Solid fuel boilers have become part of the everyday life of private households. When constructing a new building or replacing obsolete equipment, the owner is faced with the question of choosing a boiler plant.

In addition to the criteria of reliability and cost, the time spent plays an important role. For those who do not have the opportunity to fill fuel and clean ash several times a day, the Stropuva solid fuel boiler for long burning is suitable.

History of creation

The creator of the Stropuva boiler was the Lithuanian engineer Edmundas Strupaitis, who invented a top-down combustion device in 2000. Already in 2005, the sling heating boiler was awarded the CE certificate, which confirms the high quality of the device. And in 2008, in Lithuania, the construction was named “The Best Product of the Year”, and then the boiler was supplied to Russia and other European countries. Today, Stropuva boiler furnaces are sold in most EU and CIS countries.

The official distributor of the Lithuanian company in the countries of the EAEU Customs Union is Baikal Service LLC. Construction of the plant enterprise "Stropuva Baikal Service" for the manufacture of boilers in the territory of the Russian Federation began in 2012. Today, more than 100 dealers in different regions of the country are engaged in the sale of these factory products.

Review of boiler equipment and owner reviews

Stropuva - A distinctive feature of the operation of these boilers is combustion from top to bottom. Those who have used the equipment for several years have seen both their advantages and disadvantages.

About 200 kg of good quality coal is loaded at a time. The boiler must be cleaned before loading. It is noted that a lot of ash is also obtained.

Among the disadvantages: in frost, on the last day before cleaning, it is cool in the house, and you cannot "throw up" fuel, you must wait until the end of the combustion cycle.

“I worked on coal for a maximum of three days, if it’s even less on wood and it’s twice as expensive.

So this heater is not for everybody who likes to pant a lot every three days and then don’t come up, then this is the boiler for you ”.

Buleryan - users note good heat transfer, even the smallest of the proposed Buleryanov line heats a house of 80 m2, but the stove is demanding for a good draft, therefore, the chimney must be carefully insulated, or coaxial. The greatest heat transfer is observed during the period when the stove is full of firewood. A specific appearance requires a certain design approach to the entire interior of the room, otherwise it will not look.

Viadrus U22 D - a heavy boiler, for which you need to organize a reliable foundation. It is heated with short wood no more than 34 cm long. It is unpretentious in terms of fuel moisture. The automatic temperature regulator works properly, closing the smoke flap if the expected temperature is exceeded. Not all users like the small volume of the cast-iron chamber for fuel; in severe frosts, they have to monitor the temperature and throw up firewood or coal in time. Although, the very fact of such a possibility can be considered an advantage (in contrast to models in which a full fuel cycle must go through).

Due to the small combustion chamber, Viadrus U22 D shows itself as an ordinary solid fuel boiler, requiring the attention of the owner.

Buleryan stove

Galmet - the line includes models of different capacities, which can be selected individually for different heated areas and conditions (for example, manual loading or automated). When loaded manually, the oven requires attention twice a day.You can load 2 - 3 buckets of coal at a time. The unit needs to be cleaned every week.

Boilers delight owners with a stable coolant temperature and the ability to automatically adjust it based on the temperature outside the window. In addition, the boiler can be converted from one type of fuel to another. It works both on "inferior pellets" and on coal.

Users praise Galmet boilers for their easy cleaning process. Yellow plaque is peeled off the walls freely and without great physical and time costs.

Dakon DOR 12 - according to buyers, the model requires a very good coaxial chimney, preferably 8 meters high, otherwise it starts to smoke.

The smoke at the exit from the fuel chamber is about 60 ° C, which indicates a high efficiency of the device.

Dakon boilers are called “capricious” in terms of coal quality and size.

Although the device can be heated with wood, but in this case, it has to be paid much more attention.

However, if the owner manages to find the type of coal recommended by the manufacturer, then the boiler will conscientiously work out its cost.

Danko-80T - boilers of domestic production, which will always find their buyer, due to their budget. At the same time, the equipment shows good heat dissipation. And many users see only good in them, without denying that boilers require more attention to themselves than is expected from long-burning equipment.

The build quality of individual copies leaves much to be desired, leaks occur.

Due to its affordable price, Danko is a suitable boiler for the first experience and experiments (for example, you can try pellets). However, if you are looking for a “set and forget” boiler, it is better to consider other options.

Are you planning to purchase a furnace with a water circuit? Take a closer look at the Breneran water loop oven - read about design features and installation requirements.

Read on about the pros and cons of hybrid boilers for wood and electricity.

