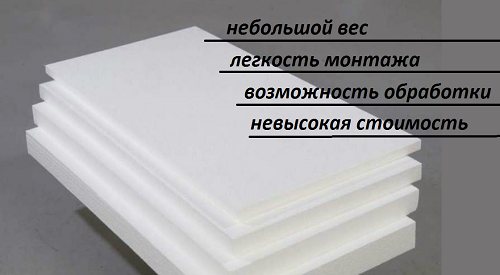

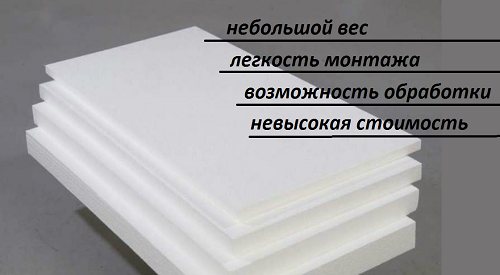

Sheet (slab) heaters are well-deservedly popular among builders and homeowners. They have very low hygroscopicity, so they do not need additional waterproofing, extremely low thermal conductivity, lightweight, and, at the same time, if necessary, you can choose a brand with a very high compressive strength. The main advantages include immunity to ultraviolet light, frost and fungal infections.

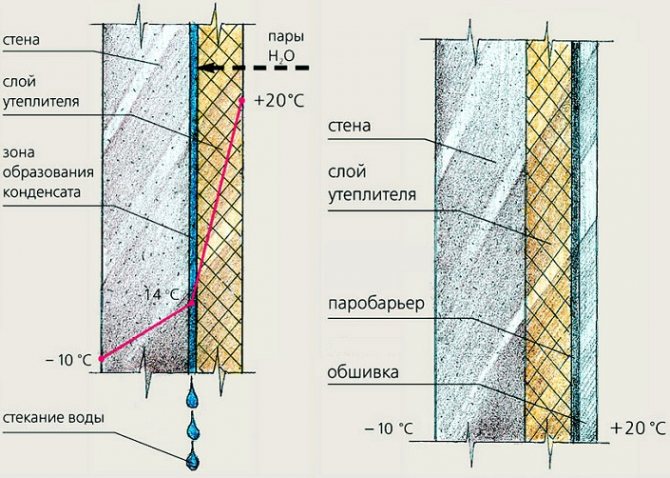

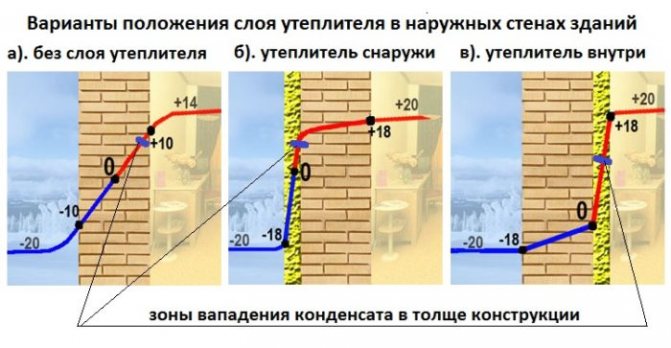

They are used everywhere, from the foundation to the roof. They also carry out external wall insulation with foam plastic. It is necessary to pay attention - it is external, although in some cases, when for some reason it is impossible, the inner surfaces of the room are also lined with it. However, this does not have a very good effect on the internal microclimate of an apartment or house, it interferes with moisture removal, because the difference between the external cold wall and the internal warm foam will lead to the formation of condensation and make the air damp. In addition, the insulation takes away a considerable useful area - after all, some kind of finishing will also be required on top of the sheet.

Therefore, wall insulation outside with expanded polystyrene (the full name of polystyrene) is a method that has much wider application. Although it costs a little more than using roll types of thermal insulation, it gives more reliable protection, and it is much easier to do it yourself. This task is not difficult at all, but only for owners of apartments located on the ground floor, or private houses. For work at height, you will have to contact specialists.

Usually, external wall insulation with foam plastic is performed with a material with a thickness of 50 mm of the M25 brand (density - 25 kg / m3)... In terms of thermal insulation qualities, it replaces 50 cm of brickwork, which is quite enough for most regions (especially considering that the existing walls do not disappear anywhere, and their thermal efficiency will still increase after insulation). It is this type of foam that provides sufficient vapor permeability, in contrast to the 10 cm material of the same brand, or 50 mm M-35. This means that the insulated wall along the outer contour will not “cry” from the accumulated moisture, creating a favorable environment for bacteria and contributing to the dampness of the base material.

From which side to insulate the house?

For the most efficient dew point output, it is best to use outdoor insulation walls. The reason for this is that the layer of insulation installed outside excludes direct contact of the wall with the outside cold air, which is why the outer surface of the wall ceases to give off heat to the atmosphere.

Wherein, the inner surface of the wall heats up from the warm air of the house and loses its ability to condense moisture... The dew point is transferred beyond its limits, deep into the insulation material, which almost completely excludes any harmful processes - inside the insulation (if installed correctly), there is nowhere to get moisture. Therefore, external insulation is much preferable to internal insulation, in which there are great difficulties with cutting off steam.

Dew point

The only serious drawback of the outdoor method of insulation is the complexity of the work - the need to use forests, sometimes you have to resort to the help of industrial climbers, etc. Specific conditions impose their limitations and can cause a lack of quality of work, therefore, the process should be carefully thought out and organized in the most efficient way.In addition, there are restrictions on the outside air temperature - in winter, external wall insulation is not performed.

These types of insulation are suitable for external and internal insulation:

- mineral wool;

- Styrofoam;

- penoizol;

- extruded polystyrene foam;

- penoplex;

- penofol;

- polyurethane foam.

About roofs and their thermal insulation

There are several ways by which roof insulation is carried out in any room:

- In the first method, plates from this material are used. up to 70 mm thick... A bituminous layer is laid on top of them, completely protected from moisture. Expanded polystyrene plates are also laid on top of the rafters so that heat loss is minimal, so that so-called cold bridges do not appear in the structure.

