In the operation of stoves and fireplaces, fire safety is considered a priority. Fireplace doors allow you to protect yourself from accidental sparks and coals that got into the room from the firebox. And if they regulate the intensity of fuel combustion and draft in stoves, then they are arranged in fireplaces to protect against fire. It should be visible, otherwise the essence of the hearth will disappear. Since it heats the room, and also makes it possible to admire the living fire.

Doors: construction

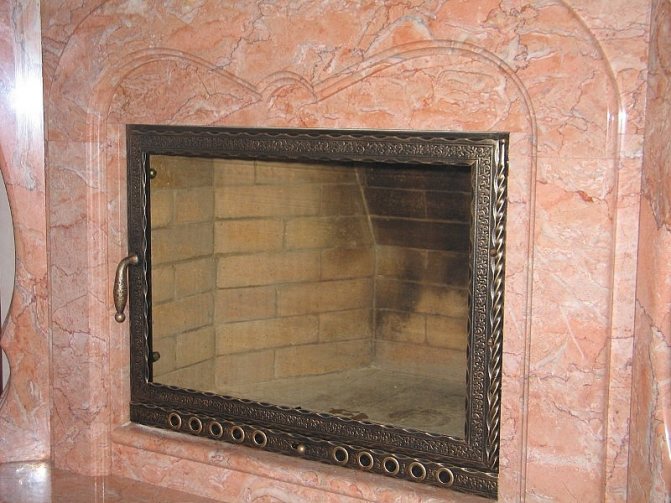

To create a panoramic effect, glass fireplace doors are used. The glass is surrounded by a metal frame around the perimeter, in which there is an insulation gasket. In fact, it is a transparent ceramic, therefore, it can withstand heating up to 800 ˚C. The configuration of the door depends on the style of the cabinet, while it occupies a large or the entire front area of the firebox.

Glass comes in different sizes: medium, small, large. In this case, geometric shapes are made as follows:

- rectangular;

- arched;

- trapezoidal;

- flat or convex;

- round, oval.

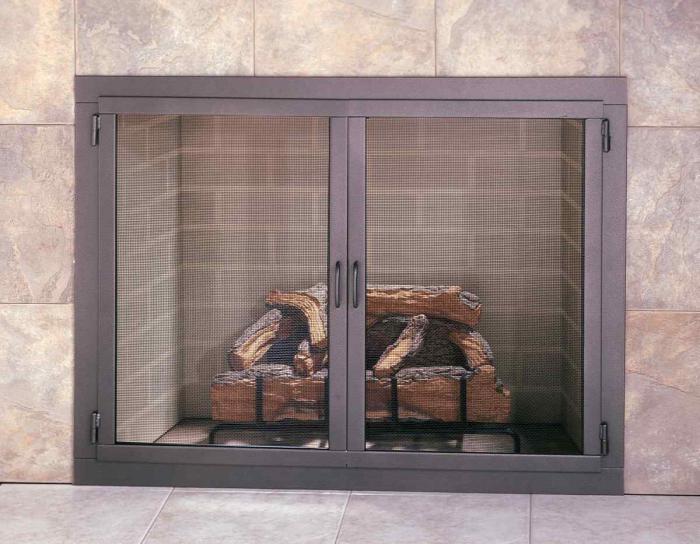

Closing the doors with glass is also possible in various versions. Among them, the most convenient:

- double hinged (two doors in the middle are connected, hung on the hinges on the sides);

- swing (one flap is on the side hinges);

- close up vertically.

Structurally, the doors for stoves and fireplaces can consist of one or more rigid parts connected to each other. Each of them is installed in the sash, pre-framed with a seal. Panoramic glasses are the most convenient for observing the flame. They are not divided into parts and are practically equal in area to the dimensions of the sash. A similar design is suitable for a large fireplace in a country house, which is equipped with a chimney structure.

Materials and glass making

In order to create a door for a furnace with glass with your own hands, you will need materials such as:

- silicone sealant;

- about 4 glass panes, suitable for the screen size;

- stones for decoration;

- metal mesh or lattice;

- a box made of metal, the size of which will match the size of the screen.

The arrangement of a glass fireplace screen is quite simple:

- Silicone sealant is applied to all 4 glasses at their edges.

- All glasses are fixed in such a way as to form a parallelepiped shape. It is important to respect right angles.

- The planes of the elements are firmly pressed against each other and remain in this position until the sealant has completely solidified.

- The remnants of the substance that have protruded beyond the plane must be cut off.

