Home / Boiler rooms

Back to

Published: 27.10.2019

Reading time: 5 min

0

3572

A boiler plant (KU) consists of an interconnected set of equipment for generating steam and hot water in generation processes (CHP, IES, NPP), production of various types of products and in central heating systems. Therefore, it is subdivided into energy, industrial and heating.

The source of steam generation in the WHB is drinking water, and the energy carrier is natural fuel. The heat transfer process is carried out through convective and radiative heat exchange using boiler tubes.

The organization of heat transfer occurs due to the coordinated work of complex units and elements of the steam generator, which are classified as main or auxiliary equipment.

- 1 Basic equipment

- 2 Boiler room auxiliary equipment

- 3 Boiler room automation

- 4 Plants for the production of boiler equipment

Subsections

BurnersGas control points (GRPB) Industrial boilersGas cleaning filtersBurner nozzles

All boiler equipment is selected in accordance with the current regulatory documentation, according to the terms of reference and the customer's questionnaire. The selected equipment is fixed to the floor or frame of the boiler room on supports and brackets, without special foundations.

Basic boiler equipment

- hot water boilers, fire-tube and water-tube boilers;

- burners for various types of fuel;

- heating system pumps of the "Wilo" or "Grundfos" brand;

- water treatment equipment in the boiler room;

- mixing valve "ESBE";

- membrane expansion tanks with a design capacity.

The number of boilers is determined by the heating capacity of the boiler house, the design scheme, and the availability of backup equipment; maximum (peak) and minimum loads for heating and hot water supply.

The coolant is supplied to the heating networks through a pipeline of the design cross-section by one of two network pumps of the Wilo or Grundfos brand, with the required capacity. The available water pressure at the outlet of the boiler room is 4.0 kgf / cm². Return network water with a temperature of up to 70 ° C, a pressure of 2.0 kgf / cm² enters the boiler. The pumps (1 working and 1 standby) work alternately and supply the coolant (chemically treated water) to the boiler. At the outlet of each boiler, a bypass line with a check valve is provided. A three-way mixing valve is used to mix a part of the return water into the direct network water, which is controlled by a microprocessor-based measuring regulator of the TPM brand. To compensate for temperature expansion in the heating system, a membrane expansion tank from Reflex is installed in front of the pumping group.

All pipelines of the heating system and hot water supply are thermally insulated to reduce heat losses inside the boiler room, as well as in accordance with sanitary and hygienic standards.

A boiler plant is a device consisting of one or more boilers and auxiliary equipment.

The auxiliary equipment is designed to ensure the normal operation of the boilers and includes:

· Devices for receiving, storing fuel and preparing it for combustion and supplying it to boilers, usually called a fuel economy;

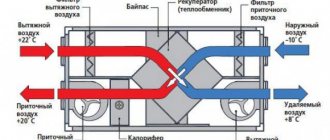

· Draft units for supplying air to boilers, ensuring the movement of gases in boilers and boiler rooms and removing gases into the atmosphere;

· Devices for ash and slag removal;

· Devices for cleaning gases from ash and other harmful impurities in order to protect the OPS from contamination;

· Water treatment plants for water purification from substances that cause scale formation, steam pollution and metal corrosion;

· Installations for the formation of hot network water;

· Installations for collecting, pumping condensate and feeding steam boilers with water;

· Pipelines for various purposes;

· Devices for safety automation, automatic regulation, control, signaling and control of technological processes;

· Electrical equipment, water supply, sewerage, ventilation and other systems.

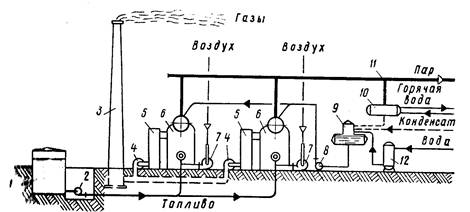

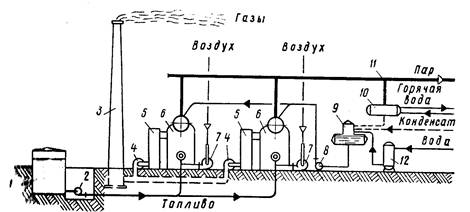

In fig. 3 shows a technological diagram of a boiler house with two steam boilers operating on fuel oil. Fuel oil is taken from reservoir 1 and supplied by pump 2 to the burners of boilers 6. Air is supplied for fuel oil combustion by blowing fans 7.

Fig. 3. Diagram of the device and operation of the boiler plant:

1 - fuel storage; 2 - fuel pump; 3 - chimney; 4 - smoke exhausters; 5 - water economizers; 6 - steam boilers; 7 - blowing fans; 8 - feed pumps; 9 - deaerator; 10 - water heater; 11 - steam line; 12 - water treatment plant.

The combustion products are sucked out of the boilers by smoke exhausters 4, they are pumped into the chimney 3, through it they enter the atmosphere and dissipate in it.

Steam from the boilers through the steam line 11 is supplied to external consumers and to the water heater 10. In the heater, steam heats the network water for heating and hot water supply systems.

Condensate from the water heater and from the steam consumers enters the deaerator 9. Here the condensate is boiled to remove corrosive gases (oxygen and carbon dioxide).

Losses of steam, condensate and water in the boiler house and in heating networks are replenished with raw water. Since the water contains various impurities that contaminate the heating surfaces with scale and sludge, the water is initially purified from solid impurities (clarified, softened) in the water treatment plant 12. Corrosive gases (oxygen and carbon dioxide) are removed from the water in the deaerator 10.

A boiler house operating on solid fuel (for example, coal) has a similar technological scheme. In such cases, the boiler room is equipped with a fuel storage and devices for supplying coal to the boilers. Slag and ash are removed outside the boiler room by various mechanical devices such as scraper buckets and scraper conveyors. To protect OPS from ash, combustion products are cleaned in ash collectors.

Depending on the purpose and nature of the connection of consumers, SNiP II – 35–76 "Boiler Plants" subdivides boiler houses into the following types:

· Heating - to provide heat to heating, ventilation and hot water supply systems for residential and public buildings;

· Industrial - for technological heat supply of industrial enterprises.

· Heating and production - to provide heat to heating, ventilation, hot water supply and process heat supply systems.

In addition, according to the type of installed boilers, boiler houses are divided into steam, hot water and steam water heating.

According to the heat supply scheme, boiler houses are divided into boiler houses operating on a closed heat supply system (all water entering the heating networks returns back to the boiler room) and boiler houses operating on an open heat supply system (part of the hot water remains with the consumer).

By capacity, boiler houses are conventionally divided into boiler houses of low power (up to 20 MW), medium power (from 20 to 100 MW) and large boiler houses (from 100 to 600 MW). Boiler houses of small and medium capacity are mainly used at the facilities of the Moscow region.

Water treatment equipment for hot water boilers

- rough mechanical cleaning;

- automatic installation of filtration and deferrization;

- automatic installation of softening.

The source water enters the coarse filter, where mechanical impurities are removed from the water.After treatment of water from coarse mechanical impurities, the water enters the deferrization station. Removal of iron compounds from water is carried out by filtration through the loading layer "Sorbent-AS". In the boiler house, for the implementation of the filtration and deferrization process, two installations of AQUAFLOU filtration equipment are used, operating in parallel. Each unit consists of a filter housing and a control unit. The housings have an upper threaded hole for installing a drainage and distribution system, loading filter materials, and fixing the control unit. The method of sodium cationization is carried out on a continuous operation unit of the AQUAFLOU SF series. The pressure of the water entering the installation must be at least 2.5 and not more than 6.0 kgf / cm².

Regeneration of the ion exchanger in the columns occurs automatically and is initiated by the water meter after a predetermined amount of water has passed. For accounting of measurements and registration of heat transferred to the consumer in the boiler room, it is envisaged to install the equipment of the heat meter "TEM-150/150/15" with electromagnetic flow converters and thermal converters. For the heating circuit, the thermal circuit provides for the accounting of the make-up water consumption using an electromagnetic converter included in the heat meter kit.

For the source of water supply, according to the buyer's technical assignment, a questionnaire for boiler room equipment and laboratory research protocols, an external network of a drinking water supply system or water from an artesian well is taken. The raw water used is counted using a mechanical cold water meter with a bypass.

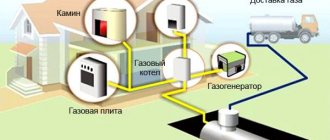

Design and layout of boiler room gas equipment

If you decide to equip a gas boiler room, then the most important and crucial stage is the implementation of the project. In order to avoid possible mistakes, the correct solution would be to contact the appropriate specialists.

The main point in choosing a specialist is that he or the organization he represents has permits for carrying out design work related to the construction and installation of gas boiler houses.

The choice of a suitable place for the heating system lies solely with the customer, but the scheme of the gas equipment of the boiler room and its placement is up to the design organization. At the same time, it is necessary to take into account the basic requirements established at the regulatory level:

- to use a gas boiler, the power of which does not exceed 60 kW, a separate room is not required. In this case, the installation of a heat generator can be carried out in any of the premises, which has a window with a window;

- for more powerful equipment (up to 150 kW), a separate room is required (such a room can be a basement or basement of a house). At the same time, the walls must be fire resistant. The room should also have a window with a window and a separate exit to the street.

- the equipment can be placed in a specially built room made of refractory bricks with windows and a separate exit.

The advantage of diesel boilers is that with the subsequent gasification of the facility, the cost of re-equipping the boiler room will be minimal.

Read about what the consumption of a diesel boiler can be here.

List of equipment in a boiler house with a capacity of 2.5 MW

| P / p No. | Boiler equipment | number |

| 1. | Steel structure: 7.2 x 2.4 x 3.1 m. (Wall and roof panels 100 mm) | 2 sections |

| 2. | Steel structure: 7.2 x 2.25 x 3.1 m. (Wall and roof panels 100 mm) | 2 sections |

| 3. | Steel water-heating boiler "KVANT-1.25". (Power 1.25 MW) | 2 sets |

| 4. | Gas block burner "VEKTOR-57/170". | 2 sets |

| 5. | Heat exchanger (heating) 1.6 Gcal / hour. | 2 sets |

| 6. | Gas supply scheme P = 10.0 kPa. | 1 set |

| 7. | Automatic gas control system SAKZ-MK –2 100 SD. | 1 set |

| 8. | Electromagnetic gas valve DN100. | 1 set |

| 9. | CO signaling device. | 1 set |

| 10. | CH4 signaling device. | 1 set |

| 11. | Gas filter FN4-1. | 1 set |

| 12. | Thermosensitive shut-off device DN100. | 1 set |

| 13. | Commercial gas metering unit consisting of:

| 1 set |

| 14. | Differential pressure sensor PROMA-IDM-DD (v) -6. | 2 sets |

| 15. | Flanged gas valve DN100. | 5 sets |

| 16. | Flanged gas valve DN80. | 2 sets |

| 17. | Flanged gas valve DN20. | 3 sets |

| 18. | Continuous sodium-cation exchange water softening system. (Make-up volume: 0.1 m³). | 1 set |

| 19. | Normally closed solenoid valve DN = 25 (mains make-up + boilers make-up). | 2 sets |

| 20. | Expansion tank for the heating network circuit 1000 l. | 1 set |

| 21. | Expansion tank for the boiler circuit 800 l. | 1 set |

| 22. | Expansion tank for source water 100 l. | 1 set |

| 23. | Electromagnetic heat meter TEM Du100 / 100/15 with pressure sensors. | 1 set |

| 24. | Honeywell valve 3-way DR100GFLA actuator M6061L1043 (heating). | 1 set |

| 25. | Industrial controller OWEN TRM32 for control and regulation of temperature in heating and hot water supply circuits | 1 set |

| 26. | Cold water meter VSX - 15 (HVO). | 1 set |

| 27. | Cold water meter VSX - 15 (source water) with bypass. | 1 set |

| 28. | FMF 150 filter (on the return water of the heating system circuit). | 1 set |

| 29. | Mechanical filter DN25 (source water). | 1 set |

| 30. | Reducer for HVO Du25. | 1 set |

| 31. | Fan VO-3.15-220. | 2 sets |

| 32. | Pump control SAU - MP 11. | 3 sets |

| 33. | KPI pump control. | 2 sets |

| 34. | Excessive pressure transducer PD100DI. | 1 set |

| 35. | Differential pressure sensor YNS-C106XWM08. | 3 sets |

| 36. | Network heating pumps: IPL 65 / 155-7.5 / 2, Q = 86m3 / h, H = 22m. | 2 sets |

| 37. | Boiler circuit pumps: Wilo-BL 65 / 130-5.5 / 2, Q = 86m3 / h, H = 17m. | 2 sets |

| 38. | Raw water pumps: MHI 203 0.55kW 3 ~ Q = 1.2m3 / h, H = 28m + frequency. | 2 sets |

| 39. | Security and fire alarm. | 1 set |

| 40. | Dispatching is a personal computer. Data transmission - GSM. | 1 set |

| 41. | Fire extinguisher, first aid kit. | 1 set |

| 42. | Chimney. Height 15.0 m | 1 set |

| 43. | External gas ducts, length 3.0 m. | 2 sets |

For all questions, please call the phone number listed in the "header" of the site.

Complete set of boiler equipment from TEPLOSTROYMONTAZH LLC

The main activity of TEPLOSTROYMONTAZH LLC is the provision of services in the market of heating systems and other engineering communications. Our engineers have been designing, installing and servicing boiler houses for more than 15 years, which has allowed us to accumulate extensive experience, which allows us to offer customers only high-quality boiler equipment that has proven its reliability over many years of trouble-free operation. The qualification of our specialists is confirmed by the fact that we are the official service center of heating equipment manufacturers: Buderus, Viessmann, Vaillant, Baxi, Protherm. You can get advice on all issues related to the sale, installation and maintenance of boiler equipment by phone or by sending your question to e-mail, specifying the phone number in the letter to contact you.