- In addition, expanded polystyrene boards can be stacked only on the back of the roof. Condensation of water vapor is prevented by creating a small ventilated surface. Such insulation is economical, at low cost, it helps to achieve significant results.

Which foam to choose for thermal insulation on the outside?

The following are currently being produced types of foam :

- PBS-S-15. Has the lowest density, used in secondary objects.

- PBS-S-25. The most used material has optimal characteristics and price.

- PBS-S-35. Material used for insulation and waterproofing of underground structures - foundations, plinths.

- PBS-S-50. The densest type used in critical facilities with difficult operating conditions.

IMPORTANT!The declared density of the material often does not match the actual, therefore, when purchasing material, it is better to insure yourself and buy a more dense one.

In addition, there are modified foam samples - for example, extruded polystyrene foam (EPS). It has a higher strength, does not crumble. At the same time, it is flammable and has a lower vapor permeability than conventional foam. In addition, it is more expensive, which somewhat limits its scope.

Pros and cons of expanded polystyrene

The characteristics of expanded polystyrene allow it to be used only for external wall cladding. For internal work, it is rarely used, and there are many reasons for this:

- Insulation expanded polystyrene burns, and when it burns, it emits highly toxic black smoke that is dangerous to human health. The material itself is harmless, but if a fire occurs, a person in the room can suffocate in a few minutes;

Emission of toxic smoke when burning

- The material is impervious to moisture, which leads to condensation. Constant high humidity leads to the formation of fungus and mold; in a private house, rodents can start in a layer of insulation;

Rodents and styrofoam

- It will be necessary to create forced ventilation in the room, otherwise it will be constantly stuffy in it.

However, for outdoor use, this is one of the best materials, which has a number of useful properties that distinguish it favorably from other insulation materials. It is worth expanded polystyrene (for example, Penoplex insulation) is inexpensive, easy to process (it can be cut with an ordinary knife or jigsaw), perfectly protects the house from both high and low temperatures.

Insulation of walls with expanded polystyrene outside is a guarantee that in the next 10-15 years you can not be afraid of the most severe cold weather.

Advice! Usually, for external insulation, polystyrene foam of the M25 brand is used, the thickness of the plate reaches up to 5 cm... It is irrational to use thicker foam plates: due to low vapor permeability, moisture will accumulate between them and the wall, which negatively affects the main material.

According to its insulating properties, such a layer will be equal to 25 cm of brick - this is quite enough even for regions with the most severe climate.It is these positive qualities that explain the high popularity of expanded polystyrene in the building materials market.

Foam thickness

An insufficient layer of insulation is fraught with a shift in the dew point

As already mentioned, the quality of thermal insulation is very significantly affected by the thickness of the foam for insulating the wall from the outside. After all, if the insulation layer is of insufficient thickness, then it is possible that the building will freeze during the cold season. This is fraught with a displacement of the "dew point" inside the dwelling, and, consequently, increased humidity and fogging of windows and walls.

Many novice builders believe that the thicker the foam, the better. This is an erroneous opinion, since there are also nuances here. For example, the desired effect will not be achieved, and material costs will increase significantly.

The best way is to correctly calculate the optimal thickness of the insulation. In this case, it is necessary to take into account the building material used in the construction of the dwelling, and the peculiarities of the climate.

Insulation will save on energy

The listed advantages will tell you how to choose foam:

- significant reductions in costs, material and installation work;

- saving heat for energy resources;

- there is no need to use additional heating devices, which also saves the family budget;

- due to the insulation of the walls with foam, it is possible to reduce the thickness of the walls from the main building material;

- stabilization of the temperature regime in the room;

- achieving the state of the ecology of the building;

- an increase in the service life of the building, since the foam will reliably protect the walls from the influence of climatic factors.

Do-it-yourself insulation of facades with expanded polystyrene: the use and selection of a heat insulator

Before you get acquainted with the detailed instructions for installing a polystyrene foam heat insulator, you need to know that:

- Expanded polystyrene should be chosen for insulating brick, reinforced concrete, cinder block houses, as well as shell buildings.

- Installation work should be carried out in warm, dry weather.

It is advisable to hold them in the last months of spring or early autumn. Rain and scorching sun negatively affect expanded polystyrene, as a result of which its thermal insulation index deteriorates. - On sale there is more material in slabs. But you can also find a sprayed version. The latter is not recommended to choose if you plan to do the work yourself, because it requires the participation of specialists.

High-quality insulation of facades with expanded polystyrene depends on the correct choice of its thickness. Therefore, we advise you to adhere to the following proportions of wall thickness to the thickness of the insulation when choosing such a material:

- 1 brick - 50 mm;

- 1.5 bricks - 38-40 mm;

- 2 bricks - 32 mm;

- 2.5 bricks - 29 mm

Materials and tools

To work with insulation, you need to prepare:

- Drill and hammer;

- Construction knife;

- Spatulas with different lengths;

- Level, plumb.

