This article will consider the capping of cast-iron pipes - what is this procedure, how to prepare for it and prevent the need for it, and also an example of how to perform caulking is given using the example of a cast-iron branch pipe.

Cast iron is a material with a very high strength and also a high weight. The density of the structure makes it possible to make massive and strong products from it that can withstand significant loads, due to which cast-iron pipes are used as elements of water supply and sewerage systems.

Pipe capping

Even taking into account the development of chemical production and the active use of pipes made of various types of plastic, when laying an external water supply system, cast iron is most often used as a more serious material. Pig-iron sewer pipes are usually used in the construction of sewage systems with very heavy loads, significantly exceeding household ones.

Buildings of catering establishments, factories processing meat and other animal products, etc. constantly create a waste stream, quite often leading to ruptures of cast iron pipes, which must be repaired immediately.

And given the fact that caulking and chasing of cast iron pipes is quite difficult, experts recommend carrying out annual scheduled inspections to avoid time-consuming repairs.

Cast iron pipes

In the case of replacing such plumbing equipment as a toilet bowl or a sewer riser, it is necessary to very carefully perform the procedure for capping cast-iron pipes first of all. With strict adherence to all the rules for capping or capping connected sewer pipes, it is possible to perform such work with your own hands.

Decorating tips

To properly dismantle a cast iron pipe, you must take into account all the rules of caution.

Helpful hints:

- Don't work alone. It is not safe. It is best if a friend helps.

- If the chasing of the pipes was made in gray, then after removing the necessary element from the system, sulfur residues must be wiped off the pipe.

- Do not use an iron hammer to caulk pipes. It can lead to cracking throughout the system. If you don't have a rubber one, you can use a wooden tool.

These simple rules will help you to make the caulking without trouble.

It is difficult, but possible, to emboss a cast-iron sewer with your own hands. However, keep in mind that even with ideally correct execution, a layman will take several times longer than a master for this work. Go for it!

In most buildings built during the Soviet era, the sewer system is made of cast iron pipes. This is due to the fact that such products have not only a long period of operation, but also do not lend themselves to various influences. However, cast iron pipes require correct installation and appropriate use.

Compared to other types of communications, residential water supply systems often need to be replaced (every few years). In addition, the installation of plumbing fixtures and repairs in the house may require changes in the design of the system. To emboss cast-iron pipes in an apartment with your own hands, it is not necessary to undergo special training. This can be done with only the skills of working with a standard tool. How to properly dismantle the old pipe and install a new one, you can find out in this article.

Decompression is performed in the following order

At first, it is necessary to very carefully, without undue effort, tap the socket part of the sewer pipe with a hammer in order to avoid a complete replacement of the riser section in case of cracking. By lightly loosening the pipe to be dismantled, it is necessary to make sure that the socket can move freely and rotate on the sides and that it can be gradually released from embossing with a cable. Now you can dismantle it in the following order: • loosen the bell in all directions; • little by little pull the rope and pick it out with a thin straight object with a screwdriver or some kind of rod; • the rope must be gripped firmly with pliers; • continue to gently loosen it and gently pull on the rope.

The ineffectual tapping and immobility of the bell indicate that the caulking was carried out using a special sulfur filling. In this case, it is necessary to perform the direct burning procedure according to the following scheme:

• it is necessary to carefully warm up the socket section of the cast-iron pipe in a circle using a blowtorch or a gas burner, while remembering to continue to loosen, twist and tap the socket section of the pipe;

• after it has moved from the place of the old embedment, it is necessary to continue to loosen it with the help of any tool, an adjustable wrench, etc. After dismantling, it is necessary to thoroughly clean the socket using any cutting tool of a knife, chisel or chisel. When stripping, special attention should be paid to the socket of the socket, on which the sealing rubber will subsequently be installed. Place a lubricated rubber seal ring in the cleaned socket. Install the required assembly into the seal.

