The flame, long tamed by man, obediently burns in the heart of the fireplace - its fuel chamber. The fireplace insert is an important part of the design used for heating modern dwellings and for organizing the efficient combustion of fuel (solid or gaseous) with the supply of oxygen-rich air.

Fireplace inserts differ in some design features and are divided into open and closed structures. There are also different materials for manufacturing: cast iron, stainless steel, the symbiosis of steel and cast iron, as well as brick. Some more differences are noted: configuration, length, height, width and area of the furnace; structure of the device, thermal efficiency, power and efficiency, burning period (economical or long burning).

The configuration and number of refractory glasses can vary from one to two elements. Furnaces are produced with two glasses located on opposite sides, they include through or, as they are also called, tunnel furnaces, double face furnaces. Structures with three facades, four glass-edges look spectacular, as an option - a monolithic round glass that can be lifted upwards like a guillotine.

By the way of opening the doors, structures are classified into the following groups: hinged, with side opening, lifting upward, under the firebox.

The fuel used to operate the fireplace can be different: solid, liquid and gaseous.

When buying a fireplace or a separate fireplace insert, you should remember that a huge number of domestic and foreign companies produce models with various technical features and equipped with additional functions.

Specifications

The technical characteristics of a cast-iron fireplace insert are determined by the properties of the material of manufacture. Cast iron is a very durable and thermoplastic material, but keep in mind that you should choose a cast iron fireplace insert with walls at least 7 mm thick. When choosing a cast-iron fireplace insert, you should pay attention to the dimensions, rated power, and minimum wood load.

Advantages of using cast iron fireplace inserts:

- cast iron furnaces are highly resistant to the formation of any deformations;

- The efficiency of cast iron furnaces is 70% - 80%;

- cast iron furnaces are able to withstand high temperatures during operation, while maintaining their original appearance;

- it is possible, if necessary, to purchase a furnace of a sufficiently compact size and low weight;

- a huge selection of models with a wide variety of configurations;

- in closed-type fireplaces, the burning time when the cast-iron furnace is fully loaded with fuel, with the doors closed, is at least 4-5 hours;

- long service life.

Views

Fireplace stoves with a cast iron firebox are divided into:

- fireplaces with an open hearth (traditional type of fireplace) have a greater aesthetic appeal;

- fireplaces with a closed hearth (fire-resistant glass is used) are characterized by a higher level of safety, the ability to heat a larger area of the room than fireplaces with an open hearth, and they also use fuel more economically.

Also, closed-type fireplaces are additionally equipped with the function of additional afterburning of gases formed during the combustion of fuel.

Depending on the design of the fireplace, closed fireboxes are subdivided:

- on fireboxes with straight glass;

- for furnaces with prismatic glass;

- on fireboxes with rounded glass;

- on fireboxes with corner glass;

- for furnaces with double-sided glass;

- on fireboxes with three-sided glass;

- and also, for fireboxes with individual glass sizes.

In the consumer market, cast-iron fireplace inserts of Russian production are gaining more and more popularity. Today, the most famous domestic manufacturers of fireplaces (both open and closed), which have established themselves as manufacturers of quality products: "Meta", "Interior".

On the Russian market, a large range of cast-iron fireplace inserts is offered by French.

The cast-iron corner firebox consists of three walls and is characterized by a semicircular or trapezoidal shape and compact dimensions, as well as a higher heat transfer than front fireplaces.

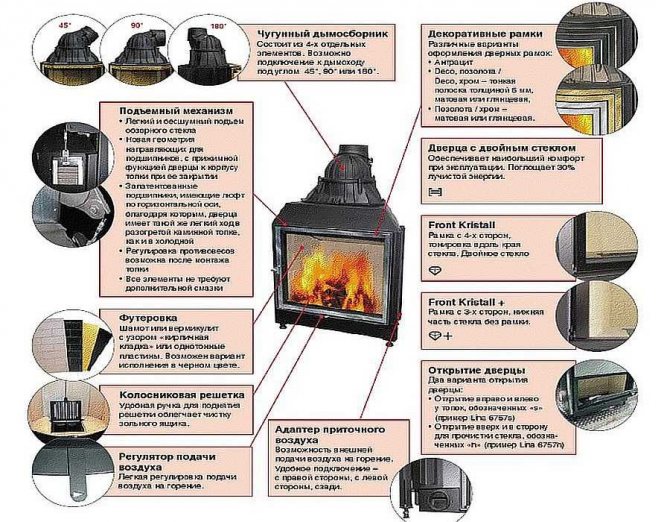

The picture shows a fireplace with a closed firebox.

