There are a large number of electric tubular electric heaters for heating on the market today. Models differ in appearance, power, degree of protection of the outer shell. But the principle of their action has not changed practically since the middle of the 20th century.

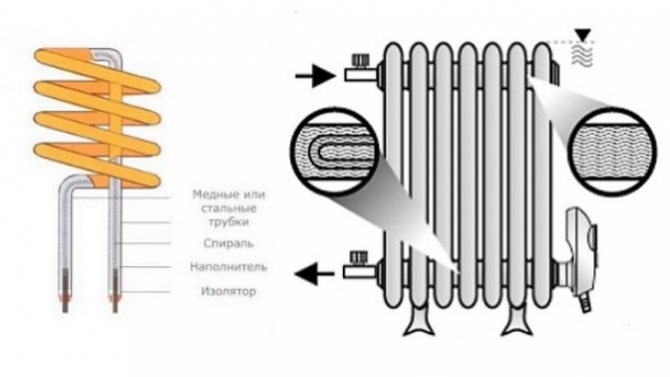

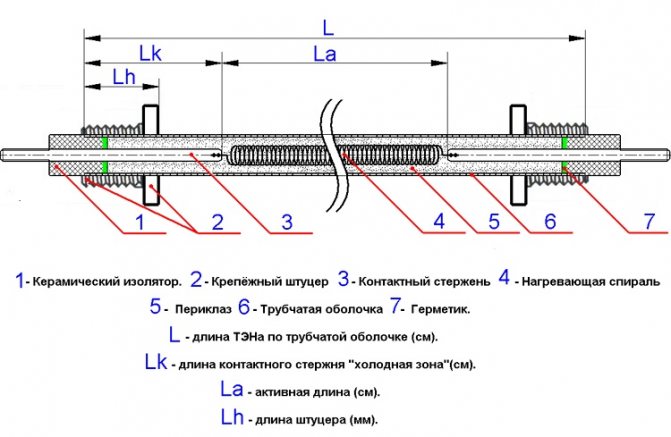

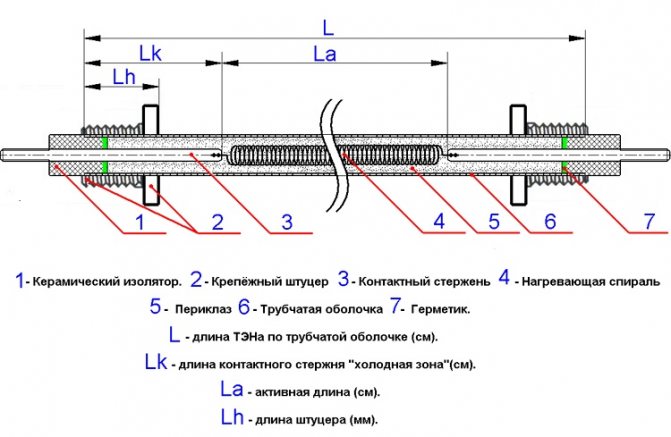

Inside the tube, made of metal with good heat-conducting characteristics, there is a wire (nichrome) twisted in a spiral and a coolant (periclase). A current is applied to this element, the wire heats up.

It is used as the main component in many household appliances:

- Washer;

- Dishwasher;

- boiler;

- electric kettle and many others.