And in this thread, there are recommendations for making the simplest home-made boilers for long burning from an iron pipe, barrel and other materials.

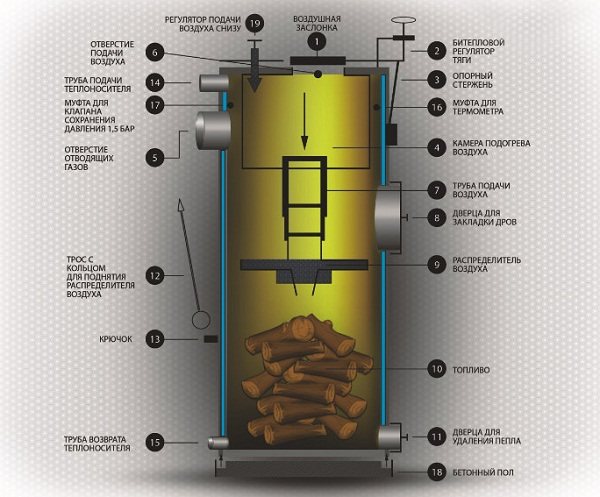

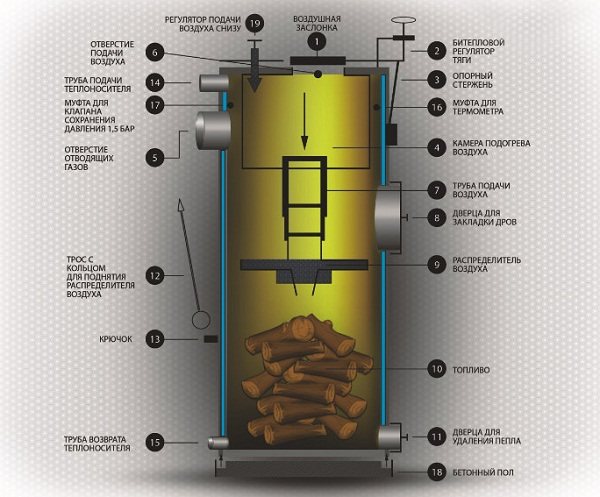

The structure and principle of operation of the wood-burning boiler Stropuva

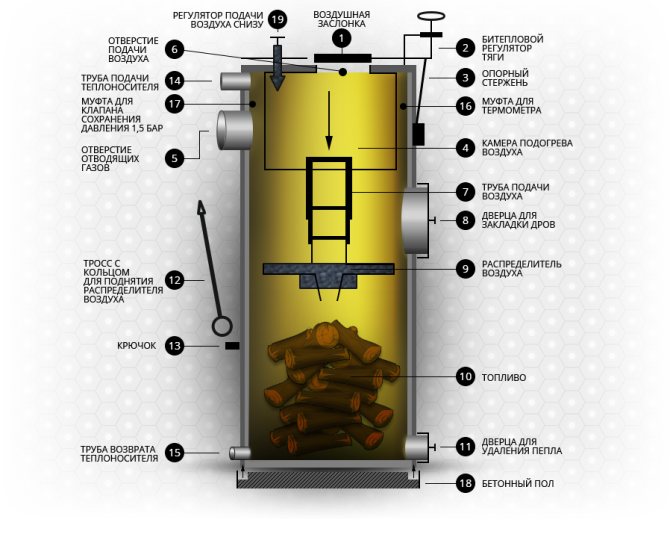

The body consists of two main parts: a cylindrical container placed in another, the same cylindrical container, which are "wrapped" in thermal insulation. The coolant circulates in the cavity between the containers. The firebox is located inside a small container.

The bit-temperature draft regulator makes it possible for the boiler to independently, without human intervention, regulate the volume of air flow into the furnace. The action of the regulator is based on the fact that the boiler body expands during warming up and the bit-temperature regulator closes the damper automatically. If the combustion slows down, then the opposite action takes place - the body cools, contracts, and the regulator opens the damper.

Just like in the Bubafon stove, the combustion process is carried out only in the upper zone of the bookmark, an adjustable volume of oxygen enters it through the air distributor pipe (also called the heel or piston), which has a positive effect on the duration of the boiler burning. Before entering the furnace, the air is preheated in a special air heating chamber located in the upper zone of the boiler.

There is always an air distributor on the tab, and when the fuel burns, it goes down.

Important! The boiler efficiency can be increased or decreased by changing the volume of air intake.

