Ferroli Italian gas boilers are the products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stability of operation, all units and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors, which are located on all critical nodes and parts of the boiler.

If any malfunction occurs or the unit leaves the specified mode, the self-diagnostic system immediately reacts by alerting the user using an alphanumeric code on the boiler display.

Let's consider her work in more detail.

The main malfunctions of gas boilers Ferroli

The design of Ferroli boilers is distinguished by a well-thought-out and high-quality study of all units and parts.

However, any system has weak points, and gas boilers are no exception..

The operating conditions of some parts of the units are very difficult, temperature loads contribute to the appearance of the phenomenon of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There can be different causes and ways to fix them, one of the most common problems.

- Pressure drops or rises. This is a serious problem that either leads to a leakage of the heating medium, which causes overheating and blocking of the boiler, or to overpressure and blockage. Especially dangerous is the increase in pressure, from which the parts of the unit may burst.

- Fan or circulation pump failure. The loss of both functions means the inability of the system to work - the impossibility of extracting smoke causes sudden overheating and blocking, and the lack of fluid movement has the same consequences, only detected by other sensors.

- Electronic control board problems. These problems are most often caused by unstable supply voltage or lack of good grounding. The boiler electronics are very sensitive to any changes in the operating mode. When jumps or jumps appear, it begins to produce a continuous series of errors that do not repeat upon restart. Often there is an accumulation of static charge on the case, which is transmitted through the ground to the control board and the ionization electrode, which causes the A02 error to appear (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for a while and restore (or create) high-quality grounding.

In addition to the above, there are a lot of problems with the combustion mode.:

- Flame too small.

- Spontaneous combustion start.

- There is no DHW heating.

- A sharp flare-up of a flame with a clap.

All these problems are associated with a deterioration in gas supply due to clogged injectors, failure of a thermocouple or a fuel valve coil.

IMPORTANT!

The elimination of all problems should be entrusted to qualified technicians from the service center; self-repair of the boiler can give the opposite result to the expected one.