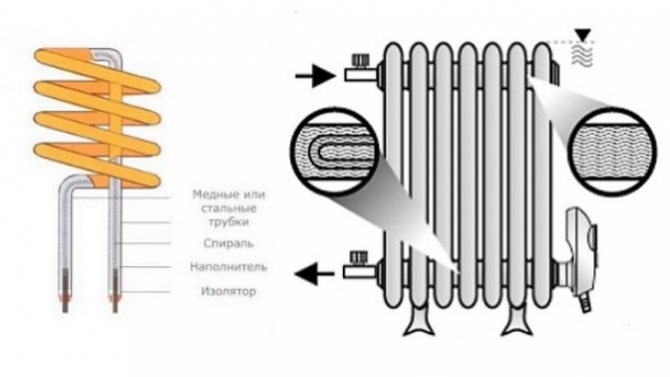

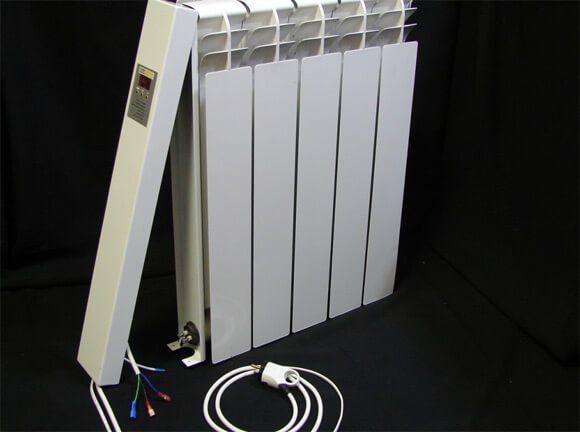

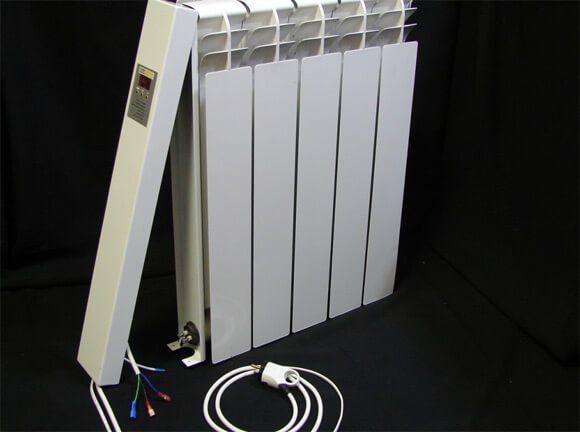

But today, heating elements for heating systems have gained great popularity. The device is inserted into the radiator, and the base with the connection point remains outside.

Such a system gives the owner a number of possibilities:

- Maintaining a comfortable temperature at any time of the year. This is especially convenient in the fall before the start of the heating season or in the spring after turning off the centralized heating;

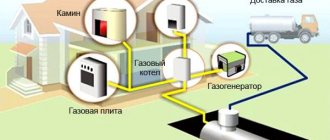

- Organization of autonomous heating on an already finished system central heating supply;

- Use for emergency heating liquids in case of accidents during the cold period;

- Saving money on air heating due to high efficiency.

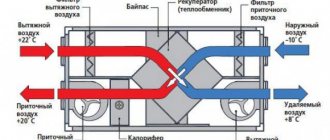

However, direct convection heating has not been canceled either, therefore the heating tube is actively used in convectors, heat curtains or guns, and so on.

Purpose of heating heating elements

Electric heating elements have gained popularity due to their versatility and high efficiency. All the electricity they consume is used for their intended purpose - to heat the surrounding space.

The main heating devices where heating elements are used are:

- Portable and stationary electric oil heaters.

- Water heating radiators.

- Heated towel rails for the bathroom.

- Electric fireplaces.

- Electric convectors.

- Electric boilers.

The specified equipment can be used as a primary or additional heating source. It is inexpensive, easy to install and does not require special skills during operation.

You can connect the heating element to a cast-iron central heating radiator after disconnecting the common riser. Such a device can be used for main and additional heating.

Scope of application of heating elements

It is possible to use a heating element for a heating radiator (shown in the photo) when arranging autonomous heaters simultaneously with a centralized heating system in order to provide additional heating of the coolant.

Most often, the decision to install a heating element in a battery is made by property owners if the heating in an apartment or house is unstable or is often turned off. This heating device is a good alternative to prevent the building from cooling down and the batteries from defrosting.