How to heat your home with a fireplace

It is realistic to provide heating not only for the room where the unit is located, but also for the neighboring rooms. How is this possible? The fact is that cast iron is a material with a very high heat capacity. This means that it not only heats up for a long time, but also gives off heat for just as long. Thanks to this, the air in the room is heated and the walls of adjacent rooms are warmed up. If the fireplace chimney passes through the inner rooms of the second floor of the house, then these rooms will also be heated.

Remember the high temperature of the unit itself and the chimney, take care of the safety of children.

Modern high-tech fireplace for the modern home.

Many fireplaces have a hob. You can even cook.

Fireplace in red and black tones - decoration of the kitchen in the style of Provence.

High-tech cast iron fireplace in the design of a portal made of natural stone is a pleasant combination of opposites.

Fireplace decoration in the style of a country house of severe Scandinavia.

In an ordinary brick fireplace, the duration of combustion is limited, since the firebox may overheat. Long-burning fireplace stoves, in which the firebox is made of cast iron, can be operated for many hours in a row. It will also make it possible to heat several rooms more efficiently.

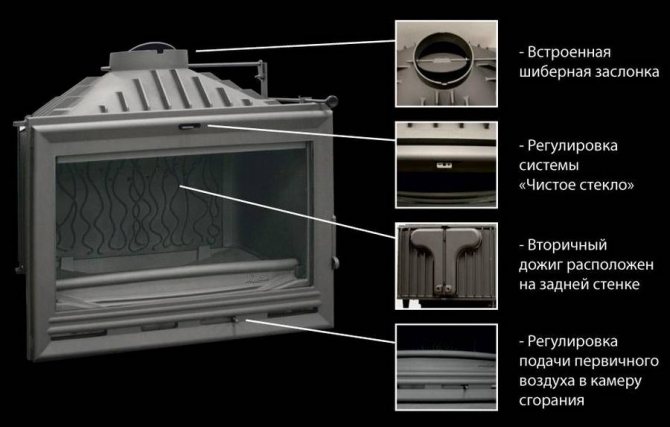

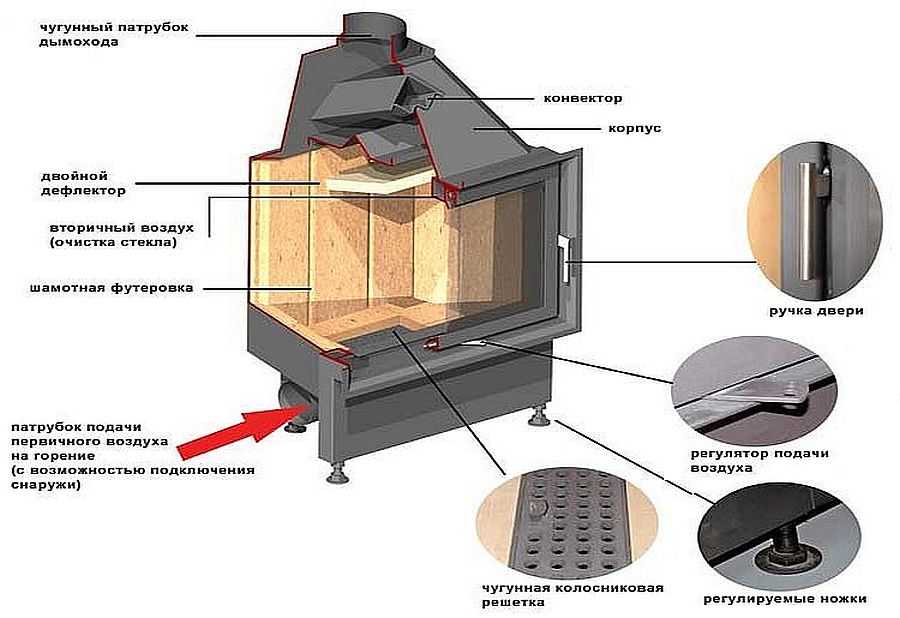

Device

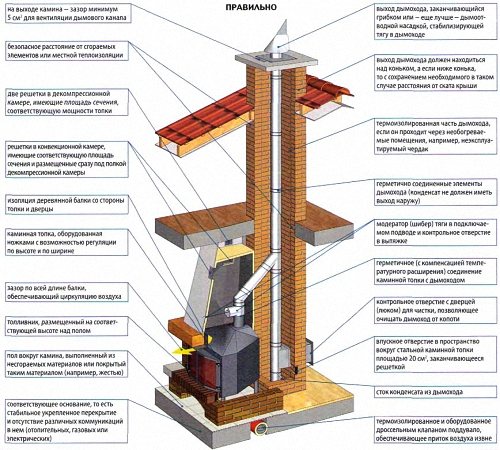

The design of a cast-iron furnace is a special chamber in which fuel is burned, in the lower part of the furnace, an ash pan is located under the chamber, and a chimney is located in the upper part of the furnace. The design of a fireplace with a cast-iron firebox must necessarily include a gate and a deflector. The gate (valve) affects the resulting draft in the chimney and makes the combustion process more efficient. The deflector is also used in chimney draft control. In closed-type fireplaces, the doors at the cast-iron firebox can open sideways and upwards.

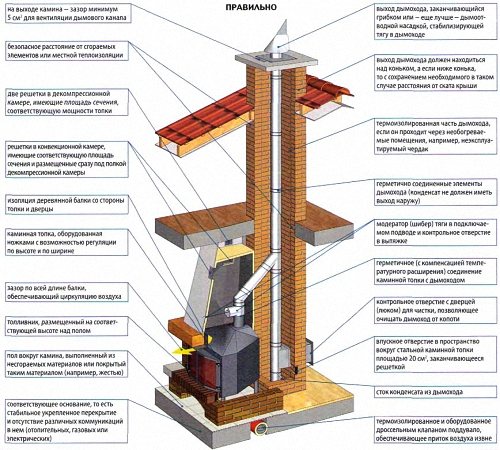

Installation

Installation of a cast-iron fireplace insert consists in equipping a heat-resistant base for the fireplace, as well as decorative facing of a cast-iron fireplace insert.

The process of arranging a base for a cast-iron fireplace insert can be conditionally divided into several stages:

- choosing a place for a fireplace (the fireplace should be located as close to the chimney as possible);

- the floor surface must be leveled;

- a waterproofing layer has been built, if the floors are wooden, then a layer of heat-insulating materials is additionally built;