Coin options

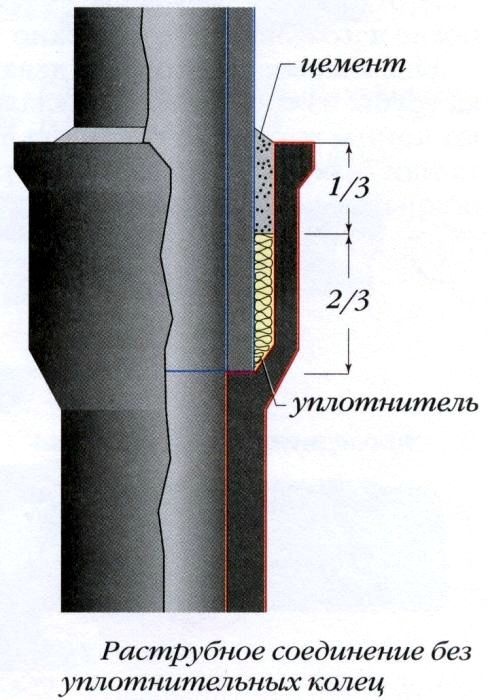

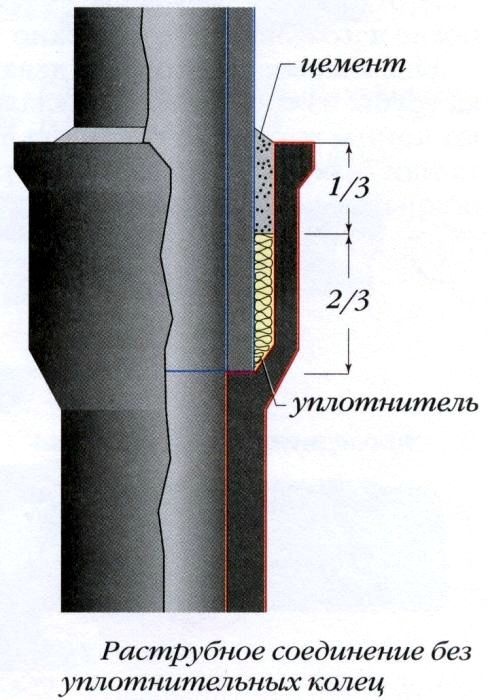

In order to firmly and hermetically construct a sewer system from cast-iron pipelines and parts to it, it is imperative to provide for the correct option to seal the gap that forms between filling the void between the pipes, which is always shown when butt-joining the inner socket part of the pipe with its outer surface part. It should be noted that the choice of the necessary consumables, the appropriate special tools for sealing work and the amount of time spent depends on the method of sealing the connection of cast iron pipes. It is proposed to consider the currently existing two options for stamping cast iron connections. 1. The first option is the use of cement mortar

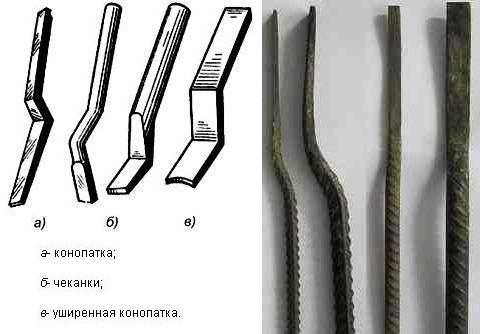

The procedure for sealing pipe joints with a cement mortar consists of the following steps: • In the formed gap between the pipes, it is necessary to lay a special tarred sealant. To perform such a gasket, a conventional bundle previously tarred in a special solution is used, which is hammered into the formed gap between the pipe and the socket to a depth equal to 2/3 of the gap space. After creating the first sealing ring, it is necessary to put the end of the rope (harness) on top of this ring so that it does not end up inside the pipe to be installed. • Next, you should seal the remaining part of the gap depth (1/3 of the remaining space) between the pipes with a prepared cement mortar, which has already been compacted with a tarred band. In order to increase the density and reliability of the caulking of the joints, it is required to use a special chasing in conjunction with a hammer, with which it is necessary to carefully tamp the cement mortar. The moment of the end of the embossing is the beginning of the rebound of the embossing from the clogged cement seal. In order to obtain a high-quality setting of the cement mortar, it is necessary to cover the compacted area with a wet cloth, for example, gauze. • In order to prepare the cement slurry, you will need to purchase cement grade 300400.It must be mixed with water in a ratio of 9/1. • It is possible to increase the speed of work during caulking with the help of such special tools as broadened chasing and caulking. In this case, the course of the entire process is accelerated by 30%. • If work is carried out in winter at low ambient temperatures, then the cement slurry in this case must be mixed in heated water, and in this case, it is imperative to temporarily insulate the cement-sealed pipe joint.

2. The second option is the use of asbestos cement

This process is slightly different from the previous one and has its own procedure: • It is necessary to knead the asbestos fiber in a dry state with cement in a ratio of 1/2, respectively; • The collected dry mix should be kneaded in water before using as a seal between pipes. The volume of water in the solution should be about 1012% of the total volume of the prepared mixture. • The process of hammering the gap between the pipes is carried out in the same way in accordance with the established procedure for the first option for sealing connections.

A procedure such as caulking or caulking connections between cast-iron pipes has its own difficulties and difficulties with its own nuances and tricks. Therefore, in order to achieve a positive result with such laborious work, it is recommended to seek help from knowledgeable and experienced professionals. In this case, there is a guarantee that you can get rid of unnecessary hassle and costs in case of unplanned replacement of risers as a result, for example, of unsuccessful tapping with a hammer of the socket part of the sewer pipe.

Installation of a new pipe section

When the place for the new pipe is prepared, it is inserted and fixed in the socket of the fan pipe. Depending on which pipe you plan to use (plastic or cast iron), you will need either a gun for a tube with silicone, or embossings, a cable and a solution of cement or an asbestos-cement mixture, since the capping of cast iron pipes differs from the capping of plastic pipes in cast iron sockets.

It should be borne in mind that cast iron pipes are preferable in all respects, therefore, a short instruction is provided, which describes the minting for these pipes.

A pipe is inserted into a thoroughly cleaned socket, and a gap of about two-thirds of the saddle height is filled with the prepared strands of the bobbin using a hammer. It is more convenient to work with strands 60-70 cm long, they are compacted in a circle, each next segment should overlap the end of the previous one by 1-2 cm.

The rest of the socket is filled by hand with a cement mortar of at least 400 grade and sealed with a stamp.

It is possible to start operating a new compound only after the cement has completely dried. It is not worth accelerating the hardening process by heating; on the contrary, it is advisable to cover the junction with a wet cloth if the ambient temperature is high enough.

Diy embossing of a cast-iron sewer pipe

Almost all Soviet buildings are equipped with cast-iron sewer lines, since such pipes are durable and resistant to wear and tear. But cast iron piping requires the right approach to use and dismantle.

Unlike sewer pipes, which can last for decades, connections within a home may need to be replaced sooner. Also, interventions in the sewer system may be forced when installing washing equipment or redeveloping a bathroom. To do it according to the rules, it is not necessary to call and wait for the master, all the work can be mastered by the owner himself, if he knows how to handle elementary tools. Dismantling the sewer should not take much time, but dismantling old products is more difficult.Let's figure out how to properly dismantle cast iron pipes.

