Gas preservation of hot water boilers

Argon reducer.

Let us first analyze the preservation of boilers with gas. The bottom line is that gas is pumped into the heater, which, in contact with wet metal surfaces, does not start oxidation processes, that is, corrosion. The gas completely squeezes out the air, which contains oxygen. Can be used:

The instructions for the preservation of hot water boilers have a clear algorithm of actions. First you need to fill the heater with deaerated water - this is water from which air is removed. But in principle, you can also fill in ordinary water. Then a gas cylinder is connected to the upper pipe of the heater.

The pressure in the gas cylinder is enormous, about 140 atmospheres. If you give such pressure directly to the heating boiler, it will burst. Therefore, a reducer is screwed onto the cylinder.

It has two pressure gauges. One manometer shows the pressure that comes from the cylinder, and the second manometer shows the pressure that is supplied to the boiler. The required pressure can be set on the reducer and when this value is reached, the gas supply from the cylinder stops. Thus, it is possible not only to safely fill the boiler with gas, but also to build up the pressure to the required value (0.013 MPa is recommended).

The process goes something like this:

- gas slowly squeezes water out of the boiler (the lower branch pipe must be open);

- after all the liquid has left, the lower branch pipe is closed;

- when the pressure in the boiler reaches 0.013 MPa, the gas stops flowing;

- the upper branch pipe to which the reducer is connected is blocked.

From time to time it is necessary to check the gas pressure and, if necessary, make adjustments. The main thing is to prevent air from entering the boiler.

4.1. Mothballed boilers and auxiliary equipment

4.1.1. It is prohibited to put steam and hot water boilers into reserve without taking the necessary measures to protect the metal of the boilers from corrosion.

4.1.2. Boilers must be preserved in one of the following ways: for up to one month - filling the boiler with an alkaline solution; for a period exceeding one month - the use of desiccants or sodium nitrate solutions.

4.1.3. For dry preservation of boilers, dehumidifiers should be used: calcium chloride (CaCl2), MSM silica gel, quicklime [Ca (OH) 2], as a result of which the relative humidity of the internal environment in the boiler should be kept below 60%.

4.1.4. Before shutting down the boiler, it is necessary to carry out the following preliminary measures:

a) install plugs on the steam, feed, drainage and purge lines of the boiler;

b) drain the water from the boiler;

c) clean the inner surface of the boiler;

d) perform acid flushing of the water economizer if mechanical cleaning is not possible;

e) clean the outer heating surfaces of the boiler and gas ducts from fly ash and slag;

f) dry the boiler heating surface with a fan through the open hatches of the boiler drums and collectors.

4.1.5. The amount of desiccant per 1 cu. m of the internal volume of the preserved boiler must be at least (in kg):

calcium chloride - 1 - 1.5;

silica gel - 1.5 - 2.5;

quicklime - 3 - 3.5.

Quicklime is used as an exception in the absence of other desiccants.

4.1.6. Upon completion of all work, an act on the conservation of the boiler must be drawn up.

4.1.7. In case of alkaline conservation, the boiler water volume must be filled with deaerated condensate with the addition of up to 3 g / l sodium hydroxide (NaOH) or 5 g / l trisodium phosphate (Na3PO4).

4.1.8.When adding to the condensate up to 50% of softened deaerated water, the addition of caustic soda should be increased to 6 g / l, and trisodium phosphate - up to 10 g / l.

Wet method for heating conservation

The wet method is suitable for both the preservation of boilers and the heating system as a whole. The method consists in filling the circuit with a special liquid that will prevent the metal from rusting. If the house is not heated at all and there is a risk of freezing, then only antifreeze (non-freezing liquids based on propylene glycol) can be used as a conservation liquid. Concentrates do not freeze even at -60, but they thicken strongly. They can be diluted to the desired consistency, thereby adjusting the minimum operating temperature. The disadvantage of antifreezes is that they are expensive, they dry rubber, they have a high degree of fluidity, and when overheated they turn into acid.

If you do not plan to use the Buderus gas boiler for several months, then it must be preserved.

The same applies to solid fuel boilers Buderus. According to reviews, this significantly prolongs their life.

If you need to preserve the boiler and there is no risk that the liquid in it will freeze, then in addition to antifreeze, you can use water with the addition of sodium sulfate. Its concentration should be at least 10 g / l. After that, the liquid is heated to remove air from it and all the pipes are clogged. The liquid is pumped using a pressure pump. They are different: manual, automatic, household and professional. We have already written about how to fill the heating system.