Maintenance and regulation of boilers Ferroli

It is not possible to adjust the hot water on the Ferroli Domiproject boiler from 24 (a twist on the control unit), it gives out about 60 degrees. When turned on for dilution with cold water on the mixer, the boiler turns off (the burner goes out) when the pressure of cold water decreases, it turns on again, tell me the solutions. If the device is new, then invite the service. If the device is not under warranty, then adjust the gas valve and change the program parameter A6 from 0 to 1.When using a double-circuit gas boiler in the heating mode of hot utility water, it is categorically not recommended to use a cold mixture in the mixer (tap). This is not a central water supply. If you need hot utility water of a certain outlet temperature, then this temperature should be set on the boiler control panel, and not mixed with too hot cold water. Damage the heat exchangers, and the boiler will constantly go into overheating. We installed, installed and connected the Ferolli Domicompact C 24 boiler. There was a problem - a failure in the DHW system. The regulator is at a minimum, and heats the water at 70 degrees. How to fix it? The Domiproject C24 boiler is in operation (DBM01 R215E board). Heating was on in the spring, but there was no hot water supply. Now, when DHW is turned on, the water is cold, the indicators on the boiler do not light up; when the heating is turned on, everything is normal (the pump is working, the ignition and the burner are turned on, the indication comes to life). They invited a specialist and offered to buy and replace the board. I checked the board - all 3 indicators blinked, then red and yellow blinked 5 times, and then only yellow blinks. Is it possible to determine by this "diagnostics" whether the board is working properly or not? It looks like the boiler simply does not see that the DHW is being analyzed and it is necessary to turn on for heating. It is necessary to see the status of the flow sensor. Switch off the boiler. Short-circuit the wires going to the flow sensor. Open the hot water tap. Start the boiler. If the burner ignites, then this is the problem. Disassemble and clean. However, you do not need to leave the flow sensor shorted. Tell me why the Ferroli Domiproject f24 boiler cannot ignite the first time and gives an error on fuel a1? But sometimes everything starts right away. All possible causes are listed in the Instructions. What exactly leads to error A1 in your case - you need to figure it out on the spot. And it is better for a specialist. The Ferroli c32d boiler began to issue an error F34 (the power supply does not suit the voltage). But in the 224 volt outlet, there is an uninterruptible regulator with a normal sine. No swollen capacitors were found. What else could be? The board is faulty - either repaired or replaced. After cleaning the Divatop boiler, nothing has changed, with a closed combustion chamber, the boiler does not want to work, the fan turns on, but it does not ignite. As soon as the combustion chamber is open, it ignites without problems. And after it started working - it turns on and off with a closed camera, it works in normal mode. What is the problem after all? Green LED flashes quickly, others are off. I understand that you need to remove the fan, check the Venturi tube? Although I also blew it when I took the chimney. It is not clear why, after the boiler has started, it starts to work as usual - it ignites itself. And can it be exploited like that even for some time? Yes, but not really. If you close it and the boiler starts up, then there is a problem with the smoke exhaust or with the manostat. But this does not mean that the manostat is faulty. This is one of the reasons. The second reason. Something is wrongly connected. The PVC tube is in the wrong place or there is debris, condensation in it. The venturi may also be dirty. The fan does not reach the declared performance due to the reduced supply voltage. Third. The smoke exhaust system is not correctly installed, dirty, longer than permitted. Not correctly brought out. The chimney turned out to be in the zone of the wind support. The insert in the fan is not the right one or should be removed altogether. Fourth. The board is defective. The ignition of the Ferroli Domiproject f24 boiler does not work, according to the error table in the instructions, this is a malfunction of the air pressure switch. Tell me how you can check this relay for performance? Bypass. If the boiler starts working after that, then the problem is in it. First you need to find out if the manostat, which you called the air pressure switch, is really faulty. Two wires go to it. They must be connected directly. If after that the boiler starts working, then the problem is in it.But this does not mean that it is defective. You may have a chimney problem. Something hit him. Or the PVC tube from the manostat to the fan is clogged. Or The venturi in the fan is clogged. It is to it that the PVC tube is attached. Or the fan does not reach the declared power. Undervoltage in the mains. In general, you need to check everything and, if necessary, blow and clean. Repair and operation of the Ferroli Diva F24 boiler. Two-pipe system 32, lower supply 25, house 53m2, water is poured, the pressure in the system is cold 1.5 when it heats up to 70, a room thermostat is installed, the boiler and radiators are only a month old. Everything worked fine. Now, when heating from 54 to 70, the sound of a boiling kettle appeared, and only on the middle modulation of the burner, for a minute. there is no sound of the flame. I blew air everywhere, tried to reduce the heating power in the test - it did not help. The water is hard (there is a lot of scale in the kettle), the mud filter is only on the return line (I looked clean). The boiler was installed by the master, but did not adjust the pressure on the burner. Can a heating radiator in a boiler clog in a month? First of all, you need to adjust the gas valve, if there is no result, then: The power in the test must be removed to the numbers on the scoreboard 70, with large readings the sound will remain. If the sound remains with such readings, as a temporary option, you can remove the f43mm diaphragm from the chimney. If in this case the sound remains, then only the replacement of the heat exchanger. There was a need to increase the boiler's capacity, we completed the construction of a room next to the house for a workshop of 500 square meters, there is a Ferroli pegasus D32 boiler in use, I want to buy a Pegasus D45 for it. I read about wall mounts and their modulation. I wondered if I could take a wall-mounted boiler like Divatop, what are their pros and cons compared to Ferroli Pegasus? They both seem to work with ROMEO. I have been using wired ROMEO, no complaints for 3 years, except sometimes the pace. In the CO, the boiler holds 55g, while the set rate is 72g. The