Internal arrangement of electric heaters

It is convenient to consider the device on the example of a tubular model. The electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange, there are insulating bushings that make it impossible for the conductive spiral to contact the heating element body.

In most models of heating elements, similar components are used, however, their durability may differ depending on the build quality

The electric heater is fastened mainly with a flange connection, which makes it possible to seal the internal environment of the heater from the external space. The disadvantage of this design is the impossibility of replacing the coil when it burns out internally.

Finned tubular electric heaters

Ribbed heaters also belong to the tubular type of elements, but they also have ribs that are located in planes perpendicular to the axis of the heater tube. Such ribs are made of metal tape, and they are attached to the tube using washers and clamping nuts. The very same device is made of stainless steel or structural steel.

This type of heating element is used in heating devices that heat air or gas. They are often found in devices such as air curtains or convectors (read: "Electric heating convectors: how to choose - little tricks"). They are used to heat rooms by means of a thermal air mass.

The principle of operation of heating elements

The heating element works according to the following principle. When connected to the network, the inner coil is heated and energy is transferred to the thermal conductor and the outer sheath. Subsequently, heat is transferred to the surrounding liquid, air or solid material.

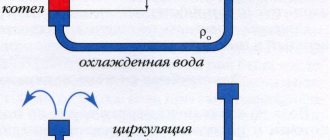

When heating a heating element immersed in oil or water, convection flows are created around the tube, which mix the coolant and contribute to its uniform heating.

Electric boilers are renowned for their reliability and maintainability. They do not have many complex parts, so they are easy to operate and maintain.

In non-liquid heaters, the heating temperature is usually limited so as not to damage the surrounding parts and cause a fire.

To speed up heat transfer, they often use a fan that circulates air both inside the device and in the surrounding room.

How to use it correctly?

In addition to the banal failure to comply with the operating instructions and safety rules, heating elements can break due to:

- shell corrosion;

- its rupture as a result of overheating;

- constant drops in mains voltage;

- and just a general depressurization of the tube.

In order for the device to heat your home as long as possible, you must follow simple rules:

- When connecting the wires, you should not be too zealous and unnecessarily tighten the nuts of the contacts of the output ends of the heating element - they may burst.

- The device must be connected to the network only when it is in the water. Otherwise, by lowering the heated spiral into water, you can get a fairly strong explosion.

- The surface of the heating tube must be descaled regularly. It all depends on the quality of the water, but with constant work, it is best to clean it once a quarter, avoiding the build-up of scale more than 2 mm.

- In case of problems with the quality of power supply, you should connect an uninterruptible power supply or stabilizer.

- For the coolant, it is best to pour distilled water into the system, the percentage of impurities in it is minimal. They are the reason for the appearance of scale on the shell of the heating element.

- Use residual current devices (RCDs) - in case of breakdowns of the heating element, it will be immediately disconnected from the network.

- It is imperative to make grounding.

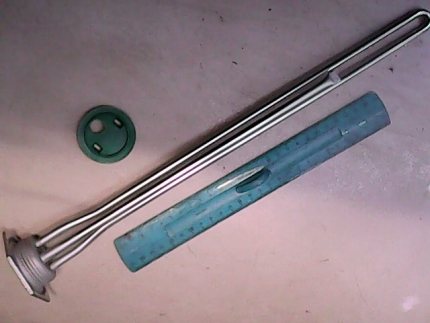

It's important to understand. By no means any heating element can be mounted in a heating radiator. You need to select specialized models in strict accordance with the required diameter.

Types of heating elements for heating devices

The simplicity of making heating elements does not always turn into convenience for users. Many manufacturers produce electric heaters with a specific shape and attachment.In the event of a breakdown, it is quite difficult to buy them in the store. Therefore, for the correct choice, it is necessary to study all possible design options.