Based on the type of boiler Stropuva, firewood, pellets and coal can serve as its fuel. To work on coal and pellets, universal boilers with a U attachment are used, equipped with a damper and a grate.

The boiler has two doors:

- Top door - for loading fuel;

- Lower door - for ash removal.

At the back there is a chimney hole. The inlet and outlet of the coolant are also located there. All boiler models for supply and return are equipped with a 32 mm pipe.

Boiler power

When choosing a quality boiler, you should always pay attention to its power. The size of the room that can be heated will depend on this indicator. So that each person can choose his own version, it produces boilers of three different classes. They all have different capacities and can be used in different conditions. Some are suitable for small houses and sheds.

View gallery

Other boilers (solid fuel) Stropuva, in turn, are designed for large stores and warehouses. Units of the first class have a power of 10 kW, while they are capable of heating up to 100 sq. m. The second type of 20 kW can already cope with a room up to 200 square meters. m. Solid fuel boilers Stropuva of the third class have the highest power - 40 kW. This is quite enough to heat an area of up to 400 sq. m.

Design advantages

- In autonomy. Long-burning wood-burning boilers have no electronics, therefore there is no dependence on electricity, and the combination with heating systems with natural circulation of the coolant makes them completely autonomous. Universal boilers that run on different types of fuel do not differ in such autonomy, because they are equipped with an automatic option for oxygen supply to the furnace, which uses 15-20W / h.

- High efficiency, which can be adjusted by decreasing or increasing the volume of incoming air.

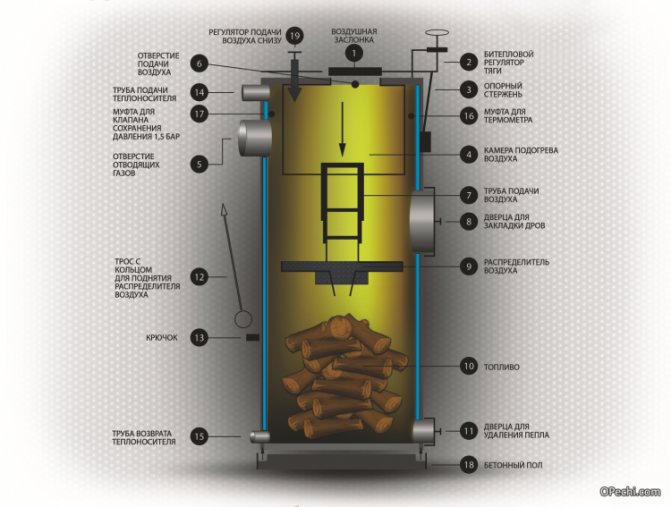

- In long work on one fuel tab. With a minimum air supply, such a boiler on one tab of firewood will work up to 31 hours, and at maximum mode - up to six hours. Universal boilers are distinguished by the most productive "performance" among the general lineup of sling. When operating on coal, the duration of combustion with the minimum mode is designed for 130 hours, and with the maximum mode - for 32 hours. When loading pellets, the burning time is calculated up to 72 hours.

- Beautifully designed.

You should also know about negative reviews, this is your safety:

For the universal S10U model, the required volume of fuel for one portion of 10 kW is:

- coal - 50 kg;

- firewood - 25 kg;

- pellets - 90 kg.

Important! For optimal operation, it is best to select the boiler power with a 30% margin compared to the area of the room that is heated.

Installation and operating recommendations

To install the device, choose an isolated room equipped with supply ventilation or an opening window. The height of the boiler room ceilings must be at least 2.5 m, the area - from 4 sq. m. Installation work is carried out clearly according to the instructions.

Installation features:

- the boiler is installed on a concrete foundation 10 cm high from the floor or on a non-combustible base;

- the bottom is lined with concrete mortar, the joint is closed with a heat-resistant sealant;

- observe the intervals: in front - at least 1 m of free space, behind - 0.6 m, from the side to the wall - 0.6 m;

- the joints of the apparatus with the chimney and the heating system are carefully sealed.

The heat generator is a source of increased danger. The boiler room should be equipped with fire extinguishing means and a container with sand for emergency extinguishing of the hearth.

Other features of operation:

- do not store fuel and other combustible materials near the heater;

- once a month, it is necessary to check the condition of the chimney using a mirror, if necessary, clean it from soot accumulations;

- operation in systems with forced circulation is not allowed in the event of a pump failure or a power outage;

- when heating with wood, ash removal is carried out as needed;

- when using peat or coal, the ash pan must be cleaned each time before a new laying;

- it is advisable to lubricate the distributor lifting cable with oil to prevent wear;

- it is necessary to inspect the doors for tightness of closing.