problem disappears when off. and incl. boiler for 1 min. I think this is the electronics that hangs with him? Will the OpenTherm thermostat work with the Pegasus D? There is no power modulation in these boilers. There is no modulating valve in the gas fittings, as on wall-hung boilers. But it will work like a simple thermostat. Should I take the wall-mounted Ferroli Divatop instead of the floor-standing Pegasus, which has no modulation? Maybe OpenTherm on the boiler will control not the modulation, but the CO temperature, that is, it decreases when approaching the set room temperature? Why does the thermostat control the modulation of the burner depending on the air temperature? To save gas and reduce the cycles of switching on and off the boiler. Why, when the set temperature is reached (it does not matter by air or by the coolant), turn off the burner, if you can modulate the power to a minimum and continue to heat the system on it without shutting down. We save not only gas, but also the resource of the boiler. We want to install a wall-mounted boiler Ferroli. Tell me, what is the difference between the Diva F and the Fortuna F? Fortuna boilers do not have models with an open combustion chamber, unlike Ferroli Diva. Branch pipes for a separate smoke exhaust system complete with a boiler. Reduced noise level. The Ferroli Domiproject 24 boiler is in operation. There is no external equipment. The warranty has ended, but before that everything was in order with the heating, but with the hot water supply it was bad. You wash, and you are doused with either boiling water or cold. It is impossible to adjust. I switched to hot water without cold impurity. I decided to do a little maintenance. I set the temperature on the boiler to 40 degrees C. The boiler, according to its own indications, heats the water up to 87 C and only after that extinguishes the burner. Then it waits for ~ 25 C, and only then ignites the flame. In the list of faults, this is interpreted as scale in the heat exchanger, but it is not there - the specialists checked it. In addition, the boiler itself measures the temperature of the leaving water and itself agrees with its parameters. An obvious defect in the controller firmware, because I'm not the only one with such a phenomenon.The service technicians have made adjustments, and now they advise turning on a large water flow, then the boiler does not have time to overheat the water. The flow sensor records the presence of water flow all the time. The pressure in the heating and hot water system is sufficient. All filters have been cleaned and checked. The chimney is clean. There is no dust in the combustion chamber. The problem with contrasting hot water preparation, as I understand it. For ABM01 board - program parameter P07 controls this comfort. Factory setting: P07 = 0. Diva F16 boiler, to which the ROMEO wired remote control is connected. The temperature of the control panel is set to 23 degrees, the boiler maintains it quite accurately, but there are, as it seems to me, unnecessary clock cycles, the temperature on the control panel is 23 or even 23.1 and the boiler does not need to be turned on, but for some reason it turns on, quickly catches up with the water temperature to set 65 degrees on and off. By observation, I found out that this set of temperature occurs very quickly, 15-20 seconds, and at the same time the boiler heats the water only inside itself, that is, the bypass turns on and it drives the water in a circle inside the boiler and when the maximum set temperature of the coolant is reached, it turns off. Why does he do that? And when the temperature in the room drops to 22.8, the boiler turns on and heats the water throughout the entire system as it should be. If it behaves in the same way without a remote control, then turn off the Comfort mode. I would like to carry out maintenance of the Ferroli Diva C 32 boiler. 2 gaskets from 4 secondary heat exchangers have leaked. Moreover, it surprised those. fastening solutions. 2 screws for 4 shims. Tightening the screws did not lead to anything, and from the very beginning, when the temperature was set in a certain interval, the boiler was noisy. This was the case on other boilers with the mixer not installed. The owners took hot water through a ball valve. In this case, the water pressure was about 4 atmospheres. When the ball valve is suddenly closed, a water hammer occurs, so it is necessary to install mixers that will restrict the flow of water. The Ferroli f 24 Domiproject boiler is installed and connected, in DHW mode it works flawlessly, when the heating is turned on, there is zero reaction, no attempts to ignite or circulate water to the heating system, the green indicator just flashes (the boiler is in standby mode, if I understand correctly) and that's it ... The pressure on the water sensor is 2 bar, the gas pressure in the system was not measured, there is no air in the heating system, and there is no air in the expansion tank either. On the terminal box where the remote control is to be connected, there is a jumper in the form of a piece of wire. Tell me what needs to be checked, what could be the reason? The expansion tank must have air in its air section of 1.0-1.2 bar. Inflates when there is no pressure in the system. Then we raise the hydraulic pressure in the heating system. Should be 1.2-1.5 bar. You can also pump air into the RB with a simple bicycle pump. We check the pressure with a third-party pressure gauge. In the heating system, we look at the pressure on the boiler pressure gauge. The Domiproject boiler is in operation. No display. 6 years. Last year, I redesigned the heating system. I worked great for the winter. This year, with the onset of cold weather, when the heating mode is turned on, the burners light up and after a couple of seconds burn very weakly. The water temperature in the system is about 30 degrees. In the water heating mode, it worked and works normally. There was a stabilizer on the boiler, which I removed in the summer. Maybe it has something to do with this? Although the phase input voltage sensor shows 220 at the input. I called the master who did the heating, asked about the filter on the return line - it might be clogged. He says that this was not the case in his practice. Moreover, the system was completely redone last year. Explain what changes in the operation of the Divatop boiler when the power of the heating system is reduced, as written in the instructions? When adjusting the boiler by gas pressure, two values are set: maximum and minimum pressure. The gas valve consists of two valves, so it is also an armature, and not a gas valve, as it is called in a simple way.There are two valves in it, not one. One valve is shut-off, the other is modulating. The modulating valve, following a signal from the extract air temperature sensor, receiving this signal from the brains of the boiler (control board), can