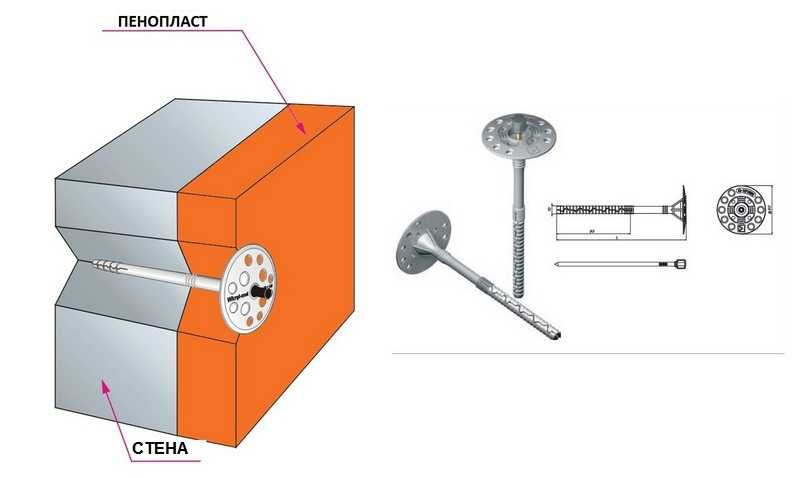

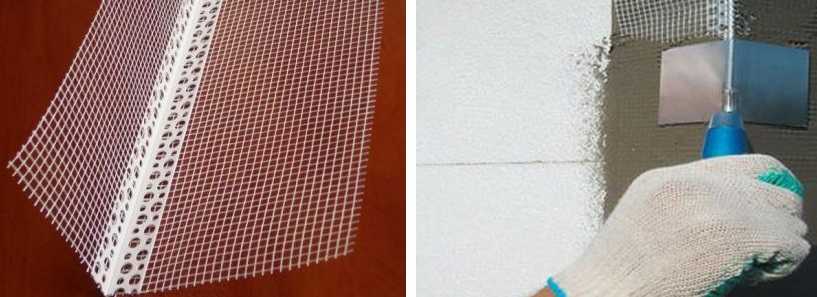

To insulate a house with expanded polystyrene, you will need the heat insulator itself, as well as fasteners in the form of construction "fungi". You also need to purchase a special adhesive. Typically, in such cases, polyurethane glue is used. To seal the gaps between the plates, you will need polyurethane foam. To prepare the facade for finishing, you need to buy a reinforced mesh. For facade work, a material with a density of 150 g / m2 is suitable. IMPORTANT! The degree of evenness of the facade surface depends on the density of the mesh.

How to determine thickness

The thermal resistance of the material (R) plays a significant role in calculating the thickness of expanded polystyrene. The quality of the building's thermal insulation depends on it. This value is individual for each region. Some of them can be viewed in the table below.

If the walls consist of several layers, then it is necessary to summarize the thermal resistance values for each material.

The calculation of the thickness of the foam is made by multiplying the indicators of thermal resistance and the coefficient of thermal conductivity, which can be found from the table.

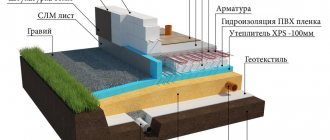

About thermal insulation of the foundation

The foundation of any building becomes the foundation, thermal comfort and durability largely depend on this element. Therefore, one of the first places should be the question related to the insulation of the foundation, especially this is true for regions where the climate is rather harsh. As the middle part of three-layer foundation blocks, polystyrene foam plates are traditionally used.

When device

basement premises expanded polystyrene also proved to be quite good. Insulation plates are placed on a specially prepared area. There can be one layer, but you can make several. Then everything is poured with concrete, the structure is erected in the usual way.

In this case, the concrete screed becomes both the base of the floor and the foundation. At the same time, the need for a point foundation for bearing supports does not disappear anywhere. Expanded polystyrene can be used for thermal insulation and in cases where it is necessary provide additional protection against freezing.

Insulation of the walls of the house with expanded polystyrene outside - stages of work

The main task of cladding insulation of a brick wall with polystyrene foam with your own hands outside is to reduce the cost of energy resources necessary to maintain an optimal microclimate inside a residential building.

Preliminary preparation of the wall

First, you should inspect the surfaces to assess the amount of work. Revealed cavities and cracks should be repaired with a cement-sand mixture. If the walls are painted, the old layer must be removed.

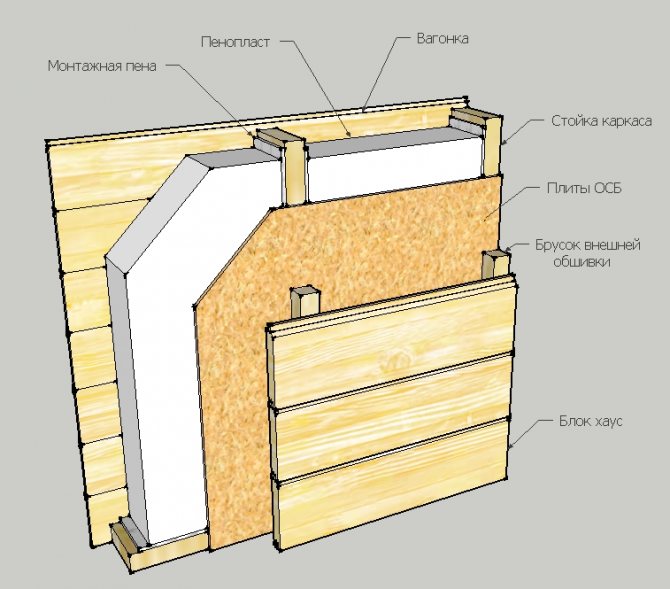

For accurate wall insulation outside the frame house, it is necessary to prepare the surfaces with high quality - eliminate irregularities and dry wet areas.

We insulate the slopes

Windows and doorways are the main areas of the square where significant heat loss occurs. Therefore, it is necessary to organize the thermal insulation of the slopes. This process consists of several steps:

- cleaning the surface from dirt;

- primer of slopes in two layers to improve adhesion;

- leveling by grouting;

- insulation cutting;

- applying a layer of glue;

- installation of plates;

- foaming of the formed cracks;

- plastering.

Finishing can be done later when finishing the walls.

Pasting the cornice

Before insulation, the cornice should be processed. In this case, it is important to follow several rules:

- choose a material of the minimum thickness so that it can adhere to the glue layer;

- strips of insulation must be started to glue from the wall;

- first, the vertical elements are fixed, and then the horizontal ones.

When the cornice is pasted over, they move on to the organization of steam and waterproofing.