Preparation for storage of boilers

Gas boilers (steam and hot water) are disconnected from the main gas and water pipelines with special plugs that cool completely, after which water is removed from them through the drainage systems. Then the boiler equipment repair specialists proceed to the internal cleaning of the boilers from scale. Scale significantly reduces the shelf life of boilers and reduces their efficiency by an average of 40%, therefore, the internal elements of the boilers are thoroughly cleaned annually. Despite the fact that boiler water undergoes preliminary chemical treatment to remove heavy calcium and magnesium salts, during the heating season a significant part of these salts is deposited on the internal heating surfaces of boiler units.

3 ways to descale boilers:

mechanical; manual; chemical.

With the mechanical cleaning method, the inner surfaces of the drums and collectors are first cleaned, and then the wall tubes. Cleaning is carried out using blunt chisels, as well as special heads powered by an electric motor according to the principle of a drill.

In places inaccessible for mechanical cleaning, manual cleaning is carried out, for which special scrapers, wire brushes, abrasive tools and blunt mild steel hammers are used. During manual cleaning, it is forbidden to use chisels and other sharp tools in order to avoid disturbing the metal surface.

The fastest and most effective cleaning method is chemical, which, in turn, is divided into acidic and alkaline. The specialists of the boiler house carry out alkaline cleaning independently, using soda ash or caustic soda. Acid cleaning is carried out by a representative of a special organization. In this case, solutions of hydrochloric or sulfuric acid are used.

Methods for preserving boilers

Preservation is necessary * to prevent corrosion. The preservation of boilers for the summer period can be done by any of four methods:

- wet;

- dry;

- gas;

- overpressure method.

When preserving boilers using the wet method, the boilers are filled with a special liquid that forms a protective film on the inner heating surfaces, which prevents oxygen penetration.

With the dry method, water is removed from the boilers, and stainless steel trays are installed inside the drums and collectors, which are filled with desiccants (granular calcium chloride or quicklime). The boilers are then sealed.

The gas method involves filling the boilers with any inert gas, which also prevents corrosion.

The overpressure method is used in cases where boilers need to be shut down for a short time (up to 10 days). In all other cases, the first three methods are used.

Observing the rules for cleaning and preserving boiler equipment during the summer period, you can achieve high efficiency of boilers during the heating season, as well as significantly reduce the cost of repairing them.

*) excerpt from PUBE:

Dry method of preserving water heaters

Dry preservation of the boiler room gives the same high guarantees of equipment safety as the above methods. The essence of the matter is to completely dry the internal channels from moisture. This can be done in several ways:

- blow through with a strong pressure of warm air;

- evaporate moisture.

In the Russian Federation, the Dakon boiler has gained prestige, therefore, its sales are constantly growing.

In Italian gas boilers Ferroli, malfunctions occur only in the event of improper operation.

You can evaporate moisture by turning on the burner or lighting a flame in the furnace of an empty (no liquid) boiler. It is important that the flame is very slow so that the heat exchanger does not burn out. Air remains in the channels of the heater, and moisture is always present in it in the form of steam. This moisture can condense under certain conditions. The presence of moisture in the air, although slowly, still leads to the destruction of the metal. Therefore, it is necessary to bookmark the moisture-absorbing substance. For this, granular potassium chloride or quicklime is suitable. The moisture-absorbing powders need to be changed periodically (every two months).

Instructions for the preservation of steam and hot water boilers

- 11 Jul /

- admin /

- popecham

A feature of the state of the energy sector today is that the number of shutdowns and downtime of boilers has increased at heating plants, this is due to a change in the mode of energy consumption and heat supply. The equipment is reserved for an indefinite period. During the boiler shutdown, the pressure of the medium decreases to atmospheric, there is a possibility of moisture and air entering it, as a result, the boilers are subject to corrosion, which is considered dangerous, since there is a possibility of damage to all heating equipment, including pipelines. Therefore, at the moment, the issue of conservation is especially relevant, and the development of technologies in this regard is progressing.

Solid fuel boiler diagram.

Thanks to the protection against corrosion formed during downtime, the working condition of the equipment is maintained, the costs of its repair and restoration are reduced, the technical and economic indicators of the operation of thermal power plants are maintained, and the production costs are also reduced.

There are several ways to preserve boilers:

- gas preservation method;

- wet preservation method;

- method of applying excess pressure;

- dry preservation method.

A daily downtime of an unmaintained boiler will lead to rusting of equipment in the circuit up to 50 kg of iron oxide. When stopping hot water boilers for a period of 15 hours or drum boilers up to 1 day, it is recommended to preserve by means of overpressure, for a short period (5-6 days) - a method of dry preservation. The choice of a suitable method to exclude oxygen corrosion is made taking into account the parameters and power of the boilers, their specificity during operation.