change the flow area in the fittings, changing the amount of gas supplied to the burner per unit of time. It changes from some minimum value to some kind of maximum. As a result, the pressure on the burner also changes. Less pressure - less gas, small flame, more pressure - more gas, large flame. That is, the flame on the burner also modulates. But in what range this modulation can occur, the manufacturer of the boiler indicates in the technical characteristics, from which min. pressure, up to what maximum. These two values are set when starting up the Ferroli Divatop boiler. The boiler reaches its specified power when operating at maximum pressure, as a rule, it works like this for no more than two to four weeks a year, since the selection takes place according to heat loss at the coldest temperature. Of course, in each region it is different, but somewhere -25 degrees. The rest of the year the boiler operates at reduced power. It starts up, reaches the maximum, and then modulates to a lower one and works on it. Of course, it can work at some kind of reduced power without shutting down, and it can still shut down even at reduced power, even in the cold season, when its power, even when operating at minimum pressure, still exceeds the heat loss in the house. So, sometimes when the boiler is too powerful, you can cheat and, as they say, clamp the boiler in terms of power, that is, reduce the maximum pressure and set it lower than indicated in those. characteristics. Since the boiler power is determined by the calorific value of the gas contained in a unit of its volume and the amount of this gas supplied to the burner per unit of time, by decreasing this parameter (the calorific value of the gas itself cannot be changed), we can accordingly reduce the boiler power. At one maximum pressure, it produced 30 kW. We pressed down on the maximum gas pressure, and it no longer produces a thermal power higher than, for example, 26 kW. But there is also a minus. By pressing the boiler at maximum power when working on heating, we will also reduce its power when working for heating hot water. And since the boiler reaches maximum power when heating DHW, and the maximum is now underestimated, the amount of hot water that will be heated with such a heat output to a comfortable temperature in a flow-through plate secondary heat exchanger will also decrease. And you will not get "tropical rain", but this is not such a significant decrease in DHW performance. Now, if you clamp the boiler to a power of 20 kW and below, then yes, the hot water will obviously not be a full-flowing channel. I installed and installed the Ferroli Diva F24 boiler, with a capacity of 24 kilowatts for me in excess, it was possible to take it for 16, but when buying, it was advised for 24 kilowatts, referring to the fact that it will have more power for heating hot water. In fact, it turned out that everything is regulated. I adjusted the valve according to the minimum and maximum pressure and programmatically limited the maximum heating power to 12 kilowatts, and the DHW operates at a power of 24 kilowatts. These boilers have a service menu. We enter it and find the parameters designated P06 and P12. The first is the maximum heating power, the second is the maximum DHW power. Values are in percentages. The default is 100% both there and there. We can change this value using the DHW buttons, for example, decrease it in our case. At the same time, if we reduce the heating power, then in the DHW mode it will remain the same as it was when the boiler was set for the maximum gas pressure. Well, of course, on the contrary, that is, we can also change the power of DHW.Of course, before performing these actions, you first need to adjust the boiler to the maximum gas pressure (power) recommended by the manufacturer, and only then work with a decrease. In this case, we will be able to know exactly at what power when lowering it in the service menu, the boiler will now work for us. For example, your boiler of 32 kilowatts will only reach its maximum power if we set the gas valve to a maximum pressure of 12 mbar. We have set it up and we know that it produces 32 kW. We go into the service menu and lower the heating power to 80%. 32 kW is 100%, so 80% is 25.6 kW. Tell me about the work of the Ferroli Domiproject F 24D boiler, the wired sensor is also Ferolli. We put 22 degrees, at a temperature of 21.8 everything starts and works as expected, when it reaches 22, the relay does not work on the sensor, but the boiler turns off at d2 and after three minutes it starts up again. Then three minutes later again in d2 and in a circle it all repeats until 22.2 degrees appears on the sensor, the relay will work and the boiler stops until the next heating, what is the reason? Should it constantly turn on and off, will it affect wear or not? Will be. The boilers do not work otherwise. First, you don't have a sensor, but a room thermostat. You set the temperature on it to which you want to heat the air in the room, but this has nothing to do with the mode in which your boiler operates. There is a concept of temperature, and there is a concept of power. So your boiler has a maximum thermal power and thermal power of 24 kW. And for your summer cottage, no more than 10-12 kW is enough, even at a street temperature of -25 degrees. It is due to the fact that you have a boiler that is too powerful for your room, and it works like a twitchy one. And the temperature outside is not below zero. And in the off-season, even the boilers selected or in the mood according to their power, tuned to match the room that they are heating, and even then they start to clock. And the capacity of which exceeds the needs of the premises by two or three times, even more so. So you first need to adjust the boiler according to the gas pressure recommended by the manufacturer. That is, call a service technician and carry out maintenance and commissioning. The fact that commissioning has been carried out, a corresponding entry is made in the warranty card. If there is no such record, then there is no guarantee for the boiler, but it is 2 years. Well, then reduce the boiler power. For your summer residence at least twice. This is done using the settings in the Domiproject boiler board. The commissioner can and should do this in the same way. But it doesn’t bother him to remind about it all the same, if he himself does not tell you that the boiler should be reduced in terms of power. In this case, only the boiler output in heating mode is reduced. In the mode of heating the service water, it will still work as 24 kW. After that, the boiler will, as before, warm up the room to your set on the remote thermostat 22 degrees, but at the same time it will work correctly. And it is not necessary to set the heating water temperature regulator on the boiler to the maximum or near it during the off-season. It is enough to set 55-60 degrees.