Algorithm of work

Depressurization of cast iron elements is one of the most difficult tasks in self-repairing sewers. To do the work as quickly and efficiently as possible, it is recommended to prepare all the necessary tools in advance.

To carry out the work you need:

- grinder (with its help you can cut a part of the pipe);

- grinding discs;

- goggles, gloves and mask;

- soldering iron (useful for heating connections);

- a hammer;

- screwdrivers of various sizes and configurations;

- pipe wrench;

- chisel.

Note! To avoid the spread of unpleasant odors throughout the room and the ingress of various debris into the pipeline, close the drain hole with a piece of cloth.

The sequence of the work performed:

- The first step, before embossing the sewer cast-iron pipe, is to tap the joint with a hammer. However, you should do it carefully. Otherwise, you can damage the structure, which will lead to a complete replacement of the riser. It is also possible to carry out such manipulations, often using a tool made of wood.

- As soon as you finish tapping, you should pay attention to the condition of the fasteners. If the pipe runs from side to side, and it is possible to disconnect it, you must do the following. You need to swing the product by prying it with a screwdriver. The rope should be hooked with pliers and carefully pulled out.

Advice! During the procedure, the pipe should be pumped more and more.

- If, even after frequent and prolonged knocking with a hammer, the pipe has not changed its position, we can conclude that the fastening was carried out using a sulfur solution. To remove the fasteners, you must first burn out the dried mixture. This can be achieved in several stages. The first step is to heat the junction with a soldering iron. This should be done in a circle. Next, you need to continue to knock with a hammer, trying not to violate the integrity of the product. If the structure of the elements begins to stagger, you can try to dismantle the element using a key.

Step-by-step caulking of cast iron pipes

In the process of repairing sewer communications with your own hands, the most difficult moment may be the embossing of a cast-iron pipe. Such manipulation may be required when repairing or reinstalling the riser. In this case, it is necessary to very carefully emboss the nipples of the cast iron pipes. This work can be done in stages like this:

- First, use a hammer to lightly tap the bell, while acting carefully so as not to break it, since negligence can lead to irreversible consequences, for example, replacing the entire riser. Better to use a wooden mallet.

- If the previous blockage was made with a cable, then after tapping, the bell should wobble freely and can be removed without additional effort. If so, do the following:

- swing the bell from side to side;

- pry with a screwdriver and pull the rope a little;

- hook it with pliers;

- slowly and carefully pull out the rope, swinging the pipe in the process.

- If, after tapping, the pipe did not start moving, it means that the previous caulking of the sockets of the sewer pipes was carried out by pouring sulfur. In this option, you will need to get rid of it by burning it out. To do this, proceed as follows:

- gently heat the pipe at the joint along the entire diameter with a blowtorch or torch;

- lightly, trying not to break the walls of the pipe, then tap it with a hammer;

- if the bell begins to wobble, try moving it using an adjustable wrench.

Please note that when working with a burner and sulfur, it is imperative to protect the respiratory tract with a mask so as not to get poisoned by poisonous fumes.

- After successful dismantling, the walls of the socket must be well cleaned with a chisel and chisel. Pay special attention to the flare seat as this is where you will place the sealing rubber.

- Having previously coated the rubber seal with a special lubricant, place it in the socket.

- Place a new structural member in the rubber ring.

Cast-iron pipes are subject to skillful hands

In modern houses, all sewer communications are made of cast iron pipes, which are quite wear-resistant, but require proper operation and replacement. If the waste pipe has served faithfully for decades, then the intra-apartment pipe connections may require repair much earlier.

Sometimes the owner, in order to increase the area of the bathroom, moves the toilet bowl to the wall, replacing the pipe with a shorter one. Sometimes the installation of a purchased washing or dishwasher requires reconstruction of the sewer system in the apartment.

To carry out such work, it is not necessary to invite a specialist, a man who knows how to handle tools can do all the necessary actions with his own hands.

Cast iron pipes are not picky to maintain, do not have specific requirements for operation.

Before installing a new piece of pipe, you will have to dismantle the old one, and make a stamping of the connection. This process is laborious and requires some skill. If you cannot do it on your own, you will have to invite a specialist and see how he copes with this task.

How the old compound is stamped

First of all, you need to prepare the front of work, tools and consumables. It is impossible to work with sewer pipes when they are drained through them, so the water in the apartment (or on the riser) will have to be shut off.

Decorating is done using the following tools:

- angle grinder (grinder) with cutting disc 230 mm;

- a machine with a small gearbox and a disc size of 115 mm;

- a hammer with a rubber or wooden attachment;

- chisel;

- pliers.

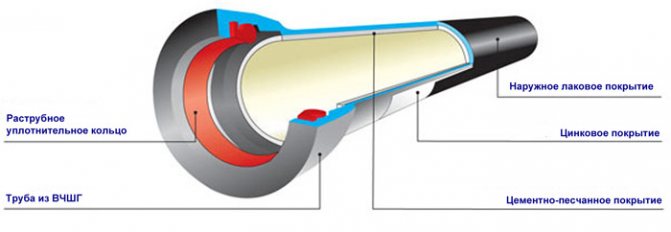

Ductile iron pipe structure diagram - ductile cast iron with spheroidal graphite

Instead of a grinder, you can use a hacksaw for metal, but then the duration of the procedure will increase to several hours.

When starting to restore the connection of cast-iron pipes, it must be remembered that the caulking, done correctly and carefully, will make it easy to securely fix new pipes.

