The South Korean company Hydrosta is known as the largest manufacturer of plumbing fixtures and components for laying a heating and water supply network. The lineup of the presented products includes ball valves, bimetallic radiators, pipe-rolling materials and elements for their fastening.

But, the most popular are gas boilers from this manufacturer. The company began to produce these products in 2003, and at the moment almost all of the enterprise's capacity is directed to this industry.

The Hydrosta gas unit is the perfect type of complete micro-boiler room. This type of equipment is intended not only for heating housing, but also for heating water.

If you hang two such boilers, then they will solve the problem of heating a house with an area of up to 400 sq. m. Equipping the unit with a closed-type combustion chamber allows it to be used in non-residential premises of a house up to five or more floors.

Design and control of these units

Of the design features of the Gidrost boilers, the following should be highlighted:

- Presence of a built-in microprocessor. It helps to track the tuning performance and smoothly change the power of the device. Also, the microprocessor controls the set temperatures of the heat carrier.

- Forced ventilation system. It effectively removes smoke gases.

- Remote Control. This is a portable mechanism: the digital indicator and sound signal present on it makes it possible to control from a sufficient distance.

- The functioning of the boiler nodal mechanisms is monitored by a telemetric system. If any breakdown occurs, a warning signal is immediately sent to the control panel.

- Modulated gas supply system. To increase the efficiency of these devices, they were equipped with electronic timers.

- Hydrosta boilers are small in size, modern design and easy to operate.

All error codes and their decoding

Consider the standard error codes for Immergas gas boilers:

| The code | Decoding |

| 01 | No ignition |

| 02 | The thermostat gave a command to block ignition |

| 03 | Smoke exhaust sensor malfunctions |

| 05 | Failure of the RH temperature sensor |

| 06 | Failure of the DHW temperature sensor |

| 08 | Unlock button does not work |

| 09 | Setting function started |

| 10 | The coolant pressure is lowered |

| 11 | Internal blocking |

| 12 | Boiler overheating |

| 15 | Boiler electronics failure |

| 16 | Fan failure, poor contact |

| 20 | The system detects a flame when the burner is off |

| 27 | Failure of air circulation |

| 31 | Control board problems |

| 37 | Critically low supply voltage |

Hinged boilers

Technical characteristics of mounted units:

- The heat carrier is completely protected from freezing.

- The wall-mounted version has a multi-level view of the security system.

- Hermetic design of the firebox.

- Hot water circuit. Equipped with two separate heat exchangers. They improve the performance of the device.

- Functioning principle. The heating of the outgoing gas is used to generate heat in greater quantities.

It's important to know: the excellent manufacturing settings of the wall unit allow it to be mounted in a very short time. There is no need to adjust the burner and do other difficult tasks.

Characteristics of floor-standing devices

Let's look at the example of Hydrosta HSB. They look like this:

These mechanisms are endowed with the same characteristics as the wall-mounted versions, but they are characterized by higher performance and additional functionality.:

- The heat exchanger is made of "stainless steel", which significantly increases the service life (up to twenty years).

- Reducing the noise level.The functioning of the mechanism was based on forced air injection, and the removal of waste after combustion. A special unit of the device - a muffler reduces the intensity of noise.

- The double-circuit mechanism Hydrosta HSB is installed in places with a large heating area. The equipment with a built-in storage tank significantly reduces the time for heating the liquid.

Diesel use

An excellent alternative to the options operating on gas is the floor-standing double-circuit diesel mechanism:

Speaking about these models, one should immediately note their shortcomings:

- Increased noise during the operation of the inflatable burner.

- The need to install a large container for fuel.

There are also some features of setting up this heating unit. They depend on the type and quality of the fuel oil.