All major error codes and their decoding and solution

Consider the main errors of Ferroli gas boilers and options for their elimination:

| The code | Decoding | Ways to solve the problem |

| A01 | No flame (unsuccessful ignition attempt) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False flame presence (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Flush the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Failure of the coolant temperature sensor | Replace element |

| A09 | Gas valve failure | Check function, replace element |

| F04 | Overheating of the flue gas thermostat | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke exhaust system, shutdown of the fan | Replace fan |

| F08 | Overheating of the primary heat exchanger | Flush the heat exchanger, replace if necessary |

| F10 | Open or short circuit of the extract air temperature sensor | Restore contact or replace sensor |

| F11 | Open circuit or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of the sensor No. 2 of the direct line of the heating circuit | Restore contact or replace sensor |

| F34 | Supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Air supply pressure drop | Find an OM leak and eliminate it |

| F40 | Excessive air pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the pressure switch of the extract air | Restore or replace the relay |

| F50 | Control board malfunctions | Replace control board |

Errors of Ferroli boilers are divided into critical (A) and non-critical (F). Those with the letter A lead to an independent blocking of the boiler, and those with the letter F do not.

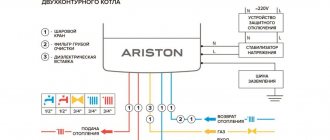

Wall models

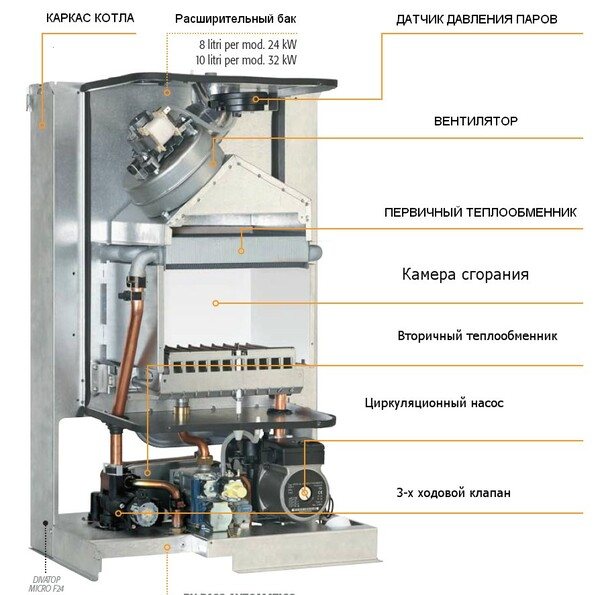

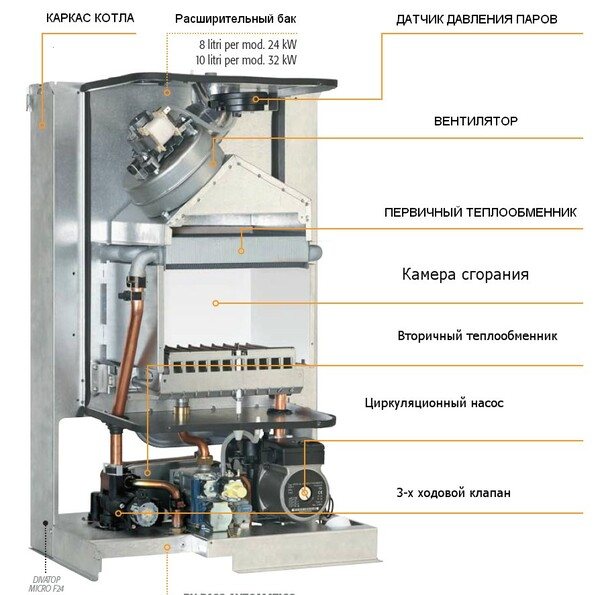

This is one of the most common types of boiler equipment, which in the line of the Italian brand is represented by the Diva, Divatop Domina, etc. models. Due to the affordable price and simple design, the Arena model is in the greatest demand. This is a gas double-circuit wall-mounted boiler Ferroli, which has two heat exchangers. The combustion chamber of such models can be open or closed, depending on the modification. The design itself allows for high heat transfer, but there are other advantages of boilers of this type precisely in the idea of Italian designers.

In particular, the developers use a primary heat exchanger made of copper, and its secondary counterpart is made of stainless steel. Branded parts are also used as accessories. For example, the valve from the company is a three-speed circulation pump - WILO brand. To ensure stable operation, the Ferroli double-circuit gas boiler is equipped with a control board that is resistant to changes in the network. Together, the listed components ensure high reliability of the equipment and safety during operation.