First, you will have to dismantle the toilet to make room for work. It should be borne in mind that if the plumbing fixture was installed with cement, it will not be possible to remove it, the way out is to break it and stock up on a new one.

When starting to dismantle a piece of cast-iron pipe, the master, as a rule, does not know how the connection was fixed, how the connection of interest was minted. If with the help of a cable, then it may be possible to remove the pipe, skipping the most difficult and time-consuming process: cutting it out. In this case, he gently taps the pipe with a hammer, trying to loosen it. If it gives in, it tries, loosening it, to take it out. Now it is necessary to thoroughly clean the released socket from everything that was pressed on there.

If the connection was made by sealing filling or during use it literally grew together, then you cannot do without a grinder (or a hacksaw).

It is necessary to saw off the pipe directly above the socket.

If the connection was fixed with a cable, then you can gently knock on the pipe with a hammer, loosen it and remove it.

It is preferable to use a 230 mm disc, the cut piece is set aside: it is no longer needed. Attention! You need to work in goggles and a respirator.

We pass to the most difficult stage. With a 115 mm disc, three to four internal cuts are carefully made along the remaining end. Care must be taken that the disc does not reach the very bell.Now, with the help of a chisel and a hammer, we pry off pieces of metal and the remains of the casting, remove with pliers. We work carefully, do not allow solid pieces to enter the sewer pipe. When solid residues of metal and casting are removed, the inner surface is finally cleaned, if necessary, it is dried using a construction hair dryer or wiped dry with a rag.

Installation of a new pipe section

When the place for the new pipe is prepared, it is inserted and fixed in the socket of the fan pipe. Depending on which pipe you plan to use (plastic or cast iron), you will need either a gun for a tube with silicone, or embossings, a cable and a solution of cement or an asbestos-cement mixture, since the capping of cast iron pipes differs from the capping of plastic pipes in cast iron sockets.

It should be borne in mind that cast iron pipes are preferable in all respects, therefore, a short instruction is provided, which describes the minting for these pipes.

A pipe is inserted into a thoroughly cleaned socket, and a gap of about two-thirds of the saddle height is filled with the prepared strands of the bobbin using a hammer. It is more convenient to work with strands 60-70 cm long, they are compacted in a circle, each next segment should overlap the end of the previous one by 1-2 cm.

The rest of the socket is filled by hand with a cement mortar of at least 400 grade and sealed with a stamp.

It is possible to start operating a new compound only after the cement has completely dried. It is not worth accelerating the hardening process by heating; on the contrary, it is advisable to cover the junction with a wet cloth if the ambient temperature is high enough.

Some precautions

When working with cast iron pipes, one should not forget about their relative fragility: from sharp and strong blows of a metal hammer, vibrations and, as a result, cracks can occur in the pipe. Then replacing defective segments will turn into an endless and expensive process.

Precautions in the repair of cast iron pipes

When working with such pipes, be sure to remember that cast iron, with its endurance, is a relatively fragile material. If you hit with a metal hammer harshly or too hard, the wall vibrates and cracks may appear. If this happens, replacing the damaged sections will be time consuming and costly. Therefore, when preparing for dismantling, stock up on the necessary tools in advance.

It is not worth working alone, it is unsafe and difficult. Better call someone for help.

It is important to know that sulfur fumes can be harmful to health, so use a gas mask, as a last resort, a respirator and goggles. Also, take care of good air circulation in the room where renovation work is taking place.

After removing the pipe from the socket, take the time and attention to clean the seat of that part. This will ensure the installation of the sealing material without defects and distortions.

All dismantled material and garbage should be immediately packed into construction bags, tied up and thrown away. An unpleasant odor will be emitted from the old pipeline.

If you are embossing cast iron pipes for the first time and after reading this article, you still do not understand how to do this, be sure to contact a professional. For an experienced craftsman, the process of dismantling cast iron pipes will take 25-30 minutes, while a beginner can spend more than 3 hours and with an unknown result.

Start and sequence of repair

Cast iron pipe caulking

It is necessary to think about how to stamp a cast-iron pipe if it is necessary to replace an element and it is impossible to correct the damage directly at the scene of the accident.

The first step is to carry out preparatory work, that is, they carefully examine the pipes and figure out exactly how they are welded to each other.

Quite often you have to deal with pipes filled with a special solution used to glue their parts together.

In this case, being underground, the elements can grow together so firmly that they cannot be disconnected without effort. At the same time, experts recommend using a gas cutter, which allows you to quickly remove the bonding compound and disconnect the pipes.

Speaking about caulking a cast-iron pipe, it should be borne in mind that the work is not easy and requires turning off the water in the whole house or even the area, if an important area is being repaired.

Pipe preparation for repair is performed using special tools:

- A damaged or burst area is cut down with a grinder;

- A new part of the pipe is installed in place of the damage;

- The seam is closed with a construction bandage with cement.

Preventing the problem

Example of capping

It should be borne in mind that for all its excellent physical qualities, cast iron is a rather fragile material. It deforms under the influence of water and the chemical reactions that occur in it, therefore all changes affect the pipes, including temperature changes, which makes them fragile and unable to withstand high pressure.

Embossing cast iron pipes is a rather complex process, the high-quality implementation of which includes the replacement of a pipe element, leaving also a certain margin for its expansion.

The new part of the pipe is inserted into the socket, after which the seam must be securely fastened with a resin strand. A tool such as a caulk is used to tightly lay and secure the threads.

