Thermal insulation of pipes: an important need

High-quality and inexpensive insulation of pipeline systems is essential everywhere, from small country houses to large industrial enterprises, shopping malls, etc.

If you initially include thermal insulation in the project and carry it out at the first stages of construction, then you can save significant funds on the repair and operation of trunk networks.

If we talk about the requirements for insulating materials for pipes, then they depend on the specific types of lines, as well as the conditions of their operation. In general, the main task of thermal insulation is to protect the insulated surfaces for the longest time possible.

Often, all these requirements are met by thermal insulation materials made of mineral fibers - their characteristics are simply ideal for various types of pipelines.

Indoor piping insulation

It should be noted that in the case of using mineral wool insulation for water supply networks, air conditioning and refrigeration equipment, it is possible to effectively protect structures from freezing, corrosion, and condensation.

In addition, high-quality materials will help reduce heat loss in the lines and significantly extend the period of trouble-free operation.

Main characteristics and features

Modern mineral wool thermal insulation is a fibrous material that is obtained as a result of melting of mountain silicates, slags, as well as their mixtures. Depending on the type of raw material used, insulating mineral wool can be either stone or slag.

In the first case, such rocks are used as basalt, limestone and diabase, while in the second - slag and metal production wastes.

Heat insulators made in the form of cylinders

Due to the processing of raw materials under high pressure and with a special temperature regime, it is possible to give mineral wool unique characteristics, in particular, in terms of its level of heat and sound insulation, as well as resistance to the negative effects of many factors, the material simply has no equal.

And in terms of cost, mineral wool is in a fairly affordable range - its price is much lower than that of polymer analogues.