Work reservation

The use of two or more boilers in the heating system is justified by the risk of damage to one of the devices. The circuit is also used to quickly build up power if necessary.

Stropuva units are easily assembled into a cascade, thereby increasing the reliability of the heating system.

Advantages of a cascade installation:

- uninterrupted operation (if one device fails, the other will continue to work);

- increased power (in the off-season, you can use one unit, in the winter - two);

- ease of repair and maintenance;

- saving space in height (for confined spaces - attics, basements).

The disadvantage of parallel connection is that for each device you have to connect a separate piping unit and chimney. Study the Grundfos circulation pump at the link.

Sling boiler: chimney

To a greater extent, the boiler efficiency will depend on the draft in the chimney. At low draft, the combustion products will not have time to leave through the chimney, and as a result, the boiler will begin to smoke, so the room will gradually fill with smoke, and the combustion process will slow down in the firebox.

Usually, lack of traction occurs for the following reasons:

- The chimney height is insufficient. It should be 50 cm higher than the ridge;

- The chimney is filled with combustion products (soot, tar, etc.);

- The chimney diameter is not wide enough;

- Incorrect dimensions of the horizontal chimney zone (length must be at least 20 cm, but not more than 150 cm).

Increased cravings result in:

- increased combustion temperature;

- excessive consumption of fuel;

- high noise during the operation of the boiler.

When arranging a chimney, special attention should be paid to fire safety. The chimney connection to the boiler must be made of metal. All joints of the joints must be tightly sealed. And one more thing - it is necessary to regularly clean not only the chimney pipe, but also its horizontal part, because accumulations of tar and soot can ignite and form a fire.

Chimney installation

The good news: Stropuva boilers can be connected with your own hands if you have experience of similar work in plumbing. If there is no skill, a direct road with specialists. Attention to the installation instructions - installation is different from other solid fuel boilers with long burning.

Stropuva

Important! If the chimney is installed incorrectly, you put yourself and the equipment at risk. Violation of the requirements leads to the following consequences:

- unstable combustion, lack of traction;

- the formation of condensation, less often - the formation of air locks;

- accumulation of carbon monoxide.

The listed cases are rare, but they happened in practice before. Today, automation will protect you in advance from such large-scale troubles. The most likely failure, due to an incorrectly installed chimney, will be the damping of the boiler and the cessation of combustion. This will be very annoying, especially on frosty winter nights with winds and blizzards.

Stropuva's boiler

Therefore, the final height of the chimney must be calculated taking into account the height of the house along the ridge. It is better for the pipe to protrude above it. If the set of equipment includes a smoke exhaust fan, it can be limited to a 4.5 meter pipe. But, it is better not to take risks and protect yourself from all sides.

Table 4. Installation parameters of chimney pipes of Stropuva boilers

| equipment identification (all the above models are universal) | Chimney diameter (recommended), mm | Height from the floor to the lower edge of the outlet for exhaust gases, mm |

| Stropuva S-U 10 kW | 180 | 155o |

| Stropuva S-U 20 watts | 180 | 1695 |

| Stropuva S-U 40 kWt | 200 | 1675 |

Tips for operating a wood-fired boiler slings

one). When loading the firebox with wood in the upper zone, it is best to lay larger logs at the edges, and smaller ones in the center (no more than 0.5 kg).This is necessary to prevent the formation of a lot of smoke during kindling.

2). It is necessary to fill the firebox completely, this will enable the boiler to work longer on one tab.

3). It is forbidden for air to enter the firebox through the ash cleaning door. During the operation of the boiler, the lower door must be tightly closed.

four). When using firewood, remember to thoroughly clean the ash once a month. When using coal, the ash is removed each time before refueling.

five). It is impossible to raise the air distributor during combustion, because after lowering it, most likely, it will take the wrong position and can sink deep into the combustion area, which can affect the operating time of the wood-burning boiler for long-term burning of the sling.