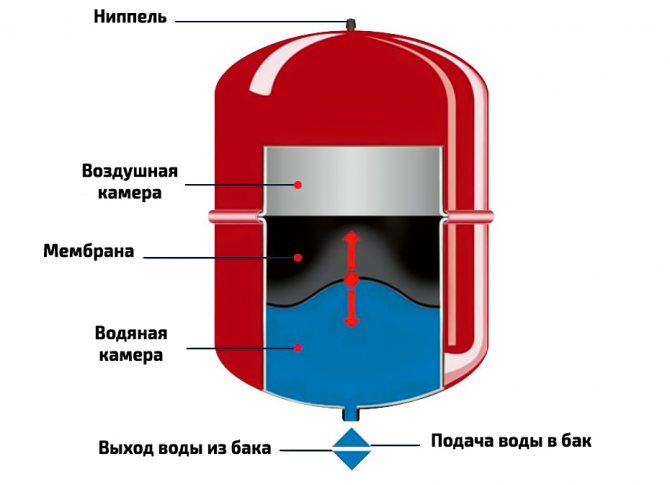

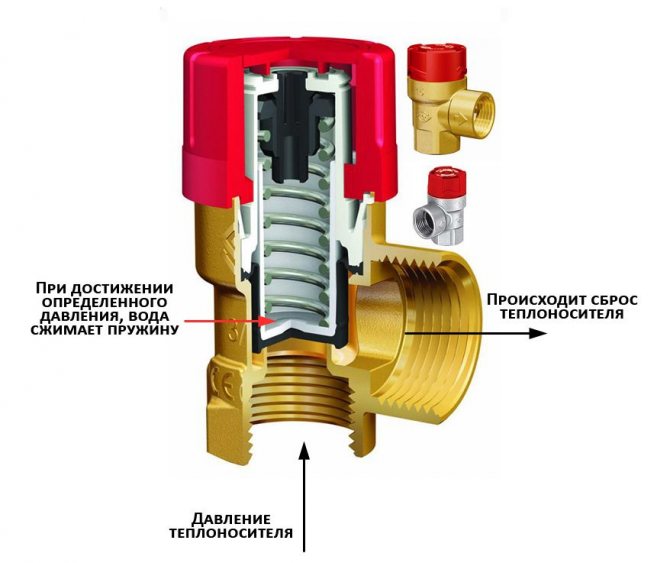

The basic set of the device assumes the presence of an expansion tank, a circulation pump and safety options are also included here. You can control these mechanisms using a remote control and even a smartphone.

It's important to know: the double-circuit diesel boiler needs regular maintenance. It includes cleaning the furnace, cleaning the chimney system, cleaning condensate and more.

If you neglect this, then as a result, the performance of the device will noticeably decrease.

