for safety reasons in the event of an accident or fire in order to be able to clean the required place.

- The system itself must not cause contamination. This is excluded in new technologies. Requirements apply to older devices requiring replacement

- The noise of the ventilation unit must comply with the standards and not amplify the noise from production

- With the prevalence of air pollution, the amount of extracted air must be greater than the supply air. If the place is clean, then the situation should be the opposite, the inflow is greater, and the exhaust is less.This is necessary to avoid contaminated air flow into the surrounding areas. In most other cases, it is necessary to maintain a balance of inflow and removal of air.

- According to the norms, not less than 30 m3 / h per person of fresh air, with increased areas of production places, the amount of clean supplied air should be increased

- The amount of incoming clean air per person must be sufficient. Calculations establish the air flow rate and its mass. The following factors are taken into account: humidity, excess heat and environmental pollution. If several or all of the above factors are observed, then the amount of inflow is calculated according to the superior value.

- The structure and type of the system at each production facility are regulated by SNiP. Any system can be installed as long as the design is carried out in compliance with laws and regulations

Design and installation

Design and installation of industrial ventilation are complex technological processes, for the competent organization of which it is necessary to be guided by factors

- Calculation of air circulation in each of the premises of the enterprise.

- Localization of formed hazardous impurities in the air (reaching the maximum permissible concentration of harmful substances).

- Operation of ventilation systems suitable for cleaning air flows in a specific production environment.

- Compliance with the feasibility study of suitable ventilation equipment.

The design of industrial ventilation requires the preliminary preparation of technical specifications, the development of which should be carried out by experienced specialists. Only qualified design engineers are able to take into account all the necessary factors in the terms of reference, among which it is necessary to highlight:

- The layout of the premises.

- Construction materials to be dealt with (to mount equipment).

- The thickness of the walls and more. dr.

Upon completion of the work, a competent specialist is obliged to provide the rules for the operation of ventilation systems. The operating instructions contain all the necessary recommendations for controlling the ventilation in the boiler room, for example, for controlling the boiler.

In order to gain a sufficient level of competence in the design and installation of industrial ventilation, there is no need to thoroughly study the cutting and manufacture of industrial ventilation ducts and other subtleties. The advice of an experienced design engineer will be enough to build a knowledge base about ventilation systems.

Emergency ventilation in production

It is an independent installation, which is necessary to ensure safe working conditions in production with the likelihood of the release of harmful and hazardous substances.

The emergency system device works only for the hood. This is necessary to avoid contaminated air getting into different places.

Ventilation of industrial premises is a labor-intensive and energy-consuming process that requires specialized knowledge and skills. Regardless of the type and type of ventilation device in production, two main factors must be observed: correct design and functionality. If these conditions are met, a correct and healthy microclimate is ensured.

Common equipment

The ventilation system of the general exchange type purifies the air environment using the method of diluting the dirty air with clean air. Consequently, its principle of operation is inflow-blowout.

Fresh air is supplied by special equipment of industrial air ducts. Most often these are powerful fans or ejectors. It is heated by heaters and cooled by spraying moisture.Local ventilation in an industrial enterprise is able to create the required type of climate both in one area and in the whole room.

The main elements of industrial ventilation air exchange are as follows:

- air shower;

- ventilation unit;

- air curtains, thermal and complex type;

- suction panels;

- air oases;

- exhaust umbrellas;

- zone ventilation;

- onboard suction;

- fume hoods;

- protective covers.

Design features

Ventilation design for enterprises has several main stages:

- Determination of the main conditions of the premises (their area, configuration features, equipment used, etc.).

- Consideration of climatic highlights (ambient temperature, wind speed and pressure).

- Purpose of the premises - for example, local ventilation may be required on a par with a supply and exhaust system of a non-specialized type.

Based on the data taken, a calculation is carried out, which includes:

- Determination of the cross-section of air ducts;

- Calculation of the frequency of air exchange;

- Determination of the area of ventilation openings;

- Calculation of equipment power;

- Determining the amount of materials needed.

go to emphasize that the design of ventilation for industrial premises is a very important and at the same time rather difficult task. Proceeding from this, without having certain knowledge, you should not take on this work with your own hands.

Ventilation equipment

Industrial ventilation equipment, in fact, differs from household equipment only in power.