Operating instructions - how to start correctly

The operation of Ferroli boilers does not differ in any specific actions and procedures.

The owner is only required to organize periodic maintenance, cleaning the body and interior of the boiler, keeping the burner nozzles in proper order.

The boiler start-up procedure resembles the method of ignition of other gas units..

A special feature is the need to maintain a pause between start attempts, during which the D3 or D4 code appears on the display (50 or 30 seconds).

Download instruction

Download instructions for gas boilers Ferroli.

The first code occurs after a critical error appears and the unit is blocked..

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start in normal mode, if the previous one was unsuccessful.

This is usually due to the presence of air in the pump, piping or heat exchanger.... Attempts are repeated until the air is removed from the boiler.

Positive reviews

The Italian technology of the Ferroli company is characterized by ease of adjustment, excellent design and ease of use. The company has been on the market for over 50 years, and this is not much when compared with other manufacturers. But during this time, the brand has become one of the European leaders in the production of heating equipment.

Consumers note that the equipment is constantly being modernized, and its appearance is characterized by an increasingly attractive design.The devices meet safety and performance requirements, which is important for the consumer, as well as maintainability and ease of maintenance.

If you are also interested in the products of the Ferroli company, you can consider the gas boilers of this manufacturer in more detail. For example, mounted models are the most popular in Russia and are presented for sale in a wide range. They are compact and practical. According to users, such a boiler is ideal for heating an apartment or a medium-sized house. The range of mounted boilers is quite wide, the manufacturer offers many models to the attention of users, this allows you to choose the desired configuration that will meet all the requirements. Owners of real estate of a more impressive area can consider Ferroli floor products, gas boilers of this line are highly reliable and durable.

How to setup

The basic setting of the Ferroli boiler is carried out at the manufacturer... At the first start, an additional adjustment of the parameters of all communications is made to ensure full compliance with the operating modes of the system and the supply of resources - gas, water, voltage.

Also, the upper and lower boundaries of the temperature and pressure of liquids, gases, and other important parameters are determined.

Most of the actions are performed from the external control panel; you have to open the casing only when carrying out complex repairs or to connect a room thermostat.

NOTE!

The adjustment must be made by a master from the service center, otherwise the warranty agreement will expire or important units of the unit will fail due to improper operation.

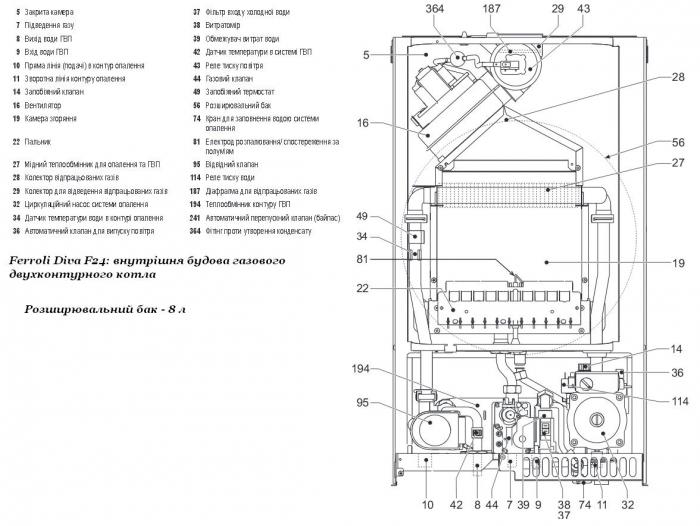

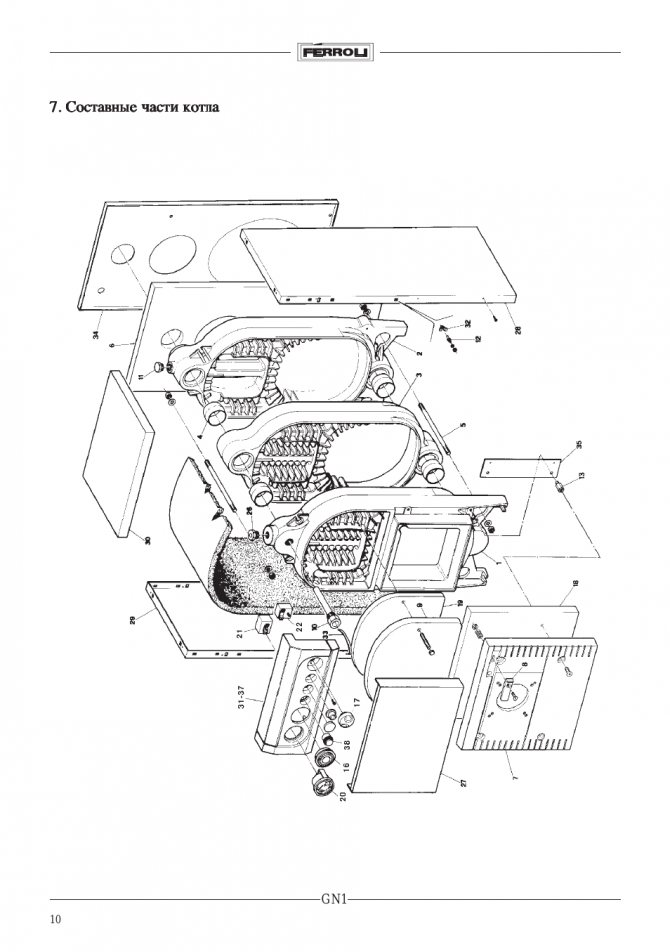

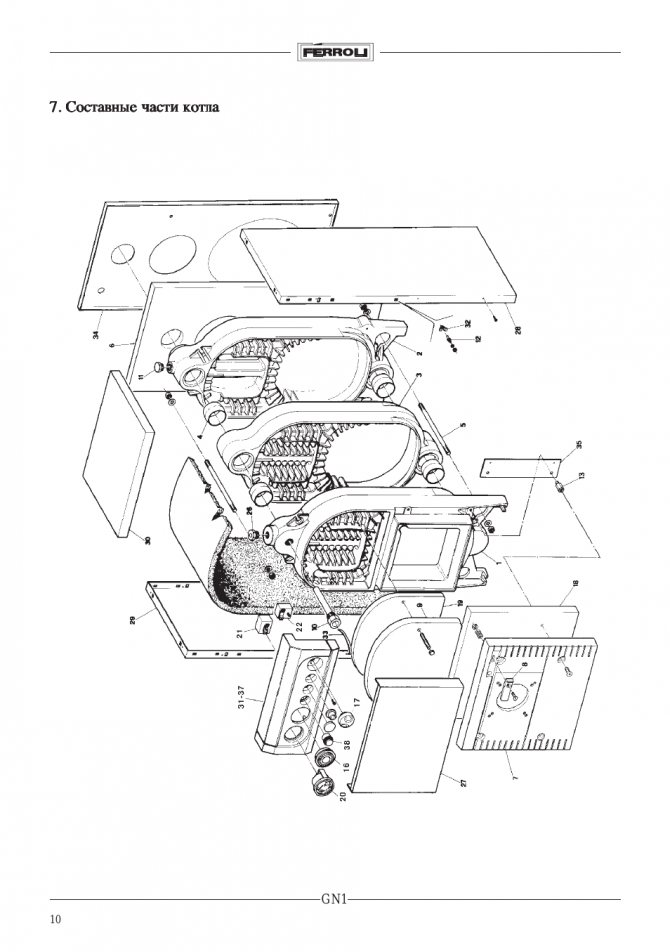

... Boiler components ...

Page 10

- Picture

- Text

RENNOi

7. Components of the boiler

-OK1-

10

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

An American company bought an airplane in the Soviet Union. This plane was neatly packed in boxes, it only remained to assemble it. When the plane was assembled in the USA, it turned out to be a steamer. Everyone was very surprised, dismantled the structure, reassembled and again instead of an airplane a steamer. Nothing to do, they called a representative from the Soviet Union. He came and collected the plane for them. Americans ask: - How did you do it? - Here in the instructions in Russian it is written: "After assembly, process with a file!"

Manualza! Manualza.ru

Still not with us?

The boiler does not start (the burner does not start)

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them there may be:

- Gas supply valve closed.

- Gas valve malfunction.

- Burner nozzles clogged with soot.

- Control board refused.

- The boiler is blocked due to a malfunction of a component.

Most of the possible causes are detected by the self-diagnostic system, and the corresponding code is displayed on the display.

However, there are some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure yourself that it is ready for work.... In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections made, the wires are confused.

IMPORTANT!

If a phase is connected to the wrong electrode, the boiler will not start. It is also highly undesirable to have an electrical potential between the working zero and ground, which causes the A02 error to appear.

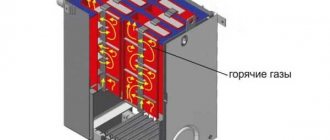

Floor heaters Ferroli

The inflatable torch must be purchased separately.