6). The moisture content of the wood should not be more than 30%, otherwise, as a rule, the fuel will not ignite at all, or it will burn weakly, which will not allow the required coolant temperature to be reached.

preparation of advertising to make ultrasound of the pelvic organs

Share on social media networks

0

Tweet

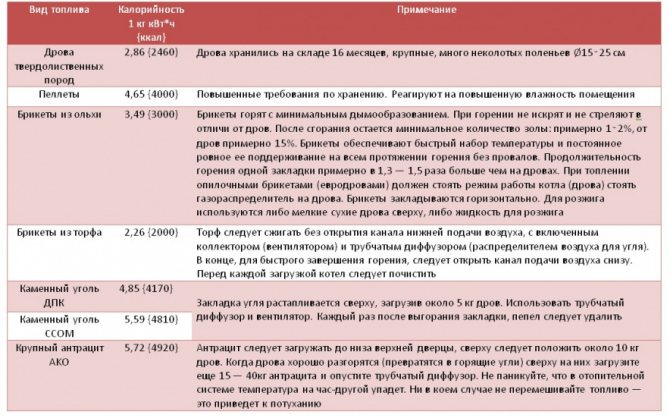

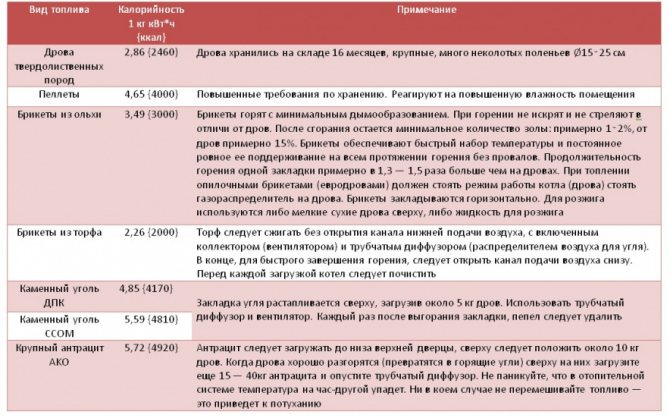

Which fuel is suitable

There are several fuels available.

Stropuva units heat:

- Hardwood. The logs are laid evenly over the volume of the firebox. Long ones in the middle, short ones at the edges. The bookmark should be completed with large wood and about 0.5 kg of wood chips or shavings for ignition. There is a lot of ash left from fuelwood, which must be removed regularly.

- Wood briquettes. Briquetted material burns longer and more evenly than firewood. It is laid horizontally. Small dry chips are taken for kindling.

- Peat and briquettes from it. When burning, the material exudes a characteristic sour smell. Working on peat raw materials, the boiler emits more harmful substances into the atmosphere than on wood. This type of fuel should not be used in urban environments.

- Large anthracite. It is used only in conjunction with wood, otherwise it burns out badly. It is recommended to remove unused pieces from the ash and add them to the firebox at the next filling.

- Coal. Combine with wood for ignition. Low-quality coal is laid in layers, alternating with logs.

Recommendations for each type of fuel are presented in the table.

Heating history

From the moment mankind needs heating in cold weather, all fuel combustion processes occur according to the same principle, the best example is the design of the Russian stove.

We put the fuel in, open the blower from the bottom, and ignite the fuel also from the bottom. The combustion process begins - the fuel begins to burn all at once, according to the principle of a fire. It burns well and hot, but not long and not efficiently - some of the fuel burns out “just like that”, and the heat flies into the pipe! To keep the combustion process at one, fairly stable level, it is very often necessary to throw in all new and new fuel. Otherwise, the combustion will die out very quickly, and the fuel will burn out ineffectively!

It is this principle that underlies the design of any of the existing solid fuel heating devices - it is always a “fire”. It doesn't matter what we are talking about - a modern pyrolysis boiler, an ordinary potbelly type boiler or pellet boilers with a hopper, a feed mechanism and an electric burner, or a Russian stove.

Fuel for boilers

Solid fuel boilers Stropuva can operate on:

- ordinary logs;

- briquettes made of wood and peat;

- sawdust;

- coal;

- pellet granules.

When using only firewood as fuel, the boiler will work up to 1.5 days on a one-time tab. The use of wood pellets can ensure the burning of one bookmark up to three days, the use of coal - up to five days. All this is possible thanks to a special patented combustion technology.

Combustion technology of the Stropuva boiler

Universal boilers Stropuva

The advantages of the multi-fuel series include the ability to operate the boiler on almost any type of solid fuel:

- Angle.

- Pellets.

- Wood waste.

- Firewood.

The universal solid fuel boiler Stropuva, according to research and consumer reviews, can be attributed to the most economical types of heating equipment manufactured by Stropuva.

The use of exclusively wood waste is not allowed. A small amount of good quality solid fuel will need to be added with each firebox. Universal dual-fuel boilers Stropuva coal-firewood need regular maintenance.