Along with this, all the main elements of the system are the same:

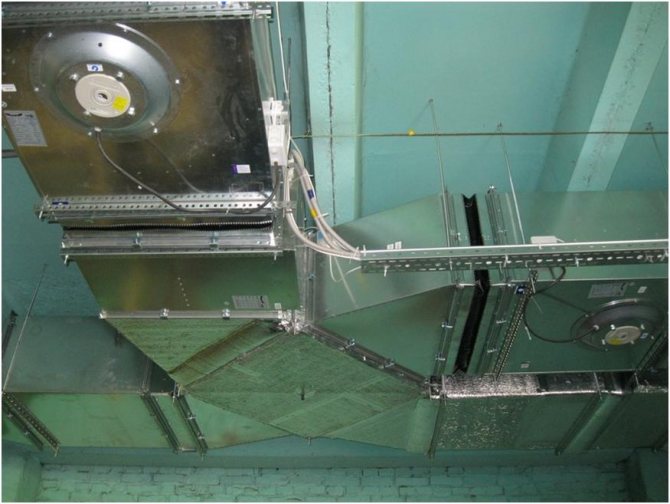

- Ventilation ducts - are pipes of different cross-sections and sizes, which supply the transportation of air flows to the place of distribution.

- Shaped parts - allow branching and turning of ventilation ducts.

- Fans - are the main element of compulsory systems, since they supply them with movement in the right direction under a certain pressure.

- Filters - provide cleaning of air streams. They differ in the degree of cleaning - from rough, which retains large impurities, to complete, which also eliminates unpleasant odors.

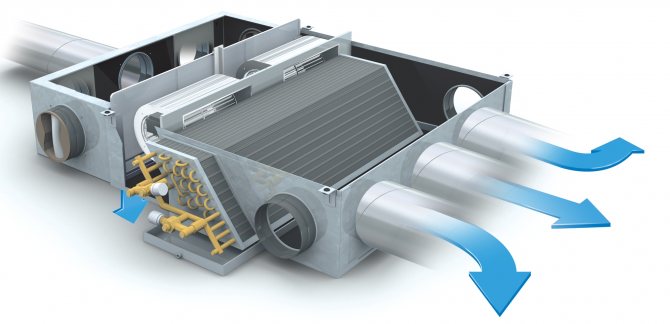

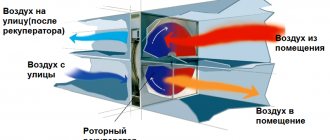

- Recuperators - supply heating of the supply air with warm exhaust streams. This device allows you to save on space heating.

- Air heaters - designed for heating incoming streams in winter.

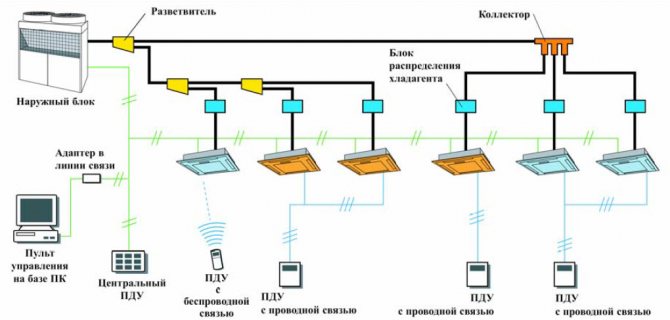

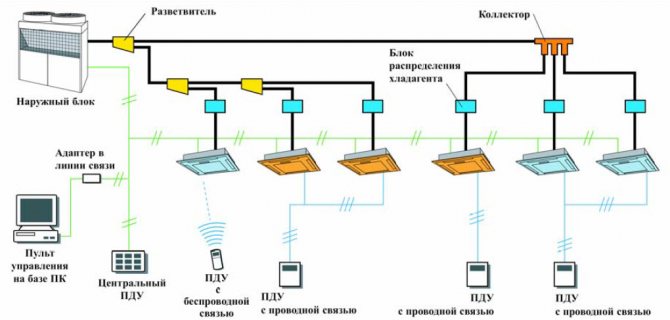

- Air conditioning systems - supply cooling of incoming streams.

Advice! Recuperators are expensive equipment, therefore, it makes sense to use them when servicing premises of a huge area.

to point out that ventilation chambers are usually used in industrial systems. In fact, these are combined devices, which combine all the necessary equipment for ventilation in one case. In particular, industrial ventilation manufacturers supply them with fans, filters, recuperators, etc.

As a result, for the functioning of the system, it remains only to connect such a device to the ventilation ducts.

Advice! In some cases, when installing air ducts, non-standard fittings may be required. Under such conditions, it is possible to make them yourself. The most important thing is to correctly cut the fittings of industrial ventilation, after which the details must be cut out of tin, bent according to the scheme and welded.

Installation

Industrial ventilation manufactured by Veervent LLC is installed exclusively by our specialists within the terms strictly agreed with the Customer. We constantly give a report on the work done, so in case of any additions to the project, we can promptly correct them directly at the facility.

Installation of ventilation can be carried out both according to ready-made templates and according to our own developed projects.