Mineral wool cylinders - comfortable and practical thermal insulation

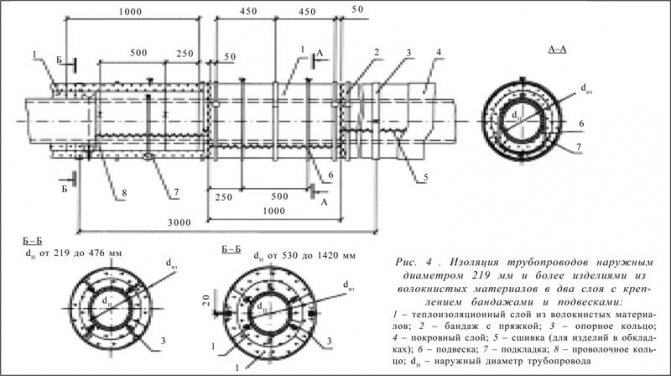

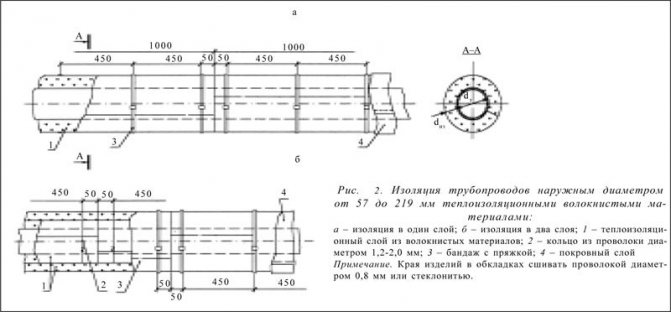

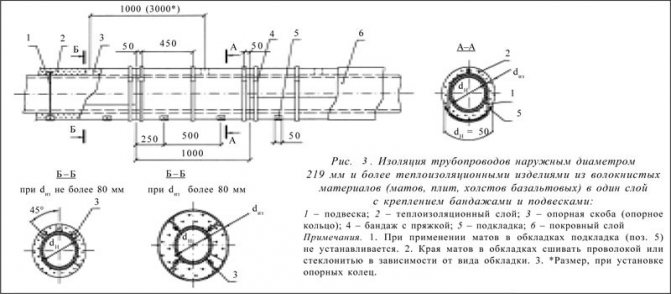

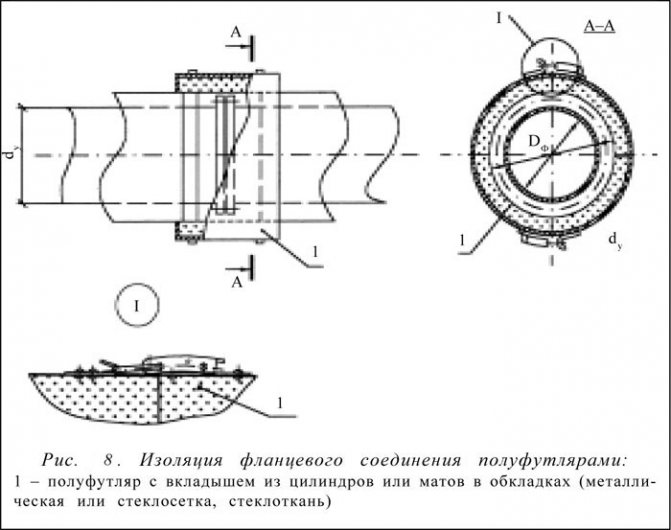

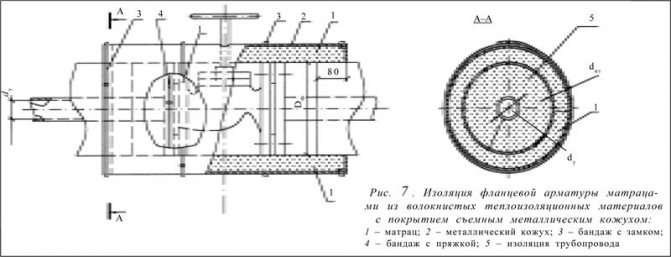

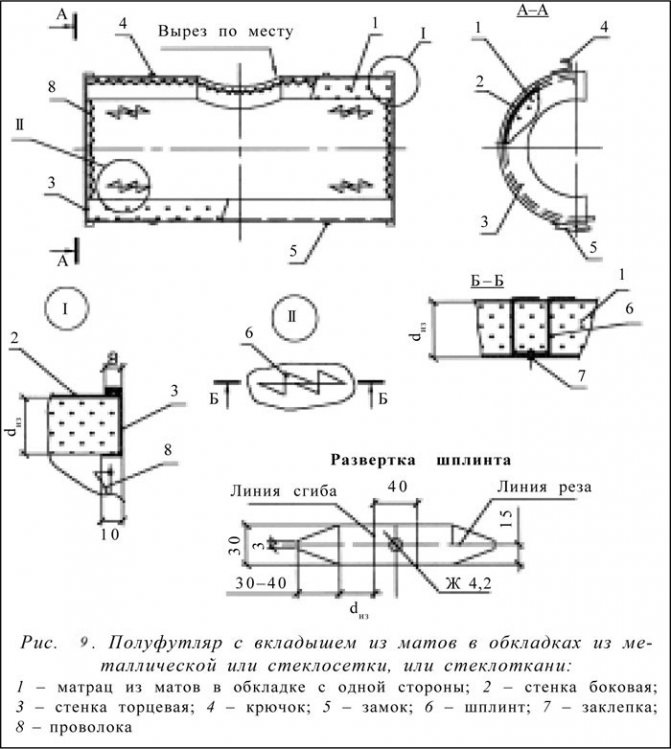

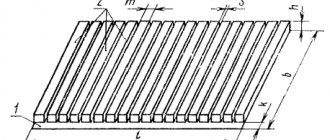

High-quality and modern heat-insulating stitched mats made of mineral wool are actively used for insulating pipes of various diameters and lengths. But at the same time, it should be noted that special cylinders made on the basis of mineral wool are more actively used.

These are products of a cylindrical shape, often made of basalt using a special winding technology.

An example of the use of basalt fiber insulation for insulation of external pipelines

Due to the use of cylinders and half-cylinders, the technology of thermal insulation of pipelines with mineral wool becomes extremely simple, it comes down to just a few basic steps.

Due to the large selection that the domestic market of heaters offers today, it is possible to choose the best option for each type of pipes, providing them with the best conditions for operation for a long time.

Advice. Cylindrical mineral wool insulation should be chosen directly under the outer diameter of the pipe. In this case, it will be possible to achieve maximum insulation values, to exclude the formation of condensation and corrosion under the layer of cotton wool.