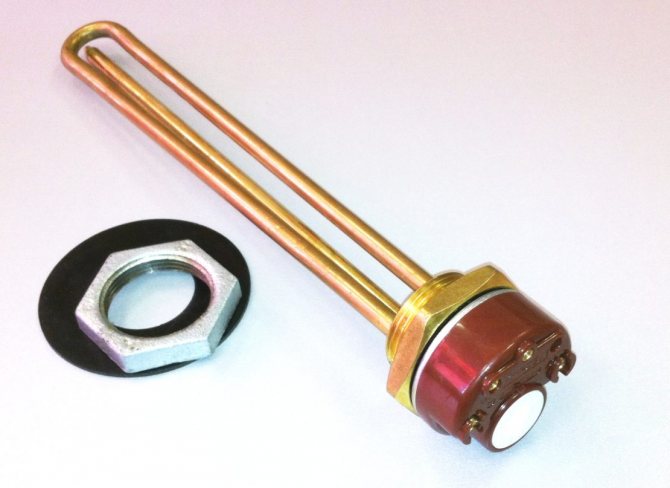

Tubular models for domestic heating

The tubular design of electric heaters is the most common in mobile oil heaters, portable and wall mounted electric radiators. Heat transfer in them can occur using: convection, infrared radiation or thermal conduction.

Ready-made heating elements with a regulator and their own power cord can be bought only if you are sure that the length of the wire will be sufficient

The shape and length of the tube in such devices can be any and is dictated only by design features. For example, the heating element of a micatremic heater is a coil located behind a mineral plate. When heated, the plate emits infrared heat.

The most common characteristics are:

- diameter - 5-18 mm;

- length - 200-6000 mm;

- shell material - steel, stainless steel, ceramics, copper;

- power - 0.3-2.5 kW.

Heating elements with a capacity of more than 2.5 kW are not used in household heating appliances, because the apartment wiring simply cannot withstand a greater load.

Ribbed version of electric heaters

Ribbed devices are a modification of the tubular heating element. Their feature is the presence of many thin steel plates along the entire length of the device. This design dramatically increases the area of contact with the environment, providing a high rate of heating.

Ribbed heating elements are more expensive, demanding on the volume of the working space, but provide higher consumer characteristics of heating equipment

Finned models are used mainly in heaters for air heating. They provide a rapid rise in room temperature, especially with a built-in fan.

Block designs of heating elements

The block version represents several tubular heaters combined on the basis of a single mount.

When choosing block heating elements, special attention should be paid to their power and the ability of a boiler with a pump to provide heat removal

This design is used when two factors are combined:

- The need for increased power of the device and a high rate of heating of the working medium.

- The impossibility of rapid transfer of thermal energy from the spiral to the environment due to the small area of the outer shell.

In fact, in a block heating element, the load on each heating tube decreases and the heat transfer rate increases. Such devices are part of domestic heating boilers and industrial electric heating installations.

The power of block models can be 5-10 kW, therefore, when they are placed in an apartment, an additional electrical cable must be pulled into the room.

Cartridge type devices

Cartridge heating elements have the form of a tube with one free end, which is due to the peculiarity of their installation. The outer shell is usually made of polished steel to ensure maximum contact with the surrounding material. Such tubes are tightly inserted into the corresponding hole of the heater.

The main disadvantage of cartridge heating elements is the small area of the heat-transfer surface, which requires the use of specific methods for removing heat energy

The fixation of cartridge models is carried out mainly using a flange connection. They are usually used in industry to heat the working parts of extruders.

There are other structural types of heating elements, but they are used mainly in industrial production and do not affect the topic under consideration.

Heating elements for heating boilers

Warm electrical and water skirting boards for heating

There is a heating element on sale for a heating boiler. The heating element is installed in the heating equipment by the manufacturer at the factory. You will have to choose a new electric heater only if it breaks down or if you need to increase the boiler power. At the same time, there are two types of heating elements: some are installed in industrial equipment, and others in boilers for domestic use.