In this simple way, you can make a screen for a fireplace.

Glass doors

Recently, the most popular doors are made of heat-resistant glass. This option is very attractive for its openness: the ability to observe the flames and sparks flying out of the fire creates an atmosphere of special comfort and coziness in the room. For the manufacture of such doors, heat-resistant glass is used, which includes heat-resistant quartz and transparent crystal ceramics. These two components provide both an attractive appearance and the required level of operational safety.

There are several types of glass doors for fireplaces and stoves:

- flat: have a thickening of one glass;

- segmented: three glasses are available;

- circular.

Combined fireplace doors are often found, when fire-resistant glass is framed in a metal frame.Decorative elements - forged or cast, made in the form of a mosaic or stained glass - are also not uncommon. Such doors bring a touch of antiquity and antiquarian to the interior of the room.

The most obvious disadvantage of a glass fireplace door is that it gets soiled and soiled quickly enough. The solution to this problem lies in the special design of the fireplace or stove at the stage of their manufacture: the unit is equipped with a soot burning system, which ensures the complete combustion of soot during combustion. The correct device and timely maintenance of the chimney is also important.

We suggest that you familiarize yourself with: How to insulate a metal chimney pipe in a bath: oven insulation, how to wrap a chimney

Glass doors are the prerogative of not only fireplace heaters, but also stoves.

Iron doors

Such doors are made entirely of metal, and their installation on a finished unit is quite simple. They retain heat remarkably, but their most important positive quality is to ensure a high level of fire safety. The doors are comfortable and reliable in operation.

The most obvious advantages of such doors are:

- Low price for the finished product (compared to glass counterparts) when it comes to buying, not making it yourself.

- Strength and durability of the structure, reliable operation. Periodic maintenance of the product, which consists of coating it with heat-resistant anti-corrosion paint, will save you from repairs and frequent replacements.

Cast iron doors

This type of door is most typical for stoves, and not for fireplaces. Their advantage is the highest resistance to high temperatures. The obvious disadvantages are the lack of the ability to observe the flame, and a shorter service life compared to metal counterparts. In order to make cast iron doors look more attractive, they are covered with heat-resistant enamel.

In addition to the above door options, depending on their material, there are also differences in the number of doors or in the color of the product (completely black or shiny stainless steel). An important feature of the purchased doors in terms of functioning is the ability to connect the air intake pipe from the room and ensure the absolute tightness of the fuel chamber.

The considered door options can be purchased at specialized stores. But, often, the process of making a fireplace or stove door on your own is not so complicated. Consideration of this process is suggested below.

Operation of doors

If your fireplace runs on wood, then soot begins to settle on its walls over time. The situation is aggravated by coniferous logs by the fact that they actively emit resin. On the walls, they settle in the form of soot. Consequently, fireplace doors become cloudy and dirty. To combat this phenomenon, a self-cleaning system has been created.

It is an air curtain created by the flow of air through the slot. It hits the upper part cold and goes down. Thus, the glass door does not need to be cleaned.

Groups of doors in the process of masonry

Furnace door

The stove has doors for various purposes. Each element has its own role. The following doors are shared:

- furnace;

- view;

- blowers;

- clean-out.

Furnace

Designed for fuel filling. The firebox door performs the following functions:

- protection of the surrounding premises from fire;

- transfer of heat from the material burning in the firebox to the room;

- preventing sparks from flying out;

- provides combustion with oxygen.

The material is chosen based on its practicality or the desire to decorate the interior of the room. The latest trend in fashion is an oven door with glass.

Blower

Installed on the ash chamber, through it the furnace is cleaned from ash, which spills into the lower compartment. The blower door provides the process with air. By opening or closing it, they regulate the flow and rate of fuel combustion.

Blowing doors are made of cast iron or steel, less often glass. They can be of a simple design, or they can be made of cast iron with a relief finish or ornament. They are performed in the same style as furnaces.

Cleaning

Close the hole in the wall of the chimney and serve to clean it from soot and soot. It is an essential element in the design of the stove to ensure its correct operation. Some builders ignore their installation, but an experienced stove-maker never goes without cleaning holes. Their presence simplifies the maintenance of the stove and its smokeless operation.

View

To prevent hot air from leaving the stove after combustion of the fuel, a valve is installed on the chimney. It is a frame with grooves along which the plate moves, covering the flue duct. The valve is placed in the brickwork of the pipe.