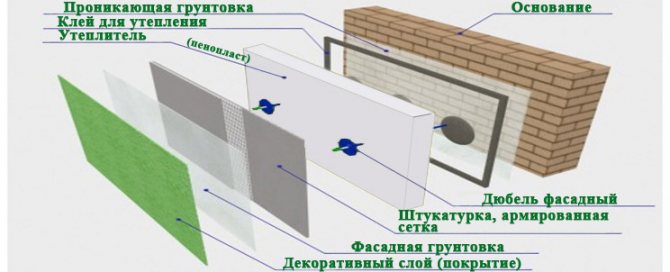

Vapor barrier and waterproofing for insulation with expanded polystyrene

Even taking into account the fact that expanded polystyrene is considered a vapor-permeable material, it requires the installation of a vapor barrier layer to prevent the formation of condensation in the voids between the wall and the insulation layer. An excellent solution is the use of membrane films. They are installed with an overlap only on completely dry surfaces. If you insulate wooden walls, the film can be fixed with a construction stapler. When working with concrete or brick buildings, glue can be used to bond the films to the frame.

The process of preparing insulation when using extruded polystyrene foam

Before installation, you should take care of the preliminary preparation of the insulation itself. If it is not corrugated, it should be processed with a needle roller on both sides. Then you should cut out the blanks for pasting the slopes and cornice. Cutting can be done with a jigsaw or a metal hacksaw.

Insulation of the foundation and basement

Since the construction of any house begins with a foundation, we will first consider the technology of its insulation. If you insulate the foundation, then instantly increase the thermal insulation performance of the whole house, and also prevent the soil from freezing. This means that you will need less money, effort and time to insulate the floor, walls and roof, and the foundation itself will last longer, since it will not freeze and thaw annually.

Basement insulation technology with expanded polystyrene:

It is possible to insulate the foundation at the stage of building a house and even after putting it into operation. In the second case, the foundation must be completely dug up around the entire perimeter, cleaned of dirt, rust and any stains. If there are residues of rolled waterproofing on the outer walls, they must be removed.

It is possible to insulate the foundation, like the walls, both from the outside and from the inside, but experts all as one advise doing it outside.To insulate the foundation and basement, it is better to use extruded polystyrene foam, taking into account its density and design thickness when choosing. The density must be at least 35 kg / m³. Before attaching the expanded polystyrene, it is necessary to waterproof the outer walls of the foundation. Any materials are suitable for this, with the exception of bitumen mastic based on organic solvents, since in contact with expanded polystyrene it will quickly destroy it.

If you want to use mastics, choose a mixture of water or polymer. Now you can attach polystyrene foam boards. For this, use a special glue designed exclusively for expanded polystyrene. Apply it around the entire perimeter and a couple of stripes in the center, wait a minute for it to harden and press firmly against the wall for 2-3 minutes.

Fasten the plates on a level to avoid distortions at the connection points. If you are going to lay the expanded polystyrene in two layers, fasten the sheets of the second layer so that their seams are offset in relation to the seams of the lower layer by half of the slab (bandaging the seams). Fill the cracks left after fixing the boards with polyurethane foam. Even extruded polystyrene foam does not have high mechanical strength and is susceptible to various damage, including damage by rodents.

For this reason, after laying the slabs on top, you need to attach a reinforcing mesh or wooden shields. Fix them with dowels along the perimeter of the foundation to the height of its backfill. If you are using a mesh, cement plaster with waterproofing additives should be applied over it. If you are insulating the foundation of a house located on damp ground with a high level of underground water, drainage should be done.

To do this, a perforated pipe is installed around the entire perimeter of the house, laying it on a powder of sand and gravel. In this case, you need to fill the foundation with sand or soft soil.To insulate the basement with expanded polystyrene, the plates must first be glued to the prepared base, and after 1-2 days, when the glue hardens, strengthen the fixation with umbrella dowels. Each slab must be reinforced with 3-5 of these dowels.

To reduce the number of fasteners, umbrellas can be installed in the joints between the plates. To protect expanded polystyrene from atmospheric and mechanical influences, it is necessary to lay a masking net on it and plaster the surface with a mineral mixture. After that, you can move on to the decorative cladding.

Despite popular practice, it is better not to insulate the foundation with polystyrene - this is not a very suitable material for such operational loads. Experts recommend replacing expanded polystyrene with more durable analogues: penoplex or polyurethane foam.

What are the parameters for choosing foam

When choosing polystyrene, they take into account the physical and technical characteristics that contribute to the performance of the functions assigned to the insulation:

- keeping warm (coolness);

- ease of installation;

- the chosen method of insulation;

- environmental friendliness for nature and safety for human health.

Let's consider the characteristics in more detail.

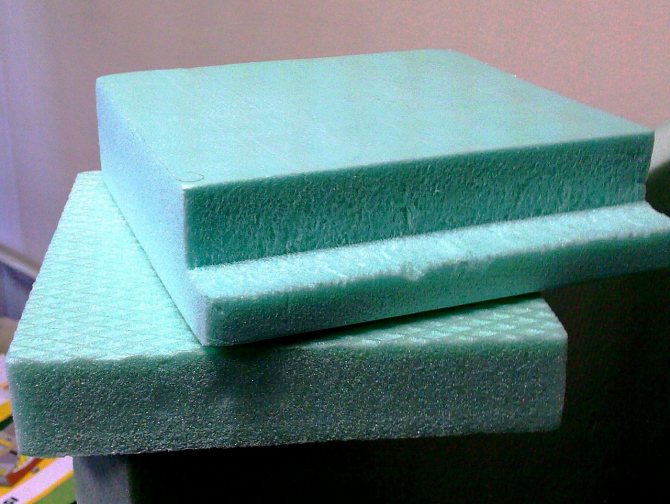

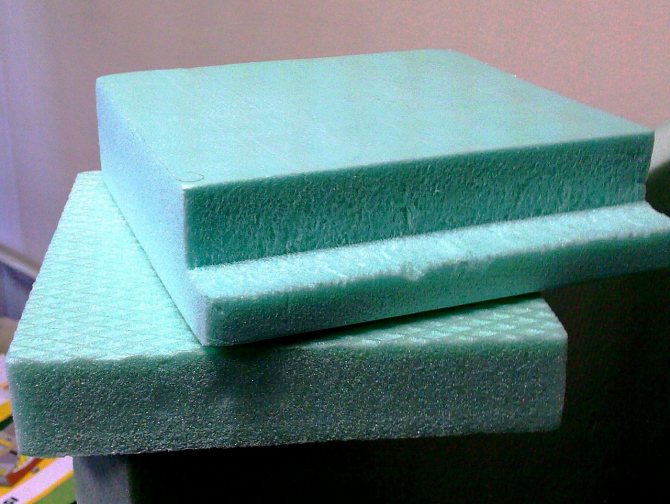

Thickness of slabs

In stores, there are sheets with a thickness of 10 to 100 mm in increments of 10 mm. The choice of thickness depends on the region and the purpose of the building. Sheets of 40, 50, 100 mm are in demand and are most often found in retail outlets, but the manufacturer is ready to make products of 20, 60, 70, 80 up to 500 mm to order. The price will remain the same in terms of cubic meters.