- equipped with a cement screed with reinforcement (a metal mesh can be used as a reinforcement);

- when the screed gains the necessary strength, it will be possible to start equipping the fireplace stand (it can be equipped with bricks and foam blocks, using a special adhesive or cement-sand mortar, or purchased ready-made);

- a layer of refractory material is laid on the prepared base;

- a cast-iron firebox is installed on the base.

The most popular facing material used to decorate fireplaces is brick.Brick accumulates heat well and does not cool down for a long time.

Facing a brick fireplace will significantly improve its operational properties and significantly improve its appearance. Facing a cast-iron fireplace insert with a brick is carried out at some distance from the walls of the firebox so that a gap remains, and it is also necessary to put several holes in it for the unhindered exit of heated air.

Furniture and interior items

50 votes

+

Voice for!

—

Against!

The main element of the fireplace, which determines the efficiency and quality of its work, is the firebox. The design of the firebox is somewhat complex and requires special care during the work. However, a properly installed firebox is a guarantor of long-term operation of the fireplace. We will consider further how to install a fireplace insert and the peculiarities of its manufacture.

Table of contents:

- Fireplace inserts: characteristics and types

- Fireplace insert photo, options: open and closed

- Cast iron fireplace insert technology

- Making and installing a fireplace insert with your own hands

Fireplace inserts: characteristics and types

Among the variety of fireplace inserts, we suggest that you familiarize yourself with their main types, which differ in certain advantages and disadvantages:

1. Open fireclay version of the firebox - it is not exposed to embedding on the surface of the fireplace portal, it is the portal itself. For the manufacture of such a fireplace insert, it is necessary to have a carefully selected fire-resistant brick, an ideal shape. The brick should not crumble and sprinkle, and the interval between the joints of the bricks should be about three millimeters.

An open firebox should be distinguished by the presence of perfectly flat walls, thus, the heat in the room will be reflected correctly. The efficiency and efficiency of this firebox directly depends on the form in which it is made.

Furnaces with a vertical rear wall and two lateral parallels have very low heat transfer. Since only one of the walls is engaged in the reflection of heat. At the same time, the firebox, in which the back of the walls is equipped with a slope, is capable of reflecting heat over the entire surface.