Clean Blower View

Wrought iron doors

It should be noted that the same requirements are now imposed on the materials of the shutters, regardless of the shape of the fireplace body. If it has an angular shape, and the sash is shaped, the metal can make up its main part. For this, cast iron or refractory steel is used, and glasses in a similar version have the form of a stained-glass window. That makes it possible to combine glass of various textures and tints.

The cast-iron fireplace door must always be closed to prevent further floor ignition. If a biofireplace is used (this is typical for an apartment), then it is made from the same materials: metal and glass ceramics. Fittings of various types of sashes usually include handles that can be removable, hinged hinges, locking mechanisms, fasteners.

Fireplace door requirements

On sale you can find ready-made cast iron fireplace inserts with glass and separate doors designed for installation in brick hearths. The door should be purchased before the start of the brickwork, otherwise it will be more difficult to find a product of the appropriate size

Fireplace doors with glass are reinforced with a sturdy cast iron or steel frame and completed with a handle. Ideally, the handle should be made of non-heating material. Fireplace doors are distinguished by size, opening principle, frame material, design. With the help of modern technologies, embossed patterns and multi-colored ornaments are applied to the glass surface. Stained-glass and tinted glass look very impressive.

The most interesting from the point of view of design are the doors opening according to the guillotine principle. They allow you to operate the fireplace not only in a closed, but also in a classic open form. Considering the heavy weight of the refractory structure, it is worth looking at the automatic opening mechanisms that provide additional protection against burns.

Single sided glass door

- Heat resistance is the most important indicator of heat-resistant glass for a fireplace. The recommended operating temperature is indicated in the passport of each product, as a rule, it is 500-550 degrees. Maximum performance (up to 1000 degrees) can be found in laminated glass. Here you should focus on the preferred fuel, for example, a higher temperature resistance is required for wood burning.

- The service life of thermal glass is indicated in hours. The higher the operating temperature, the less the glass door will last. Manufacturers recommend adhering to a combustion temperature of no higher than 550 degrees, while ensuring normal traction.

- The thickness of the glass fireplace screen determines its strength, in this case it is better not to skimp and purchase a product with a thickness of 3.5-4 mm.

- Laminated glass is superior to single-layer glass in all respects, but experts believe that one layer is quite enough for a home hearth.

- Self-cleaning fireproof glass for a fireplace is coated on the inside with a thin layer of metal oxide. The invisible coating increases the surface temperature so that the soot burns away without leaving a trace.

- Soundproofing protects residents from the pleasant, but quickly annoying sound of the crackling of burning fuel.

Double-leaf patterned door

Externally, stove or fireplace doors with glass, as a rule, look modest. And they represent a metal rectangular "frame", inside which is inserted the same rectangular glass (sometimes double).

A custom-made door will cost 2 or even 3 times more

True, there are some design deviations. For example, the frame is made rounded. They attach beautiful original handles to it, create fancy patterns on it. Or they install spros - decorative overlays for glass in a box.

The dimensions of fireplace doors with glass are determined by the dimensions of the fireplace itself. Those. in width it is 15-80 cm, and in height - 15-60. The weight of the oven doors is impressive: from 3 to 35 kg - depending on the size and specific materials.

Heat-resistant glass is slightly yellowish, but its transparency is high

How safe is a glass door for a stove or fireplace? We answer: all 100! After all, heat-resistant glass is used - quartz, which, unlike ordinary silicate glass, is more refractory. Plus, it is polished, treated with special compounds, hardened. And it becomes practically "immortal" - it can withstand temperatures from 700 to 1000 ° C.

And so that soot does not settle on the glass, it is subjected to pyrolysis treatment - it is covered from the inside with metal oxide (and in the structure of the fireplace itself there is a secret that does not allow the glass to get dirty). The soot on the glass, when the fire starts, burns out.

Can you install plain tempered glass in oven doors? No, because the "threshold of tolerance" for such glass is 150 ° C. The temperature in the fireplace is much higher.

Frames for fireplace doors are made of steel and cast iron, which are also not in doubt. However, steel is still stronger, and when making a door, a small volume of it is sufficient. Cast iron is looser, the doors from it are massive (so more reliable) and heavy.

The stove, like the fireplace, is classified as a special heating unit, the structural elements of which are characterized by high heating. Often fireplaces are installed not for heating the room, but for interior design.

The main function of the structure is still heating the room, the requirements for heating units are increased:

- If you make a door from the fireplace yourself, then you must definitely use fire-resistant materials, it is better to pay attention to cast iron and fire-resistant glass.