Types, advantages and disadvantages

Heaters for heating equipment are of block and cartridge type. As a rule, block structures are used, in which several tubes are fixed on one base. As a result, the load on each element is less, and the rate of heat transfer is higher. These devices are built into domestic boilers or additionally connected to the heating system. Since the power of such a heating element is quite high, you need to pull a separate wiring to the boiler that will withstand such loads.

By design features, the following types of electric heaters for boilers are distinguished:

- with a smooth surface of the elements;

- finned devices with washers and clamping nuts;

- single-ended units are suitable for electric heating boilers (they resemble a boiler);

- double-end devices have special contacts that are attached to the two ends of the tubular element.

Important! To achieve the required output, more than one electric heater with a minimum output of 1 kW can be built into one boiler.

The advantages of electric heaters for heating boilers are their efficiency, the ability to heat the house and provide hot water supply. The devices do not emit harmful emissions during operation. They are compact and lightweight, therefore they do not increase the weight of the heating equipment.

The disadvantages are associated with the rapid formation of scale. To adjust the heating power, all heaters must be turned off. When operating without water, the device quickly burns out, therefore, additional circuit breakers are installed.

Additional functions of electric heaters

Above, the simplest designs of devices were considered that do not have any built-in adjusting mechanisms.

The thermoregulation unit can have mechanical or electronic automation. The latter is more accurate, but demanding on the parameters of the home electrical network.

But electric water heaters can be equipped with the simplest automation that provides the device with additional functions.

These include:

- Thermoregulation... Heating elements with a built-in thermostat for heating have a temperature sensor that is triggered when the working medium heats up to a certain level. The electric heater is adjusted from the outside of the flange.

- Anti-freezing... This function is provided by a simplified thermostat that only works when the temperature drops to 0-2 ° C. It prevents water from freezing in heating pipes, consuming a minimum of electricity.

- Turbo heating, which provides forced heating of the working environment at the initial start-up of the equipment. It must be remembered that the electrical wiring of the room must withstand a short-term increase in power.

There are not so many devices that support additional functions, because often the regulation of the operation of heating devices as a whole is carried out using a separate automation unit.

Electric heaters with thermostat

Electric heaters for heating with a thermostat are currently the most common. Their main purpose is to heat the liquid. Hot air heaters with thermostats are installed on almost all equipment that is used to heat water. The maximum temperature to which the heating element heating medium can be heated for a radiator with a thermostat is 80 degrees.

TEN with a thermostat is made of nickel-chromium wire.The wire inside the tube of the device with an electric thermostat is filled with a special compressed type powder, which is magnesium oxide and has excellent insulating properties, but at the same time has a high thermal conductivity. You can build such a TEN into an electric heating battery.

How to choose a heating element for heating equipment?

When choosing a heating element for replacement in a water heater or in a radiator, you need to pay attention to its power, design, tube length and the availability of additional features. Therefore, before buying, you need to find out as much as possible about all its characteristics.

Calculation of the power of the device

The large power of the heating element is not always a positive quality.

When choosing, it is important to consider several factors that are related to the level of energy consumption:

- the maximum heat transfer power of the heater as a whole;

- electrical wiring capabilities;

- the volume of the room.

You cannot buy a device with a power that is more than 75% of the maximum heat transfer level of the heating equipment.

For example, there is a radiator with 10 sections, each of which gives off 150 watts of heat to the air, a total of 1.5 kW. When an electric heater with a power of 2 kW is installed in it, the surface of the battery will not be able to quickly give up all the generated energy. As a result, the heating element will constantly turn off due to overheating.

The reason for the rapid breakdown of the heating element may be the wrong choice of the power of the device. As a result of systemic overheating of the coil, it burns out over time

In apartments with worn-out wiring, the constant load on the outlet should not exceed 1.5-2 kW, otherwise it may catch fire and lead to sad consequences. Therefore, before buying a heating element, you need to check the condition of the wiring and, if necessary, dismantle the old one and lay a new power grid.