To make it easier to understand, on average, 10 cm thick foam polystyrene retains heat in the same way as 45 cm thick timber, 73 cm foam concrete masonry, 150 cm brick wall or 300 cm concrete wall. This is enough to insulate walls in any region of the country.

The size

The length and width of the sheets are more difficult to choose. Here, the standard dimensions are 500x1000, 1000x1000 and rarely 1000x2000 mm. For the installation of insulation around window and door openings, the sheets are cut with a sharp knife or file with fine teeth.

For large objects, electric cutters are purchased and made on their own - this way the material crumbles less, the edges remain even, which is convenient for further finishing.

Density

The main parameter characterizing the field of application is density.

For use in construction, manufacturers produce products of three varieties, which are conventionally designated by numbers in the name - 15, 25, 35. Their brief comparative characteristics are given in the table.

Table. Characteristics of different brands of foam.

| Brand | Specific weight, kg / m3 | Thermal conductivity, W / (m * K) | Compressive strength, MPa | Retail price, rub / m3 | Appointment |

| PSB-S-15 | 10 — 11 | 0,04 | 0,05 | 1700 | Thermal insulation by the "frame" method or between the main wall and the facing brick |

| PSB-S-25 | 15 — 16 | 0,035 | 0,1 | 2500 | Insulation "wet" facade |

| PSB-S-35 | 25 — 27 | 0,033 | 0,16 | 3800 | Thermal insulation of horizontal surfaces "under the screed" |

If we compare thermal conductivity, then the values for different types of expanded polystyrene do not differ much, unlike the price, so you should not overpay "for density".

Flammability

Styrofoam burns only when exposed to open fire. The freezing time (self-burning) is 3 - 4 seconds.

At the same time, during the combustion of polystyrene, highly poisonous substances are released, causing death from suffocation.

Preparing for installation

When everything is planned and thought out, the matter becomes the installation of the insulation belt. Fortunately, the technology of using expanded polystyrene plates for wall insulation is extremely simple and even an amateur in the construction industry can handle it.

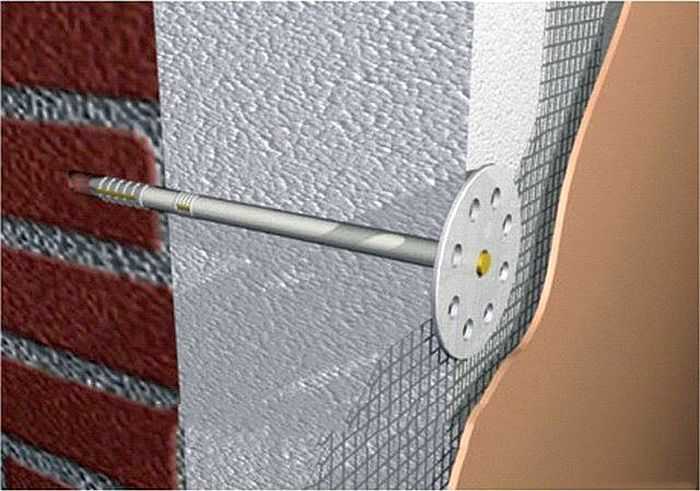

Fastening of expanded polystyrene plates is carried out by glue and mechanical methods. The former is preferable, but it is even better to combine both options. The disc dowels will provide reliable fixation during the setting period and will allow further finishing without waiting for the glue to dry completely. As a result, external insulation with a thickness of up to 150 mm tolerates wind shocks well and does not exert a significant load on the supporting structure.

True, the choice of an adhesive must be approached with all responsibility. PPP dissolves instantly with adhesives containing acetone, benzene and esters, therefore, special chemically inert mixtures should be used.

Insulation with expanded polystyrene is carried out, as a rule, according to the technology of a wet facade. Vapor barrier on the inside of the walls is not provided so that the natural regulation of air humidity remains possible: the walls will absorb some of the moisture and give it back harmlessly when the internal atmosphere dries out.

The material copes well with cyclic moisture saturation and freezing in this state, therefore the dew point is usually taken away into the insulation layer. In order to exclude the appearance of fungus and mold, it is useful to treat the walls with an antiseptic before sticking the PPS, or to provide a space for air of about 20-30 mm.If the facade is finished with facing masonry, air is provided on both sides of the insulation.

In order for the insulation of the walls of the house from the outside to be really high-quality, you need to use expanded polystyrene with a thickness of 10 cm or more. This size will be enough to keep the room warm. If it is not possible to purchase this option, then you need to put a thinner insulation in 2 rows.

To attach the slab to the wall, use special adhesives and dowels, fungi. It is advisable to purchase the glue from the same manufacturer as the expanded polystyrene. In this case, the grip will be as reliable as possible. Prepare the glue according to the instructions on the package.

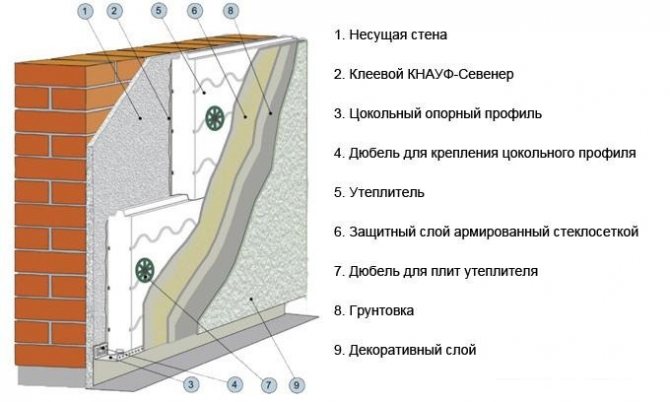

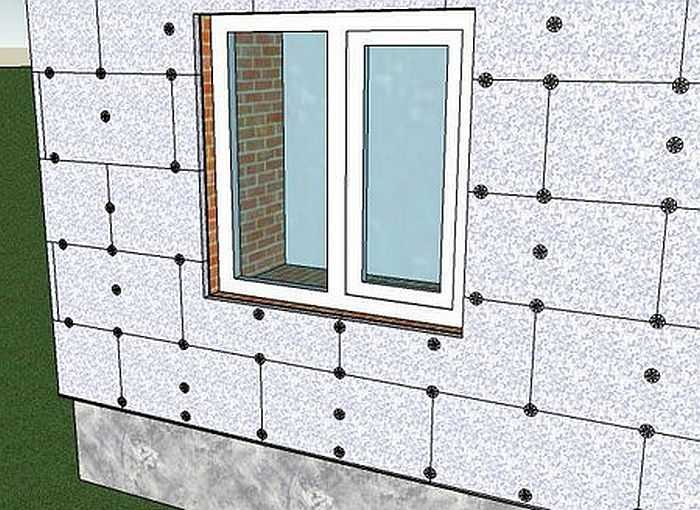

We proceed to the installation of the plates:

- A vertical crate is constructed from the basement profile. The step between adjacent profiles is 30 cm. A special corner basement profile is attached to the corners.

- Before attaching the expanded polystyrene, one of the sides is treated with sandpaper. Such actions contribute to greater adhesion of the glue and the sheet of insulation material.

- The glue is applied to the board with a notched trowel, about 1 cm thick.

- They begin to mount, moving up from the bottom. This method will prevent the top sheets from sliding down under their own weight.

- Additionally, the expanded polystyrene plates are fixed with dowels.

Wait for the glue to dry well before finishing the exterior walls. The manufacturer indicates the drying time on the packaging of the adhesive.

How many have already said that without high-quality preparation of the walls it makes no sense to talk about normal insulation - and now we will repeat: in order for expanded polystyrene to really perform its function, make sure that the main walls are extremely even and carefully processed with appropriate materials.

- carefully examine the wall, find all the bulges and depressions;

- remove them or level the difference between the levels to a few centimeters;

- if the surface of the wall is painted and in many places the paint is already “successfully” peeling off, then it is best to scrupulously clean this painting from A to Z.

We offer you to familiarize yourself with Drains with your own hands from scrap materials: again plastic bottles

It is easy to check the success of grinding: just slide your hand along the wall - if it remains clean, and the pores do not cling to knots and irregularities, then the process can be considered completed.

Another plus of using expanded polystyrene for insulation is the practical readiness for use at any time. Especially if you have purchased a material with a corrugated embossing, which ensures perfect adhesion to the adhesive composition. If you have ordinary polystyrene foam, then before starting the sheathing, you should process it with a needle roller.

Before installing polystyrene foam boards

... It is necessary to remove all parts, structures that can interfere with the process of laying the insulation. The walls are cleaned of old plaster and paint. It is advisable to check the evenness of the walls. If there are significant indentations, it is best to level them using plaster. Although expanded polystyrene can also be mounted on uneven walls, moisture will accumulate in the existing recesses, which can cause unpleasant phenomena. If the wall decoration is loose, then additionally you need to walk along their surface with a primer.

The material itself does not require preparation. But when using an extruded variety (penoplex), you need to roughen its smooth surface. To do this, you can use the same construction knife with which shallow notches are applied to the material.

Next, you should build ebb tides, insulate the slopes. Ebb tides should be equal to the thickness of the expanded polystyrene, plaster layer of backlash of several centimeters. Insulation of slopes in places of window openings is mandatory. For this, a similar heat insulator with a thickness of 2 cm or more is suitable.

Material advantages

We have already understood that polystyrene is an excellent material that is used to insulate walls, as well as soundproof a room. It doesn't matter what size it is. This material is very lightweight and compact, which does not cause big problems during transportation. It is very well cut to the required dimensions, so it can be used for insulation of various sizes and shapes. Poor sound conductivity allows the use of this material not only for insulation and sound insulation of residential buildings, but also significantly expands the scope of its application.

Reinforcing mesh fixing works

After the facades have been insulated with polystyrene foam with their own hands,

... Assembly glue is used to fasten the mesh material. Corners, slopes are covered with strips of mesh 30 cm wide. Small canvases are attached to the facade surface, while the mixture for installation is applied in a layer of 0.3 cm.

IMPORTANT! The mesh is overlapped by 10 cm.

After fixing the mesh, the walls are traversed with a rubberized spatula. To ensure that the reinforcing material is evenly covered with glue, you can add it in the required amount. Once the mesh layer is dry, sandpaper it.

Only after about 24 hours have passed, you can start sanding the expanded polystyrene surface and then - to glue the reinforcing mesh on the wall. Here's the sequence in this case:

- the adhesive is applied to the prepared surface of the insulation;

- the mesh is glued;

- then another layer of glue is applied, closing the glass mesh between two layers of the applied composition.

It is better to start gluing the mesh on the wall from the corners, while it is not at all worth sounding the alarm if the edges of the fragments overlap one another. Ideally, they should generally go in about 2 thirds, which contributes to better strengthening of the mesh and the fulfillment of its direct function.

Corresponding Foam Advantages and Disadvantages

In the information disseminated by manufacturers and traders of this material, there is not a word about its shortcomings, there is only a list of advantages. This is quite understandable, because the ultimate goal of an enterprise and a store is to make a profit from the sale of goods. But since polystyrene has been used as a heater for more than 50 years, over such a long period of practical application, it was possible to identify its weaknesses.

They are not widely publicized, but in order to choose the right material for facade insulation, this information is very valuable. After all, foam has both nuances and restrictions on the scope of application.

Styrofoam and pests

One of the advantages of this type of insulation material is the fact that the foam granules are not suitable for food for rodents. The facts are not so straightforward. The practice of using this type of material in construction shows that rodents really do not accept PPP as a food source. But at the same time, they are able to gnaw the insulation, significantly damaging it.

The only sure way to escape this misfortune is to block any access to the foam sheets for rodents. A practical homeowner would do just that.

The effect of ultraviolet radiation on foam

Manufacturers of foam products do not advertise information that the material is not resistant to ultraviolet rays. The direct rays of the sun are especially dangerous for him. Often, the consumer remains unaware that this radiation changes the coefficient of chemical stability of expanded polystyrene and contributes to its intensive aging. Styrofoam is a polymer material that is subject to gradual degradation. Exposure to ultraviolet light contributes to a significant acceleration of this process.

This disadvantage can be attributed to not too significant, since it is possible to protect the insulation material from the effects of UV rays, simply by hiding it from the direct sun. When the insulation foam layer is already fixed on the facade of the building, you need to start finishing work on the cladding as soon as possible.

Soundproofing qualities of PPP

Assurances of expanded polystyrene sellers about the high quality of sound insulation of the material are very doubtful. The owners of frame houses who have used polystyrene foam to insulate their homes, massively complain that the level of sound absorption was much lower than expected.

This fact lends itself to a simple explanation: more than 90% of air is present in the composition of expanded polystyrene. It perfectly accumulates heat and at the same time successfully conducts sound. This means that you should not place too high hopes on the fact that this material will help reduce the permeability of the walls of the building for sounds from the outside.

Water vapor permeability of PPP

The reduced level of vapor permeability of expanded polystyrene in a practical sense means that an obstacle from expanded polystyrene plates will appear on the path of vapor flows from the inside of the dwelling to the outer contour of the building. Often the air temperature outside is much lower than in an apartment or house. Condensation will become inevitable, and as a result, moisture will accumulate in those places where the joints of the heat insulator with the wall structure are located. This will significantly increase the risk that adjacent materials may become damp.

The only reasonable solution would be to correctly calculate the dew point, the design thickness of the insulating material. The dew point should not coincide with its limits. The right solution in this case will be the arrangement of the ventilation facade. It is worth taking into account the following information - the ability of the insulation to pass steam can only be considered in conjunction with a detailed overview of the structure as a whole. The material for the construction of the walls, the presence or absence of steam and waterproofing, the height of the foundation of the building and many other factors affect.

The choice of foam in terms of heat conductivity

The best thermal insulation qualities are shown by insulation materials based on polystyrene foam with a low density level, such as extruded polystyrene foam. Its thermal conductivity is one of the lowest, since the material is low-density (from 25 to 35 kg * m3).

According to experts, a 20-cm layer of expanded polystyrene produced by extrusion is comparable in terms of the level of heat savings with a 30-cm layer of foam, having a density of 15 kg * m3 and 25 kg * m3.

Characteristics of polystyrene materials: moisture proof + thermal insulation

Of polystyrene materials, two types of insulation are used today: polystyrene and polystyrene foam. Both are created by foaming polystyrene, but with different additives. As a result, some specifications do not match.

Due to the large amount of air in the foamed structure, the foam is not inferior in thermal insulation to more expensive heaters

General properties of foam and foam:

- Both heaters are characterized by low moisture absorption. They do not absorb vapors, like basalt materials, therefore they cannot lose their thermal insulation properties when wet. True, penoplex is absolutely impervious to water, and foam is low-permeable, but still capable of absorbing moisture.

- The level of heat saving is high. It is believed that it is practically impossible to provide such a low thermal conductivity with another material.

- Expanded polystyrene refers to combustible materials. Without a doubt, if set on fire, they will burn. But for this there is a finishing finish to protect the insulation from possible fire. The tree also ignites easily, but the owners rarely worry about this.

- Long service life. This parameter is really high when the insulation is isolated from sunlight, high temperatures, winds, etc.If you let the expanded polystyrene lie in the open air for a week or two, then its "eternal" properties will instantly come to naught. Those. when buying a heater, you must immediately mount it and hide it under the topcoat, and not leave it unprotected for a couple of months until the finish is completed.

- Compression resistance. Squeezing the insulation with your finger is not so easy, if only you try hard. And in house structures, it perfectly withstands the pressure of finishing on the floor or soil on the walls of the foundation.

Classes and brands of foam

Polyfoam as a material for finishing and insulation of the facade can have different brands, corresponding classes - each of them has its own purpose, composition and characteristics.

Styrofoam classes

There are two classes of finishing materials on the modern construction market:

- Pressed - it is made by pressing equipment.

- Non-pressed - materials are sintered at high temperatures.

To which class a particular finishing material belongs can be determined, so to speak, by eye, visually. So unpressed sheets of material are granules of a round or oval shape firmly glued together with a special composition, while the structure of the sheet itself is porous. The overlapped sheets are smooth, but the density can be different, depending on the brand of the product itself.

Styrofoam grades

Figure 3. Storage of facade foam

Non-pressed polystyrene is abbreviated as PSB, but pressed - PS. Although the material itself has different letter designations.

- A - the canvas is made in the correct geometric shape, namely in the parallelepiped format, with a flat edge;

- B - the edge of the sheet itself has a cut in the form of the letter L;

- R - cutting of the canvases is carried out using a hot stream;

- F - facade type or it is applicable using decorative elements;

- C - self-extinguishing type of finishing material;

- H - the material is applicable for outdoor decoration.

So the numbers in the name of the PPP will coincide with the density indicators.

Extruded foam grades

Picture 3 - BPP stamps

- PSB - 15 is the most expensive material with high brittleness. It is used as a heat-insulating and packaging material, characterized by low levels of hygroscopicity. They are used for finishing and insulating balconies, summer cottages, outbuildings.

- PSB - 25, often in the marking is supplemented with the letter F and is applicable for facade insulation. Due to its density, it is also applicable for the manufacture of decorative elements.

- PSB - 35 is a material widely used in construction and decoration. For example, for insulation of pipelines carrying heat and gas, it is applicable in the process of manufacturing a multi-layer type of panels as a heat-insulating gasket.

- PSB - 50 has the highest density, perfectly insulates heat and sound, therefore it is used on all objects, regardless of purpose.

Where is it used depending on the size?

This durable moisture-resistant insulation is used when performing outdoor work. To insulate the wall with foam, you first need to determine what density, size, type of polystyrene foam will be required for work.

The choice depends on the expected loads that this material will bear during the period of operation.

When insulating a vertical wall, the loads will be minimal; a sheet of any brand will do.

Even PSB-S 15 will give the same result as PSB-S 25 when it comes to wall insulation in areas with mild winters.

This is due to the fact that the principle of operation of the foam is based on gluing polystyrene balls, between which and inside there are multiple air chambers.

It is known that the less mass and more air, the better the effect of thermal insulation is.

It is inconvenient to work with sheets of low density, which are more fragile and break. PSB-S 25 has a high density, it is easier to finish with it.

Expanded polystyrene 25 is often used for external insulation of walls of non-residential premises. They are used to decorate balconies, loggias, garages, shopping centers, and various institutions.

For northern regions with cold winters, it is believed that a leaf thickness of 5 cm is enough to keep warm indoors on the coldest nights.

Polyfoam grade 100 is used for thermal insulation of industrial freezers, as well as for warming houses in the harsh climate of the Far North.

A sheet size of 10 cm will maximize the thermal protection index. When choosing a brand of expanded polystyrene, you can choose a sheet that has various parameters.

A non-standard sheet 500x500 is sometimes much more convenient to work with than a standard long sheet with dimensions of 2000x1000 mm.

For insulation of the walls of the house, sheets of 1000x1000 and 1000x500 mm in size are suitable. It is convenient to work with them, there are fewer joints that will have to be hermetically sealed.

To fill smaller areas, the existing sheets are cut into suitable pieces. For all non-standard situations in finishing, it is better to use a large sheet to make it easier to cut configurations.

In the process of laying, such sheets are adjusted to the desired parameters, cutting the expanded polystyrene into pieces. This material is easily cut.

Expanded polystyrene with dimensions of 2000x1000 mm is more difficult to install. Working alone, it is easier to stack two sheets of 1000x1000 than one sheet measuring 2000x1000 mm.

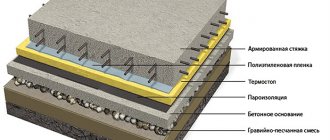

Floor insulation

Even if you insulated the foundation and the basement, this does not mean that the floor insulation can be neglected. This issue is especially acute for residents of the first floors of multi-storey buildings and owners of private houses. Thermal insulation of the floor with expanded polystyrene can significantly reduce heating costs, and also eliminate the causes of "domestic" diseases associated with hypothermia.

If you work with the floor on logs, it is better to use PSB-S15 expanded polystyrene for insulation, since the main load will not be on them, but on the logs. In terms of power, 10 cm is required for thermal insulation of floors on the first floors, and 5 cm for interfloor floors.

For the insulation of concrete coatings, a more durable polystyrene foam from PSB-S35 and higher is needed.

First, a rough leveling is carried out with plates of various capacities, but experts advise to make a leveling screed before insulation. Before laying the insulation plates on the floor, put a waterproofing film. Expanded polystyrene is covered with a 2 cm layer of cement mortar, in which the reinforcing mesh is recessed, after which a finishing screed 5-8 cm thick is made. Technological gaps along the perimeter are filled with fiberglass or polyurethane foam.

How is it transported?

The cut and ready-to-sell expanded polystyrene is packed by the manufacturer in transport bags and transported. GOST permits transportation unpacked if there is a guarantee that the sheets will not be damaged on the way.

When forming the package, the requirements of GOST 21929-76 must be observed. The height of the formed package should not be more than 0.9 m. With a slab thickness of 500 mm, the package is formed from two slabs.

On the side edge of the product or package, there must be a marking containing the stamp of the Quality Control Department of the enterprise that manufactured these products, the type and brand of the plate.

Marking must be made in accordance with GOST 14192-77 and contain the name of the enterprise or its trademark, date of manufacture of the product, its name and batch number.

Indicate the brand and type of plates, their number in the package.

There should be a designation of the standard on the basis of which these products were manufactured.

Foam cost

Expanded polystyrene made by extrusion is called polystyrene foam. Such plates are more durable than polystyrene, and their price is much higher. The cost of one plate (1200x600x50 mm) is 183 rubles, in terms of 1 m3 it is 5080 rubles.

On sites selling heaters, you often find such a product name as 50 mm foam. This is an ordinary sheet material with dimensions of 1000x2000 mm. The price of one plate is 180 rubles.Now, in comparison with penoplex, it can be seen that a cube of ordinary foam 50 mm thick costs 1,800 rubles, and this is 3,200 rubles cheaper than extruded polystyrene foam.

So, a cube of ordinary foam, depending on the density, costs:

- PSB-S15 - 2160 rubles;

- PSB-S25 - 2850 rubles;

- PSB-S35 - 4479 rubles;

- PSB-S50 - 6699 rubles.

Floors and ceilings: Thermal insulation

Reducing the transmission of impact noise is a task that expanded polystyrene perfectly copes with if it is used for thermal insulation of ceilings and floors. So it can not only protect against possible heat loss. In this case, the slabs must have a thickness at least 50 mm. Expanded polystyrene is laid on top, on a material with insulating properties. The seams that form during this process are necessarily sealed. Finally, at the last stage, they are laid on top concrete or sand-cement mix up to 6 cm thick, or grooved chipboard.