Practical experience shows that cracking in a cast iron water pipe is only part of a problem that grows unless drastic measures are taken. Patching holes with the help of special compounds temporarily helps, but sooner or later, replacement will still be required, so it is easier to immediately deal with the breakdown.

Selection of sealant for sewer cast iron pipes

It is necessary to seal the joints of the sewer cast-iron pipe dia. - 120mm with sockets. The house is wooden there is a movement of the foundation, I tried to wrap the joints with fiberglass with cement mortar. It costs several years, then the connections on the site with a minimum slope begin to undermine. Of the materials now there is fiberglass and asbestos cord without impregnation. Please recommend a good quality, flexible, high adhesion sealant for the job.

Polyurethane roofing sealant.

Remark, re-emboss with gray filling.

ssrr, thanks for the recommendation. While it is not possible to find a polyurethane sealant in Kostroma, there is only silicone and acrylic. We found Sazilat-51 in two-component buckets of 15 kg., We are looking further ... stager, if possible, describe briefly your method of sealing with sulfur filling. Earlier I believed that the joint, sealed with one gray, is very hard and brittle. Filling is only possible with a vertical pipe. How is it possible to seal joints using sulfur on a horizontal section of pipes?

Hmm. IMHO - no need to invent a bicycle. Mark with a bobble. Cover with cement mortar. Paint the seam with Kuzbass varnish. To avoid ground movements, make a sand cushion. Or, as an option, to refuse minting as such. And try to pick up the rubber cuffs.

gayanovv wrote: IMHO. Mark with a bobble. Cover with cement mortar. Paint the seam with Kuzbass varnish. To avoid ground movements, make a sand cushion.

Thanks for the suggested option. The joints were sealed with asbestos cord + cement mortar on top. The house is wooden, a horizontal section of the sewer runs through the whole house in the basement, the pipes lie without pillows, right on the sandy ground. After a few years, some of the joints began to undergo digging, apparently due to shrinkage of the house and / or movement of the ground.Will PUR sealant with asbestos and fiberglass stand better in these conditions compared to embossing bobbles or not? The cost of the sealant in this case is secondary.

gayanovv wrote: Or, try to pick up rubber cuffs.

Rubber specialized cuffs are available for cast iron pipes dia. 120 mm? To install them, it will be necessary to disassemble the entire pipe section. If the connection is more durable and reliable, it will be possible to sort out the pipes.

DICOM wrote: Rubber specialized cuffs are available for cast iron pipes dia. 120 mm?

you can try to stretch (with soap) 123/110 cast iron / plastic. There are also round thick rings for HTUGs.

IMHO, find the bobbin and stamp, wrap the joint with Guerlain tape on top. It will be forever. Guerlain is:

DICOM wrote: A quality, flexible, high adhesion sealant for the job.

You can also manage to score a joint with them. but it is sticky

DICOM wrote: Thanks for the suggested option. The joints were sealed with asbestos cord + cement mortar on top. The house is wooden, a horizontal section of the sewer runs through the whole house in the basement, the pipes lie without pillows, right on the sandy ground. After a few years, some of the joints began to undergo digging, apparently due to shrinkage of the house and / or movement of the ground. Will PUR sealant with asbestos and fiberglass stand better in these conditions compared to embossing bobbles or not? The cost of the sealant in this case is secondary.

Rubber specialized cuffs are available for cast iron pipes dia. 120 mm? To install them, it will be necessary to disassemble the entire pipe section. If the connection is more durable and reliable, it will be possible to sort out the pipes.

A heel is a strand of linen soaked in iso. butane (you can't pronounce it without half a liter). And, asbestos is easily washed away with water. Maybe that's the reason? Indeed, you can buy ordinary 123x110 cuffs and try to cut them. If it succeeds, it will certainly keep it. IMHO Throwing new plastic pipes will be easier than sorting out cast iron.

gayanovv wrote: it will be easier than sorting through cast iron.

And less deposits in them.

The pipe joints were sealed with polyurethane sealant ISOFLEX P-40 (which I could find in the city) with filler. The sealant is relatively inexpensive, 220 rubles for 600 ml. Hope it lasts a long time. If there are problems, I will replace the cast-iron pipes with plastic ones. Thank you all for your help and recommendations, I learned a lot!

This is how the textbook advises to mint. :

§ 41. Assembly of cast iron pipes with cementing of sockets

Cast iron sewer pipes and fittings are connected by sealing the gap between the inner surface of the bell and the outer surface of the pipe end or fitting inserted into the bell (84). After caulking, a cement mortar is prepared, and then the space left in the socket is sealed with moistened cement and tightly coined with chasing and hammer. To seal the socket, cement grade 300-400 is used, which is thoroughly mixed with water in a proportion of nine parts of cement to one part of water (by weight). The bell is filled with cement mortar using a scoop and coined until the latter begins to bounce off the cement. In order for the cement mortar to set well, it is recommended to cover it with a wet rag at the end of rapping. In hot weather, the cloth should be moistened with water from time to time. The sockets can be caulked and chased with broadened caulkers and chases that cover up to lU of the pipe circumference, due to which the caulking and chasing process is accelerated by 25-30%. In winter, the cement slurry is prepared in hot water, and the sockets are heated. The joints are insulated after sealing. Instead of cement, asbestos cement is used to seal the socket.An asbestos-cement mixture for sealing joints is prepared by mechanical mixing of cement grade not lower than 400 and asbestos fiber (not lower than VI grade) in a ratio of 2: 1. Immediately before sealing each joint, the dry asbestos-cement mixture is moistened by adding 10-12% of water by weight of the mixture. With an asbestos-cement mixture, the joint is sealed at about 7th of the socket height. Then the pipe inserted into the bell of the lower part is centered with three metal wedges so that the width of the annular gap between the pipe and the bell is the same everywhere, and the wedges are driven in with light hammer blows (87, c). To seal the prepared joints, cement is first poured into the vessel for preparing the solution. Vasiliev's device (85, a) consists of a metal plate 7 and a bracket attached to it on the hinge 2. The bracket is pressed against the plate and locked with a wedge-shaped check 3, which allows the pipes to be held in an upright position. Kozlov's adaptation (85, b) is more perfect. A carousel stand (86) is also used to assemble assemblies from cast-iron sewer pipes with a diameter of 50 and 100 mm. The carousel has six workstations with pneumatic clamps, each of which can be brought to the collector by turning the table manually. Carousel diameter 2046 mm, height 880 mm.