2. The second option is cast iron fireplace inserts. Most often, this option is suitable for wood-burning fireplaces. In the inner part of the firebox, firewood is burned, and heat accumulates in the cast iron and is gradually released into the room.

There are two options for arranging such furnaces:

- open;

- closed.

Closed furnaces are more common, this is primarily due to their fire safety. This type of furnace is in the form of a glass-metal module, inside of which combustion takes place. There are two options for opening the door: side or top. The classic version of the closed fireplace insert has a front panel that is one meter wide and about 75 cm high. The radial version of the insert is distinguished by the presence of a semicircular glass surface, behind which the fire is visible. The tunnel-type firebox has a glass door not only at the front, but also at the back. It is used if the fireplace is arranged in two rooms at once.

Corner fireplace inserts have a special frame around the perimeter and a glass door. In addition, it is possible to manufacture an architectural non-standard firebox, which is constructed in accordance with the individual preferences of the owners of the fireplace.

Advantages of using a cast iron furnace:

- lack of tendency to deformation;

- resistance to high temperatures;

- good thermal conductivity and heat capacity;

- resistance to burnout and a high level of strength;

- duration of operation;

- smoke-repellent characteristics in some models, so the glass does not need to be cleaned of soot.

There are special projections on the rear wall of the furnaces that increase the area of heat exchange. There is a section between the surface of the firebox and the fireplace itself, which also improves heat transfer.

3. Arrangement of a fireplace insert with bricks is less and less common in the construction of fireplaces. Among the advantages of an open brick firebox, they highlight the attractiveness of its appearance and the ability to enjoy the burning of firewood. However, such a fireplace is unsafe, especially when there are small children at home. In addition, the manufacture of such a furnace requires professional intervention, and the purchase of bricks is of high quality, a rather expensive process.

The fireplace, in which there is a circuit, is distinguished by the presence of a special tank in which the water is heated. Water is used for domestic needs. This equipment allows not only to heat the room, but also supplies its owners with hot water.

Water fireplace inserts have a double wall, which, with the help of hot smoke, heats the water. This firebox works in the same way as a solid fuel boiler with a double circuit. A fireplace insert with a contour allows you to double the level of efficiency of the fireplace.

Fireplace insert photo, options: open and closed

We offer to compare the pros and cons of open and closed fireboxes installed in the fireplace. The open version of the firebox is made of brick, metal or cast iron. This firebox has a low efficiency, about 25%, and is more of a decoration of the room than a heating device.

To equip such a fireplace, it is required to build a solid fireproof foundation, during the manufacture of which concrete or brick will be required.

Installing such a fireplace on a wooden base is unacceptable. The floor surface, located 80 cm in front of the fireplace, should also be covered with a fireproof material, in the form of tiles or stones. A fireplace with an open hearth is installed in a room of the largest area, near a load-bearing wall, which is made of any materials except wood.

Among the advantages of an open firebox are:

- the presence of an attractive type of open fire and flame;

- cheap manufacturing.

Among the disadvantages are:

- low efficiency;

- the possibility of a fire, unsafe use;

- the need for repairs, reassembly of the furnace and replacement of damaged bricks;

- lack of a large selection of fireboxes.

The closed version of the fireplace insert is made of cast iron or metal. One or more walls have a steel door. On some models, the door automatically rises and the firebox becomes open.

The lower part of the furnace is equipped with an ash pan, which saturates the combustion chamber with oxygen. With the right choice of finishing materials for the fireplace, it becomes as attractive as devices with an open hearth.

Among the advantages of a fireplace with an open firebox are:

- variety of choice of furnaces of almost any shape and configuration;

- high level of efficiency, the ability to use the fireplace as the main or additional heating element;

- duration of operation;

- high fire safety;

- the ash is collected in the ash pan, and therefore it does not enter the room;

- the ability to simulate a brick open firebox.

Despite this, a closed firebox has certain disadvantages:

- lack of open fire, which is located behind the glass;

- the need to clean the glass;

- high price.

Cast iron fireplace insert technology

These fireboxes allow you to equip the base for the fireplace directly on the floor, but this cannot be done only if the screed that is on the floor is floating.

The installation of a cast iron firebox begins with the arrangement of the base on which it will be located.We offer you to study the instructions that will help you complete all the work with high quality:

1. Start at the place where the fireplace is to be installed. This element should be clearly visible from any part of the room. After that, a base is built on this site, for the manufacture of which a reinforced cement screed is required.