When the issue with the electrics and the capabilities of the equipment is resolved, you can begin to calculate the required power to maintain a comfortable temperature in the room.

In well-insulated houses and apartments, a level of 40 W / m3 will be sufficient. And if there are gaps in the windows, the heating power should be increased to 60-80 W / m3. You can buy a specific model only after taking into account all the above energy factors.

Consideration of design features

Most heating elements have an alloy steel shell, which provides strength and resistance to corrosion. Copper devices are mainly used in water heaters, although there are no restrictions on their use in homemade radiators.

In cast iron and steel radiators, the use of heating elements made of non-ferrous metals is undesirable. This can lead to accelerated wear of materials and connections.

Also, when choosing, it is necessary to take into account the direction of the thread of the plug, which can be right or left. Different models of electric heaters also differ in the diameter of the flanges. They can range in size from 0.5 to 1.25 inches.

Usually, a short instruction is attached to a heating element of a good manufacturer, which describes its design parameters. Studying them will help you buy a device that will exactly fit your existing heating equipment.

Heating tube length

The length of the tube is one of the main characteristics that determine the efficiency of the device.

Its large length with equal power leads to an increase in the surface area of the electric heater and an acceleration of heat exchange with the working medium. This has a positive effect on the durability of the heating element and the rate of circulation of the coolant.

Heating elements with a long tube are ideal for installation in self-made registers, which are convenient for heating large rooms and outbuildings

It is desirable that the tube runs along the entire length of the working area of the heater, not reaching the opposite wall by 6-10 cm. This recommendation will allow you to quickly and evenly warm up the coolant.

Availability of additional functionality

It is not always necessary to overpay for additional features of heating elements. If the heater is used as an auxiliary heater and does not have its own built-in automation, then buying a model with a thermostat makes sense.

But if the radiator or electric convector has its own temperature sensors and temperature control mechanisms, additional functions will remain unclaimed.

The electronics built into the heating element plug must have safety mechanisms so that in the event of a breakdown of the control board, a fire does not occur

Therefore, it is recommended to purchase expensive electric heaters with built-in automation only if there is a clear need for such equipment. If you need an individual selection of the temperature background, it is better to buy a thermostat in an outlet, which can be used periodically.

As for the manufacturers of heating elements, their choice is not fundamental. The main suppliers are firms from Russia, Ukraine, Turkey and Italy. The quality of their products is about the same, so there is no point in overpaying for the brand.

Design and principle of operation

The device of the electric heating element is rather primitive. It looks like a metal cylinder, inside which a copper or steel strong wire spiral is placed in a special insulator. In view of the fact that the heating element for heating batteries is mounted together with a thermostat, in addition to the heating function, it is also used to adjust the temperature of the coolant.

The spiral cylinder is protected by a housing, which is equipped with control sensors. Their task is to monitor the device against overheating. In addition, the device is galvanized for added reliability. Chrome and nickel plating increase the strength of the heating element and thereby create additional protection that prevents human contact with electricity.

In addition to the main tasks of heating and thermoregulation, modern heating elements for heating radiators perform additional tasks:

- In the "anti-freeze" mode, a constant temperature of the coolant is maintained at + 10 ° C, which is quite enough to prevent the coolant from freezing in the pipes. After the water is heated to the required temperature, the heating elements are turned off until its temperature drops below the set mark.

- When completing an autonomous heating system in a private house with batteries with integrated heating elements, the most successful will be the use of the "Turbo" mode. The device operates at full capacity, thanks to which the system and the air in the room heats up almost instantly. In the future, the task of heating elements is to maintain the set temperature level in the system, which allows you to significantly save energy during heating.

Among the majority of consumers, there is an opinion that the best option as a coolant for radiators with built-in heating elements is technical oil, due to its properties of rapid heating and slow cooling. But this does not mean that such radiators cannot be used in a water heating system.