As a rule, in most cases, all mineral wool mats and cylinders are additionally covered with a layer of aluminum foil, fiberglass, and fiberglass mesh - this helps to protect them from damage, fire and other negative factors.

Due to the special packaging in which the products are sold, it is very convenient to store and transport them.

Photo of material with additional coating of aluminum foil

Benefits of fiber ceramics

- Ceramic fiber mats are characterized by increased heat resistance, up to 1400 degrees Celsius. The price for these materials in the capital and the Moscow region varies at the level of 4700-4800 rubles per m³.

Designed for industrial applications, the insulation in private construction is used for the finishing of high-temperature equipment - in particular, for the insulation of stove and fireplace chimneys.

- High-density mineral wool panels have significant advantages in terms of compactness, but are more laborious to install with your own hands. Rigid insulation is fixed on the insulated surface with welded metal pins and disc washers.

- This method of fastening ensures a snug fit of the insulator, which has a positive effect on its effectiveness.

We can find high-quality insulation for air ducts! +7

Benefits of using mineral wool cylinders

A thermal insulation cord made of mineral wool or a full-fledged cylinder made of a unique material is the best option for insulating pipelines of various types.

The use of just such a form of heat insulator has a lot of advantages and benefits, among which are:

- Low level of thermal conductivity. Inside the layer of a cylinder made of mineral wool, a large volume of air is contained, which (due to the thin and flexible fibers of the material) remains stationary, does not allow heat to pass through;

- Resistant to fire and high temperatures. The instruction for the mineral wool cylinders says that they are non-flammable, do not melt and do not lose their shape even under the influence of extremely high temperature conditions (from -150C to + 750C);

- Long term of trouble-free operation. The use of basalt rocks as a raw material, as well as slag, extends the service life of mineral wool-based heaters by almost decades. On average, even the most inexpensive heat insulator can last 50-60 years without losing its performance;

Variety of choice of shapes and sizes of insulation materials

- Durability and reliability. Mineral wool can withstand even the highest loads and pressures with ease. Cotton wool has closely intertwined fibers, and therefore its density and strength are significantly increased;

- Hydrophobicity. The insulation has increased resistance to moisture due to protective layers of foil and fiberglass, due to this, it is not afraid of direct ingress of water. If necessary, you can additionally process materials with special hydrophobizing compounds;

Advice. If the pipeline is supposed to be used in conditions of high humidity, then it is best to subject the mineral wool to additional processing. Thus, it will be possible to extend the life of the highway, significantly reduce the cost of maintenance and repair.

- Availability. The price of mineral wool heat insulators is in an affordable range, which allows them to be used for insulating even long pipelines;

- Ease of use. Everyone can insulate even large volumes of pipelines with their own hands. The process of thermal insulation is quite simple, it requires the use of only available materials;

Mineral wool half-cylinders

- Environmental friendliness. Cylinders and half-cylinders made from natural raw materials are absolutely safe for human health and the environment. As a result, mineral wool materials can be used to insulate any pipes.

The effectiveness and benefits of using mineral wool heaters for pipes

Thermal insulation materials made of mineral wool, made in the form of cylinders, allow to achieve high efficiency, to provide the best operating conditions for the lines:

- Heat losses in straight sections of pipelines when using mineral wool will be reduced by almost 3.6 times. Unlike other materials, it loses only 8% of heat, which is very important, especially for hot water supply systems;

- Reducing the time spent on thermal insulation. It is no longer necessary to wrap pipes with fiberglass and mineral wool mats - the cylinders have an inner diameter similar to the dimensions of the line;

Easy cutting of the material with a knife during assembly

- Protective coatings will help to exclude damage to the cylinders from the insulation, to maintain the level of thermal insulation for a long time. At the same time, throughout the entire service life, the thickness of the insulating layer is not lost.

Advice. The use of a construction knife will help to simplify the process of covering pipes with mineral wool insulation in the form of cylinders and half-cylinders. Cutting materials with such a tool is much easier, and the dimensional accuracy can be observed.

Thermal insulation materials made on the basis of mineral wool in the form of cylinders are an excellent option for pipes of all types, sizes and lengths.

It should be noted that the domestic market is filled with offers from various manufacturers, you can choose the right type of insulation specifically for a specific pipeline with a specific diameter, length and types of transported material.

The use of special coatings for additional protection of thermal insulation materials from the negative effects of mechanical damage and other factors

Why do you need to monitor the state of insulation?

Insulation quality control of pipelines is a procedure that can and should be performed at all stages: from laying to scheduled repairs. Thanks to various methods and devices, it is possible to control the quality of the insulating material, the degree of surface cleaning, the integrity and thickness of the applied coating layer. In addition, in the course of research, there is a chance to identify all the "weak points" and defects of the insulating layer, and even in those cases when the structure is laid in a trench and covered with soil. It is for these purposes that devices and systems have been developed and produced that allow such actions to be performed.

Output

Mineral wool is a heater with unique characteristics, the best option if it is necessary to protect pipelines of various categories from the negative effects of temperature changes, the negative effects of various factors, ranging from chemicals to mechanical damage.

Due to its convenient shape and affordable cost, it is possible to choose the most optimal heat insulators for each specific case, ensuring the performance of a wide range of works without wasting time and money.

In the video presented in this article, you will find additional information on this topic. The process itself is very simple, accessible to everyone, even those who are not prepared for construction work.

Main types of devices

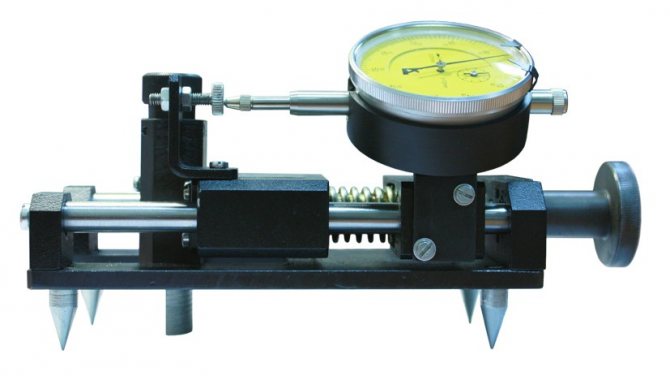

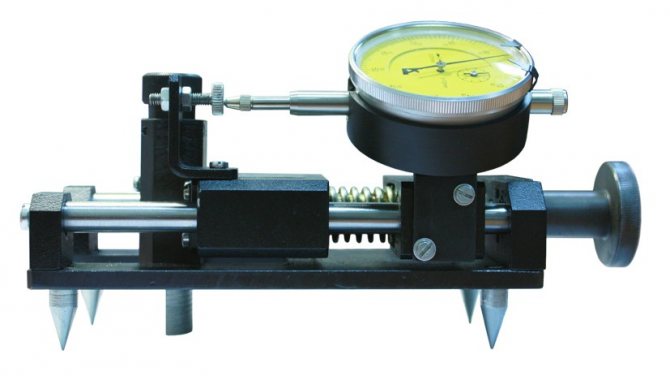

- Adhesion testers. Used to determine the bond strength between two materials. The devices, presented in different variations and based on different methods, make it possible to reveal: how reliable and resistant the structure is to the effects of aggressive media.If the coating is of high quality, then the system will last a very long time, and in order to improve adhesion, it is necessary not only to choose the right insulating material, but also to carefully prepare the surface before applying it.

- Thickness gauges. These are pipeline insulation monitoring devices, endowed with a number of advantages: ease of use, reliability, functionality and mobility. In addition, they are affordable, especially if purchased on the official website. The choice of a thickness gauge depends on the characteristics of the object under study, and if in some cases it is appropriate to use ultrasonic models, then in others, to solve the problem, electromagnetic ones will be required. Eddy current testing of pipeline insulation is also in demand in a professional environment, for which appropriate thickness gauges are used.

- "Searchers". This large group includes various devices (insulation damage seekers, metal detectors and locators) that help to contactlessly establish the state of the insulating layer and whether there are any defects on it, as well as at what depth and how the system is located. That is, control of pipeline insulation can be carried out without carrying out "excavations".

- Electrospark flaw detectors. They allow you to easily detect defects in coatings, and the operation of such devices is based on the use of a high-voltage method. If the insulating layer is thin, then care must be taken when carrying out such tests.