- When installing doors, you need to take into account that air must flow to the combustion chamber. Now they are producing such design options where the oxygen supply is regulated.

- Doors must be fireproof. This is done for reasons of protecting housing and its interior; it is important to understand that a spark can fly out even through a gap.

Compliance with these requirements guarantees safe and durable operation of the fireplace.

Metal door

Today it is very common to see fireplaces, the doors of which are made of thermal glass. The first do-it-yourself fireplace door was made of metal. The difference between such structures is that they could not be integral. An important feature is also the shape of the doors. The point in this case is that the fireplace was able to heat the room solely due to thermal radiation, which required an open hearth.

The advantages of metal doors include their visual appeal. There are several disadvantages. In such doors, there is practically no protection against the resulting smoke. In addition, they will obscure the view of the fire, thereby depriving it of its special charm. Fireproof metal fireplace doors also differ from others in that they prevent heat radiation. And this is not particularly welcomed by the owners of the house. Although the doors do not interfere very much, since the metal can heat up and then give off a little heat to the room.

Decor and other functions of the fireplace door

Against the background of the shortcomings of an open firebox, the fireplace door is just a miraculous salvation from all of the listed shortcomings. Even though the flame is hidden behind the glass door of the firebox, you can continue to admire it through the transparent glass. Everyone knows about the decorative functions of closed fireboxes, so let's go straight to technical issues.

Good to know: Arrangement of a fireplace with air heating, how to make it yourself

A closed firebox allows you to install a water circuit in the fireplace, and this is already a prerequisite for the full use of the fireplace as a heat generating device, moreover, the main one.

Due to the special design of the door, it is possible to use slow burning technology. By adjusting the air supply, they achieve a better combustion of fuel, therefore, an increase in efficiency. By installing protection, you can rest assured about safety, even if children are playing in the room.

Classic fireplace design

Glass fireplace doors

Glass is a very fashionable material today. It became widespread in the twentieth century. And the appearance of fire-resistant glass completely changed the views on the design of the fireplace. This new material made it possible to observe the flames. In addition, it became possible to control the combustion, supplement it, change it without checking each time by constantly opening the doors.

Among the glass fireboxes, you can see facades of different nature: convex, prismatic, angular, three- and two-sided - whatever the consumer chooses. They will not hide the flame from the eyes at all, but quite the opposite - they can increase the viewing angle.

Types depending on the design of the stove

A heat-resistant cord is laid in a sealed door around the perimeter

If you need a door for the oven, you should pay attention to its design. They can be leaky, sealed or airtight.

Ordinary doors

This is a common classic model with a swing handle securing the door from opening. Installed in simple brick stoves in old country houses. It is not airtight. Such a design may have a mechanism that tightly presses it to the hearth.

Hermetic doors

Oven doors with glass can be airtight. To seal the gap around the perimeter, an insulating cord made of heat-resistant material is laid. A tightly closed door contributes to strong combustion, high speed of fuel combustion and rapid heating of the room. Sealed doors prevent the penetration of combustion products into the surrounding room and air pollution.

Strained glass

It is made from simple glass by tempering: it is heated to a temperature that causes softening, after which it is very quickly cooled. Due to this painstaking work, glass is able to acquire the characteristics that are necessary. Resistance to high temperatures (400 degrees) appears. In addition, along with this parameter, resistance to various mechanical damage arises. This figure is 2.5 times higher than that of a simple glass coating.

Quartz glass

It is made from silica (quartz or sand), not glass.Other impurities are not added at all, or at a minimum. Such glass has the most elementary composition, but the production technology is highly complex. It has a very high melting point, which makes it difficult to process and process. But today it is increasingly used in the manufacture of fireplace doors. It is thanks to the high efforts that were put into production that this glass has a high price, being considered one of the most expensive.

How to install a fireplace door with your own hands - a step by step diagram

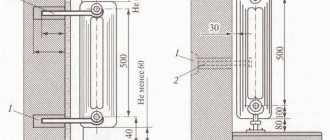

Step 1: Determine the size

Manufacturers of fireplace doors do not produce them wider than 70 cm - such a design would be too heavy for a fireplace. Therefore, the door for the fireplace with glass, which you are going to buy, should not be wider than 50 cm in the optimal version. Focus on the existing opening and select the door a little wider than the opening so that you can insert it more tightly. When the door is purchased, remove the glass from the door to avoid unexpected situations during installation. This is usually quite easy to do - the glass is clamped with bolts.