To prevent parking corrosion of the metal of the heating surfaces of boilers during overhaul and current repairs, only preservation methods are applicable, which make it possible to create a protective film on the metal surface that retains its properties for 1-2 months after the preservative solution is drained, since emptying and depressurization of the circuit in this case are inevitable.

SP 89.13330.2016 Boiler plants.

Updated edition of SNiP II-35-76

Relevant information, notice and texts are also posted in the public information system - on the official website of the developer (Ministry of Construction of Russia) on the Internet This set of rules establishes requirements for the design, construction, reconstruction, overhaul, expansion and technical re-equipment of boiler houses, and also establishes requirements for their safe maintenance and operational characteristics, which ensure the fulfillment of the requirements,,,. The main priorities of this set of rules are: - the priority of the requirements aimed at ensuring the safe and reliable operation of boiler houses; - ensuring the safety requirements established by technical regulations, federal rules and regulations in the field industrial safety, as well as regulatory documents of federal executive bodies; - protection of protected

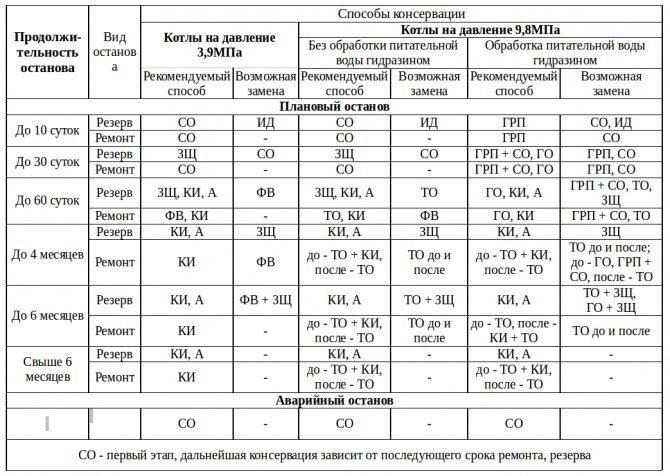

RD 34.20.591-97. Methodical instructions for the preservation of thermal mechanical equipment

With the introduction of these Guidelines, “Guidelines for the conservation of heat and power equipment: RD 34.20.591-87” (Moscow: Rotaprint VTI, 1990) are no longer valid.

... Mothballing of boilers and turbine plants is carried out to prevent corrosion of the metal of the internal surfaces both during operational shutdowns (withdrawal to the reserve for a certain and indefinite period, withdrawal to current, medium and major repairs, emergency shutdown), and during shutdowns in a long-term reserve or repair (reconstruction) for a period exceeding 6 months.

Courses

These Guidelines are an addition to the current ones and apply to power and hot water boilers and turbine plants of thermal power plants.

The methodological guidelines determine the main technological parameters of conservation, establish criteria for the selection of parameters, the technology for conservation of boilers and turbine plants when they are taken out for repair or a long-term reserve.

1.2. Protective effect

RD 34.20.591-97 Guidelines for the conservation of thermal mechanical equipment

With the introduction of these Guidelines, “Guidelines for the conservation of heat and power equipment: RD 34.20.591-87” (Moscow: Rotaprint VTI, 1990) are no longer valid. ... Mothballing of boilers and turbine plants is carried out to prevent corrosion of the metal of the internal surfaces both during operational shutdowns (withdrawal to the reserve for a certain and indefinite period, withdrawal to current, medium and major repairs, emergency shutdown), and during shutdowns in a long-term reserve or repair (reconstruction) for a period exceeding 6 months.

... On the basis of the Guidelines at each power plant, a technical solution for organizing the conservation of specific equipment should be developed and approved, which determines the methods of conservation for various types of shutdowns and downtime, the technological scheme and auxiliary equipment for conservation.

When developing a technical solution, it is advisable to involve a specialized organization.

Technical execution of conservation

The whole procedure consists of three stages. The first stage removes all kinds of contaminants from the surfaces of the equipment, as well as traces of corrosion. If necessary and technically feasible, repair operations can also take place.This stage is completed by measures for surface degreasing, passivation and drying. The next stage involves processing with protective equipment, which are selected based on the individual requirements of the operation of the technical equipment. For example, preservation of boilers may include treatment with high-temperature compounds, which in the future will provide structures with optimal resistance to high temperatures. Versatile treatments include anti-corrosion powders and a liquid inhibitor. The final stage involves packaging the equipment.