In practice, it has been proven that coal is the best choice for a combi boiler. This type of fuel significantly increases the battery life from one bookmark, as well as the efficiency of heat transfer. In normal mode, without extreme loads, the unit is capable of operating up to 130 hours. The firebox has a capacity of 220 kg. It is not allowed to lay coal during the combustion.

Installation and operation of boilers Stropuva

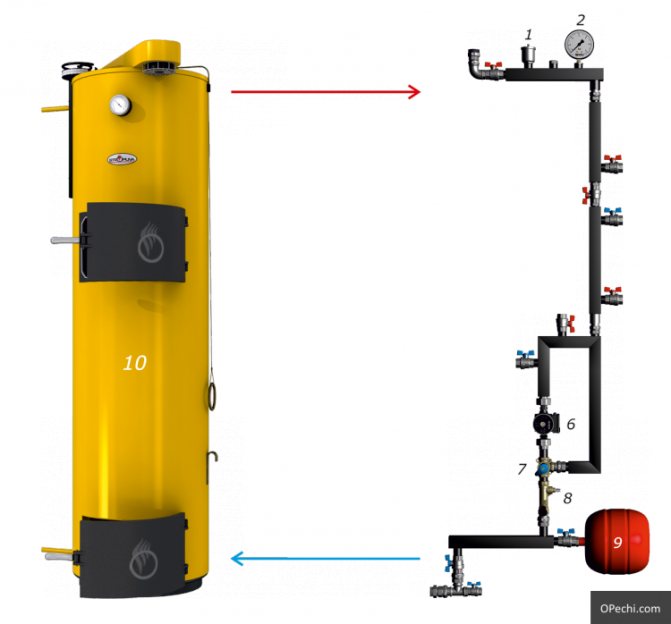

During installation and connection, it is necessary to adhere to the basic rules that apply to all solid fuel units. In the building there are two taps for supplying and returning the coolant, and connecting to the central heating of the house.

Installation of an overheating protection system is mandatory. If necessary, install circulation equipment.

A check valve and a coarse filter must be installed in the boiler piping. For the universal and pellet model, you will additionally need to purchase and install an air manifold.

The chimney is located at the rear of the body. Installation of the chimney with insulated sandwich pipes is recommended.

Cleaning from carbon deposits is necessary after each burning out of fuel. It is carried out through a special hatch located at the bottom of the boiler.

The kindling is carried out as follows:

- The air damper opens, and the draft regulator is fixed in the raised position with the help of a cable.

- Firewood is laid in layers. As a rule, large logs are located in the center of the firebox, small ones along the edges.

- The top layer is filled with sawdust and chips. Throwing up firewood until the already laid fuel has burned out will not work, due to the internal structure and the principle of operation of the unit. Therefore, it is immediately necessary to fill the firebox (except for the first kindling) completely.

- The reason for the lack of draft may be the accumulation of soot in the chimney, as well as insufficient heating of the chimney. Therefore, it is recommended to leave the damper open until the firewood is on fire. This will provide good traction and reduce condensation.

Stropuva boiler piping schemes

Stropuva boilers were able to truly solve the problem of the autonomy of solid fuel equipment. Of course, they also have their drawbacks, but their choice is the best solution when heating a private house with no gasification capability.

Reviews of different types of boilers brand "Stropuva"

By visiting a store of relevant products, you can find universal boilers for long burning and those that run on solid fuels. The latter variety can use not only firewood, but also wood waste during its operation. According to users, the main distinguishing feature of these devices is independence from power supply. With the help of such units, it will be possible to heat the room, even if there is no electricity.

The universal boiler "Stropuva" is also a popular product of the company. It is possible to load wood waste, firewood, peat and sawdust briquettes into the furnace of such a device, regardless of their moisture level and quality. As users emphasize, for the operation of such a device, an electrical connection is required. This is the only way to regularly supply oxygen to the furnace. In one hour, the boiler will consume 20 watts, which is very economical.

Reviews about the boiler "Kotlant KG-10"

This boiler (solid fuel) long burning reviews from consumers are very diverse. In general, this company is quite famous not only in Russia. This model differs in ease of use. At the same time, it is very comfortable in service. This was largely achieved due to the well-thought-out design of the device.

Thus, ash can be removed very quickly. At the same time, the door is quite large, and its handle never heats up. The temperature of the device can be monitored by indicators. Additionally, this boiler (solid fuel) of long burning has good reviews due to the air flow control regulator. As a result, the user has the opportunity to customize the equipment personally according to his needs. As the owners note, this model is in demand in small houses, as well as in summer cottages.