Section 42. Assembly of cast iron pipes with expansion cement

Sealing the sockets of cast iron pipes with resin strand and cement requires a lot of labor, significant consumption of strands and a long time for the cement to set. In addition, the tightness of the joints depends on the quality of caulking and chasing. First, the necessary pipes and fittings are selected. Then they are cut on a hand press or on a driven machine, parts of the required size are obtained and pipes and fittings are adjusted. After that, clean the joints from dust and dirt with a stiff brush and rinse with water.After the part has been removed from the bath, inventory wedges are knocked out of the joints with light hammer blows, and the holes from them are sealed with a solution of expanding cement. The prepared pipeline units can be sent to the installation sites no earlier than 16 hours after the joints are sealed.

§ 43. Assembly of cast iron pipes with sulfur and lead sealed sockets

Sealing of sockets with gray. Sealing the sockets j of cast-iron sewer pipes with expanding cement requires exposure to cement setting, and, consequently, large areas at assembly plants or CZM. To seal the sockets of cast-iron sewer pipes, industrial sulfur (powder or lumpy) is used. Lumpy sulfur is preliminarily crushed into pieces with a volume of no more than 1 cm3. The joint, sealed with one gray, is very hard and fragile, therefore, when transporting units to construction sites, the tightness of the joints is broken. To make the butt joint soft, add 10-15% of ground kaolin to the sulfur. Before assembling the sewer units, the sulfur together with kaolin are heated in a special bath (88). "! Sulfur is charged through an opening located at the top of the bath. Vapors and gases are also discharged through this opening. The tank 1 for sulfur is mounted inside the bath and is washed by a heating medium - mineral oil 3, which is heated to a temperature of 130-135 ° C by four electric heating elements 4 installed inside the bath. When the temperature rises above 135 ° C, sulfur becomes inactive and brittle when it cools. It is necessary to warm up the sulfur slowly for 1.5-2 hours. The bath is protected by thermal insulation 5. The molten sulfur cannot be stored in the tank for more than 2 hours. The process of sulfur hardening after pouring the sockets takes 5 minutes for pipes with a diameter of 50 and 100 mm, for pipes with a diameter of 150 mm - 10 min. The labor intensity of sealing joints with gray compared to sealing with expanding cement is reduced by 40%, the cost of sealing by 33%. When working with sulfur, the following safety rules must be observed: the content of sulfur dioxide in the working area should not exceed 0.02 mg / l; the bath for heating sulfur must have local ventilation; flammable materials should not be located near the place where sulfur is heated; the temperature of heating sulfur should not exceed 135 ° С, since at higher temperatures, sulfur ignites in air.If sulfur ignites, it is necessary to stop heating the bath and close it with a lid; burnt sulfur should be extinguished with sand. When laying cast-iron water pipes, the size of the gap between the ends of the smooth end of the pipe and the stop in the socket is recommended to be taken according to table. 16. The joints when laying the pipeline on a straight section of the route must be centered so that the width of the socket slot, taking into account the tolerances for the diameters of the socket and the flanged end of the pipe, is the same along the entire circumference. The joints of bell-shaped cast-iron water pipes are sealed with resin (or bituminized) hemp strand, rubber rings or a rubber cord. The hemp resinous strand is introduced into the socket in succession with three bundles. Each tourniquet is sealed to failure with a blunt caulk. After compaction of the strand, the remaining free space in the annular gap of the socket is coined with asbestos cement, consisting by mass of 30% of asbestos fiber not lower than grade 4 and 70% of cement grade not lower than 400. A gap of 3-10 mm is left between the end of the pipe and the socket to compensate lengthening of pipelines. The dry asbestos-cement mixture for sealing the sockets should be diluted with water (10-12% of the mass of the dry mixture) to make it crumbly. Prepare it immediately before starting work in the amount required to seal one socket. When sealing the joints of bell-shaped cast iron pipes with asbestos cement at an air temperature below -5 ° C, instead of water, 15-17% '(of the mass of the mixture) of fine-crystalline well-crumbling snow should be added to the asbestos-cement mixture. The dry asbestos-cement mixture is cooled to the outside air temperature before mixing it with snow. It is necessary to prepare an asbestos-cement mixture with snow in such an amount that is necessary for a one-day work. The mixture is supposed to be stored in closed boxes. It is not allowed to use the thawed mixture for sealing joints. Covered joints are covered with wet matting or sprinkled with wet soil and kept wet for at least 4-8 hours for better adhesion. Sealing the sockets of cast-iron water pipes with lead is carried out in the following sequence. First, the inner surface of the bell and the outer end of the pipe to be connected are cleaned, after which the pipe is pushed all the way into the bell and the pipes to be connected are sprinkled with soil. Then, a bituminized strand is introduced into the slot of the socket with bundles and compacted well with caulking. In this way, the socket is filled up to 2/3 of the height. After caulking, a casting mold is formed around the socket joint. To form a shape on the pipe close to the socket, one turn of the rope is made (the diameter of the rope must correspond to the size of the gap), previously coated with liquid clay. Then a clay roller is made around the socket, bringing the ends of the rope outward, after which the rope is pulled out of the roller. Inside a clay roller in the zone of tree plantations and aquifers with a pipe depth of more than 5 m is not allowed.