2. After it dries, waterproofing works are carried out, in the presence of wooden floors, thermal insulation is also installed. The minimum thickness of the screed is 100 mm, and a metal mesh is required to strengthen it.

3. After the screed dries well and gains the required strength, a pedestal should be made to install the firebox. For these purposes, brick or aerated concrete is used. In addition, the option of making a pedestal from natural stone is possible.

4. If the overlap is fragile enough, then it is best to choose aerated concrete for making a fireplace, since this material has the lightest weight, it is easy to work with it. Further finishing of aerated concrete is carried out with such materials as ceramic tiles or piece stone.

5. Blocks are laid using a special glue or mortar based on sand and cement. To level the surface of the pedestal, plaster it.

The next stage involves the implementation of work related to the direct installation of a furnace made of cast iron. Before performing this process, a heat-insulating material is laid on the pedestal, in the form of iron or basalt wool.

Tip: When determining the place where the fireplace will be equipped, take into account the fact that there must be a distance between the firebox and the wall, which will serve as a convection gap.

For the correct installation of the firebox, wooden beams should be placed under it, with the help of which its position will be adjusted. To make a chimney, prepare a steel sleeve or pipe,

Making and installing a fireplace insert with your own hands

The furnace installation procedure must be carried out in compliance with the following rules:

- walls, floor and ceiling located near the fireplace must be made or finished exclusively with non-combustible materials;

- it is recommended to use tiles or stone for finishing the floor; before installing, check it for horizontal and evenness;

- a metal sheet is laid at the bottom of the firebox, which provides additional fire safety;

- in the space between the floor and the ceiling, it is recommended to use basalt wool, which can withstand temperatures of more than 700 degrees;

- the firebox gradually rounds out at the top, therefore, when laying each row, each of the rows should be reduced;

- after laying the brick, the excess mortar is removed with a sponge;

- the side walls of the fireplace should be at least six centimeters, and the back - nine;

- the firebox is brought out one meter behind the building;

- the fireplace insert and chimney are connected using special steel clamps, but in addition, to increase the sealing of the joints, it is recommended to use sealants that are resistant to high temperatures.

Do-it-yourself fireplace insert:

1. In order to independently make a fireplace insert, you need a tremendous skill in working with metal. It is better to give preference to purchased options, as they will be cheaper and more reliable.

2. If the fireplace insert is closed, then work is carried out to install heat-insulating material on the floor.

3. The base on which the fireplace will be erected and the firebox installed must be durable and fire resistant. To build a base, it is necessary to reinforce it, and then strengthen it with concrete mortar. The minimum thickness of the concrete screed is 15 mm.

4. On the surface of the screed, brick, fire-resistant type or aerated concrete must be laid. It is these materials that are resistant to high temperatures.

five.In order to assemble the pedestal, you will need to use a cement-based mortar. A variant of the use of mastic is possible, which is characterized by a higher resistance to high temperatures.

6. The installation procedure for the fireplace insert begins with the assembly of the fireplace trim. Its choice depends on the general interior of the room, the individual preferences of its owners and on other factors. The body of the fireplace should be equipped with small openings through which air can circulate.

7. When choosing fireplace inserts, the dimensions should be determined based on the dimensions of the fireplace itself and the area of the room in which it will be installed.

8. Before installing a purchased firebox, you should read the instructions, in which the manufacturer specifies in detail the technology for carrying out this process.

9. If you plan to install a firebox made of cast iron, then you should properly organize the space under it. Since 30% of the heat goes to the lower part of the firebox, and 70% is released into the room.

10. To organize the space under the firebox, a pipe made of polyvinyl chloride or corrugated should be connected to it.

11. An important factor is the equipment of the ash pan, in which ash from the burnt fuel accumulates. The ash pan is equipped with a door that helps to remove products from combustion.

12. A fireplace insert with your own hands requires the installation and connection of a chimney to it. For this, there are clips in the form of radiators with grilles.

13. To manufacture pipes, stainless steel is required, the thickness of which is at least one millimeter.

14. In addition, it is recommended to wrap the pipe surface with basalt-based cotton wool. Thus, it will be possible to prevent the formation of condensate masses inside the chimney.

15. It is better to install the fireplace insert on wood substrates in the form of bars, which, after all the work, must be removed.

Please note that the fireplace insert must be installed in compliance with all technologies, since its incorrect installation will lead to malfunctions of the fireplace and damage to the materials used in the process of its manufacture.

Fireplace inserts video: