Home / Gas boilers

Back to

Published: 26.07.2019

Reading time: 4 minutes

0

1076

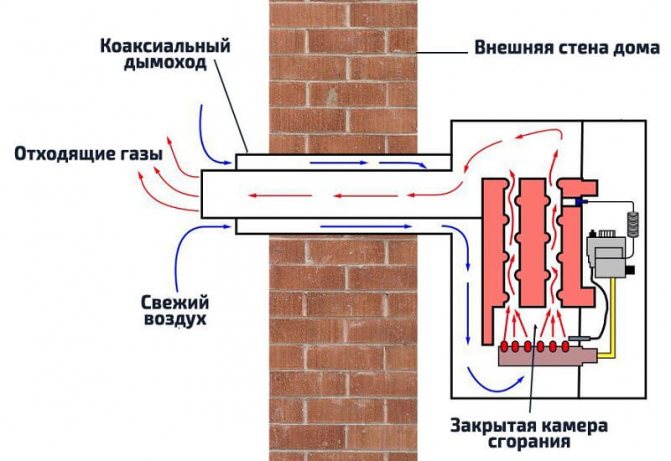

Many boiler owners have no idea what a parapet boiler is, although they have been using them for a long time. This modern unit belongs to the class of energy efficient devices and removes flue gases using a coaxial chimney mounted in a through hole in the building wall.

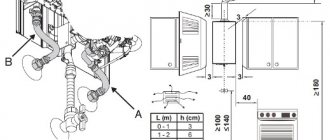

Units equipped with a closed firebox, it is allowed to install them in small rooms. Since the oxygen required for combustion is not taken from the living area, it is not hazardous. The heating unit is so compact that it can easily fit even in the kitchen under the windowsill.

- 1 What is a parapet boiler

- 2 The principle of operation of parapet gas equipment

- 3 Types and prices

- 4 Installation of a parapet boiler

What is a parapet gas boiler?

Parapet gas boilers are heating units that combine the features of atmospheric and turbocharged models. They are completely non-volatile, but equipped with a closed combustion chamber.

A special feature of this design is the use of a coaxial chimney that connects to the rear of the unit and leads out into the street. The extraction of smoke and the intake of fresh air occurs as a result of convection processes.

When starting the boiler into operation, there are no smells in the room, there are not even traces of soot and other combustion productsI.

In addition, oxygen does not burn out in the room, which allows maintaining the microclimate in a normal state.

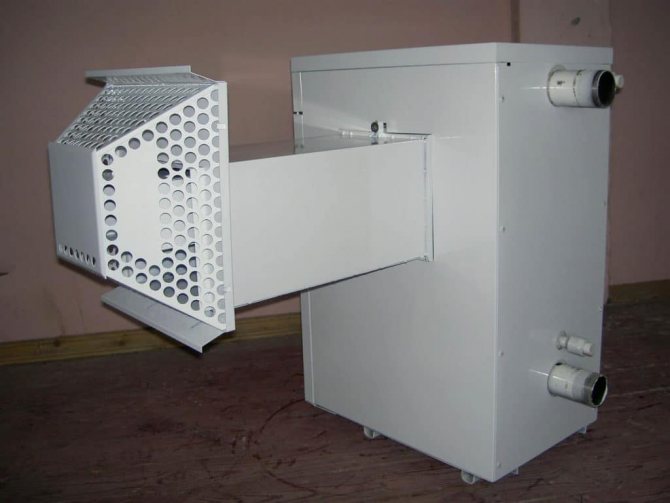

Another feature of parapet boilers is the ability to use them as independent heating elements. In the lower part of the case there are special holes through which hot air comes out.

It circulates in the room and provides the set temperature in it.

Boiler installation in the house: SNiP standards

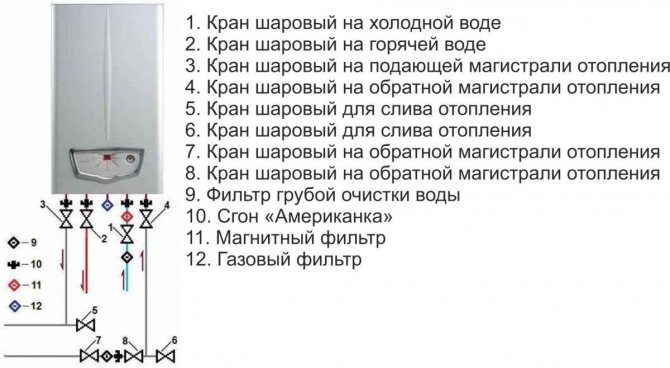

Before installation work, it is necessary to obtain all permits. Self-assembly is not only illegal, but also unsafe (especially if the device will be operated in a high-rise building).

The basic requirements and standards for gas equipment are written in SNiP 42-01-2002 "Gas distribution systems". You can also read a lot of requirements in SNiP "Gas Supply" 2.04.08-87. This document is no longer relevant today, but it still contains useful information.

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile structure and no impact on the internal atmosphere of living quarters.

If an ordinary atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then the parapet models are completely isolated and do not violate the air exchange mode.

Another difference is the ability to independently heat the air, which makes the parapet boiler similar to a stove.

Boiler requirements: selection criteria

For safety and ease of use, the correct choice of the main component of the heating system is required. To do this, you need to familiarize yourself with its varieties, since differences can be both in functionality and in the filling of the device.

The main criteria are:

- acceptable installation location;

- device power;

- the materials from which the heater is made, the number of circuits;

- auxiliary automatic devices for safety;

- the need for a pairing device.

All of these criteria are interdependent. The inaccessibility of the required area leads to the installation of the unit with less than necessary capacity. The need to heat additional volumes of water for household needs makes the purchase of a double-circuit boiler.

When choosing, it is important to consider the need for maintenance. If there are no special workshops nearby, then you will have to look for additional options or install one that is easier to maintain. Functionality becomes the main prerequisite for equipment selection.

Pros and cons

The advantages of parapet boilers include:

- lack of electricity consumption;

- internal air is not used, there is no additional load on the ventilation system;

- there is no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

The disadvantages of the models can be considered:

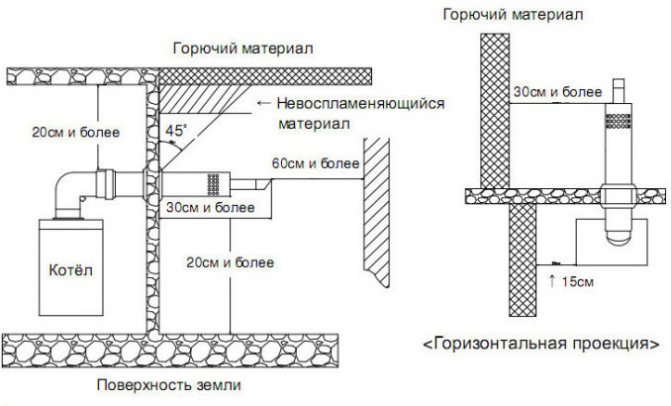

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is possible only near an outer wall;

- there is no way to provide full-function control and protection of units and parts of the unit (for non-volatile models).

Despite the shortcomings, parapet boilers are highly rated by users. The demand for them is constantly growing.

Why is the boiler blowing in the wind and what to do in this case

Blowing out may indicate a violation of the connection of the chimney and automation, more often this indicates the absence of wind protection on the head. However, in general, blowing out the flame of the burner with the wind is a significant and most well-known problem of parapetniks, which is why they never gained superpopularity.

As a rule, the casing of a coaxial chimney, manufactured at the factory, already has a special insert that protects against gusts of wind. If it is not included in the kit, then you will have to look for a suitable deflector or make it yourself: give the galvanized steel sheet the desired shape, and then attach it to the head with press washers or rivets.

Factory wind protection and an example of a homemade solution from the owners.

When the boiler, after installing the protection, still fades out, it is already pointless to do anything further: you can, of course, continue to install new heads and deflectors, build on the bends of the coaxial pipe, remove the vertical chimney, but then the whole point in installing the parapet model will be lost.

Device

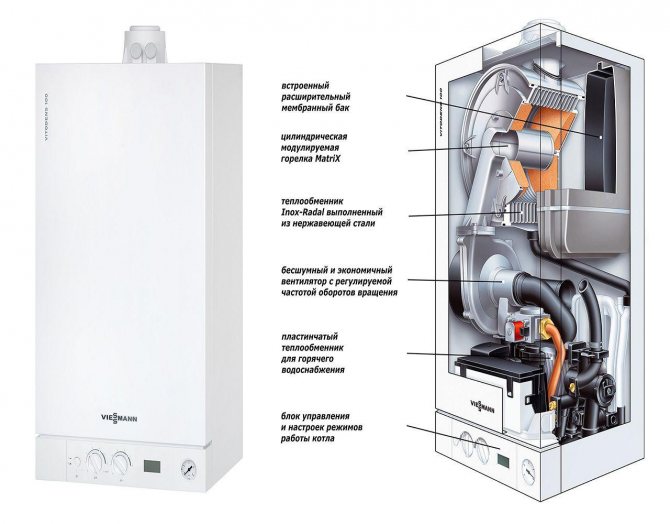

The design of the parapet unit almost completely repeats the design of any non-volatile boiler.

The coolant enters the primary (main) heat exchanger, where it receives a high temperature and enters a three-way valve (mixing unit). In it, a colder "return" is added to the hot liquid, as a result of which the temperature of the heating system takes on the parameters set by the mode.

In double-circuit models, before entering the three-way valve, the coolant passes through a secondary heat exchanger, where DHW is prepared.

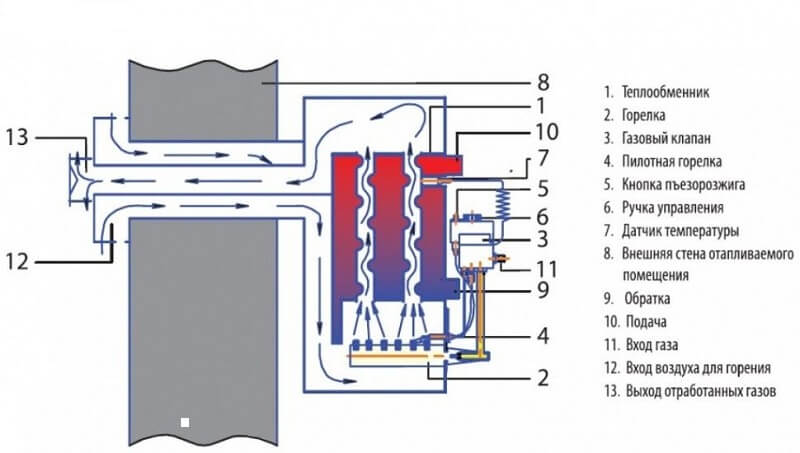

The difference lies in the structure of the combustion chamber and chimney, which are not typical for such devices.... To remove smoke, a coaxial double pipe is used, through the outer cavity of which fresh air enters, and the inner one is a chimney.

Air is sucked into a closed combustion chamber and enables the combustion process. It expands from heating and displaces smoke and other gases that occur during fuel combustion. Some models are equipped with two separate pipes, one of which supplies air and the other exits smoke.

This option allows you to enhance convection and stabilize the processes of gas movement.

How to calculate the minimum required power

In most cases, to determine the power (Q), a simplified formula is used, where 1* kW of thermal energy.

- *approximate heat loss of a brick building with 2.7 m ceilings from the middle climatic zone of Russia.

For example, for a residential building of 120 m2 located in the Moscow region, the minimum required power of a parapet gas boiler will be Q = 120 ÷ 10 × 1 = 12 kW.

We also recommend making a reserve of 15–20% of the power, so as not to operate the heat generator at the limit for a long time, i.e. for the same object Q≈14-15 kW. Also, if we are talking about a two-circuit model, then about 15–20% will have to be added to provide hot water supply, in total it will turn out that Q≈16–17 kW.

In an apartment of 120 m2 (not angular) heat loss is a priori less by 10-15%, therefore, for a unit with one circuit Q≈12.5-13 kW, with two Q≈14.5-15 kW.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Views

There are different options for the design of parapet boilers, which can be conditionally divided according to specific characteristics.

By installation method:

- wall. Installed in a hinged way on an external (load-bearing) wall. According to the installation conditions, they are limited in weight and power;

- floor. Floor-mounted. If it is wooden, a non-combustible stand is required. They have no restrictions on weight, dimensions and power.

By way of power supply:

- volatile. The design contains units that require the use of electricity - a circulation pump. electronic control board, etc .;

- non-volatile. They work only on mechanical control. A good choice for remote villages and areas with power outages.

By feature set:

- single-circuit. They are only able to provide heating of the coolant;

- double-circuit. In parallel with heating, heating agents are capable of preparing hot water for domestic needs.

NOTE!

Most users prefer the single-circuit floor standing models, which show the greatest efficiency.

Main differences and characteristics

Parapet boilers can have 1 or 2 circuits - for heating and hot water supply

The various models are available in floor and wall mounting, left-hand and right-hand designs. Depending on the purpose, they are equipped with one circuit - only for heating or two - to additionally heat water for domestic purposes. In terms of control level, devices are automatic and manual. Electricity is required for the automation to work. If it disappears, the boiler shuts down. Manual products are practically independent of external conditions and can even operate on a gas cylinder. The burner is switched on and off by a thermocouple and a permanent burning wick.

Principle of operation

The operation of a parapet boiler differs little from the normal operation of gas convection units.

The burner heats up the coolant, which gives part of the energy for the preparation of DHW or is led out to the heating circuit after preparation in a three-way valve.

There are no changes in this. A specific feature is the boiler's ability to perform the function of a convector, which makes it possible not to install radiators in the room where the unit is located.

In addition, a special method of air supply and smoke extraction is used. When the burner is ignited, an excess air pressure builds up in the upper part of the combustion chamber, forcing it to be discharged along with the smoke to the outside.

At the same time, a vacuum is formed in the lower part, which creates a suction of fresh flow through the outer part of the coaxial pipe. This creates a pressure difference similar to that used in conventional furnaces.

This allows a closed combustion chamber to be used without a turbo fan.

IMPORTANT!

In some designs, the chimney and the air intake branch pipe are made separately, but this does not change the principle of operation.

Is it possible to make a boiler with your own hands

Craftsmen who want to save money make heating boilers on their own.The main material for this is a gas cylinder or column.

In both cases, precise drawings of the device are required. The main element here is a gas cylinder with a volume of 50 liters. A hollow tube for air intake (nozzle), together with a piston and a circle adapted to it, almost covering the diameter of the cylinder, are placed inside the base. Arcuate blades are welded to the circle, which will form a vortex (turbulator swirler). For a boiler from a gas cylinder, it is necessary to have a chimney and a pump for circulating the coolant.

It is also possible to make heating for a small area from a gas boiler. To do this, you will have to turn off the water pressure regulator, add a pump for its circulation, provide room ventilation and adjust the hydraulic arrow. In this case, you will have to constantly monitor the operation of the boiler from the gas water heater, since all regulators of the normal operation of the device are turned off.

Rating of TOP-5 parapet gas boilers

Parapet boilers are devoid of many disadvantages of wall-mounted models, so their range is constantly increasing.

Let's consider the most popular models:

Lemax Patriot-12.5

Floor standing non-volatile parapet boiler of domestic production. The power of the unit is 12.5 kW... It is suitable for rooms up to 125 sq. m.

Main characteristics of the unit:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 0.75 m3 / hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

The boiler is single-circuit, but it is possible to connect an external boiler. This will allow you to get a full-fledged DHW line.

Lemax Patriot-20

Floor-standing parapet boiler produced by the Taganrog plant. The power of the unit is 20 kW, so the size of the room should not exceed 200 sq. m.

Only the basic task is performed - heating the coolant. If you need to expand the functionality, you should purchase and connect an external storage boiler.

Boiler parameters:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 1.2 m3 / hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Users and specialists note the low fuel consumption, which increases the efficiency of the unit and allows for significant savings.

Lemax Patriot-16

Another example of domestic heating technology. Floor-standing parapet boiler 16 kWdesigned for use in rooms up to 160 sq. m.

Like other models in the Patriot series, this is a single-circuit unit with a steel heat exchanger.

Its characteristics:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 0.95 m3 / hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Units of the Patriot series with a capacity of 16 and 20 kW represent the same design, only one of the models has an artificially reduced performance.

Lemax Patriot-10

A product of engineers from Taganrog. A parapet boiler with a capacity of 10 kW is suitable for a country or private house with an area of up to 100 sq. m.

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to Bar;

- gas consumption - 0.6 m3 / hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

NOTE!

Reliability and low fuel consumption make Lemax Patriot parapet boilers the most successful choice for all users.

ATON Compact 12.5E

Ukrainian-made gas parapet boiler. The power of the model is 12.5 kW, and the service area is up to 160 sq. m. Non-volatile unit designed for floor mounting.

The main parameters of the boiler:

- Efficiency - 90%;

- coolant temperature - 90 °;

- system pressure - up to 1.5 bar;

- gas consumption - 1.39 m3 / hour;

- dimensions - 630x700x275 mm;

- weight - 50 kg.

The unit is equipped with a stainless steel heat exchanger and a safety gas valve.

How to legalize the installation of a boiler

For the installation of gas heating, documentation is required. You should have in stock:

- gas supply contract;

- decorated gas meter.

If the first two points are present, the choice of the boiler begins. Before installing, you will also have to:

- Make changes to the registration certificate of the house in the BTI.

- Submit an application to the gas service to create a project.

- Install the boiler, contact a special inspection for the installation of the gas piping and commissioning.

- Obtain permission after the conclusion of a specialist.

Dignity

Parapet boilers are very small

- The presence of a closed combustion chamber. Thanks to this, the device becomes universal. It can be mounted in an apartment, because there is no need for a chimney and pipes on the roof. In an apartment, such a boiler is best placed against the outer wall in the kitchen. And if this room has a free area under the windowsill, then the boiler can be placed there.

- Extensive assortment. The power limits of modifications presented in sales are as follows: 15 - 40 kW. This allows you to choose a version for rooms of different sizes.

- Possibility of application for obtaining hot water supply. This requires a two-circuit model.

- Installing the boiler does not affect your electricity bills in any way.

- Compactness of dimensions.

- The case has a modern design. For this reason, boilers fit well into many interiors.

- Acceptable prices.

- Possibility of self-assembly.

- It can be configured to operate on a propane-butane composition. Such a need usually arises when it is not possible to join the main gas network.

These boilers also have some disadvantages:

- They are susceptible to weather influences. For example, a strong wind can blow them out. Therefore, a wind screen is often placed in front of the chimney.

- Modest power. It is extremely difficult with them to heat premises of an impressive area with high quality. This technique is more suitable for heating tasks in small houses and apartments.

- Sensitivity to defects that can occur when installing a coaxial chimney.

Top Models

Before you buy a double-circuit parapet gas boiler, you need to figure out which manufacturer is better. This will help to significantly reduce not only the number of models, but also to understand what quality the products will be. Agree, it's easier to compare several of the best models:

- The Zhytomyr-M ADGV 15 CH model, created by Artyom, is a reliable device with an efficiency of 92%. The cost of an affordable unit is in the region of 18-20 thousand rubles.

- The "Termomax-C 12E" boiler, developed by the Termomax brand, has an efficiency of 90% and is capable of heating rooms of 120 sq.m.

- The Slim 2.300 Fi device, designed by the Baxi ravings, is a double-circuit boiler with an adjustable output from 14.9 to 29.7. The unit is suitable for rooms with a size of 140-160 sq.m. The device belongs to the expensive segment, the price of the device ranges from 120 to 140 thousand rubles.

- The ecoCompact VSC D INT 306 / 4-5 190L model, designed by the German brand Vaillant, is a reliable but expensive device capable of heating an area of 150-170 sq.m. The unit is equipped with a 190 liter boiler.

If you need a budget and high-quality boiler, you can choose one of the Zhytomyr models created by the Artyom brand.

Outcome

Parapet-type gas boilers are the best solution for an apartment or a small house. A wide range of models allows you to choose the optimal solution both in terms of quality and price. A properly chosen device will provide warmth for many years.

It is important to know how to properly install a parapet gas boiler in a building. The video shows all the subtleties of installing heating equipment.

The best boiler manufacturers

There are many popular manufacturers from Europe, Russia, Korea, China, etc. on the heating system market. The assortment of each brand has successful and effective models, but most often such units belong to the expensive segment. Naturally, the quality of European equipment is much higher than that of Chinese heating systems, but the price is correspondingly higher.

Features of equipment from different manufacturers:

- The Korean company Navien produces inexpensive devices and a large number of spare parts for them. Of course, the quality of the cheapest devices of the company is not high, but you can find several good models in the expensive segment.

- Baxi is a renowned Italian manufacturer. The company's boilers are distinguished by their functionality and reliability, despite the fact that most of the units are assembled in China.

- The domestic brand Lemax produces many good parapet boilers that are notable for their low price and acceptable quality. The assembly of equipment is slightly below European standards, but the cost compensates for this disadvantage.

- The renowned Ariston brand also produces good heating systems. The company's technology stands out for its economy and quality.

- The German brand Vaillant is a renowned manufacturer of premium heating equipment. If funds allow, then it is worth giving preference to the parapet boilers of this company.

- Some devices of the Slovenian company Protherm can be compared in quality and reliability with Baxi units. The cost of the company's gas boilers is significantly lower than that of the Italian brand.

- Artyom company is a well-known Ukrainian brand that produces inexpensive and reliable boilers.

Many Russian and Ukrainian companies are engaged in the development and production of heating systems, but only a few of them create high-quality equipment.

Which gas boiler is the most economical Gas boiler Bosch 6000 which is it

Operating principles

Piezo ignition for boiler

The operating cycle of this equipment includes the following stages:

- At start-up, the user can activate the pilot burner. Piezo ignition is used.

- Gas is automatically supplied to the main burner. It is activated.

- The very hot exhaust gases flow into the heat exchanger. The water heats up.

- When the boilers are not connected to the heating network, hot air is supplied through special openings. They are called conventional and are located on the body of the device. They are covered with decorative grilles.

Scheme:

- The heat carrier (most often water) in the heat exchanger reaches 90 degrees. When the extreme values are reached, the sensor acts. And the gas valve stops the fuel supply.

- The heat exchanger is cooling down. The sensor works in the opposite way. Fuel is supplied and operation of the main burner begins.

In the event of a gas cutoff, the ignition burner and the boiler itself are turned off. Piezo ignition is used to resume work.

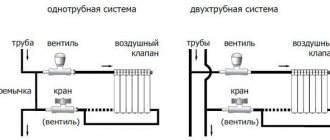

Devices with one and two circuits

Parapet boilers are produced in a standard rectangular shape, one- and two-circuit, left- and right-handed, which makes their installation easy and convenient.

Single-circuit are intended only for heating. They are equipped with a plate heat exchanger, which ensures the rate of heat exchange between the gas burner flame and the heating medium.

An additional copper coil is provided in the double-circuit parapet boiler, which provides the house with hot water supply. Water heating occurs only in a flowing manner. If we use a storage tank, then the size of the equipment will increase significantly, which will make it impossible to install it in an ordinary apartment.