We troubleshoot Gidrost gas boilers

_______________________________________________________________________________

_______________________________________________________________________________

The double-circuit wall-mounted boiler Hydrosta HSG 160SD does not start. While pressing the start button, the burner is functioning. But it is worth not fixing the button, the device immediately goes out. Explain the cause of the breakdown? Perhaps the thermocouple is out of order or the gas valve is broken. There may also be a reduced gas pressure in the supply pipeline. In some cases, there is a lack of voltage on the electronic board. There is a problem. The start is very difficult. The igniter is on, but there is no flame on the main burner. Help me figure out what is the reason? Most likely, a functional failure of the ignition device. We advise you to service the boiler and clean the ignition unit. Why does the wall-mounted boiler Hydrosta 100 not turn off when it reaches the required temperature? It heats up to 85C, then goes into an accident. After the restart operation, the problem starts again. Perhaps the control board is out of order, the boiler water temperature sensor is damaged, the protection sensor button has a problem. It cannot be ruled out that an error has occurred in the adjustments of the automation. Please tell me why the boiler does not heat above 70 C? We need to raise the temperature, but the display says that this is the maximum parameter. How to increase the heating temperature? If the unit is unable to realize an increase in the heating circuit temperature, the following causes are likely. In the adjustments, the maximum heating temperature limit is set to no higher than 70C. A decrease in the chimney draft is noted. The Hydrosta HSG 200SD boiler is unstable in terms of heating the hot water supply system. From the tap, alternately cold water is poured, then hot. Can you tell me why this is happening? The sources of the malfunction may be as follows. There is cold water mixing due to the 3-way valve not working properly. The heat exchanger is very dirty. We recommend that you clean it up. Water leaks regularly from the tap under the boiler. The device itself does not turn on. What should I do? Apparently, there is a discharge of the coolant from the safety valve. In this case, this indicates a high pressure in the system. Also, the filling valve of the system could not be closed or it was necessary to pump up the expansion tank. Could you tell me what kind of malfunction happens when the pressure jumps up around the clock and at the same time the relief valve comes into action? The display shows a constant heating symbol when the unit heats up. How to be? There is a problem with the heating circuit temperature sensor. The water circulates poorly in the heating line.What is the problem if the Khudrost wall-mounted gas boiler periodically turns off? In particular, the ignition has not functioned at all recently. The instrument was cleaned that month. What could be? It looks like there is a problem with the flue gas venting device. A chimney inspection is required. Incorrect operation of the ignition element means damage to its parts due to intermittent voltage or water leakage. Can you help me fix my chimney problem? It will soon be three days, as the reverse draft is observed, while the smoke immediately penetrates the kitchen. The chimney was made by myself. It consists of a metal tube. There must be an error in the calculations. The boiler heats up DHW without any problems, but when heating starts, the water quickly boils and the unit stops working. What can be faulty and how can I fix it? Perhaps the circulation pump is not working, the electronic board is out of order, the temperature sensor is faulty. The filter mesh could also be clogged. In the hot water supply cycle, the unit alternately began to produce cold and hot water. I just can't understand what it depends on. How to regulate the heating of the heating medium? Apparently, the heating system is dirty or the heat exchanger needs cleaning. In addition, there may be damage to the pressure control switch or the circulation pump may break. The main factor is the incorrectly manufactured structure of the chimney. Soot can build up on the pipe walls, which greatly impairs its effectiveness. In addition, it is advisable to control the hood in the house. We use a double-circuit boiler Hydrosta HSG 100SD. He instantly picks up the temperature to 96 C, but then gets up with overheating. Later, when it cools down, it starts to start on its own. How to fix the breakage? Suspension of overheating operation means that there is no circulation process. Initially, you need to monitor the heating radiator taps. They must be in the open position. Next, an inspection is carried out for clogging of the filter, and you should also make sure that the heat exchanger is not clogged. I installed this model in the fall of that year. After about 2 months, the device sometimes began to make noise. Explain why he is making noise? The presence of scale in the heat exchanger is likely. If the water is hard, limescale deposits will eventually build up on the pipe wall in the radiator. We would like to connect the Gidrosta 160 gas double-circuit boiler to the heating system. Tell me how to correctly put such a unit into operation? For the correct start-up of this equipment, you must do the following. Connect the power supply to the unit. Open the gas valve. Then we turn on the main burner. Then adjust the desired temperature. I need repairs. Please advise how to drain the water from the device yourself? According to the manual, this procedure is implemented as follows. Disconnect the device from electricity. We turn off the gas valve. We open a little automatic air vent. Open the drain valve completely. Then we remove the spilled water. If necessary, the water can be drained using the relief valve. This valve is mounted at the bottom of the apparatus. Please tell me how you can diagnose a three-way valve? I think that this part does not fully open. In heating mode, it does not pump distant radiators, however, the pipe heats up to the DHW to supply the coolant under the boiler. Of course, we recommend checking the three-way valve for the presence of a hanging of its stem in the middle position. We also recommend checking your heating system. I installed and connected the HSG 130SD boiler in the country. Until this morning, he acted without question. At the moment, after five seconds after switching on, it began to go out. It seems that he is unable to deliver water to the system. Tell me, what is the source of the problem? A possible factor for this failure may be the ignition electrode, which does not detect fire, or a lack of circulation.The other day, there was a problem with this unit. While working, he began to whistle. I decided to restart - the attempt was successful, but no changes occurred. Maybe someone will explain what is the reason for the whistle? Very often, a sharp whistle appears if the pressure setting on the gas burner nozzles is incorrect. It is required to check the gas pressure adjustments and correct if necessary. The boiler was recently filled with water, and it began to function intermittently. For example, if you set any temperature, and the heating mode goes from strength to 25 degrees, and then the unit turns off. Tell me what could be out of order? If the control board unit has been flooded with water, it is most likely damaged. Try to reboot it by completely disconnecting the device from the mains. Then re-enable and test its functionality. A week ago, we installed a gas double-circuit wall-mounted boiler Hydrosta HSG 250SD. Today, during start-up, the wick burns for 8 seconds, the main burner does not catch the flame, which is why the device goes out. How can I fix the breakdown? Probably, the ignition mechanism is out of order or a malfunction in the burner. In any case, see if the phasing is correct when connecting to the mains. We launched the same device in the middle of this year. Presumably after 4 months, there was a malfunction in the DHW circuit, although the heating mode is functioning normally. I tried to use hot water, but it only indicates the temperature, and is not going to heat up. What is the cause of the problem? Possibly the problem is the 3-way valve. He needs to be replaced. I would like to know why a safety temperature sensor is needed in the boiler? This component stops the gas supply to the gas burner unit in case of overheating of the water in the main heat exchanger. It is required to wash and clean the main water heat exchanger. Can you tell me what steps to take to remove it professionally? The primary heat exchanger can be easily removed from the unit with a simple screwdriver. The following is the order of dismounting. We drain the water from the device using the drain cock. The next step is to empty the hot water supply system. Unscrew the heat exchanger fastening screws and remove it from the frame. We connected the Khudrost boiler. After about three months, the water pressure in the unit dropped. He constantly slows it down and stops. More precisely, it does not hold pressure at all. What could be faulty? If the unit does not build up water pressure, there may be a leak from the make-up valve. If a shutdown occurs and the water pressure drops to 0, then the three-way valve has a defect. Explain how to clean the cold water filter? The first is to drain the hot water system. Second, unscrew the flow sensor nut. Then we take out the sensor together with the filter from the recess. After removal, we clean the accumulated impurities and dirt. The HSG 400SD boiler hummed earlier during the switch-on period, but now the noise has increased. At first, the sound was not heard for long, but now it is heard much longer. Has anyone met this problem? The appearance of additional noise indicates the presence of limescale inside the heat exchanger, which heats up unevenly due to the different wall thicknesses. The more the heat exchanger becomes dirty, the more distinct the sound of the noise, and, accordingly, the heat transfer decreases. The appliance is functioning, but water does not seem to be circulating through the system. Very hot return pump What could have happened? Most likely, the mud filter is clogged or there are closed taps somewhere, which interferes with the passage of the coolant. The circulation pump may also fail. What causes the hot water to stop heating? The water is barely warm. Tell me what happened? Damage search is carried out in the following directions. For example, a breakdown of the DHW temperature sensor, it is required to replace the sensor. It is possible that the power adjustments of the device for heating hot water have gone astray. A breakage of the spark is constantly visible during ignition.The burner is not dirty, the chimney is normal, the draft is good. What could be the malfunction? The device does not detect a spark due to a weak signal from the combustion mechanism. Here it is necessary to diagnose the wiring between the ionization sensor and the electrode. You might need to tighten it up. There may also be damage to the sensor insulation, which must be replaced.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

The Baxi main four 240 boiler is in operation, it turns off with an error E35 (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 24 kw boiler, single-circuit with built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you turn off the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation.When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a malfunction?

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit.Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When it works on a unit, it beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently started showing error 14. How can you fix the breakage?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?