Step 2: cutting the grooves

The dirtiest and dirtiest work awaits you, because you will have to cut nothing but a brick, and even in an enclosed space. With a high power grinder, you can reduce the amount of dust if someone else pours water onto the cutting line, but if the grinder is less powerful, you will have to cut it extremely dry. In this case, do not even think to do without a respirator (or at least a gauze bandage) and safety glasses, otherwise all this dust will settle on your lungs and eyes. After you have gone through one seam, you can chop off the pieces of brick with a hammer and chisel. Try on the door - if it fits tightly, then we have achieved the desired goal.

Step 3: insert the door

Stir the heat-resistant oven mixture as thoroughly as possible following the directions on the package. It is best to knead in small portions so that you can work it out in half an hour. When the solution is ready, soak the asbestos cord in it and wrap it around the door in at least two layers, trying to achieve its uniformity. When the cord is wound, carefully insert the fire door into its place, if necessary, tapping with a rubber mallet on its surface.

Additionally, the door must be fixed on ceramic dowels - it must have the appropriate connectors. If somewhere around the perimeter you notice a gap, even a small one, it is best to seal it up with the same asbestos cord - dip it in the solution and push it into the gap with a screwdriver, and carefully seal the surface with the rest of the solution.

Step 4: First firebox

When the solution has set properly, insert the glass in its place. A few days after installation, lightly heat the fireplace - see if smoke passes somewhere, if the fire burns well. You may need to widen the blower as the air flow has decreased significantly. When a closed fireplace is made according to all the canons, some craftsmen generally supply air from the street so that the fire does not "eat up" the oxygen in the room. If the work was done well, you will not have any problems, and you can proceed to other stages of the work, for example, tiling the fireplace.

- Author: Mikhail Malofeev

Rate the article:

- 5

- 4

- 3

- 2

- 1

(3 votes, average: 1 out of 5)

Share with your friends!

Borosilicate glass

This glass is made from a large amount of silica with the obligatory addition of boron oxide. This chemical element is famous for being able to provide a low melting point, which means that the glass will have plasticity. The finished product is capable of having a high degree of heat resistance (about 800 degrees). In addition, it will be endowed with a special mechanical strength, 5 times higher than that of ordinary glass.That is why fireplace doors are so often made from it.

Making doors

These works are not very difficult, therefore, they can also be performed by a non-professional. You do not need specific skills and knowledge. Production takes place in this order:

- According to the required parameters, a corner is cut out, which is laid out on an absolutely flat surface. Then it is inserted into the mold.

- The uniformity and correctness of the connections is checked using a square.

- The joints of the elements are fixed together by welding.

- Residues of welding are cleaned.

- A frame is installed on a metal sheet, and door contour marks are also made on the sheet.

- If the metal is about 2mm thick, then you don't need to weld a separate frame. Now its size is drawn - a little more than the internal one. The sheet will overlap, so it can protect the room from smoke.

- The metal element is cut with a cut-off wheel and a grinder.

- The curtains are welded to the frame, after which a pre-prepared element is exposed. Then the accuracy of placing the curtains is checked, as well as their further tacking to the metal.

- The weld rush is removed, after which the handle is attached.

Now it is clear that it is quite possible to make a door with your own hands. Anyone can make this product. At the same time, it can be operated for a very long time.

Summing up, it can be noted that any type of doors is good in its own way. Materials for fireplaces are selected depending on the conditions of their operation. Consequently, this is the responsibility of the fireplace manufacturer.

Do-it-yourself fireplace door with glass

To get a beautiful fireplace door with glass, you need to prepare a metal frame of a certain size or frame elements. Next, they need to be welded to each other by welding, forming a piece of the desired length. It is imperative to fix and then clean the joints of the elements from the remnants.

Glass doors must not only be correctly installed, but comply with the norms during their production in order to get a quality product as a result:

- Production must be continuous, or with short interruptions;

- Polishing is best done at high temperatures;

- Also, a key stage is the coating of the glass surface with special chemical elements, thanks to them, it becomes much stronger.

Fireplace doors are equipped with glass that can withstand high temperatures

You also need to pick up and weld curtains, the final stage is the installation of glass doors into the finished frame and their fixation. Before starting work, it is imperative to protect your eyes from the ingress of debris and shavings, and when working with welding, wear a special protective helmet. It is better to wear gloves on your hands, and when working with electric tools (grinder, emery), you must follow all safety rules.