How to stamp a cast iron sewer pipe: stamping and how to stamp an old pipe

Not all users know how to mint a cast-iron sewer pipe. moreover, not everyone knows what it is about. However, during the assembly or renovation of the sewer system, the ability to properly mint pipe joints will come in handy.

In many houses, old cast iron pipelines are still preserved, which it is impractical to completely change to modern plastic. The pipes are still strong, capable of working for more than a dozen years. As a rule, they are left intact, replacing only the apartment horizontal wiring sections. Consider how the connection of cast iron pipes is made when installing drainage systems.

Cast iron fittings

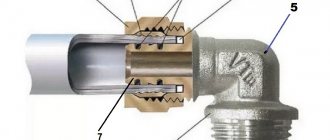

The elements are manufactured from wrought iron. Fittings made of this metal can only be used to connect cast iron communications. They are not suitable for steel products.There are several types:

- threaded;

- compression;

- press fittings.

To increase reliability, such products are coated with zinc. According to the connection method, threaded elements are divided into 3 groups:

- with internal thread;

- external thread;

- external-internal thread.

When assembling the pipeline, different fittings are used, different in shape and configuration:

- revision - used to eliminate blockage, with the help of such an element, preventive cleaning of the system is performed;

- coupling - allows you to do the joining of pipes of the same diameter;

- cross - used to change the direction of the pipeline, create several directions;

- transitions - used when connecting communications of different diameters;

- tee - allows you to combine pipelines in three directions or perform wiring;

- indent - used in cases when it is necessary to slightly change the direction of the pipeline;

- knee - an element with two exits located at an angle of 90 °;

- elbow - resembles a knee, however, the angle of rotation of the outlet holes relative to each other is much smaller (45 ° or less).

Features of cast iron pipes

Cast iron pipes were used everywhere in Soviet times. Alternative materials for manufacturing were used on a limited scale, for the assembly of special sewer lines. The properties of cast iron pipelines allow the old system to work until now. The advantages of these pipelines:

- tendency to corrosion;

- heavy weight;

- fragility, inability to withstand sharp blows;

- the complexity of the assembly.

The most significant drawback is the complicated connection procedure, or the chasing of cast iron sewer pipes. Combined with the heavy weight of the parts that put significant stress on the supporting structures, these drainage lines were difficult to install and maintain. However, the durability and reliability of cast iron systems are appreciated by experts. All networks, the state of which does not inspire concern, are still effectively used for wastewater disposal.

Connection methods

The assembly of cast iron pipelines is a complex and demanding task. There are several types of connections:

- into the bell. This is the most popular type, which is called "caulking of sewer pipes". The process requires accuracy and experience, strict adherence to technology requirements. Correct capping can withstand several decades of leakage operation;

- coupling connection. This option is used for socketless pipes. Special couplings are used that tightly wrap the edges of the elements to be joined. The build quality is high; no special experience and skills are required to complete the work. However, it is not always necessary to install the coupling.

There are couplings that are not equipped with threaded clamps. They represent two sockets into which the ends of the elements to be connected are inserted. The assembly of such lines also requires chasing of sewer pipes, carried out according to standard technology.

The procedure consists in filling the socket gap with a sealant, and sealing with hardening compounds. A tarred hemp strand is most often used as a sealant, which is stuffed 2/3 of the socket and carefully compacted. Then the remaining third is filled with a strong protective compound. To do this, use cement, plumbing sulfur. In pressure lines, chasing with lead is sometimes used, the procedure is complex, but very effective.

How to stamp a bell

During repair work, reconstruction or expansion of the drainage system, it is often necessary to connect different lines.Before you mint a sewer pipe, you often have to disassemble an old, defective connection. It is extremely difficult to rake out the bell, which has overgrown with monolithic layers over the years. The main problem becomes the danger of destroying the socket of a whole pipe or tee. If this happens, the entire riser or horizontal pipeline will have to be disassembled and replaced.

Before embossing the old cast-iron sewer, it is necessary to clean the connecting element, remove all foreign objects and layers. As a rule, various temporary patches of paint, additional layers of mortar, and other materials are applied over the standard joint. All such areas are subject to complete removal.

After that, it is necessary to determine what material the insulating seal is made of, since it is much easier to stamp out a cast-iron sewage system than sulfur. If cement mortar is used, the disassembly process will be easier. However, if plumbing sulfur was used, the procedure will be difficult. The material will have to be heated with a gas torch or blowtorch, since it will not be possible to simply break and remove particles from the gap - sulfur has high strength and viscosity. You will have to work in a gas mask, since poisonous gases will be released when heated.

Procedure

In order to emboss a cast-iron sewer, you must first remove the cement or sulfur filling (1/3 of the socket depth), and then remove the hemp strand (2/3 of the depth). The first stage requires caution and accuracy. There is a great risk of breaking the socket of the tee or other receiving element. First, they act with a chisel, then with a screwdriver with a long thin blade. With gentle hammer blows, the screwdriver is immersed in the gap, breaking off small pieces of the seal.