Floor-standing cast iron boilers are available with built-in and removable (inflatable) burners. To begin with, consider models with a built-in burner.The complete set of the simplest boilers (up to 1 thousand Euro) is very modest:

- single stage burner;

- cast iron heat exchanger;

- gas valve HoneyWell or Sit;

- connectors for additional equipment (pump, thermostat).

Boilers at a price of 1 thousand euros, in addition to the standard set, are equipped with a display, connectors for connecting a three-way valve, a pump for a boiler, street temperature sensors, and boiler sensors. Thanks to this set of options, the heater can itself control the degree of heating of the coolant according to weather conditions. The complete set of each model is indicated in the operating instructions for the Ferroli boiler.

Units over 2 thousand Euro, for example Pegasus-DK, have a built-in boiler for 130 liters and a 12 liter expansomat, two pumps, a magnesium anode is installed in the boiler. A magnesium anode is needed so that the boiler tank does not rust. This is a consumable material, the anode must be changed periodically (as it splits). Heaters for 3 thousand Euros (Pegasus 2S and PegasusF3 N2S) have the same equipment as the cheapest models, with the exception of the burner - in expensive units it is two-stage. This allows you to expand the range of boiler power regulation.

If any problems arise during the operation of the Ferroli gas boiler, a malfunction code is displayed on the liquid crystal display.

A feature of boilers with a removable inflatable heating pad is that they can operate on both gas and diesel fuel, it depends on the type of burner:

- for gas - Sun M;

- for diesel - Sun G.

In the Atlas heater, it is possible to connect an internal one or two stage gas burner instead of an external inflated burner. In a rich set, for example Atlas DK, there is a built-in expansomat for 10 liters and a boiler for 100 or 130 liters, two pumps, an LCD display. An external inflatable burner is not included and is supplied separately.

The better the glue for thermal insulation you use, the better the result of the insulation work.

How to properly insulate a house from the inside with mineral wool is described in this article.

Why does the pressure drop

The pressure drop in the boiler can be due to three reasons:

- The appearance of a leak in the heating circuit (including in the boiler itself). A feature of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is fed. In this case, you need to find the place of the leak. First of all, you need to check the condition of the drain valve or valve, whether it is open, or whether it is out of order. If no malfunctions are found in this unit, the entire heating circuit is sequentially checked. Sometimes they forget to close the dump valve on the radiators, there are fistulas in the pipelines, and the connections fail. The most difficult thing to detect is a leak if the tap is feeding a water floor heating system that is poured into a concrete screed. You can detect a problem by a wet spot on the floor or on the ceiling of the lower floor, and then for this you often have to remove the floor covering or stretch ceiling.

- Failure of the circulation pump. This problem is immediately detected by the self-diagnostic system, and it is easy to check the pump's performance. It is enough to make a visual inspection of the element and take appropriate measures.

- Expansion tank diaphragm rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process stops. Then, an uncontrolled increase in pressure is possible, especially intense when the temperature of the extract air rises. If it turns out that the problematic element is precisely the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with the temperature expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant expenses for repair and restoration of the boiler's operability.

Main series

DIVAtop

The list of models of heating equipment put on the market by Ferroli is very wide.Therefore, within the framework of this article, we will consider only the most significant series from the entire product range.

The DIVAtop series is one of the first to be introduced to the Russian market. The series is based on high-performance double-circuit boilers for domestic use.

- DIVAtop devices are distinguished by a stylish design of the case, which allows them to be installed directly in residential premises.

- A key design feature of the DIVAtop range is a three-way valve with a separate actuator.

- The heat exchanger for the hot water supply system, which has a plate structure, is responsible for efficient heat transfer.

DOMIcompact

Units from the DOMIcompact series are focused not so much on heating (although they perform this function quite effectively), as on the fastest possible receipt of hot water. At the same time, a specially designed heat exchanger installed in the boiler does not overheat, and practically no scale forms in it.

- The DOMIcompact boiler can be operated using both conventional adjusting knobs and a liquid crystal display. A built-in chimney can be used to remove combustion products.

- The DOMIcompact-B version includes a more modern heat exchanger. The use of steam condensation energy allows to increase the boiler output, while reducing fuel consumption.

- Also, this modification has significantly reduced the percentage of emissions of harmful gases into the atmosphere.

Econcept

The Econcept series represents the embodiment of the ecological paradigm. Distinctive features of the Econcept series boilers are:

- High-strength aluminum heat exchanger-condenser.

- Continuous modulation cermet burner, equipped for different types of gaseous fuels.

- Microprocessor control system for the boiler operation, adapted for the installation of a weather-dependent control system.

- A plate heat exchanger that provides the fastest possible heating of water in the hot water supply circuit.

At the same time, the Econcept series is characterized by the minimum volume of atmospheric emissions, as well as very impressive indicators of safety and resiliency.