Many sources recommend that you first tap the socket around the circumference with a hammer, and then check to see if the pipeline has mobility. This is useless advice, since it is impossible to stamp a cast-iron sewer in this way. Until the top layer of cement or sulfur is removed, the pipe will not swing. In addition, hammer blows can break the bell, which will significantly increase the amount of work.

When the solid plug is removed, the joint will become flexible. They move it a little to the side, pick up the rope and pull it, swinging the pipe to the sides to facilitate the process. After that, the socket is completely released, the connecting element can be easily removed.

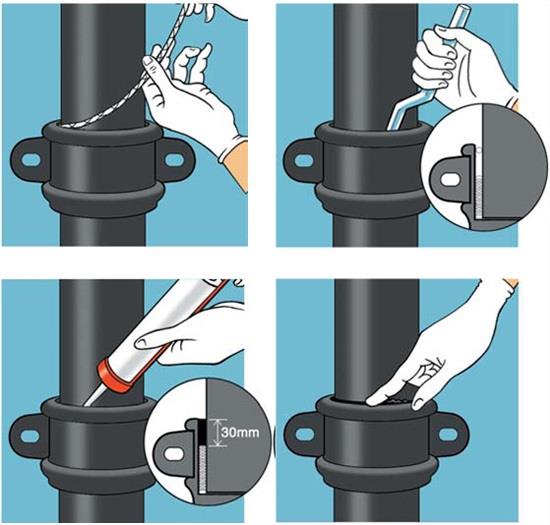

Re-compactor - an alternative to chasing

The tool with which the minting is done

The minting is short-lived, there are several reasons for this: temperature drops, high humidity, ground shifts. But there is an additional sealant - fittings that reduce the duration of pipe repair, prevent leakage and improve the quality of the connection. The design of the device is simple: two breakable rings are completed with a rubber gasket, bolts and nuts for a tie. The element is installed on the bell and then fixed with a wrench. Work can be performed without shutting off the pressure, but only by reducing it.

- The clamp should be sized to match the pipe diameter.

- Before installation, clean the pipe surface near the socket.

- Mount the gasket with the flat side to the socket. The ends of the seal are connected.

- Close the clamp around the pipe, install the studs, tighten the nuts.

It is necessary to install an additional sealant on water and sewer lines. For enhanced protection, an anti-corrosion epoxy coating is used.

Video: installation of an additional seal for flare connections

The tightness of the joints is important in both internal and external communications. Sealing materials are durable polyethylene tapes, liquid rubber (silicone sealing rings). To switch from cast iron to plastic, use a rubber adapter lubricated with silicone sealant.

Breakouts on the line caused by the destruction of the pipe at the junction are eliminated for a long time, and the result of the work does not always turn out to be of high quality. Making a tight connection in a hard-to-reach place is always a difficult and painstaking job. Planned preventive measures will help avoid accidents and save money.

Did you like the article? Share it:

How to mint

Caulking is a procedure for sealing, sealing a connecting element. It is necessary to prepare materials, tools:

- oiled rope (hemp strand);

- cement (or asbestos-cement) mortar;

- a wooden spatula that fits freely into the gap of the socket;

- long screwdriver;

- a hammer.

The capping of the sockets of the sewer pipes takes place in 2 stages:

- stuffing the gap with tow or rope (cable). Using a cord is considered a more efficient option. The sealant is inserted into the gap, they begin to wind on the pipe, constantly ramming it with a spatula. The material must be compacted and immersed in the gap until it stops. The process is stopped when the gap is filled to 2/3 of the depth;

- cement mortar is poured into the gap over the seal. It is pushed with a wooden spatula or screwdriver, evenly distributing the material over the entire volume of the cavity. The quantity should be such that the entire gap is completely filled up to the very top of the socket.

Causing the bell with gray is not practiced at home. It is necessary to melt lump sulfur with 10-15% kaolin, which requires special equipment and enhanced ventilation. This method is only possible in the factory.

Methods for capping pipes and options for neutralizing it

Embossing a pipe, that is, connecting its elements, can be done in three ways. Moreover, each of them requires its own specific approach.

Nowadays, in order to connect the elements, it is not at all necessary to stamp a pipe. This can be done using a special adapter sleeve. Moreover, such an element can connect pipes made of various materials, for example, cast iron and plastic.

Embossing of pipes can be made from different materials. Various pipe punching and ways to eliminate it:

- It will be easiest to separate the elements if they have been capped. This is a rope that is wound around pipes and compacted. To check if this method has been used, you need to hit the bell several times with a rubber hammer, and then try to loosen it. If the pipe yields, then most likely the cable was used. In this case, you need to pick out the top layer of the rope with a screwdriver, find its end and pull it out. Throughout the entire work, it is necessary to gently loosen the pipe. Stagger it until it is possible to pull out the required element. If the bobbin was covered with cement mortar from above, then it must first be knocked down. To do this, a screwdriver is placed on it at an angle, which is tapped.

- During the Soviet era, the bobble was rarely used. Sulfur was much more common. In this case, you will have to do a rather dangerous job. For her, you will definitely need to wear a gas mask, because sulfur vapors will be released, which are extremely poisonous. It is also necessary to air the apartment. So, it is necessary to melt the sulfur with a blowtorch so that it becomes a liquid state. When heating, it is periodically necessary to tap the pipe until a noticeable stirring appears. When the pipe itself heats up, it will need to be taken with an adjustable wrench and pulled with effort. This will free the required element.